Lagrangian formulation for the rapid estimation of helicopter rotor

advertisement

The Aeronautical Journal

August 2014 Volume 118 No 1206

861

Lagrangian formulation for the

rapid estimation of helicopter

rotor blade vibration

characteristics

I. Goulos

i.goulos@cranfield.ac.uk

V. Pachidis and P. Pilidis

Centre for Propulsion

Cranfield University

Bedford, UK

Abstract

This paper presents a numerical formulation targeting the rapid estimation of natural vibration

characteristics of helicopter rotor blades. The proposed method is based on application of

Lagrange’s equation of motion to the kinematics of blade flap/lag bending and torsion. Modal

properties obtained from Bernoulli-Euler beam and classical torsional vibration theory, are utilised

as assumed deformation functions in order to estimate the time variations of strain and kinetic

energy for each degree of freedom. Integral expressions are derived, describing the generalised

centrifugal force and torsional moment acting on the blade in terms of normal coordinates, for flap/

lag transverse displacement and torsional deformation. Closed form expressions are provided for

the direct analysis of hingeless, freely-hinged and spring-hinged articulated rotor blades. Results

are presented in terms of natural frequencies and mode shapes for two small-scale rotor blade

models. Extensive comparisons are carried out with experimental measurements and nonlinear

finite element analysis. Predictions of resonant frequencies are also presented for two full-scale

rotor blade models and the results are compared with established multi-body dynamics analysis

methods. It is shown that, the proposed approach exhibits excellent numerical behaviour with

low computational cost and definitive convergence characteristics. The comparisons suggest very

good and in some cases excellent accuracy levels, especially considering the method’s simplicity,

computational efficiency, and ease of implementation.

Paper No. 4021. Manuscript received 19 June 2013, accepted 16 March 2014 .

Downloaded from http:/www.cambridge.org/core. IP address: 78.47.19.138, on 01 Oct 2016 at 13:30:09, subject to the Cambridge Core terms of use, available at

http:/www.cambridge.org/core/terms. http://dx.doi.org/10.1017/S000192400000960X

862

The Aeronautical Journal

August 2014

Nomenclature

Roman Symbols

A,B,C,D

A(r), Ip(r)

mode shape equation integration constants used in classical methods

blade cross-sectional area/polar moment of inertia, m2, m4

flap/lag/torsion

A Lagrange

Lagrange’s equation coefficient matrix

ABernoulli Bernoulli–Euler theory matrix of equation coefficients

ATorsion classical torsion theory matrix of equation coefficients

dFx , dFy , dFzcentrifugal force components acting on a beam element of differential mass dm

on the X, Y and Z axes respectively, Newton

dm beam element differential mass, = ρA(r)dr, kg

torsion

dMcentre

centrifugal torsional moment component acting on a beam element of differential

mass dm and centre mass offset from elastic axis Yoffset(r), Nm

e blade root/hinge offset distance from the centre of rotation as a fraction of rotor

blade radius

E, G material Young’s/Stress modulus, Pa

f i,jflap/lag/torsionhub-spring inter-modal coupling coefficient between the ith and jth assumed

modes

G i,jflap/lag/torsionoverall effective stiffness inter-modal coupling coefficient between the ith and jth

assumed modes

G flap/lag/torsion overall effective stiffness inter-modal coupling matrix

I i,jflap/lag/torsion effective centrifugal stiffening inter-modal coupling co-efficient between the ith

and jth assumed modes

I flap/lag(r) blade cross-sectional area moment of inertia, m4

flap/lag/torsion

k i,j

elastic inter-modal coupling coefficient between the ith and jth assumed modes

K flap/lag/torsion blade hinge/pitch-control system spring stiffness, Nm/rad

l actual blade length, = R(1 – e), m

flap/lag/torsion

m i,j

inertial inter-modal coupling coefficient between the ith and jth assumed modes

flap/lag/torsion

M

inertial inter-modal coupling matrix

N number of assumed mode shapes

flap/lag/torsion

qi

(t)time-dependent generalised coordinate of the ith mode shape

flap/lag/torsion

flap/lag/torsion

qi

ith eigenvector of Lagrange’s equation coefficient matrix ALagrange

Qi flap/lag/torsion generalised centrifugal force/moment corresponding to the ith coordinate

r local beam element radius, m

R rotor blade radius, m

t time, sec

T flap/lag/torsion kinetic energy of the rotor blade, Joules

u flap/lag(r, t) beam element X axis displacement, m

T flap/lag/torsion strain energy of the rotor blade, Joules

w flap/lag(r, t) time-dependent transverse displacement, m

Wflap/lag/torsion virtual work done by the centrifugal force, Joules

x

effective modal ordinate, = r – eR, m

xBernoulli Bernoulli–Euler vector of integration constants, = (A B C D)T

Downloaded from http:/www.cambridge.org/core. IP address: 78.47.19.138, on 01 Oct 2016 at 13:30:09, subject to the Cambridge Core terms of use, available at

http:/www.cambridge.org/core/terms. http://dx.doi.org/10.1017/S000192400000960X

Goulos et al Lagrangian formulation for the rapid estimation of helicopter rotor blade...

863

xTorsion classical torsion theory vector of integration constants, = (A B)T

flap/lag/torsion

Xi

(r)shape for the ith mode of motion, m

Yoffset(r)

aerofoil centre mass offset from elastic axis, m

Greek Symbols

ρA 2

ωB

EI

β

Bernoulli–Euler beam modal frequency parameter, == 4

γ

classical torsion theory modal frequency parameter, = T

I p ,midspan

GJ midspan

ε, ηLagrangian frequency relative error for transverse displacement and torsion

respectively

θ(r, t) time-dependent torsional deformation angle, rad

ρ

material density, kg/m3

flap/lag/torsion

φi

(r)assumed deformation function of the ith mode shape, rad

flap/lag/torsion

Φi

(r)assumed mode shape vector, ( φj flap/lag/torsion(r), j = 1; ...N )T

flap/lag/torsion

ωi

Natural vibration frequency of the ith mode of motion

Bernoulli–Euler beam theory modal frequency, rad/sec

ωB ωT classical torsion theory modal frequency, rad/sec

nominal rotorspeed, rad/sec

Ω

Superscripts

(˙), (¨) 1st and 2nd derivative with respect to time, t

( )′, ( )″

1st and 2nd derivative with respect to beam radius r or modal ordinate x

flap/lag/torsion

()

referring to the flap/lag/torsion degree of freedom respectively

Subscripts

()i,j ()midspan mode number indices

value corresponding to the blade midspan position

Acronyms

DOF

FEA

IM

ODE

PDE

RHS

TM

Degree of Freedom

Finite Element Analysis

Integrating Matrix

Ordinary Differential Equation

Partial Differential Equation

Right-Hand Side

Transmission Matrix

1.0Introduction

The main rotor of a helicopter is undoubtedly a mechanically complex structure. Part of the reason

for its mechanical complexity arises due to its function as a lifting, propulsive, and a control device

simultaneously. Its constant operation within a highly unsteady aerodynamic environment in

forward flight, essentially results in also highly unsteady exerted hub loads. Obtaining time-accurate

estimates of the rotor imposed forces and moments on the aircraft fuselage, is essential for flight

Downloaded from http:/www.cambridge.org/core. IP address: 78.47.19.138, on 01 Oct 2016 at 13:30:09, subject to the Cambridge Core terms of use, available at

http:/www.cambridge.org/core/terms. http://dx.doi.org/10.1017/S000192400000960X

864

The Aeronautical Journal

August 2014

dynamics simulation, especially regarding applications which include higher frequency rotor

dynamics. This prerequisite has been brought to the helicopter community’s attention, partially

due to its necessity for the design of reliable hingeless and bearingless rotor control systems.

In an effort to address the aforementioned requirement, the departure from the typical disc-like

treatment of the main rotor and the adaptation of methodologies involving individual blade treatment

was necessary. This essentially acted as an enabler in terms of including more sophisticated rotor

inflow and blade aerodynamics models. Some of the earliest individual-blade mathematical formulations would treat each blade as a rigid body. Hub springs and effective hinge offsets were assumed

in order to simulate the actual hub stiffness of hingeless blades. Such models include the ‘Genhel’

rotor model, developed by Howlett(1) for the UH-60 Blackhawk. Subsequent improvements were

carried out on the Genhel model, reported in Refs 2-5. Other rigid-blade rotor models include those

due to Curtiss, Chaimovich, Miller, Talbot, and Padfield, described in Refs 6-10 correspondingly.

Several studies are reported in the literature, where flexible blade models have been used

in order to study the effects of blade elasticity on the dynamics of various helicopter rotors.

Shupe(11-12) examined the effects of the second flap bending mode of a hingeless blade on the

transmitted hub moment. He emphasised that, the pronounced radial non-linearity in the once-perrev aerodynamic forcing during forward flight, essentially contributes to the excitation of higher

flap bending modes. It was therefore concluded that, inclusion of higher order modal content in

flight dynamics simulation is essential for the correct hub moment prediction of hingeless rotors,

especially considering high-speed flight conditions.

Lewis(13) used a multi-body dynamics formulation in order to investigate the aforementioned

effects on the dynamics of the UH-60 articulated rotor. The effects of blade flexibility were found

to be quite small in hover and increase slightly with increasing speed. Sturisky(14) reports that, for

the AH-64 articulated rotor, inclusion of higher order inflow dynamics along with flexible blade

modeling, may indeed improve the prediction accuracy of the rotor’s off-axis response to pilot

control inputs. Turnour et al(15) deployed the elastic rotor model described in Ref. 16 coupled with

the fuselage equations of the ‘UM-Genhel’ flight dynamics model(5) and a finite-state induced flow

model(17). Their goal was to evaluate the influence of blade flexibility on the frequency response

characteristics of an articulated rotor helicopter. It was concluded that, for the particular rotor

configuration, including flexible blade modeling along with higher order inflow dynamics, does

not improve the prediction accuracy of the off-axis rotor response to pilot control inputs.

In light of what has been described, it is understood that the effect of blade flexibility on the

rotor response characteristics is rather pronounced for hingeless rotor systems and relatively

moderate for articulated rotors. Most of the elastic blade formulations deployed in the aforementioned references, are based either on Finite Element Analysis (FEA), or on multi-body dynamics.

Hence, they require detailed knowledge of the geometry and overall structural properties of the

rotor blade as well as the corresponding computational infrastructure associated with FEA. They

are also accompanied by a relatively large computational overhead which may be prohibitively

large with regards to the application for which they are designated for. It is therefore realised that,

a computationally efficient methodology of sufficient fidelity, comprehensiveness, generality, and

ease of implementation is required for the inclusion of rotor blade flexibility in flight dynamics

applications. The approach has to enable existing as well as future potential flight simulation codes,

to account for blade elasticity without resorting to cost-inducing FEA or multi-body dynamics.

This paper describes a comprehensive methodology targeting the rapid estimation of natural

vibration characteristics of helicopter rotor blades. The present theory makes use of the Lagrangian

equation of motion for a rotating, continuous system of nonuniform mass and stiffness properties.

Any set of boundary conditions corresponding to the hub support of a helicopter rotor blade is

Downloaded from http:/www.cambridge.org/core. IP address: 78.47.19.138, on 01 Oct 2016 at 13:30:09, subject to the Cambridge Core terms of use, available at

http:/www.cambridge.org/core/terms. http://dx.doi.org/10.1017/S000192400000960X

Goulos et al Lagrangian formulation for the rapid estimation of helicopter rotor blade...

865

applicable. The proposed structural formulation is applied for an articulated and a hingeless smallscale experimental rotor model. Results are presented in terms of predicted flap-lag-torsion natural

frequencies and mode shapes for both investigated rotor blade models. It is shown that, the proposed

method exhibits excellent numerical behaviour with definitive convergence characteristics and low

computational cost, for every mode of motion presented. Extensive comparisons are carried out with

experimental measurements as well as with results from nonlinear FEA. Predictions of resonant

frequencies are also presented for two full-scale rotor blade models and compared with results

from established multi-body dynamics formulations employed in comprehensive rotorcraft codes.

2.0Background

2.1Nonlinear kinematics and natural vibration characteristics helicopter

rotor blades

The effort to determine the dynamic behaviour of rotating blades started quite early in the literature.

Houbolt and Brooks(18) derived the coupled differential equations of motion for combined flapwise/

chordwise bending and torsion for twisted nonuniform rotor blades. Their derivation was based

on the principles of classical engineering beam theory. Nonlinear terms of secondary nature, such

as shear deformation and rotary inertia were omitted. Linear coupling terms, mainly associated

with the blade’s centripetal acceleration due to the hinge’s pre-cone angle and steady state blade

flapping under external lift loads, were included. Exact solutions for continuous systems that

are governed by the Houbolt and Brooks equations do not yet exist. However, several analyses

can be found in the literature where approximate solutions have been acquired for the coupled

equations given in Ref. 18, or for some of their uncoupled sub-cases.

Hodges and Dowell(19) were able to develop a more generalised nonlinear theory considering

the elastic bending and torsion of long, straight, slender, homogeneous, isotropic beams undergoing moderate deflections. The equations of motion were derived by means of two individual

methods: the variational method based on Hamilton’s principle, and the Newtonian method

based on integration of forces and moments acting on a differential beam element. The associated

nonlinear strain-displacement relations were developed using the classical definition of strain,

and were considerably simplified in accordance with the premise of a long, slender beam subject

to moderate deformations.

Hodges et al(20) presented a thorough analysis considering the kinematics associated with

the elastic motion of Bernoulli-Euler beams subject to large deflections. A comprehensive

mathematical approach was presented using linear algebraic expressions in order to relate the

dominant kinematic variables expressed in the locally deformed principal axes, to a space-fixed

Cartesian axes system. Subsequently, Hodges(21) extrapolated the methodology of Ref. 20 to the

nonlinear dynamic analysis of pre-twisted, rotating beams. The nonlinear analysis of Ref. 21

attempted to abandon the common practice of assuming moderate rotations caused by structural

deformations in the description of the associated beam element kinematics. However, is is noted

that in order to derive the kinematic expressions for the orientation of the deformed beam crosssection, the assumption of small extensional strain on the elastic axis compared to unity, was

effectively invoked.

Murthy(22) deployed the Transmission Matrix(TM) method(23) in an effort to acquire approximate

solutions to a series of sub-cases of the Houbolt and Brooks Equations(18) for twisted nonuniform

rotating blades. The TM method requires that, the differential equations of motion are reduced

Downloaded from http:/www.cambridge.org/core. IP address: 78.47.19.138, on 01 Oct 2016 at 13:30:09, subject to the Cambridge Core terms of use, available at

http:/www.cambridge.org/core/terms. http://dx.doi.org/10.1017/S000192400000960X

866

The Aeronautical Journal

August 2014

to a set of first order Ordinary Differential Equations (ODEs) by appropriate selection of a state

vector. Murthy(22) noted that, the state vector can be selected in several ways but it is preferable

for it to consist of physical quantities such as deflections, slopes, moments, and shears. Following

the derivation of the transmission matrix of the defined ODEs, the frequency determinants and

the modal functions were obtained for a given set of boundary conditions. The cases of combined

flapwise bending/chordwise bending/torsion, flapwise bending/chordwise bending, and flapwise

bending/torsion were studied. Murthy concluded that, the TM method yielded highly accurate

results with regards to the specific application.

Hunter(24) applied the Integrating Matrix (IM) method in order to determine the natural vibration

characteristics of a twisted, rotating propeller blade with nonuniform, asymmetrical cross section

and cantilever boundary conditions. The integrating matrix can be regarded as a tensor operator

of numerical integration, applicable to any function expressed in terms of discrete values at equal

increments of the independent variable. It was derived by essentially expressing an integral as a

polynomial in the form of Newton’s forward-difference interpolation formula. After expressing

the differential equations of motion in matrix form, the constants of integration were evaluated

based on the applied boundary conditions. The matrix differential equation was subsequently

integrated repeatedly, using the integrating matrix as a tensor operator. This process resulted in the

formulation of the classical eigenvalue problem. Hunter compared the IM method’s predictions

of natural vibration frequencies with experimental data as well as with known exact solutions.

He concluded that the IM method yields very accurate results.

Surace et al(25) applied an integral approach using structural influence (Green) functions in

order to estimate the coupled motion modal characteristics of rotating, nonuniform, pre-twisted

blades. They utilised a system of appropriate Green functions for a cantilever beam in order to

acquire approximate solutions to the Houbolt and Brooks equations. Weighting matrices were

used for integration and differentiation, similarly to the approach followed in Ref. 24. As a result

of its numerical formulation, the specific method requires a defined set of Green functions for any

imposed set of boundary conditions that the analyst may wish to specify. Although Green functions

are readily available for a cantilever beam, they may need to be re-derived for an articulated rotor

with flap and lead-lag springs in order to comply with the corresponding boundary conditions.

Thus, the methodology presented in Ref. 25, is not readily applicable-implementable for the

analysis of freely-hinged or spring-hinged articulated helicopter rotor blades.

2.2Minimum potential energy methods

The methodologies described in the aforementioned references, have tackled the problem of rotor

blade flexibility by evaluating numerically the fundamental differential equations of motion for

a nonuniform, pre-twisted rotating beam. Further to the references above, a series of analyses

can be found in the literature where the sub-cases of the uncoupled problem have been addressed

through deployment of approximate energy methods, such as Lagrange’s and Rayleigh’s methods

as well as the classical and modified Rayleigh-Ritz procedures. These approaches are based on

the principle of minimum potential energy and the deployment of a finite series of assumed

displacement functions-deformation modes, in order to estimate the system’s kinetic and strain

energies as functions of time. Their detailed descriptions along with their derivations can be

found in Refs 26-28.

Wilde et al(29) described a comprehensive methodology for the estimation of flapwise vibration

frequencies and mode shapes of a helicopter rotor blade. They tried to acquire a numerical

solution for the flapwise bending differential equation of motion, which included the aerodynamic

damping terms based on the assumption of linear aerodynamics. Their methodology consisted of

Downloaded from http:/www.cambridge.org/core. IP address: 78.47.19.138, on 01 Oct 2016 at 13:30:09, subject to the Cambridge Core terms of use, available at

http:/www.cambridge.org/core/terms. http://dx.doi.org/10.1017/S000192400000960X

Goulos et al Lagrangian formulation for the rapid estimation of helicopter rotor blade...

867

a combination of Rayleigh’s principle of variation and Fourier series expansion techniques. The

solution method included the assumption of a pre-supposed, periodic aerodynamic loading which

was expanded in a Fourier series about the azimuthal coordinate. The acquired series expression

was subsequently included in the corresponding differential equation of motion. Thus, the specific

methodology is not applicable for a complete aeroelasticity analysis where coupling with more

refined aerodynamic response and rotor inflow theories may be required for time-domain analysis.

Fasana et al(30) deployed the Rayleigh-Ritz method in order to investigate the vibration characteristics of sandwich beams with a constrained viscoelastic layer. Their analysis included the use

of simple polynomial expressions as assumed deformation functions. A total of 20 polynomial

functions were used in the analysis. It was reported that no sensible variation was detected in the

acquired results when the number of polynomials was increased up to a total of 80 functions.

Predicted natural frequencies corresponding up to the fourth bending mode for a cantilever beam

were presented. Results were compared with those from other various numerical schemes that

can be found in the literature. Good agreement was observed regarding the lowest mode natural

frequencies. There was however a noticeable deviation in the predicted higher mode frequencies

among all compared techniques. Fasana et al concluded that the Rayleigh-Ritz procedure was in

concurrence with the rest of the compared schemes regarding the particular application.

Hodges(31) extrapolated the analytical Ritz procedure to the case of nonuniform rotating beams

with radial discontinuities in bending stiffness and mass per unit length. Hodge’s method recognised

that, the analytical derivatives of the admissible deformation functions have to account for the

presence of discontinuities in the beam’s structural properties. Hence, a number of M + 1 discrete

segments were designated along a beam with M discontinuities in bending stiffness and mass per

unit length, each segment essentially having continuous structural properties. The deformation

of each beam segment was approximated with the employment of a power series formulation

of N terms, instead of using standard polynomial expressions. Geometric continuity conditions

were enforced at the corresponding boundaries of each beam segment. Hodges concluded that,

this approach always converges to exact solutions and that the magnitude of discontinuities does

not significantly affect neither the method’s accuracy, nor the rate of convergence. However,

the author of Ref. 31 emphasised that, using the corresponding terms of a simple power series

as admissible functions, may result in deteriorated accuracy and numerical instabilities due to

ill-conditioned matrices, when higher order terms (N) are required to be employed in the analysis.

It is understood from the discussion above that the accuracy of minimum potential energy

methods has been limited so far to the realms of approximation and only for the lowest modesfrequencies. This is due to the fact that, their success is highly dependent on the selection of

assumed displacement functions in terms of both quantity and quality. A relatively larger number

of functions is required so that the system is allowed to deform within most of its potential

displacement modes. Selecting a small number of assumed functions may essentially lead to

artificially imposed stiffness in the system which may result in acquired frequencies higher than

normal. This is a well known deficiency of Rayleigh’s method(28) which is based only on the first

assumed mode of deformation.

The assumed displacement functions need to comply with three fundamental requirements in

order to be used within the context of minimum potential energy analysis. These can be listed as

follows: (1) They need to satisfy the structure’s boundary conditions, (2) They must be linearly

independent-orthogonal with one another, and (3) They have to be as close as possible to the

actual deformation modes(28). It is also desirable, but not a prerequisite, that the first and second

spatial derivatives of the assumed functions are provided as analytical expressions. This is due to

the fact that, numerical differentiation errors could hinder the accuracy of the overall procedure.

Downloaded from http:/www.cambridge.org/core. IP address: 78.47.19.138, on 01 Oct 2016 at 13:30:09, subject to the Cambridge Core terms of use, available at

http:/www.cambridge.org/core/terms. http://dx.doi.org/10.1017/S000192400000960X

868

The Aeronautical Journal

August 2014

This is especially important when exceptionally large terms need to be well conditioned within

the deployed analytical expression.

The first and second bending modes may be relatively easy to approximate using standard

polynomial expressions found in the literature(32-33). However, when it comes to refined modeling,

which may require the inclusion of higher order assumed functions, the deviation between such

polynomial expressions and the actual modes of deformation becomes quite large. Hence, the

use of the aforementioned polynomial functions is rendered progressively invalid as the energy

method is further refined, and therefore higher order functions need to be included in the analysis.

2.3 Scope of present work

This paper describes a minimum potential energy method, capable of rapidly estimating the natural

frequencies and mode shapes of rotating helicopter blades with respect to flap/lag bending and

torsion. Lagrange’s equation of motion is utilised for a continuous system of nonuniform mass

and stiffness properties. The aforementioned weakness of energy methods is mitigated with the

employment of modal characteristics obtained from Bernoulli-Euler beam and classical torsion

theories as assumed deformation functions, instead of standard polynomial expressions found in

the literature. Computational efficiency is established by achieving quick convergence of calculated

modal frequencies to definite values. Only a relatively small number of assumed deformation

functions is required for convergence due to them originating from classical vibration analysis

methods instead of simple polynomial expressions.

The structure’s boundary conditions are implicitly catered for in the Lagrangian approach,

through application directly within Bernoulli-Euler beam and classical torsion theories. The

cases of hingeless, freely-hinged, and spring-hinged articulated rotor blades, are treated in detail

and closed form expressions are offered that can be readily implemented as assumed deformation functions. Integral expressions, describing the generalised centrifugal force and torsional

moment exerted on the blade, are derived and employed within Lagrange’s equation of motion.

The classical eigenvalue problem for a nonuniform, rotating structure with any set of imposed

boundary conditions, can therefore be formulated and solved with customary matrix techniques.

The solution of the devised eigenproblem essentially results in the structure’s natural frequencies

and mode shapes.

The flap-lag-torsion Degrees of Freedom (DOFs) are treated separately and thus neither elastic

nor aerodynamic or inertial coupling is taken into account during the formation of the Lagrangian

eigenproblem. This is due to the fact that, the proposed approach is predominantly designated for

dynamic response analyses in the time domain. Any imposed aerodynamic or nonlinear inertial

loads may therefore be treated as a time-history of external forcing using the convolution integral

to obtain the dynamic response of the blade.

It is thus understood that, the proposed approach essentially constitutes a readily implementable

integrated framework, applicable to the structural analysis of helicopter rotor blades during

preliminary design. Flight dynamics applications may benefit from this methodology, since it acts

as a fundamental baseline for the transition from classical rigid blade modeling, to a complete

framework for rotor aeroelasticity analysis, without resorting to computationally expensive

FEA or multi-body dynamics. The implementation of the described approach does not require

any external dependencies or computational infrastructure and can be realised within less than

a thousand lines of FORTRAN code. It is shown that, execution times required for a complete

analysis, including modal content reaching up to the fifth mode for all DOFs, may be constrained

to less than 0·6 seconds on a low-end personal computer.

Downloaded from http:/www.cambridge.org/core. IP address: 78.47.19.138, on 01 Oct 2016 at 13:30:09, subject to the Cambridge Core terms of use, available at

http:/www.cambridge.org/core/terms. http://dx.doi.org/10.1017/S000192400000960X

Goulos et al Lagrangian formulation for the rapid estimation of helicopter rotor blade...

869

3.0Theoretical Model Development

3.1Derivation of assumed deformation functions

In order to utilise the Lagrangian equation of motion, a finite series of assumed deformation functions

is required with respect to the blade’s flap/lag transverse displacement and torsion. These can be

obtained by treating the rotor blade as a non-rotating solid beam of uniform structural properties

and subsequently applying the classical Bernoulli-Euler beam and torsional vibration theories. Due

to the potential existence of an actual hinge/root offset from the centre of rotation, it is deemed

appropriate to define an effective modal ordinate as the spatial independent variable based on the

local beam radius r ∈ (eR, R), where e is the hinge/root offset as a fraction of rotor blade radius R.

The effective modal ordinate is defined as x = r – eR, x ∈ (0,l), where l = R(1 – e) is the actual blade

length. This transformation is performed in order to ensure correct application of boundary conditions.

The governing equation for the time-dependent transverse displacement w(x,t) of a non-rotating

beam with variable bending stiffness EI(x) and mass per unit length ρA(x), subjected to a vertical time

varying distributed load per unit length P(x,t), is a fourth order Partial Differential Equation (PDE):

2

2 w( x, t )

2 w( x, t )

( EI ( x)

) A( x)

= P ( x, t )

2

2

x

x

t 2

. . . (1)

where t is time in seconds. The corresponding governing equation for the torsional deformation

angle θ(x,t), of a non-rotating body of variable torsional rigidity GJ(x) and polar moment of inertia

per unit length ρIp(x), subjected to unsteady torsional moment loads per unit length M(x,t), is a

second order PDE:

( x, t )

2 ( x, t )

(GJ ( x)

) M ( x, t ) = I p ( x)

x

x

t 2

. . . (2)

At this point, constant values of ρA(x), ρIp(x), EI(x), and GJ(x) along x are assumed. Representative

values of structural properties are selected at the blade mid-span location x = l/2. In order to obtain

the natural frequencies and mode shapes of the idealised non-rotating structure, the eigenproblem

has to be formulated. This is achieved through application of free vibration conditions by setting

P(x,t) = 0 and M(x,t) = 0 in Equations (1)-(2) respectively. This leads to the expressions:

4 w( x, t )

2 w( x, t )

=0

EI midspan

A

midspan

x 4

t 2

. . . (3)

2 ( x, t )

2 ( x, t )

= I p ,midspan

GJ midspan

2

x

t 2

. . . (4)

Assuming that Equations (3)-(4) are separable in terms of space x and time t, the transverse

displacement w(x,t) and torsional deformation angle θ(x,t) can be re-written as:

w( x, t ) = ( x) Q w (t )

. . . (5)

( x, t ) = ( x) Q (t )

. . . (6)

Downloaded from http:/www.cambridge.org/core. IP address: 78.47.19.138, on 01 Oct 2016 at 13:30:09, subject to the Cambridge Core terms of use, available at

http:/www.cambridge.org/core/terms. http://dx.doi.org/10.1017/S000192400000960X

870

The Aeronautical Journal

August 2014

where Φ(x), Θ(x) are the spatial mode shapes and Qw(t), Qθ(t), are time-dependent generalised

coordinates. The mode shapes for transverse displacement and torsion can be acquired from the

solution of the spatial parts of Equations (3)-(4) in that order, giving:

4 ( x) 4

( x) = 0

x 4

. . . (7)

2 ( x ) 2

( x ) = 0

x 2

. . . (8)

where β, γ are the Bernoulli-Euler and torsional vibration frequency parameters respectively.

These are essentially defined as:

A

4 = midspan 2B

EI midspan

GJ midspan

2 = ( T )2 , c =

I p ,midspan

c

. . . (9)

. . . (10)

with ωB, ωT being the natural frequencies of vibration for transverse displacement and torsion

respectively. Equations (7)-(8) have known solutions of the form:

( x) = ASinx BCosx CSin h x DCos h x

. . . (11)

( x) = ACosx BSinx

. . . (12)

Equations (11)-(12) provide the transverse displacement and torsional mode shapes of the idealised

structure, for designated frequency parameters β, γ. The parameters A, B, C and D are constants of

integration that are determined through application of the appropriate boundary conditions. Those

are essentially defined by the rotor blade’s hub support. Applying the corresponding boundary

conditions at the blade hub (x =0) and tip (x = l) modal ordinates within Equations (11)-(12),

results in the formation of the corresponding linear systems of equations:

A Bernoulli x Bernoulli = 0

. . . (13)

ATorsion xTorsion = 0

. . . (14)

where and xBernoulli = (A B C D)T and xTorsion = (A B)T .The matrices ABernoulli, ATorsion contain coefficients that depend on the frequency parameters β, γ as well as on beam length l.

In order for Equations (13)-(14) to have non-trivial solutions, the determinants of ABernoulli,

ATorsion must be equal to zero:

det A Bernoulli = 0

. . . (15)

det ATorsion = 0

. . . (16)

Downloaded from http:/www.cambridge.org/core. IP address: 78.47.19.138, on 01 Oct 2016 at 13:30:09, subject to the Cambridge Core terms of use, available at

http:/www.cambridge.org/core/terms. http://dx.doi.org/10.1017/S000192400000960X

Goulos et al Lagrangian formulation for the rapid estimation of helicopter rotor blade...

871

Solution of Equations (15) and (16) provides the frequency parameters β, γ, required for determination of the corresponding mode shapes. Equations (15) and (16) are transcendental equations

with infinite solutions that are evaluated numerically for the first N mode shapes to be included in

the Lagrangian analysis. Subsequent use of Equations (13) and (14) leads to the ratios between

the integration constants.

Reference (34) discusses the application of the corresponding boundary conditions for hingeless,

freely-hinged, and spring-hinged articulated rotor blades. The torsional vibration case is also

elaborated considering configurations employing pitch-control systems of infinite as well as finite

torsional stiffness. A brief summary is provided below, along with readily implementable closed

form expressions for the direct analysis of all rotor blade configurations mentioned above.

3.1.1 Hingeless rotor blades

Application of boundary conditions corresponding to a hingeless rotor blade, leads to the following

closed form expression for Equation (15):

CoslCos h l 1 = 0

. . . (17)

The integration constants C and D within xBernoulli are essentially zero. The ratio of the remaining

non-zero integration constants is given by:

B

Sinβ l Sin h β l Cosβ l Cos h β l

=

A

Cosβ l Cos h β l Sin h β l Sinβ l

. . . (18)

3.1.2 Freely-hinged articulated rotor blades

Considering the boundary conditions corresponding to a freely-hinged articulated rotor blade,

Equation (15) results in the following closed form expression:

. . . (19)

Sin h lCosl Sin lCos h l = 0

The integration constants B and D within xBernoulli are essentially zero. The ratio of the non-zero

integration constants is given by:

C

Sinl Cosl

=

A Sin h l Cos h l

. . . (20)

For the specific set of imposed boundary conditions, the Bernoulli-Euler beam has a rigid body

mode of motion which corresponds to ωB = β = 0. Setting β = 0 in Equation (7) results in the

following rigid body mode shape:

Φ( x) = Ax

. . . (21)

3.1.3 Spring-hinged articulated rotor blades

As regards the case of a spring-hinged articulated rotor blade employing a spring with stiffness

K at the hub, Equation (15) leads to the following closed form expression:

K (1 CoslCos h l ) EI midspan(CoslSin h l Cos h lSinl ) = 0

. . . (22)

Downloaded from http:/www.cambridge.org/core. IP address: 78.47.19.138, on 01 Oct 2016 at 13:30:09, subject to the Cambridge Core terms of use, available at

http:/www.cambridge.org/core/terms. http://dx.doi.org/10.1017/S000192400000960X

872

The Aeronautical Journal

August 2014

The ratios of the integration constants contained in xBernoulli for a value of β that satisfies Equation

(22), are given by the following closed form expressions:

Sinl

Sin h l

B=

A

Cosl Cos h l 2 EI midspan

Sin h l

K

1

2 EI midspan B KA

C=

K

D = –B

. . . (23)

. . . (24)

. . . (25)

3.1.4 Rotor blade pitch-control system with infinite torsional stiffness

Considering the torsional vibration case where a pitch-control system of theoretically infinite

stiffness is employed, application of the respective boundary conditions in Equation (12) leads to:

BCos( l ) = 0 Cos( l ) = 0

. . . (26)

with A = 0 and Bγ ≠ 0. The corresponding mode shapes are given by Equation (12) by setting A = 0.

3.1.5 Rotor blade pitch-control system with finite torsional stiffness

Application of boundary conditions corresponding to a pitch-control system with finite torsional

stiffness Ktorsion in Equation (12), leads to the following condition:

K torsion

Cosγ l − γ Sinγ l = 0

GJ midspan

The ratio between the integration constants in xTorsion is:

B

K torsion

=

A GJ midspan γ

. . . (27)

. . . (28)

3.1.6 Normalisation of assumed mode shapes

Application of a normalisation condition results in the final transverse displacement and torsion mode

shapes for designated frequency parameters β and γ. The normalisation conditions used within this

paper, with respect to the cases of transverse displacement and torsion can be expressed as follows:

l

2

. . . (29)

0Amidspan ( x)dx = 1

l

l

2

0 ( x)dx = 2

. . . (30)

The aforementioned process is applied for the N first mode shapes with respect to the cases

of flap/lag bending and torsion. The acquired modes are subsequently transferred from

the effective modal ordinate domain x, to the beam element local radius domain r and are

φiflap (r ), φlag

φtorsion

(r ), i = 1,...N . Thus, the N first deformation modes for

expressed as i ( r ),

i

flap-lag-torsion, with respect to an idealised non-rotating structure with constant bending stiffness,

Downloaded from http:/www.cambridge.org/core. IP address: 78.47.19.138, on 01 Oct 2016 at 13:30:09, subject to the Cambridge Core terms of use, available at

http:/www.cambridge.org/core/terms. http://dx.doi.org/10.1017/S000192400000960X

Goulos et al Lagrangian formulation for the rapid estimation of helicopter rotor blade...

873

torsional rigidity, mass per unit length, and polar moment of inertia distribution along the beam

radius, are obtained. The acquired functions are orthogonal with one another, they comply with the

structure’s boundary conditions, they are relatively good approximations to the actual mode shapes

of the nonuniform-rotating structure(27), and their derivatives with respect to r readily available in

analytical form. Hence, they are deemed excellent candidates for use as assumed deformations

functions in Lagrange’s equation of motion.

3.2Lagrangian formulation for rotor blade flap-lag-torsion dynamics

Having derived a finite series of well-conditioned assumed deformation functions, the Lagrangian

problem can be formulated. This process requires that the strain and kinetic energy of the system,

as well as the virtual work done by the external forces and moments, are expressed as functions of

generalised coordinates. The rotor blade is now treated as a continuous system of variable bending

stiffness, torsional rigidity, polar moment of inertia, and mass per unit length along the blade radius.

Neither elastic, nor inertial or aerodynamic coupling between flap-lag-torsion dynamics is accounted

for within the formulation described in this paper. The proposed approach is predominantly

designated for dynamic response analyses in the time domain where any imposed aerodynamic

or nonlinear inertial coupling loads (such as due to Coriolis acceleration) are essentially treated

as a time-history of external forcing. All three DOFs are therefore approached separately. Instead

of the local modal ordinate , the local beam radius is used as the independent spatial variable.

Lagrange’s equation of motion(28) for a system whose space configuration can be expressed by

a finite series of time-dependent generalised coordinates qi(t), i = 1, ...N dictates that:

d T

T U

( )

= Qi , i = 1,...N

dt qi qi qi

. . . (31)

where T and U are the kinetic and strain energy of the system in that order, while Qi is the generalised

external force corresponding to the ith coordinate. Expressing the time-dependent transverse

displacement for flap-lag bending motion wflap/lag(r,t), along with the torsional deformation angle

θ(r,t), in terms of the finite series of assumed modal functions obtained from Bernoulli-Euler beam

and classical torsional vibration theory respectively, gives:

N

. . . (32)

w flap (r , t ) = iflap (r )qiflap (t )

i =1

N

wlag (r , t ) = ∑φilag (r )qilag (t )

(r , t ) = torsion

(r )qitorsion (t )

i

. . . (33)

i =1

N

. . . (34)

i =1

where qi flap(t), qi lag(t) and qitorsion(t) are generalised coordinates expressing the contribution of the

assumed modal functions on the blade’s flap-lag transverse displacement and torsional deformation

respectively. Assumption of small deformations allows to set T

qi

0

d T

U

( )

= Qi , i = 1,...N

dt qi

qi

in Equation (31) which becomes:

. . . (35)

The next step is to express the blade’s strain and kinetic energy as functions of the defined

generalised coordinates. For the formulation presented in this paper, the assumed kinetic energy

Downloaded from http:/www.cambridge.org/core. IP address: 78.47.19.138, on 01 Oct 2016 at 13:30:09, subject to the Cambridge Core terms of use, available at

http:/www.cambridge.org/core/terms. http://dx.doi.org/10.1017/S000192400000960X

874

The Aeronautical Journal

August 2014

includes only terms associated with the first derivatives of transverse displacement and torsional

deformation, considering the respective DOFs. This is due to the fact that, any inertial terms

related to the blade’s rotation are meant to be treated as external forcing. The virtual work done

on the blade due to them, is therefore calculated independently. The blade’s strain and kinetic

energy are therefore given by:

1 R

1

U flap/lag = EI flap/lag (r )( w'' flap/lag (r , t )) 2 dr K flap/lag ( w'' flap/lag (eR, t )) 2

. . . (36)

eR

2

2

1 R

1

U torsion = GJ (r )(' (r , t )) 2 dr K torsion 2 (eR, t )

eR

2

2

. . . (37)

1 R

T flap/lag = A(r )( w flap/lag (r , t )) 2 dr

2 eR

. . . (38)

1 R

T torsion = I p (r )( (r , t )) 2 dr

2 eR

. . . (39)

1

K flap/lag ( w'flap/lag (eR, t )) 2 has been included in the Right-Hand Side (RHS) of Equation

The term 2

(36), in order to account for the added strain energy in the system due to the existence of a discrete

spring K flap/lagwith stiffness at the blade hinge location (r = eR) for the case of a spring-hinged

articulated rotor. For a hingeless or a freely-hinged articulated rotor, the specific term can be

1 torsion 2

K

θ (eR, t ) in the RHS of Equation (37), represents

removed from the analysis. The term 2

the strain energy of the pitch-control system in the case of specifying finite torsional stiffness

Ktorsion at the blade root/hinge location (r = eR).

Substituting Equations (32)-(34) in Equations (36)-(39) results in the following expressions:

1 N N

/lag/torsion flap/lag/torsion

U flap/lag/torsion = ki ,flap

qi

(t )q jflap/lag/torsion (t )

j

2

i =1 j =1

. . . (40)

1 N N flap/lag/torsion flap/lag/torsion

flap/lag/torsion

(t )q j

qi

(t )

∑∑ fi, j

2 i =1 j =1

1 N N

/lag/torsion flap/lag/torsion

T flap/lag/torsion = ∑∑miflap

qi

(t )q jflap/lag/torsion (t )

,j

2 i =1 j =1

. . . (41)

The inter-modal coupling coefficients within Equations (40), (41) are defined as follows:

R

/lag

/lag

. . . (42)

miflap

= A(r )iflap/lag (r ) flap

(r )dr

,j

j

eR

R

/lag

ki ,flap

= EI flap/lag (r )i'' flap/lag (r )''j flap/lag (r )dr

j

eR

. . . (43)

/lag

/lag

fi ,flap

= K flap/lag φi'flap/lag (eR )φ'flap

(eR )

j

j

. . . (44)

mitorsion

= I p (r )torsion

(r )torsion

(r )dr

,j

i

j

R

eR

. . . (45)

Downloaded from http:/www.cambridge.org/core. IP address: 78.47.19.138, on 01 Oct 2016 at 13:30:09, subject to the Cambridge Core terms of use, available at

http:/www.cambridge.org/core/terms. http://dx.doi.org/10.1017/S000192400000960X

Goulos et al Lagrangian formulation for the rapid estimation of helicopter rotor blade...

875

Ω

Z

eR+(r-eR)cosβ(r,t)

dF=dFx

dm

wflap(r,t)

β(r,t)

Y

a)

X

r-eR

Ω

(r-eR)cosζ(r,t)

eR

ζeff(r,t)

Z

uflap(r,t)

(r-eR)cosβ(r,t)

r-eR

eR

X

ulag(r,t)

ζ(r,t)

wlag(r,t)

dFx

ζeff(r,t)

dm

dFy

2

dF = dFx + dFy

2

Y

b)

Rotating blade

Elastic axis

dr

Ω

δ

Z

dm

δ = arcsin(

Yoffset (r )

2

(r )

r 2 + Yoffset

dm = ρA(r )dr

dFcentr

)

dm

δ

dFcentr , y

dFcentr

dFcentr ≈ ρA(r )Ω rdr

dFcentr , y = dFcentr sin δ

X

dFcentr , x

2

Y

Yoffset (r )

r

δ ≈ arcsin(

Yoffset (r )

r

)

2

dFcentr , y ≈ ρA(r )Ω Yoffset (r )dr

c)

Figure 1. Beam element kinematics: (a) Flap bending motion, (b) Lag bending motion,

(c) Centrifugal force component due to centre mass offset Yoffset(r) from the elastic axis.

R

kitorsion

= GJ (r )i'torsion (r )'torsion

(r )dr

,j

j

. . . (46)

fi ,torsion

= K torsion φtorsion

(eR )φtorsion

(eR )

j

i

j

. . . (47)

eR

/lag

/lag

/lag

miflap

, ki ,flap

and fi ,flap

where

are the inertial, elastic, and hub-spring inter-modal coupling coeffi,j

j

j

cients respectively between the ith and jth assumed modes of motion for flapwise and lagwise

bending. The coupling coefficient fi,jflap/lag is non-zero, only for the case of an articulated rotor with a

, kitorsion

, and fi ,torsion

discretely defined hub spring. The coefficients m

itorsion

and express the inertial, elastic,

,j

,j

j

and torsional-spring inter-modal coupling respectively, between the ith and jth assumed modes of

Downloaded from http:/www.cambridge.org/core. IP address: 78.47.19.138, on 01 Oct 2016 at 13:30:09, subject to the Cambridge Core terms of use, available at

http:/www.cambridge.org/core/terms. http://dx.doi.org/10.1017/S000192400000960X

876

The AeronAuTicAl JournAl

AugusT 2014

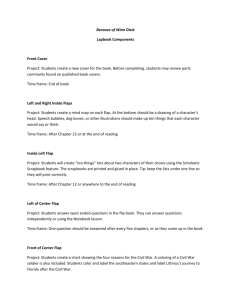

Z

M+

θ (r , t )

Yoffset (r )

torsion

dM centr

Y

z

X

dm

z = Yoffset (r ) sin ϑ (r , t )

dFcentr , y

torsion

dM centr

= −dFcentr , y z ⇒

2

torsion

dM centr

≈ − ρA(r )Ω 2Yoffset

(r )θ (r , t )dr

Figure 2. Blade element kinematics for torsional vibration.

torsion

mitorsion

, kiThe

,term

and fi ,torsion

motion considering torsional vibration.

is non-zero, only with respect to the case

,j

,j

j

of finite pitch-control system torsional stiffness. Equations (40) and (41) essentially express the

blade’s strain and kinetic energy as functions of time-dependent generalised coordinates for the

cases of flap/lag bending and torsion.

3.3 derivation of generalised centrifugal force and moment expressions for

flap-lag-torsion

The next step is to obtain closed form expressions for the virtual work done by the centrifugal

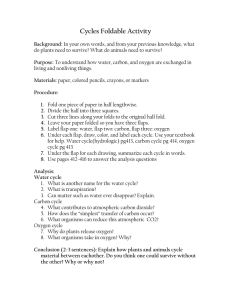

force acting on the rotating blade within each DOF. Figures 1, (a) and (b) illustrate the kinematics

of a beam element of mass dm = ρA(r)dr and local radius r, for flapwise and lagwise bending

respectively. The centrifugal force is directed outwards and away from the centre of rotation.

Figure 1, (a) shows that for the case of flapwise bending, the external centrifugal force component

acts only in the direction of the X axis, hence dF = dFx. Therefore dF produces work only when

the beam element is displaced on the X axis (uflap(r,t)). For the case of lagwise bending, Fig. 1,

(b) demonstrates that there are force components on both X and Y axes (dFx and dFy respectively

with dF = dFx2 + dFy2 ). Thus, work is done when the beam element is displaced on both dimensions

(ulag(r,t) and (wlag(r,t) correspondingly). Figure 1(c) demonstrates that, for the case that there is

an effective offset Yoffset(r) of the beam element’s centre mass from the elastic axis, a centrifugal

force component dFcentr,y appears pointing towards the direction of the Y axis. Figure 2 shows that,

for a given torsional deformation angle θ(r,t), the centrifugal force component dFcentr,y produces a

torsion

torsional moment dMcentr

about the elastic axis, which effectively tends to twist the blade element

to zero pitch angle.

The virtual work done by the centrifugal force on the entire blade within each DOF, due to the

elementary displacements δuflap(r,t), δlag(r,t), δwlag(r,t) and torsional deformation δθ(r,t), is given

by the following expressions:

R

W flap = u flap (r , t )dFx flap

eR

R

R

eR

eR

W lag = u lag (r , t )dFxlag wlag (r , t )dFy

. . . (48)

. . . (49)

Downloaded from http:/www.cambridge.org/core. IP address: 78.47.19.138, on 01 Oct 2016 at 13:30:09, subject to the Cambridge Core terms of use, available at

http:/www.cambridge.org/core/terms. http://dx.doi.org/10.1017/S000192400000960X

Goulos et al Lagrangian formulation for the rapid estimation of helicopter rotor blade...

877

Z

w ' (r , t )

duz

w ' ( r , t ) dr

dux

w ' (r , t )

Y

dm

dr

X

Figure 3. Elementary dislocations of a beam element for flap bending motion.

R

torsion

W torsion = (r , t )dM centr

eR

. . . (50)

where dFxflap/lag are the X axis centrifugal force components for the flap and lag case respectively.

(δwlag (r , t )) 2

has been omitted in formulating

2

It is noted that a nonlinear term proportional to Equation (49). Expressing Equations (48)-(50) in terms of generalised coordinates gives:

N

. . . (51)

W flap/lag/torsion = Qi flap/lag/torsionδ qiflap/lag/torsion

i =1

where Q

are the generalised external forces and moments corresponding to the generalised

coordinates q

for blade flap, lag, and torsion respectively. They are defined as:

flap

R u

(r , t )

. . . (52)

dFx flap , i = 1,...N

Qi flap =

eR

qiflap

flap/lag/torsion

i

flap/lag/torsion

i

lag

lag

R w

R u

(r , t ) lag

(r , t )

d

dFy , i = 1,...N

Qilag =

F

x

lag

lag

eR

eR

qi

qi

. . . (53)

R ( r , t )

torsion

dM centr

Qitorsion =

, i = 1,...N

eR q torsion

i

. . . (54)

It can be shown from Figs 1 (a) – (c) and Fig. 2 that:

dFx flap = A(r ) 2 (eR (r eR)Cos(r , t ))dr

. . . (55)

dFxlag = A(r ) 2 (eR (r eR)Cos (r , t ))dr

. . . (56)

wlag (r , t )

dFy = A(r ) 2 DSin (arc Sin

) dr

D

. . . (57)

Downloaded from http:/www.cambridge.org/core. IP address: 78.47.19.138, on 01 Oct 2016 at 13:30:09, subject to the Cambridge Core terms of use, available at

http:/www.cambridge.org/core/terms. http://dx.doi.org/10.1017/S000192400000960X

878

The Aeronautical Journal

August 2014

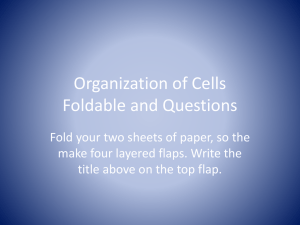

Figure 4. Relative frequency error ε for the case of transverse displacement: a) Hingeless blade boundary

conditions, b) Spring-hinged articulated blade boundary conditions (A logarithmic scale is used for clarity).

dFz = 0 . . . (58)

. . . (59)

torsion

2

dM centr

= A(r ) 2Yoffset

(r )Sin(r , t )dr

where Ω is the nominal rotorspeed in rad/sec and D is the distance of beam element dm from the

(r , t ) = arcSin

rotation axis as shown in Fig. 1(b). The values wlag (r , t )

w flap (r , t )

(r , t ) = arcSin

and

r eR

r eR

are the effective beam element lap and lag angles respectively. Having assumed small displacements

with regards to wflap, wlag and θ(r,t), and , it can be considered that Cosβ(r,t) ≈ 1, and Cosζ(r,t) ≈ 1

and Sin θ(r,t) ≈ θ(r,t) . Equations (55)-(59) therefore give:

Downloaded from http:/www.cambridge.org/core. IP address: 78.47.19.138, on 01 Oct 2016 at 13:30:09, subject to the Cambridge Core terms of use, available at

http:/www.cambridge.org/core/terms. http://dx.doi.org/10.1017/S000192400000960X

Goulos et al Lagrangian formulation for the rapid estimation of helicopter rotor blade...

879

dFx dFx flap = dFxlag A(r ) 2 rdr

. . . (60)

dFy = A(r ) 2 wlag (r , t )dr

. . . (61)

torsion

2

dM centr

A(r ) 2Yoffset

(r )(r , t )dr

. . . (62)

It is noted that no approximation is made with regards to dFy.

Having obtained closed form approximations for the differential centrifugal force and

torsion

2

moment components dFxflap/lag, dFy and dM centr

,what

in

A(rremains

) 2Yoffset

(r )order

(r , t )to

dr acquire expressions

for the generalised forces given by Equations (52)-(54), is the designation of the partial derivatives

flap

u

(r , t ) u lag (r , t ) wlag (r , t )

θ (r , t )

qiflap (t )

,

qilag (t )

,

qilag (t )

, and

qitorsion (t )

i 1,...N .

Figure 3 presents the elementary dislocations during flapwise bending for a straight-line beam

element of infinitesimal length dr. It is illustrated that, for a first spatial derivative of transverse

displacement equal to w′(r,t), there is an inboard total dislocation within the infinitesimal radial

distance dr. The components of du along the X and Z axes are defined as dux and duz respectively.

It can be shown from Fig. 3 that:

. . . (63)

du = dr ( 1 w' (r , t ) 2 1)

du x = du Cos w' (r , t )

. . . (64)

du z = du Sin w' (r , t )

. . . (65)

The dislocation component dux is of interest both for flap and lag bending motion. This is due to

the fact that there are centrifugal force components acting on the X axis considering both DOFs.

Expanding Equation (63) using a McLaurin series up to the first term gives:

1

du ≈ w' (r , t ) 2 dr

2

. . . (66)

Assuming small w′(r,t), Equation (64) leads to dux ≈ du. A similar analysis can be conducted for

the lag DOF yielding similar expressions for du and dux. Integration of Equation (66), starting

from the beam root/hinge location (r = eR) up until the local beam element radius r, provides the

total displacement of a beam element on the X axis for flap and lag bending motion respectively:

1 r

u flap/lag (r , t ) = w'flap/lag (, t ) 2 d

2 eR

. . . (67)

where ξ is an independent spatial integration variable. The negative sign has been added in front

of the RHS of Equation (67) to signify the inboard nature of the dislocation considering both

DOFs. This convention essentially leads to negative X axis differential displacement for positive

values of w′(r,t) and vice-versa.

The terms uflap and ulag can now be expressed as functions of generalised coordinates. Substitution

of Equations (32)-(33) into Equation (67) leads to the following expression:

1 N N

/lag

u flap/lag (r , t ) = aiflap

(r )qiflap/lag (t )q jflap/lag (t )

,j

2 i =1 j =1

. . . (68)

Downloaded from http:/www.cambridge.org/core. IP address: 78.47.19.138, on 01 Oct 2016 at 13:30:09, subject to the Cambridge Core terms of use, available at

http:/www.cambridge.org/core/terms. http://dx.doi.org/10.1017/S000192400000960X

880

The Aeronautical Journal

August 2014

where the parameters ai,jflap(r) and ai,jlag(r) are defined as follows:

r

/lag

/lag

aiflap

(r ) = i'flap/lag ()'flap

()d

,j

j

eR

. . . (69)

Derivation of Equations (68), (33) and (34) with respect to their generalised coordinate (qiflap(t),

qilag(t), qitorsion(t) and for flap-lag-torsion in that order) gives:

N

u flap (r , t )

flap

. . . (70)

= aiflap

(t )

, j (r )q j

flap

qi (t )

j =1

N

u lag (r , t )

lag

=

ailag

, j ( r ) q j (t )

qilag (t )

j =1

. . . (71)

wlag (r , t )

= lag

i (r )

qilag (t )

. . . (72)

(r , t )

= torsion

(r )

i

qitorsion (t )

. . . (73)

for i = 1, ...N. Combining Equations (70)-(73) and Equations (52)-(54) results in closed form

expressions for the generalised centrifugal external forces and torsional moments as functions of

generalised coordinates:

N

/lag/torsion flap/lag/torsion

Qi flap/lag/torsion = I i ,flap

qj

(t ), i = 1,...N

. . . (74)

j

j =1

lag

torsion

where I flap

are the effective centrifugal stiffening inter-modal coupling coefficients

i,j , I i,j , and I i,j

for flap-lag-torsion respectively which are defined as follows:

R

r

eR

eR

2

'flap

I i ,flap

()'flap

j = A( r ) r i

j ()ddr

2

'lag

lag

'lag

2 lag

I ilag

, j = A( r ) r i () j ()ddr A( r ) i ( r ) j ( r )dr

2

I itorsion

= A(r ) 2Yoffset

(r )torsion

(r )torsion

(r )dr

,j

i

j

R

r

R

eR

eR

eR

R

eR

. . . (75)

. . . (76)

. . . (77)

3.4Eigenproblem formulation and solution

Substituting the acquired expressions for strain and kinetic energy from Equations (40) and

(41) along with the generalised centrifugal force and moments expressions from Equation (74)

into Equation (35), results in the following systems of ODEs describing flap, lag, and torsional

vibration respectively:

Downloaded from http:/www.cambridge.org/core. IP address: 78.47.19.138, on 01 Oct 2016 at 13:30:09, subject to the Cambridge Core terms of use, available at

http:/www.cambridge.org/core/terms. http://dx.doi.org/10.1017/S000192400000960X

Goulos et al Lagrangian formulation for the rapid estimation of helicopter rotor blade...

N

m

j =1

N

flap/lag/torsion

i, j

j =1

qjflap/lag/torsion (t )

( k

881

flap/lag/torsion

i, j

f

flap/lag/torsion

i, j

I

flap/lag/torsion

i, j

)q

. . . (78)

flap/lag/torsion

j

(t ) = 0, i = 1,...N

Assuming periodic motion, we can consider a potential solution for the ith generalised flap-lagtorsion coordinate of the form: qi = qi Sin(ωit + ψi). Substituting the aforementioned expression

in Equation (78) results in the following systems of equations:

N

(ω

) m

)q

(G

j =1

flap/lag/torsion

i, j

i

flap/lag/torsion 2

flap/lag/torsion

i, j

flap/lag/torsion

j

= 0, i = 1,...N

. . . (79)

where ωiflap/lag/torsion is the natural frequency of the mode for flap, lag, and torsional vibration in

that order. G i,jflap/lag/torsion = k i,jflap/lag/torsion + f i,jflap/lag/torsion + I i,jflap/lag/torsion, is the overall effective stiffness

coupling coefficient between the ith and jth assumed modes of flap-lag-torsion, including elastic

ki,j, hub-spring/pitch-control system fi,j, and centrifugal stiffening effects Ii,j.

Equation (79) essentially describes the formulated eigenproblem whose solution leads to the

determination of the system’s N first natural frequencies (ω iflap/lag/torsion), i = 1, ...N) and mode

shapes for flap, lag, and torsional vibration. Arranging Equation (79) in matrix notation leads to

the following expression:

flap/lag/torsion

A Lagrange

q flap/lag/torsion = 0

. . . (80)

T

where q = [q1 , q2 ,...qN ] with respect to the flap, lag, and torsion cases respectively, while

flap/lag/torsion

flap/lag/torsion

A Lagrange

square =symmetric

matrices of size N.

qare

0

In order for Equation (80) to have non-trivial solutions, the following condition needs to apply:

flap/lag/torsion

det A Lagrange

=0

. . . (81)

Equation (81) is another transcendental equation that can be evaluated numerically. This can

be achieved through marching within the ωiflap, ωilag, ωitorsion and domains respectively, until the

first N values of ωi flap/lag /torsion i = 1, ...N that satisfy Equation (81) are obtained. The vectors

flap

torsion

A Lagrange

, A lag

qiflap , qilag , qitorsion , i = 1,...N are essentially eigenvectors of matrices

Lagrange and A Lagrange

flap/lag/torsion

(when the corresponding mass matrices M

, which contain the inertial inter-modal coupling

coefficients m flap/lag/torsion

,

are

used

for

weighting

instead

of the unit matrix) and are associated with

i,j

Ωiflap/lag/torsion respectively.

flap

torsion

A Lagrange

, A lag

Since

Lagrange and A Lagrange are square symmetric matrices, their eigenvectors are orthogonal

with one another. The eigenvector orthogonality condition dictates that:

{q flap/lag/torsion }Ti M flap/lag/torsion {q flap/lag/torsion } j = 0, i ≠ j , i, j = 1,...N

. . . (82)

The final N first mode shapes of the nonuniform rotating blade, are provided as the dot products of

flap/lag/torsion

flap/lag/torsion

the assumed mode shape vectors and the eigenvectors of matrices A

.qThis

yields:= 0

Lagrange

X i flap/lag/torsion (r ) = flap/lag/torsion (r ) {q flap/lag/torsion }Ti , i = 1,...N

. . . (83)

Downloaded from http:/www.cambridge.org/core. IP address: 78.47.19.138, on 01 Oct 2016 at 13:30:09, subject to the Cambridge Core terms of use, available at

http:/www.cambridge.org/core/terms. http://dx.doi.org/10.1017/S000192400000960X

882

The Aeronautical Journal

1st Mode

3rd Mode

5th Mode

7th Mode

9th Mode

10 −5

August 2014

2nd Mode

4th Mode

6th Mode

8th Mode

10th Mode

Relative frequency error η

4.870

4.868

4.866

4.864

4.862

4.860

0

Relative frequency error η

10 −5

2

4

6

8

10

12

Number of assumed mode shapes N

a)

9

8

7

6

5

4

0

b)

2

4

6

8

10

12

Number of assumed mode shapes N

Figure 5. Relative frequency error η for the case of torsional deformation: (a) Infinite

pitch-control system torsional stiffness, (b) Finite pitch-control system torsional stiffness.

where Φ(r) = (φj(r), j = 1, ...N)T are the assumed mode shape vectors for flap-lag-torsion respectively. It is shown in Ref. 34 that the orthogonality between the acquired eigenvectors of matrices

flap

lag

torsion

A

Lagrange , A Lagrange and A Lagrange and due to their symmetric nature, also leads to the orthogonality of

the acquired mode shapes given by Equation (83). Therefore, it applies that:

R

flap/lag

flap/lag

A(r ) X i (r ) X j (r )dr = 0, i j, i, j = 1,...N

torsion

torsion

I p (r ) X i (r ) X j (r )dr = 0, i j, i, j = 1,...N

eR

R

eR

. . . (84)

. . . (85)

The conditions expressed by Equations (29)-(30), used for the amplitude normalisation of the

Downloaded from http:/www.cambridge.org/core. IP address: 78.47.19.138, on 01 Oct 2016 at 13:30:09, subject to the Cambridge Core terms of use, available at

http:/www.cambridge.org/core/terms. http://dx.doi.org/10.1017/S000192400000960X

Goulos et al Lagrangian formulation for the rapid estimation of helicopter rotor blade...

883

assumed modal functions, are also incorporated in order to acquire the amplitude of the final mode

shapes given by Equation (83), thus giving:

R

2

flap/lag

eRA(r )( X i (r )) dr = 1, i = 1,...N

. . . (86)

R

l

2

torsion

∫eR( X i (r )) dr = 2 , i = 1,...N

. . . (87)

3.5Rotor blade model generation and analysis

The overall data required by the proposed approach for the generation and analysis of a complete

rotor blade model, broadly comprises information related to general dimensions, boundary

conditions, structural properties, as well as the operating conditions of the blade. As regards data

related to general dimensions, only values for the the blade radius R and any potential hinge-offset

ratio e (yielding the actual blade length l = (1 –e)R)) are required. This information is initially

utilised during the derivation of assumed deformation functions through the application of classical

methods. The rotor blade’s boundary conditions are taken into account through application directly

within Bernoulli-Euler beam and classical torsion theories.

Data related to the structural properties of the blade in terms of radial distributions of mass and

polar mass moment of inertia per unit length (ρA(r) and ρIp(r)), flapwise and lagwise bending

stiffness (EIflap/lag(r)), torsional rigidity (GJ(r)), and any potential hub spring stiffness (Kflap/lag/torsion),

is also required. This information is used in combination with the aforementioned data on general

blade dimensions, for the evaluation of the definite integrals corresponding to the inertial, elastic,

and hub-spring inter-modal coupling coefficients (mi,j, ki,j, and fi,j) between the ith and jth assumed

modes of motion as expressed by Equations (42)-(47).

Since the current approach is aimed towards estimating the natural vibration characteristics of

a nonuniform rotating blade in vacuum, the only required information considering the operating

conditions of the blade is rotorspeed Ω. No aerodynamic loads are considered at this point since they

are meant to be treated as external forcing during a dynamic response analysis along with nonlinear

inertial coupling loads (such as due to Coriolis acceleration). Rotorspeed is utilised, along with the

radial distribution of aerofoil centre mass offset from elastic axis (Yoffset(r))), for the numerical evaluation of the definite integrals expressing the centrifugal stiffening inter-modal coupling coefficients

between ith the jth and assumed modes of motion as stated by Equations (75)-(77).

Having utilised the required rotor blade data for the evaluation of the aforementioned definite

integrals, the corresponding mass and effective stiffness matrices (Mflap/lag/torsion and Gflap/lag/torsion

respectively) can be populated for each DOF. The computational procedure described in section

‘Eigenproblem formulation and solution’ can be subsequently be deployed leading to the estimation

of the natural frequencies and mode shapes corresponding to each DOF.

4.0Results and Discussion

4.1Lagrangian approximation error

In order to evaluate the influence of the Lagrangian linearisation assumption , (

T

0) on the

qi

accuracy of the proposed method, a comparative evaluation has been carried out between the

exact Bernoulli-Euler beam/classical torsional vibration theories and the approximate Lagrangian

Downloaded from http:/www.cambridge.org/core. IP address: 78.47.19.138, on 01 Oct 2016 at 13:30:09, subject to the Cambridge Core terms of use, available at

http:/www.cambridge.org/core/terms. http://dx.doi.org/10.1017/S000192400000960X

The Aeronautical Journal

Normalized mode frequency ω/Ω

884

1st Flap

3rd Flap

5th Flap

40

30

25

20

15

10

5

0

0

Normalized mode frequency ω/Ω

2

4

6

8

10

12

14

16

Number of assumed mode shapes N

1st Lag

3rd Lag

5th Lag

60

2nd Lag

4th Lag

50

40

30

20

10

0

0

2

4

6

8

10

12

14

16

Number of assumed mode shapes N

b)

Normalized mode frequency ω/Ω

2nd Flap

4th Flap

35

a)

c)

August 2014

1st Torsion

3rd Torsion

5th Torsion

80

2nd Torsion

4th Torsion

70

60

50

40

30

20

10

0

0

2

4

6

8

10

12

14

16

Number of assumed mode shapes N

Figure 6. Influence of number of assumed deformation functions on the normalised

modal frequencies of the articulated rotor blade model described in Ref. 35,

Ω = 69 rad/sec (660rpm): (a) Flap modes, (b) Lag modes, (c) Torsion modes.

Downloaded from http:/www.cambridge.org/core. IP address: 78.47.19.138, on 01 Oct 2016 at 13:30:09, subject to the Cambridge Core terms of use, available at

http:/www.cambridge.org/core/terms. http://dx.doi.org/10.1017/S000192400000960X

Normalized mode frequency ω/Ω

Goulos et al Lagrangian formulation for the rapid estimation of helicopter rotor blade...

1st Flap

3rd Flap

5th Flap

250

225

200

175

150

125

100

75

50

25

0

0

Normalized mode frequency ω/Ω

6

8

10

12

1st Lag

3rd Lag

5th Lag

250

225

200

175

150

125

100

75

50

25

0

0

14

16

2

4

6

2nd Lag

4th Lag

8

10

12

14

16

Number of assumed mode shapes N

b)

Normalized mode frequency ω/Ω

4

2nd Flap

4th Flap

Number of assumed mode shapes N

a)

1st Torsion

3rd Torsion

5th Torsion

80

2nd Torsion

4th Torsion

70

60

50

40

30

20

10

0

0

c)

2

885

2

4

6

8

10

12

14

16

Number of assumed mode shapes N

Figure 7. Influence of number of assumed deformation functions on the normalised

modal frequencies of the hingeless rotor blade model described in Ref. 36:

Ω = 105 rad/sec (1,000rpm) (a) Flap modes, (b) Lag modes, (c) Torsion modes.

Downloaded from http:/www.cambridge.org/core. IP address: 78.47.19.138, on 01 Oct 2016 at 13:30:09, subject to the Cambridge Core terms of use, available at

http:/www.cambridge.org/core/terms. http://dx.doi.org/10.1017/S000192400000960X

886

The Aeronautical Journal

August 2014

formulation. Modal characteristics obtained from application of the former have been deployed

as assumed deformation functions in the latter. Figures 4 and 5 present the Lagrangian method’s

relative errors ε/η , regarding the predicted natural frequencies for the first ten modes of motion of

a uniform non-rotating structure, considering transverse displacement and torsional deformation

respectively. The relative frequency errors ε and η are defined as follows:

| Lagrange Bernoulli

|

B

= B

Bernoulli

B

. . . (88)

| Lagrange TClassical |

= T

TClasssical

. . . (89)

With respect to the transverse displacement case, results are presented for boundary conditions

corresponding to a hingeless (Fig. 4(a) and a spring-hinged articulated rotor blade (Fig. 4(b). As

regards blade torsion, Fig. 5(a) presents frequency errors corresponding to boundary conditions

dictating infinite pitch-control system torsional stiffness, while a finite value of Ktorsion is assumed

for the calculations presented in Fig. 5(b). The influence of the total number of deployed assumed