Flexible | Efficient | Powerful

advertisement

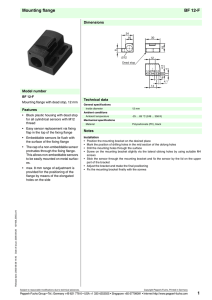

Motors | Automation | Energy Three Phase Low Voltage Motors Flexible | Efficient | Powerful WEG Worldwide WEG was founded in 1961, in south of Brazil. Now it has 26 factories in 11 countries and more than 1100 service centers around the world including the largest motor manufacturing plant of the world in Brazil with 2,500,000 square meters. WEG supplies solutions in five business unites: motors, automation, energy, transmission & distribution and coatings. Flexible | Efficient | Powerful China is a modern country and became the factory of the world due to its huge structure. To support this scenario, the country is facing new challenges and also is ware about the environmental protection. This new line is flexible for various applications, performs high level of efficiency and is reliable during its usage avoiding stop of machines and high demand for maintenance. W20 motor— because development demands flexibility and efficiency. Contents: Standard features / optional features ------------------------------------------------------------------------------------- 5 Construction features --------------------------------------------------------------------------------------------------------- 6 Mounting types ----------------------------------------------------------------------------------------------------------------- 7 IP55 Standard IE1-2P -------------------------------------------------------------------------------------------------------- 8-9 Why choose WEG ------------------------------------------------------------------------------------------------------------- 10-11 IP55 Standard IE1-4P -------------------------------------------------------------------------------------------------------- 12-13 IP55 Standard IE1-6P -------------------------------------------------------------------------------------------------------- 14-15 IP55 Standard IE1-8P -------------------------------------------------------------------------------------------------------- 16-17 Mechanical data --------------------------------------------------------------------------------------------------------------- 18-19 Standard features Three-phase multi-voltage, IP55, TEFC Cast iron frames (80 to 355) V'Ring on both endshields Drain: Automatic Plastic Stainless steel nameplate AISI 304 Design N Class “F” insulation Paint color: RAL 7000 (gray) Optional features Degree of protection: IP56 Bearing seals: Lip seal / Oil seal Class “H” insulation Thermal protection:Thermistors for frame 255 to 355 Roller bearings for frame 225 to 355 Construction features Frame Mechanical Features Nameplate Mounting Frame cast iron Materials Degree of protection Grounding Cooling method Materials Fan Fan cover Materials Endshields Materials Drain Inside the terminal box and frame Double grounding Plastic Steel Plate cast iron Aluminium Plastic Automatically operated Shielded/Clearance (DE) Shielded/Clearance (NDE) Bearings Locating bearing configuration NDE bearing fitted with wave washer DE bearing locked with inner bearing cap and fitted with wave washer in the NDE bearing DE bearing locked with outer bearing caps and fitted with pre-load springs in the NDE bearing Drive end Non-drive end Bearing seal Lubrication Grease Type Grease fitting Terminal Block Terminal Box Material Main T-Box Leads Inlet Plug Material Shaft Furo roscado Key Vibration Balancing level Nameplate Material Plan Painting Color With grease fittings in DE and NDE bearings None 6 Terminals Steel plate Thread size Plastic plug for transport and storage purposes China key type China key type With 1/2 key Stainless Steel grey Electrical Features Design Voltage Winding Material Insulation Class Service factor Rotor Thermal Protection Copper Die-cast Aluminium None Mounting Configurations Assembly Standardized mounting configurations Configuration Reference Frame with feet Details left Terminal box Assembly right left right left Top left right right flange FF without feet Top left right right base or flange FF left Top flange FC Configuration Reference right left Terminal box with feet with feet Frame Details Top left base or rail Mounting right left right left Top right left Top with feet Top bottom bottom left base or flange FC Mounting Assembly left right right with feet without feet right Top left wall right Top wall Configuration Reference Details Frame Terminal box without feet bottom Top left left Assembly Mounting left with feet with feet with feet bottom Top bottom right Top left wall or flange FF flange FF right Top left right without feet Top wall or flange FC wall or flange FF Reference Details Terminal box Mounting bottom Top left left left with feet with feet with feet front front front right wall Top left right wall Top left right ceiling Top left left flange FC Configuration Frame bottom Top IP55 Standard IE1-2P Output Frame High-output design Cn I I /I n IA /I N T I /Tn MA /M N Tb /Tn M K /M N Inertia rpm min-1 % of full load Efficiency Power factory Cos IP55 Standard IE1-2P Output rpm min-1 Hign-output design % of full load Efficiency Power factory Cos rpm min-1 % of full load Efficiency Power factory Cos IP55 Standard IE1-4P Output Frame High-output design Cn I I /I n IA /I N T I /T n Tb /Tn MA /M N M K /M N Inertia rpm min-1 % of full load Efficiency Power factory Cos IP55 Standard IE1-4P Output rpm min-1 High-output design % of full load rpm min-1 % of full load IP55 Standard IE1-6P Output Frame High-output design Cn Inertia rpm min-1 % of full load IP55 Standard IE1-6P Output Frame High-output design Cn Inertia rpm min-1 % of full load IP55 Standard IE1-8P Output Frame High-output design Cn Inertia rpm min-1 % of full load IP55 Standard IE1-8P Output rpm min-1 High-output design % of full load rpm min-1 % of full load Mechanical data Shaft dimensions Frame Note Shaft dimensions for II pole motors, only for direct coupling. All dimensions are in millimeters. The average values shown are subject to change without prior notice. To obtain guaranteed value, please contact with our nearest sales office. Bearings Mechanical data Frame “FF”Flange No of holes Frame Frame “C-DIN” Flange No of holes “C” Flange No of holes