1 | Page

advertisement

INSTALLATION & SETTING INSTRUCTIONS

P/N: PS -P

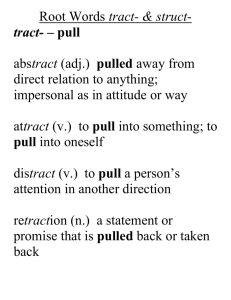

YELLOW INDICATION FLAG:

P/N STP-F

The Indication Flag should

be fitted when there is more

than one switch used on the

conveyor as noted in AS17552000 Clause 2.7.9.1 (e)

FIRST SUPPORT

OTHER SUPPORTS

600mm

MINIMUM

3000mm

ENSURE CLEARANCE FOR PULL

WIRE FIXINGS TO FIRST WIRE

SUPPORT WHEN PULL WIRE IS

FULLY ACTIVATED.

ROPE

28 GRIP

P/N STP-50-SS

MAX. DISTANCE:

50 METRES - STRAIGHT CONVEYOR

30 METRES - INCLINE CONVEYOR

MATCHED SS

COMPENSATION SPRING

P/N PS-60

161

13

PULL WIRE SHOULD BE STRAIGHT AND CLEAR OF OBSTRUCTIONS

(see note below)

33.5

SHACKLE

P/N STP-70-SS

ROPE THIMBLE

P/N STP-40-SS

20mm

Conduit

TURNBUCKLE

P/N STP-20-SS

11

NOTE: Turnbuckle MUST

have Locking Nuts fitted.

PULL WIRE 7x19 STAINLESS STEEL RED PU

COATED 3mm ID x 5mm OD P/N STL-10-REDSS or PULL WIRE 3mm ID x 5mm OD RED PU

COATED VECTRAN P/N STL-10-V

See SAFE-T-LANYARD brochures for details.

4 x M6 Mounting Holes

(Can be mounted at remote end of Pull Wire)

WIRE SUPPORT

P/N STG-200,

STG-200-SS

ROPE GRIP

P/N STP-50-SS

ROPE THIMBLE

P/N STP-40-SS

75

NOTE: - FIRST SUPPORT

MUST BE ON CENTRE LINE

OF SWITCH PULL ROD

SET

For further

SITION

28

161

requirments refer to AS 4024-1-2006

“Safeguarding of Machinery” Part 1: General

principals and AS 1755-2000 “Conveyors

Design, Construction, Installation and Operation,

Safety requirements,” respectively for coveyors

used in Australia.

13

NOTE: TO COMPLY WITH AS 1755-2000

Clause 2.7.9

33.5

A matched compensation spring must be fitted to

the remote end of the Pull Wire to allow tripping

in both directions.

125

20mm

Conduit

30

AS 1755-2000 is the Australian Standards for

Conveyor – Safety Requirements.

11

4 x M6 Mounting Holes

52.5

75

52.5

SET POSITION

SWITCH CANNOT BE RESET UNTIL PULL WIRE IS CORRECTLY TENSIONED

ie. 75mm from pull rod end to switch body.

1|Page

Standards

The

complies with the relevant parts of these Standards:

IEC 60947-5-1:2003

AS 60947-5-1:2004

IEC 609475.5:1997

AS 4024.1-2006

AS 1755-2000

Control circuit devices & switching elements

Control circuit devices & switching elements

Control circuit devices & switching elements

- Electrical emergency stop devices with mechanical latching function.

Control circuit devices & switching elements

- Electrical emergency stop devices with mechanical latching function.

Safety of Machinery.

Conveyors-Safety requirements.

Ce Conformity to:

98/37/EEC

73/23/EEC

Machinery Directive

Low Voltage Directive

Harmonised Standards:

EN ISO 12100

EN 60204-1:1997

EN 418:1992

Parts 1 & 2 Safety of machinery

Safety of Machinery-Electrical equipment of machines

Safety of machinery-Emergency stop equipment

AS 3947.5.5:2000

Product Life Expectancy

Kinder and Co. estimate the product life expectance to 10-15 years.

A shorter or longer product life maybe experienced due to environmental situations.

Kinder and Co. can’t give a written life expectance on any of it’s products due to the different situations the products are used.

Maintenance Procedure

All

switches require minimal maintenance but as in AS 4024.1:1996 & AS 1755:2000 a maintenance

procedure should be carried out.

Maintenance at 3 Month Intervals

1.

2.

3.

4.

5.

6.

7.

Check that the switches are installed as per installation instructions.

Visual inspection of enclosure to ensure IP67 rating and correctly operating device. i.e. Damaged enclosure, bent pull

rod, damaged dust boot etc.

Inspect compensation springs (Overall relaxed size is 138mm +/- 10mm)

Inspect all attachments are tight, free from obstructions and not worn and replace if necessary.

Inspect pull wire supports for wear, deteration and build up of material, replace if necessary.

Inspect pull wire for wear or deteration and replace if necessary.

Check that the pull rod is tensioned to the set position as per installation instructions.

2|Page

FIGURE 1

Axis Pull Wire Test

Up to 100 metres

Maximum of 3 metres from

Switch in the middle of 2 guides

Reading should be no

higher than 230N (23kg)

to Trip the Switch

STEP 1

STEP 2

Pull direction

Reading should be no

higher than 230N (23kg)

to Trip the Switch

7.0 kg

7.0 kg

7.0 kg

Pull direction

Pull direction

Reading should be no

higher than 230N (23kg)

to Trip the Switch

7.0 kg

Pull direction

7.0 kg

7.0 kg

Pull direction

Lanyard Switch

Maximum 3 metres from

Compensation Spring in

the middle of 2 guides

Centre of Pull Wire

Pull direction

Remote

Compensation

Spring

STEP 3

PULL W IR E

PULL

WIRE

Pull tight

TEST PULL ROPE

ATTACHMENT METHOD

(Note: Comes with Safe-T-Scales)

Loop end of

Test Rope and

attach to Scales.

8.

Test that the

Lanyard works as per Australian Standards AS1755-2000

Attach the SAFE-T-SCALES or other weight measurement device to the pull wire via the SAFE-T-SCALES rope or other

means (See Figure1). The test needs to be conducted along the axis of the pull wire in both directions. Pull the wire along the

axis until the switch trips then check the amount of force used to activate a trip. The reading must be less than 230N (23Kg).

This must be done at intervals at the centre of pull wire’s length, 3m-4m from the switch and 3m-4m from the compensation

spring in both directions (See Figure 1). After each trip the switch will need to be reset before the next axis trip test is to

be conducted. If the reading is higher than 230N then recheck steps 1-7, then retest the axis pull test. If the problem is still

present contact the supplier of the product for advice.

Reset the

and attach the SAFE-T-SCALES or other weight measurement device to the pull wire (See

Figure 2), 90 degrees to the pull wire axis. A length measurement needs to be taken as well. The test needs to be conducted

90 degrees to the pull wire’s axis at the same positions as test 1 and at the centre, between supports (See Figure 2). Pull the

wire to the 90 degree axis and using the SAFE-T-SCALES or some other weight measurement device, measure the amount

of force it takes to trip the switch. Once the switch trips check to see how far the pull wire needs to be pulled to activate a

trip using a tape measure or ruler. The force used to activate a trip must not exceed 70N (7Kg) and the amount of pull must

not exceed 300mm. If the readings are higher than 70N-300mm then recheck steps 1-7, retest the 90 degree axis pull test. If

the problem is still present contact the supplier of the product for advice.

3|Page

FIGURE 2

90 Degree Pull Wire Test

Up to 100 metres

Maximum of 3 metres from

Switch in the middle of 2 guides

Maximum 3 metres from

Compensation Spring in

the middle of 2 guides

Centre of Pull Wire

7.0 kg

7.0 kg

7.0 kg

Remote

Compensation

Spring

Pull direction

Pull direction

Pull direction

Reading should be no

higher than 70N (7kg)

to Trip the Switch at

300mm.

MEARSUREMENT

Reading should be

no higher than

70N (7kg) to Trip

the Switch at 300mm.

Reading should

be no higher than

70N (7kg) to Trip

the Switch at

300mm.

PULL WIRE

7.0 kg

Lanyard Switch

SAFE-T-SCALE

9. After activation test, check that the set position of the pull rod is as per installation instructions, if not readjust turnbuckle

so the pull rod is at the set position and redo step 8-9.

10. If the switch is not working return to authorised distributor for assessment if under warranty or replace.

Every 12 Month Period

Remove cover & check for corrosion or water ingress. Replace if necessary.

Check electrical connections for security and corrosion.

Clean lid seal and replace cover & torque down lid screws as per limit switch wiring diagram.

4|Page

TE C H NI C A L DATA

POSITIVE BREAK TYPE

TECHNICAL DATA

CONTACT FORM - SPDT

Performance to VDE 0660, part 200 7/92

(EN 60947, IEC 947.

Direct positive opening.

Long overtravel after direct positive opening.

NC

Permenant current

6A (max. 10A)

Breaking capacity

AC 15 250 V AC/1,5A

Insulation

4kV/3

Contact type

NC/NO/change over

Protection degree IP 40

Mechanical life

10 million operations

Self cleaning contact pieces

Temperature range

-40°C to +85°C

Type A, DIN 41636

NO

COM

STANDARD SWITCH TYPE

CONTACT SPECIFICATIONS

SWITCHING CAPACITY PER LOAD (REFERENCE VALUES)

Non-Inductive Load

Model

Voltage

Resistive Load

NC

V-15

Lamp Load

NO

250 VAC 15 A

NC

Contact

Inductive Load

Inductive Load

NO

NC

Motor Load

NO

NC

2A

10 A

3A

8 VDC

15A

4A

10 A

6A

30 VDC

10 A

4A

10 A

4A

125 VDC 0.6 A

0.1 A

0.6 A

0.1 A

250VDC

0.05 A

0.3 A

0.05 A

0.3 A

NO

Inrush

current

Specification

Rivet

Material

Silver Alloy

Gap (Standard

value)

1mm (F gap) or

0.5mm (G gap)

NC

36 A max

NO

Minimum applicable load

160 mA at 5 VDC

CONTACT FORM - SPDT

CHARACTERISTICS

Operating speed

0.1 mm to 1 m/s (pin plunger models)

Operating frequency

Mechanical: 600 operations/min max.

Electrical: 30 operations/min max.

Insulation resistance

100 MΩ min. (at 500 VDC)

Contact resistance (initial value)

15 MΩ max.

Dielectric strength (see note 2)

1,000 VAC, 50/60 Hz for 1 min between terminals of

the same polarity.

1,500 VAC, 50/60 Hz for 1 min between currentcarrying metal parts and ground, and between each

terminal and non-current-carrying metal parts.

Vibration resistance

Malfunction:

Shock resistance

Destruction: 1,000 m/s2 {approx. 100G} max.

300 m/s2 {approx. 30G} max.

Durabilit

NC

NO

COM

10 to 55 Hz, 1.5-mm double amplitude.

Mechanical: 50,000,000 operations min.

(60 operations/min)

100,000 operations min.

(30 operations/min)

Electrical:

Degree of protection

IEC IP40

Degree of protection against electric shock

Class I

Proof tracking index (PTI)

175

Ambient operating humidity

-25°C to 80°C (at ambient humidity of 60%max.)

(with no icing).

-25°C to 150°C for heat resistive model at ambient

humidity of 60%max.) (with no icing).

Weight

Approx. 6.2g (pin plunger models)

Note:

1. The data given are

initial values.

2. The dielectric strength

values shown in the

table are models with

a separator.

5|Page