medical electrical equipment

advertisement

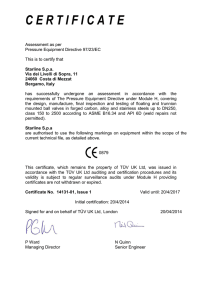

COMPLEMENT MEDICAL ELECTRICAL EQUIPMENT Doc: 703-CRC-001-E Review: 08 Page: 1/20 Prepared by: Eliana Shimoda Verified by: Karen C. Martins Approved by: Lester Amaral Jr Approval date: 24/07/2015 1 – PURPOSE These Requirements for Conformity Assessment (RAC) establish the criteria for Conformity Assessment Program (PAC) for Electrical Equipment under Health Surveillance, meeting the requirements of the standards listed in Additional Documents, seeking the safety of the user. Note: This document presents the Inmetro Regulation (Regulation nº 350, of September 06th, 2010). The prescriptions of RDC 27,of June 21st, 2011 (Anvisa) and current Normative Instruction, concerning the certification’s process, must be considered too. 2 –COMPLEMENTARY DOCUMENTS ABNT NBR IEC 60601-1 Medical Electrical Equipment - Part 1 - General Requirements for Safety. and its amendments. ABNT NBR IEC 60601-2, all series Medical Electrical Equipment - Part 2 – Particular Requirements for Safety of Equipment. ABNT NBR ISO 13485:2004 Medical devices - Quality management systems - Requirements for regulatory purposes. Normative Instruction of Anvisa, which is current Establishes technical standards adopted for certification of compliance for Medical Electrical Equipment under Health Surveillance. Law nº 9.933, of December th 20 , 1999 Provides requirements for the powers of Conmetro and Inmetro, establishes the rate of Metrological Services, and other requirements. Law nº 8078, of September 11th, 1990 Provides requirements for consumer protection and other requirements. Law nº 6.437, of August 20th, 1977 Sets violations of federal health legislation, establishes the respective sanctions, among other requirements. Regulation Inmetro nº 179, of June 16th, 2009 Approves for its faithful observance of the Regulations for Use of Trademarks, Symbols of Accreditation, Recognition of Conformity to the Principles of Good Laboratory Practices - GLP and of Inmetro Seal of Identification. Interministerial Regulation MS/MDIC nº 692, of April 8th, 2009 Defines the operation of technical cooperation activities for the Quality Assurance and Safety of Medical Devices subject to the system of sanitary control, as provided in the Technical Cooperation between the Ministry of Health (MOH) and Ministry of Development, Industry and Foreign Trade (MDIC). Board Resolution of Anvisa RDC/ANVISA nº 27, of June 21st, 2011 Provides requirements for Compulsory Certification of Medical Equipment under Surveillance Scheme. Board Resolution of Anvisa RDC/ANVISA nº 59, of June Provides the requirements of Good Manufacturing Practices and Control of Medical Products. COMPLEMENT MEDICAL ELECTRICAL EQUIPMENT Doc: 703-CRC-001-E Review: 08 Page: 2/20 27th, 2000 3 ABBREVIATIONS ABNT Brazilian Association of Technical Standards ANVISA National Agency for Health Surveillance CNPJ National Register of Legal Entities Conmetro National Council of Metrology, Standardization and Industrial Quality CRC TÜV Rheinland do Brasil Ltda’s Certification Rule Complement DIPAC Programs Division Compliance Assessment (Inmetro) DQUAL Quality Board (Inmetro) IEC International Electrotechnical Comission Inmetro National Institute of Metrology, Standardization and Industrial Quality IN Normative Instruction of Anvisa ISO International Organization for Standardization MOU Memorandum of Understanding MDIC Ministry of Development, Industry and Foreign Trade NBR Recorded Brazilian Standards OCP Product Certification Body accredited by INMETRO RAC Requirements for Conformity Assessment RDC Board Resolution RMP Master record of the product RTQ Technical Requirements for Quality SBAC Brazilian System for Conformity Assessment SGQ Quality Management System VISA Health Surveillance 4 DEFINITIONS For purposes of this CRC, the following definitions are adopted: COMPLEMENT MEDICAL ELECTRICAL EQUIPMENT Doc: 703-CRC-001-E Review: 08 Page: 3/20 4.1 Certificate of Compliance Statement, based on a decision made after the review, that the specified requirements has been demonstrated. 4.2 Original features (characteristics) Technical specifications, details and purpose of use, physical characteristics, including a list of critical components and accessories, chemical characteristics (where applicable), the content of accompanying documents, and the markings on the equipment, which are the design features of a equipment at the time of granting the certification. It must still meet the specification of registered equipment, or to be registered, at Anvisa. 4.3 Authorized Company Authorized company is the manufacturer or importer. 4.4 Type test Tests carried out in one or more units, manufactured according a particular project, to demonstrate that this project meets the conditions specified in the relevant standards adopted by this CRC. 4.5 Routine tests Test to which each manufactured unit is subjected during or after manufacturing, to see if it meets the conditions specified by this CRC. 4.6 Electrical equipment under Health Surveillance The Electrical Equipment under Health Surveillance, including parts and accessories, are powered by electric mains supply or internal power supply-intended to medical, dental, laboratory and physiotherapy purposes, directly or indirectly used for diagnosis, treatment and monitoring of human beings, and with the further purpose of beautification and aesthetics. 4.7 Manufacturer Manufacturer is the entity responsible for designing, manufacturing, packaging and labeling of a medical product, assembly of a system or adaptation of the product before being placed on the market or running, regardless of the fact that these operations are performed by that person or their behalf by a third party. 4.8 Family The characterization of the family is as set out in Annex D of this CRC. 4.9 Importer It is the entity responsible for the entry of goods originating from outside the national territory and has the responsibility to ensure the achievement of the routine tests prescribed in this CRC. 4.10 Testing Laboratory Public entity, private or mixed, accredited by Inmetro, according to the criteria established by itself, to conduct tests based on the principles and policies adopted under SBAC. 4.11 Master list of quality documents This list is the index or equivalent procedures where are listed all the documents of the quality system (procedures, work instructions, etc.), and where the versions of the current documents are indicated. 4.12. Batch production Amount of product that is produced in a manufacturing cycle, and whose main characteristic is its homogeneity. 4.13 Model or type COMPLEMENT MEDICAL ELECTRICAL EQUIPMENT Doc: 703-CRC-001-E Review: 08 Page: 4/20 Designation given by the applicant that distinguishes products. 4.14 Product Certification Body (OCP) Public entity, private or mixed, the third party, accredited by Inmetro, according to the criteria established by itself, to perform services for conformity assessment of products, based on the principles and policies adopted in the Brazilian System for Conformity Assessment - SBAC. 4.15 Master record of the product (RMP) The RMP is a compilation of records containing the complete drawings of the product, its formulation and specifications, procedures and specifications for manufacturing and purchasing, the procedures and requirements of the quality system and procedures of the finished product on the packaging, labeling, technical assistance, maintenance and installation. 4.16 Historical record of the project (RHP) RHP is a compilation of records containing the complete history of the project to a finished product. 4.17 Requirement for Conformity Assessment (RAC) Document that sets out specific rules and systemic treatment for conformity assessment of products, processes, services, people or quality management systems, in order to provide adequate level of confidence in relation to the requirements of the standard or RTQ. 4.18 Seal of Identification of Conformity Graphical representation to identify objects evaluated according to the SBAC, as indicated in Annex C. 4.19 Serial Number Designation given by the applicant to uniquely identify each unit produced. 4.20 Applicant Person or entity, public or private, national or foreign, legally established in the country that develops the following activities: production, assembly, creation, construction, processing, importation, distribution, free or not, or marketing of electrical equipment under Health Surveillance, covered by this CRC. It is responsible for requesting certification of the product by TÜV Rheinland do Brasil Ltda, which holds the concession for the use of the Seal of Conformity Identification. 4.21 Pilot unit The pilot unit corresponds to one unit of output or number of units produced following the criteria established in the production process of product design. 5 MECHANISM OF CONFORMITY ASSESSMENT 5.1 The mechanism used in the conformity assessment system of electrical equipment under Health Surveillance contemplated by this CRC is a voluntary certification, except for products which the Regulator, Anvisa, requires the compulsory certification on current IN / Anvisa. 5.2 This CRC establishes the Model with Assessment of the SGQ (QMS) with the production process and product testing (type and routine) of the product. At any time, verification tests to ensure maintenance of compliance can be carried out during the term of certification. 5.3 The steps involved in conformity assessment, described in item 6, shall be conducted by the Product Certification Bodies - OCP. 6 STEPS OF THE PROCESS OF CONFORMITY ASSESSMENT This chapter sets out the conformity assessment process for granting and maintaining authorization for use of the Seal of Identification of Conformity. COMPLEMENT MEDICAL ELECTRICAL EQUIPMENT Doc: 703-CRC-001-E Review: 08 Page: 5/20 6.1 Model with Assessment of the Quality Management System of Product Manufacturing Process and Testing in Product 6.1.1 Initial evaluation 6.1.1.1 Request to Start Process The applicant must submit a formal request to TÜV Rheinland do Brasil Ltda which must include the name and characteristic of the product to be certified by attaching the technical documentation of product, including user manual and descriptive, containing a clear indication of the use and the target people for whom the equipment is designed, and documentation of manufacturer's quality management system (quality manual and master list of quality documents), all in the latest version. 6.1.1.2 Analysis of the Request and Documentation Before starting the certification process, TÜV Rheinland do Brasil Ltda must review the request and must evaluate the documents submitted for compliance and compatibility with the requirements expressed in this CRC, including those inherent to the process of manufacturing the product. If the certification request is deemed feasible, TÜV Rheinland do Brasil Ltda must formally inform the applicant the reason for the infeasibility of the service, technically justified based on the scope of application of the technical standards adopted and characteristics of equipment, and must return all sent documents. Note: The final decision on the applicability of the compulsory certification of the product under this CRC is from Anvisa in accordance with current IN. 6.1.1.3 Initial Tests (Type Test) The tests must be carried out and recorded, taking into account the following steps: 6.1.1.3.1 Definitions of tests to be carried out 6.1.1.3.1.1 Type tests of the product must be carried out in the samples, as defined in item 6.1.1.3.3, following the prescriptions of applicable technical standards listed in item 2 of this CRC. 6.1.1.3.1.2 The type test must be fully carried out in the pilot unit or in the sample of production line of the equipment in the certification process. 6.1.1.3.1.3 In the initial evaluation, the type test reports of the equipment tested in Brazil or abroad will be accepted provided that the date of issuance of test report does not exceed 2 (two) years and that all changes made in the project are properly documented and the relevant tests have been performed and also documented. 6.1.1.3.1.3.1 If no changes have occurred in the project in this period, the manufacturer of the equipment under certification process, whether national or foreign, must submit a document stating that after the issue date of the test report the product did not suffer changes requiring new tests to be carried out. 6.1.1.3.1.3.2 TÜV Rheinland do Brasil Ltda must make an evaluation of the presented test report, of the initial design of the equipment to which the report was issued, and the current project of the equipment, in order to verify the compliance of the test report of the current design of the equipment. This evaluation must be documented and include the documentation of the equipment certification process. COMPLEMENT MEDICAL ELECTRICAL EQUIPMENT Doc: 703-CRC-001-E Review: 08 Page: 6/20 6.1.1.3.2 Definition of Laboratory TÜV Rheinland do Brasil Ltda must select the laboratory to be hired to carry out the type tests of the product certification process, in agreement with the applicant respecting the provisions of section 12 of this CRC. 6.1.1.3.3 Definition of Sampling 6.1.1.3.3.1 TÜV Rheinland do Brasil Ltda must use in the assessment process a representative sample of the product being certified. 6.1.1.3.3.1.1 The representative sample must be a pilot unit or a product already in production line. 6.1.1.3.3.1.2 In cases of certification of family of equipment, a representative sample of the family must be chosen by the configuration model that is more critical. 6.1.1.3.3.2 For a product that is already in production line, the sample collection held at the production site must be a random choice, made by TÜV Rheinland do Brasil Ltda, a product that has been inspected and released by the quality control of the factory that is packaged and ready for commercialization. If there is a need for other samples, the same procedure must be used for selection. 6.1.1.3.3.3 In the case of pilot units, the manufacturer can collect and forward the sample to the laboratory or TÜV Rheinland do Brasil Ltda, by agreement between the parties and the responsibility of TÜV Rheinland do Brasil Ltda. If there is a need for other samples, the same procedure must be used for selection. 6.1.1.3.3.3.1 The approval of the pilot unit in the initial tests does not release TÜV Rheinland do Brasil Ltda to validate the products after the initial operation of the production line. 6.1.1.4 Initial Audit After evidence of conformity related to items 6.1.1.2 of this CRC, TÜV Rheinland do Brasil Ltda must schedule the audit of the SGQ (QMS) of the manufacturer, in agreement with the applicant. 6.1.1.4.1 For the initial audit to evaluate the SGQ (QMS) of the factory, TÜV Rheinland do Brasil Ltda must: a) verify compliance with requirements detailed in Annex B of the CRC; b) check that the routine tests, described in Annex A, are performed by the manufacturer in 100% of units produced; c) monitoring the fabrication of the products included in the scope of certification; d) evaluate the RHP and RMP of the product to be certified. 6.1.1.4.2 During the audit, the manufacturer must submit, if available, copies of reports of audits / inspections of its SGQ (QMS), issued respectively by a health authority or OCP in Brazil (Anvisa, VISAs etc) and the corrective actions which have been implemented where identified. 6.1.1.4.3 If the manufacturer maintains certification for its quality management system within the SBAC, according to ABNT NBR ISO 13485:2004 or Certificate of Good Manufacturing and Control of Anvisa, according to RDC / ANVISA n° 59 / 00, the certificate can be accepted instead the necessary verifications prescribed in Annex B, provided that the last audit report of such certifications allows TÜV Rheinland do Brasil Ltda to evaluate that the requirements set out in Annex B have been checked and conform. In both cases, the certificate must be valid. 6.1.1.4.3.1 In the case of adoption of ABNT NBR ISO 13485:2004 or RDC / ANVISA n° 59/00, the audits conducted by TÜV Rheinland do Brasil Ltda must evaluate only the sub-items b, c and d of item 6.1.1.4.1. 6.1.1.5 Issuance of the Certificate of Conformity This step must be performed after completion of all requirements prescribed in items 6.1.1.1, 6.1.1.2, 6.1.1.3 and 6.1.1.4 of this CRC. 6.1.1.5.1 The certificate shall only be granted to the applicant who has eliminated all non-conformities in his process. COMPLEMENT MEDICAL ELECTRICAL EQUIPMENT Doc: 703-CRC-001-E Review: 08 Page: 7/20 6.1.1.5.2 If the product is compliant, TÜV Rheinland do Brasil Ltda must formalize the grant of permission to use the Seal of Identification of Conformity for a period of five (5) years as provided in Chapter 9, for the product that meets the criteria established in this CRC. 6.1.1.5.3 The area Manager or interim Substitutes as established in the cross-matrix of responsible for signing checklists and certificates (700-F0-027) approves the Certification. The Approver of the process do not participate in any way of the certification execution steps. 6.1.1.5.4 The decision regarding the Certification is manifested by e-mail sent by approver to the technician responsible for the process. If the approver decides not to approve the process, this decision is justified and the technician takes the necessary actions for the necessary corrections, and only then resubmit the process for approval. 6.1.1.5.5 The certificate must contain at least the following information: a) Company Name and National Register of Legal Entities number, and assumed name of the licensed company and manufacturer, when applicable; b) Full address of the licensed company and manufacturer; c) Identification (number) of the certificate; d) Complete data from TÜV Rheinland do Brasil Ltda (name, accreditation number and signature); e) Data of the certified product with the identification of the brand name and certified models; f) Identification of the testing laboratories and test reports, with dates of issue; g) Date of original issue (the first granting of the certificate), date of revision and date of its validity; h) Identification of technical standards applied for the certification; i) List of accessories and parts tested with the product; j) Version of the user manual and of the project of the product evaluated for the grant of certification; k) Version of the evaluated software, or equipment with embedded software that comes with it. 6.1.1.5.5.1 Where the audited site is of a manufacturer contracted by the product manufacturer to perform the manufacturing under its responsibility, the address, company name and CNPJ (where applicable) of the contracted manufacturer must be included too in the issued certificate. 6.1.1.5.5.2 The certificate may consist of multiple pages and must contain no attachments (annexes). Pages must be numbered and each page must contain the number of the certificate and its date of issue. The initial page must inform the total number of pages of the full certificate. 6.1.2 Maintenance Evaluation Maintenance of certification is performed to verify, through assessments, that the conditions that led to the initial granting of the authorization to use the Seal of Identification of Conformity are being maintained. The achievement of conformity assessment services for maintenance is the sole responsibility TÜV Rheinland do Brasil Ltda. 6.1.2.1 Planning of Maintenance Evaluation 6.1.2.1.1 The process of maintenance of certification is established in the annual assessment of the requirements prescribed in Annex A, B and C of this CRC. At any time, Inmetro Anvisa or may request to carry out type tests for verification of continued compliance of certified products. 6.1.2.1.2 TÜV Rheinland do Brasil Ltda can perform extraordinary audits provided that there is evidence to justify them. 6.1.2.2 Maintenance Testing This item defines the tests necessary to prove that the product object of conformity assessment, after issuing the certificate of compliance in the initial assessment, it remains in compliance with regulatory requirements COMPLEMENT MEDICAL ELECTRICAL EQUIPMENT Doc: 703-CRC-001-E Review: 08 Page: 8/20 prescribed in this CRC. The maintenance tests must be performed and recorded, taking into account the following steps: 6.1.2.2.1 Definition of tests to be carried out 6.1.2.2.1.1 Each year TÜV Rheinland do Brasil Ltda must select a representative sample of the certified product, according to the item 6.1.1.3.3.2, to monitor implementation of the routine tests, annex A, and verify compliance to conformity. These tests can be conducted on the site of the manufacturer. If certified product is manufactured by order, TÜV Rheinland do Brasil Ltda must schedule to monitor the implementation of routine tests, annex A, and verify compliance with the conformity of this product. 6.1.2.2.1.2 TÜV Rheinland do Brasil Ltda must check that the product is unchanged from the original characteristics evaluated in the granting of certification, through the evaluation of the RMP and RHP (eg, comparison between the lists of components made in granting and maintenance, found on the production line and check by physical means, such as external and internal pictures of the product and / or technical drawings of the production line, among other findings). 6.1.2.2.1.3 If changes in the design or upgrade of parts, pieces, components or software version have occurred, TÜV Rheinland do Brasil Ltda must verify the impact of these changes on product certification. If necessary, new type tests on a representative sample of the product must be conducted in accordance with the technical standards listed in Item 2 of this CRC. 6.1.2.2.1.4 When the product is not being sent to new tests, despite the finding of changes in it, TÜV Rheinland do Brasil Ltda must prepare a report justifying each change made, based on technical and scientific knowledge, and why new type tests were not carried out on the product. A copy of this report must be in possession of the authorized company. 6.1.2.2.1.4.1 This report must be part of the maintenance process for approval, as prescribed in 6.1.2.4.3. 6.1.2.2.1.5 Anytime Anvisa or Inmetro can request type tests to be carried out according to established items 6.1.1.3, during the term of the certificate, in order to verify the compliance of maintenance of conformity of the equipment. 6.1.2.2.2 Definition of Laboratory TÜV Rheinland do Brasil Ltda must select the laboratory to be hired to carry out the tests on the process of maintaining the certification of the product, in agreement with the applicant, following the prescriptions of item 12 of this CRC. 6.1.2.3 Maintenance Audit 6.1.2.3.1 For the maintenance audit to evaluate the quality management system of the manufacturer, TÜV Rheinland do Brasil Ltda must: a) verify compliance with requirements detailed in Annex B of the CRC; b) verify that the routine tests, described in Annex A, are carried out by the manufacturer in 100% of units produced; c) monitoring the fabrication of the products included in the scope of certification; d) assess the RHP and RMP amendments of the certified product. 6.1.2.3.2 If the manufacturer maintains certification for its quality management system within the SBAC, according to ABNT NBR ISO 13485:2004 or Certificate of Good Manufacturing and Control of Anvisa, according to RDC / ANVISA n° 59 / 00, the certificate can be accepted instead the necessary verifications prescribed in Annex B, provided that the last audit report of such certifications allows TÜV Rheinland do Brasil Ltda to evaluate that the requirements set out in Annex B have been checked and conform. In both cases, the certificate must be valid. 6.1.2.3.2.1 In the case of adoption of ABNT NBR ISO 13485:2004 or RDC / ANVISA n° 59/00, the audits conducted by TÜV Rheinland do Brasil Ltda must evaluate only the sub-items b, c and d of item 6.1.1.4.1. 6.1.2.4 Formalization of Maintenance Conformity COMPLEMENT MEDICAL ELECTRICAL EQUIPMENT Doc: 703-CRC-001-E Review: 08 Page: 9/20 This step must be performed after completion of all requirements in this CRC. 6.1.2.4.1 The certification must be maintained only for the authorized company that has eliminated all nonconformities in its process. 6.1.2.4.2 If the product is in accordance with the criteria established in this CRC, TÜV Rheinland do Brasil Ltda must formalize the maintenance of the authorization to use the Seal of Identification of Conformity provided in Chapter 9. 6.1.2.4.3 The area Manager or interim Substitutes as established in the cross-matrix of responsible for signing checklists and certificates (700-F0-027) approves the maintenance of Certification. The Approver of the process do not participate in any way of the maintenance of certification execution steps. 6.1.2.4.4 The decision not to grant the maintenance of certification entails the immediate suspension of the certificate and therefore the disempowerment for use the Seal of Identification of Conformity for the reproved product. Other actions may also occur, such as the withdrawal from the market (recall). 6.1.3 Treatment of Deviations in Conformity Assessment Process If any activity conducted by TÜV Rheinland do Brasil Ltda identifies non-conformity, TÜV Rheinland do Brasil Ltda must issue a report of non-conformity and send it to the authorized company / applicant to ensure that the necessary actions to correct non-conformity are made. 6.1.3.1 Treatment of non-conformities in the initial assessment process If the product is not approved by the type tests, the manufacturer must implement corrective actions and present evidence before the implementation of new tests. If non-conformities are identified in the SGQ (QMS) of the manufacturer, it must implement the corrective actions needed to adapt its system, evidence of implementation must be submitted to TÜV Rheinland do Brasil Ltda. 6.1.3.1.1 TÜV Rheinland do Brasil Ltda must evaluate the need to conduct a new audit to verify implementation of corrective actions and non-conformities have been properly resolved. 6.1.3.2 Treatment of non-conformities in the maintenance process The reproved products, in the possession of the company must be disposed of with the monitoring of TÜV Rheinland do Brasil Ltda, unless it is possible to reprocess them. 6.1.3.2.1 This decision must be properly grounded to ensure that products with non-conformities or with compromised safety are not in the market. Records from the authorized company and manufacturer must be provided to TÜV Rheinland do Brasil Ltda in order to perform the analysis of the extent of these disapprovals. The certification and therefore permission to use the Seal of Identification of Conformity in the reproved model must be suspended until all corrective actions are implemented by the company. 6.1.3.2.2 If the non-conformities are found during the testing of maintenance carried out on the certified product, TÜV Rheinland do Brasil Ltda must verify the need for new type tests according to item 6.1.1.3 in the laboratory chosen according item 12 of this CRC, in a representative sample of the product. This decision must be documented and include the documentation of the process of certification. 6.1.3.3 Treatment of non-conforming products on the market In the event of non-conforming products to be distributed or sold, TÜV Rheinland do Brasil Ltda must monitor the process of replacement or repair of products that were sold / marketed, being the authorized company responsible for this action. 6.1.3.3.1 The impact of non-conformities must be considered on the risks associated with the use of the product and the need for withdrawal of non-conforming products from the market, if it is not possible to repair / fix them. This decision must be documented by TÜV Rheinland do Brasil Ltda and to integrate the documentation process of certification. 6.1.3.3.2 If it is not possible to repair a product, non-conforming products must be collected and destroyed with the monitoring of TÜV Rheinland do Brasil Ltda. If it is possible to repair the product, after been repaired the product must be subjected to all tests required to release the finished product in order to check whether non-conformities have been properly eliminated. COMPLEMENT MEDICAL ELECTRICAL EQUIPMENT Doc: 703-CRC-001-E Review: 08 Page: 10/20 6.1.3.3.3 The tests outlined in item 6.1.3.3.2 can be carried out by the manufacturer in its dependencies, and their results must be duly recorded, including ensuring the traceability criteria required for the SGQ (QMS) for medical products RDC / ANVISA n° 59/00 and ABNT NBR ISO 13485:2004. 7 TREATMENT OF COMPLAINTS The authorized company must maintain records of all complaints or mistakes brought to its attention concerning the certified product, as well as the appropriate actions taken to meet the requirements of certification, making them available to TÜV Rheinland do Brasil Ltda, when requested. 7.1 A Policy for Handling of Complaints and signed by its executive greater, which demonstrates the company: a) values and gives effective treatment to complaints submitted by its customers; b) knows and undertakes to comply with and be subject to the penalties provided in the laws (Law n° 8078/1990, Law n° 9933/1999, or others); c) stimulates and analyzes the results and takes the appropriate steps, according to statistics on complaints received; d) defines responsibilities regarding the handling of complaints; e) undertakes to answer the Inmetro any complaint that it has received within the time established by it. 7.2 A person or team formally designated, properly trained and freedom for the treatment due to complaints. 7.4 Procedure for Handling of Complaints, which must include a simple form to record the customer's complaint, as well as screening, investigation, response, resolution and closure of the complaint. 7.5 Proper records of each of the complaints received and processed. 7.6 Conducting an annual critical review of statistics on the complaints and evidence of implementation of the corresponding corrective actions, as well as opportunities for improvements. 8. SEAL OF IDENTIFICATION OF CONFORMITY The identification of conformity within the SBAC indicates that the products addressed in this Regulation are in line with the provisions of Regulation n° 179/2009 Inmetro, and in accordance with the requirements and conformity assessment mechanism prescribed in this CRC. 8.2 Specification 8.2.1 The specification of the Seal of Identification of Conformity is defined in Annex C of this CRC. 8.2.2 The Seal of Identification of Conformity must meet the requirements of this CRC and it will be under the responsibility of the authorized company. Inmetro may at any time request samples of seals in order to check if they meet the requirements. 8.3 Traceability The licensed company must implement a control for the traceability of products bearing the Seal of Identification of Conformity, which control must be available to Inmetro for a period of time equivalent to the expected life of the product, but in no case less than 5 (five) years from date of commercial distribution by the manufacturer. TÜV Rheinland do Brasil Ltda must verify the implementation of this control, as well as the effectiveness of the traceability of certified products. 9 AUTHORIZATION FOR THE USE OF SEAL OF IDENTIFICATION OF CONFORMITY 9.1 The Authorization for use of Seal of Identification of Conformity has its validity linked to the validity established in the certification. COMPLEMENT MEDICAL ELECTRICAL EQUIPMENT Doc: 703-CRC-001-E Review: 08 Page: 11/20 9.2 Grant of Authorization 9.2.1 The granting of authorization to use the Seal of Identification of Conformity takes place when a product complies with the criteria in this CRC. 9.2.2 The granting of authorization to use the Seal of Identification of Conformity occurs through the submission of a formal instrument, the certificate, that must contain at least the data mentioned in item 6.1.1.5.5. 9.3 Maintenance of Authorization 9.3.1 The maintenance of the authorization for use of Seal of Identification of Conformity is conditioned if there are no non-conformities during the evaluation process of maintenance, as defined in item 6.1.2 and 6.1.3.2 of this CRC. 9.4 Suspension, cancellation or renewal of authorization The suspension, cancellation or renewal of authorization to use the Seal of Identification of Conformity occurs when compliance with any of the requirements of this CRC is not met. 9.4.1 In case of cancellation or suspension of license because of non-conformities with any requirement prescribed by this CRC, the authorization to use the Seal of Identification of Conformity is under the same condition. In these cases the company holding the authorization must cease use of the Seal of Identification of Conformity and any advertising that has to do with it. 9.4.2 The termination of suspension, full or partial, of the authorized company is subject to verification of the correction of non-conformities that led to the suspension. 9.4.3 The applicant who has your permission to use the Seal of Identification of Conformity canceled must be evaluated by a new and complete certification process. 9.4.4 Upon renewal of certification type tests must be repeated in the following situations: a) after 5 (five) years from the issuance of test report; b) change in the revision of any technical standard used in the initial test; c) changes in the structure of the equipment that involves changes in the previously evaluated product line; d) upon determination of Anvisa. Note: to the item 9.4.4.a, the regulator (Anvisa) may establish its own terms for specific equipment through normative statement. 10 RESPONSABILITIES AND OBLIGATIONS 10.1 For the authorized company: a) Maintain technical and organizational conditions that formed the basis for obtaining permission to use the Seal of Identification of Conformity. b) Comply with all conditions prescribed in this CRC, in the legal and contractual arrangements concerning the certification regardless of their transcription. c) Communicate to TÜV Rheinland do Brasil Ltda any changes to the evaluated product and submit to TÜV Rheinland do Brasil Ltda review and approval any changes made prior to the marketing of the modified product. d) Assume directly the technical, civil and criminal responsibility for the product he sold, as well as all documents relating to conformity assessment, with no possibility of transferring this responsibility. e) Comply with the relevant decisions taken by TÜV Rheinland do Brasil Ltda certification, calling in a first instance to TÜV Rheinland do Brasil Ltda and 2nd instance the ombudsman of Inmetro in cases of complaints and appeals. COMPLEMENT MEDICAL ELECTRICAL EQUIPMENT Doc: 703-CRC-001-E Review: 08 Page: 12/20 f) Comply with all conditions of the technical standards related to item 2 of this CRC, the legal and contractual arrangements regarding the authorization, regardless of their transcription. g) Facilitate TÜV Rheinland do Brasil Ltda or its contractor, upon proof of this condition, the audit and monitoring, as well as other testing and certification activities under this CRC. h) Apply the Seal of Identification of Conformity of all certificated equipment, according to criteria established in this CRC. i) Ensure that a certified product does not hold the same encoding of a non-certified product (code and model). j) Carry out routine tests, according to annex A, in 100% of units manufactured. k) Carry out type tests according to item 6.1.1.3, or by determination of Anvisa or Inmetro, in order to proof continued compliance of certified products. l) Ensure that the RHP and RMP are kept updated at any time for certification, under penalty of suspension or cancellation of certification. m) Promptly report to Inmetro the interruption of manufacturing, importing or marketing of the product. n) Inform TÜV Rheinland do Brasil Ltda when completely ceases the manufacture and / or importation and marketing of equipment for which holds the authorization for the use of the Seal of Conformity. o) Meet all other legal requirements for manufacturing, importing and marketing the product, under penalty of suspension or cancellation of the certificate. p) Use the identification of conformity in advertising, after the authorization of the Board of Quality - Dqual, http://www.inmetro.gov.br/qualidade/autSelo.asp, since that makes it clear which products really have assessed their compliance, and submitting the advertising materials that will be used, according Regulation Inmetro n° 179/2009. 10.2 For TÜV Rheinland do Brasil Ltda a) Implement the program of conformity assessment, provided by this CRC, as the requirements prescribed herein, and to resolve questions with Inmetro. b) Use the supplied database system of Inmetro to maintain updated information about the certified products. c) Immediately notify the Inmetro and Anvisa about the suspension, extension, reduction and cancellation of certification. d) Submit to Inmetro for review and approval, the Memorandum of Understanding, under the scope of this CRC, established with other certification bodies. e) Comply with any penalties imposed by regulatory agencies of the product. f) Forward for the authorized company all requirements established by Inmetro that impact it. g) Be responsible for selecting and hiring third party entities such as laboratories and organisms for evaluating the product and factory. h) For tests performed by foreign laboratories, provided that agreed by the regulator, it must be observed equivalence of the test method, the supply voltage and frequency of the tested equipment and the used sampling methodology. Additionally, these laboratories must be accredited by Inmetro or by an accreditation body that is signatory of a mutual recognition agreement which also Inmetro has part. i) Maintain in its website, clear and easy to access, the status of all certificates issued, with electronic copy, allowing the full reading of the texts and information related to these certificates, or through consultation from the reports at data-center, containing all information included in the issued certificates. j) Monitor the site of the regulator (Anvisa) publication of reports of adverse events associated with products certified by him. TÜV Rheinland do Brasil Ltda must evaluate whether the adverse published event has an impact on such certification, if so, must take appropriate action with the authorized company to monitor COMPLEMENT MEDICAL ELECTRICAL EQUIPMENT Doc: 703-CRC-001-E Review: 08 Page: 13/20 corrective actions taken to remedy the problem that caused the adverse event. This action must be documented and form the documentation of the process of certification. k) Monitor and implement the determinations of the regulator (Anvisa) regarding the need of type tests for certified product. l) Issue consolidated reports and other documents when required by the regulator (Anvisa). 11 PENALTIES 11.1 The applicant or authorized company that makes improper and / or abusive use of the Seal of Identification of Conformity will be subject to penalties in accordance with the provisions of Inmetro n° 179 of June 16, 2009. 11.2 The authorized company that fails to meet the requirements of this CRC is subject to the penalties of suspension and cancellation of certification, defined and operationalized in accordance with the certification scheme of TÜV Rheinland do Brasil Ltda and Inmetro. 11.3 Under the SBAC the following will be considered violations subject to penalties, among others: a) provide products with the Seal of Identification of Conformity outside the standards of quality established in this CRC; b) use the Seal of Identification of Conformity on not authorized products; c) fail to report or give false information regarding certified products; d) prevent access by auditors to documents and records from your system; e) not accept the verifications and collections on time stablished in this CRC. 11.4 For products subject to registration at Anvisa, the noncompliance of the prescriptions of this CRC, in the applicable items, is subject to the penalties described in Law n° 6437/77 and Art. 273 of the Brazilian Penal Code - Law n° 2848/40. 12 USE OF TESTING LABORATORY 12.1 Type tests prescribed in this CRC for conformity assessment must be performed by a 3rd party laboratory accredited by Inmetro for the scope provided in this CRC. Note: If a single laboratory is not capable of performing all required tests more than one laboratory can be used, observing the criteria prescribed in item 12 of this CRC. 12.2 In exceptional character and precarious, since it depends upon an assessment by TÜV Rheinland do Brasil Ltda, non-accredited laboratory can be used for the specific scope, when one of the situations described below occurs: a) When there is no laboratory accredited by Inmetro for part of the program scope of conformity of the product. b) When the laboratories accredited by Inmetro not meet in no more than 6 (six) months, from signing the contract, the deadline for starting the tests described in the CRCs. 12.2.1 The assessment carried out by TÜV Rheinland do Brasil Ltda in the laboratory not accredited by Inmetro must be done by professional of TÜV Rheinland do Brasil Ltda that have registered at least three audits in the past three successive years in the Standard ISO / IEC 17025:2005. 12.2.2 The OCP must obtain objective evidence that the laboratory not accredited by Inmetro is able to carry out all tests required by the regulations prescribed in this CRC. Note: If a single laboratory is not capable of performing all tests required more than one laboratory can be used, according to the criteria prescribed in item 12 of this CRC. COMPLEMENT MEDICAL ELECTRICAL EQUIPMENT Doc: 703-CRC-001-E Review: 08 Page: 14/20 12.3 When one of the situations described above occurs, TÜV Rheinland do Brasil Ltda must follow the following order of priority in the selection of laboratory non-accredited by Inmetro but qualified for the specific scope: a) Laboratory of 3rd part accredited to the others scopes of tests; b) Laboratory of 1st part accreditation; c) Laboratory of 3rd part that is not accredited; d) Laboratory of 1st part that is not accredited. 12.4 Considering the possibilities described in items 12.2 and 12.3, TÜV Rheinland do Brasil Ltda must register through documentary evidence, the reasons which led it to select the laboratory. 12.5 For tests carried out by foreign laboratories, it must be observed equivalence of the test method and sampling methodology prescribed in this CRC. Additionally, these laboratories must be accredited by Inmetro or by an accreditation body that is signatory to one of the following mutual recognition agreements, which Inmetro has part: a) Interamerican Accreditation Cooperation – IAAC b) European Cooperation for Accreditation – EA c) International Laboratory Accreditation Cooperation – ILAC Notes: 1) The list of accredited laboratories can be obtained by consulting the website of Inmetro www.inmetro.gov.br, the cooperation and the signatory agencies of such agreements; 2) The scope of accreditation of the laboratory must include the testing method applied under this CRC; 3) The test reports issued by the laboratory must contain clear and unambiguous identification of their status as accredited laboratory. 13 ACTIVITIES CARRIED OUT BY FOREIGN OCP 13.1 The conformity assessment activities, carried out by a foreign body may be accepted provided they meet all the following conditions: a) The OCP in Brazil (TÜV Rheinland do Brasil Ltda), accredited by Inmetro, must have a Memorandum of Understanding (MOU) with the foreign body; b) The foreign body must be accredited by the same international rules adopted by Inmetro for the same or equivalent scope; c) The foreign activities must be equivalent to those regulated by Inmetro; d) The body accredited by Inmetro must issue the authorization to use the Seal of Identification of Conformity of the Brazilian regulations and must assume responsibility for all activities undertaken abroad and due to this issue, as if it had conducted all activities; e) TÜV Rheinland do Brasil Ltda, accredited by Inmetro, in Brazil, must be responsible for the judgment and granting, maintenance and renewal of the authorization for use of the Seal of Identification of Conformity and f) Inmetro must approve the MOU. 13.2 In case of evaluation done by a foreign OCP do not cover all requirements of this CRC, the OCP must complement the assessment by carrying out the requirements not met. 14. CLOSURE OF THE CERTIFICATION PROCESS 14.1 TÜV Rheinland do Brasil Ltda must schedule a special audit to verify and register the following requirements: COMPLEMENT MEDICAL ELECTRICAL EQUIPMENT Doc: 703-CRC-001-E Review: 08 Page: 15/20 • Quantity of items and manufacture date of the last batch of production; • Available material for new productions in stock; • Quantity of finished product in stock and when the authorized company foresees that this lot will be consumed; • If the requirements of this regulation have been met since the last maintenance audit; • Collect samples for termination testing prescribed in Annex A of this CRC. 14.2 TÜV Rheinland do Brasil Ltda must also schedule the termination testing of the process. These tests are those that would be made in the evaluation of subsequent maintenance. 14.3 If the results of these tests presents any non-conformity, before approving the closure of the certification process, TÜV Rheinland do Brasil Ltda must ask the authorized company the relevant treatment as prescribed in item 6.1.3 of this CRC. 14.4 The audit and termination tests results must be documented and integrate the documentation of the process of the certified product. 14.5 Once completed the above steps, TÜV Rheinland do Brasil Ltda notifies the cancellation to its, INMETRO and ANVISA. 15. Revision Revision 07: Change in encoding of the document. Revision 08: Updating the text of the certification approval process. COMPLEMENT MEDICAL ELECTRICAL EQUIPMENT Doc: 703-CRC-001-E Review: 08 Page: 16/20 ANNEX A - ROUTINE TESTS A.1 Routine tests must be carried out in accordance with the requirements prescribed in clauses 18, 19 and 20 of ABNT NBR IEC 60601 - 1:1994 and amendment 1:1997, besides checking the functioning of product, the object of certification, specifically: a) Operation of equipment (items to be tested will be subject to agreement between TÜV Rheinland do Brasil Ltda and the manufacturer to ensure the safety of the product to be certified in accordance with its intended use) b) Grounding (clause 18); c) Leakage current (clause 19); d) Dielectric strength (clause 20). A.2 Routine tests for dielectric strength must be carried out in accordance with the requirements prescribed in clause 20 of ABNT NBR IEC 60601 - 1:1994 and amendment 1:1997. The time specified in this clause may be reduced, according to the manufacturer's preference, provided that such application is duly justified by the manufacturer and agreed with TÜV Rheinland do Brasil Ltda. COMPLEMENT MEDICAL ELECTRICAL EQUIPMENT Doc: 703-CRC-001-E Review: 08 Page: 17/20 ANNEX B - TECHNICAL REQUIREMENTS FOR THE EVALUATION OF THE QUALITY SYSTEM BY ABNT NBR ISO 13485:2004 B-1 In the initial and maintenance evaluation of the SGQ (QMS) of the manufacturer using the ABNT NBR 13485:2004 for the products object of certification, TÜV Rheinland do Brasil Ltda must verify compliance with the requirements listed below: 4.2.3 Control of documents 4.2.4 Control of records 7.1 Planning of product realization 7.2.3 Customer communication (ref. handling customer complaints 7.2.3.c) 7.3.6 Design and development validation 7.3.7 Control of design and development changes 7.4.3 Verification of purchased product 7.5.1 Control of production and service provision 7.5.2 Validation of processes for production and service provision 7.5.3 Identification and traceability 7.5.5 Preservation of product 7.6 Control of monitoring and measuring devices 8.2.3 Monitoring and measurement of processes 8.2.4 Monitoring and measurement of product 8.3 Control of non-conforming product 8.5.2 Corrective action COMPLEMENT MEDICAL ELECTRICAL EQUIPMENT Doc: 703-CRC-001-E Review: 08 Page: 18/20 ANNEX C - IDENTIFICATION OF CERTIFICATION UNDER SBAC C.1 Identification of the certified product, prescribed in this CRC, must contain the information prescribed in this Annex and in accordance with the scope, which can be compulsory or voluntary. C.2 The authorized company must follow the following guidelines for the use of the Seal of Identification of Conformity: a) The seal, according to Figure 1a, can only be used on products that are listed in the existing IN / Anvisa which establishes the technical standards adopted for certification of conformity for medical electrical equipment under health surveillance; b) In the packaging, the label can be printed or a label can be used with characteristics of indelibility and permanence, provided it meets the minimum dimensions as defined in Figure 1a and 1b of this CRC; c) In the product, if the Seal of Identification of Conformity which is stamped, printed or placed by the label, defined in Figure 1a and 1b of this CRC does not fit in front of the medical electrical equipment, it can be affixed in other parts; d) The black and white version can be used only if the packaging has the same color like the colored label. C.3 TÜV Rheinland do Brasil Ltda must ensure that the affixing of the Seal of Identification of Conformity is made so indelible, permanent and visible as well as the electrical system under Health Surveillance can be tracked by sequential numbering or other means prescribed by TÜV Rheinland do Brasil Ltda in agreement with the authorized company. Figure 1a - For Compulsory Figure 1b - To Volunteer COMPLEMENT MEDICAL ELECTRICAL EQUIPMENT Doc: 703-CRC-001-E Review: 08 Page: 19/20 Figure 2: Compact Seal COMPLEMENT Doc: 703-CRC-001-E MEDICAL ELECTRICAL EQUIPMENT Review: 08 Page: 20/20 ANNEX D - DESCRIPTION OF FAMILY No 1 – Are the products of this family produced by the same manufacturer or manufacturer group, with the same production process and under the same SGQ (QMS)? Yes 2 – Do the products of this family have identical operation functions? No Yes 3 – Do the products of this family have the same indications and intended use? No Yes No 4 – Do the products of this family have the same precautions, restrictions, warnings and similar special care? Yes No 5 – Do the products of this family have the same constructive mechanical characteristics: plastical and metalic materials used in fixation methods, finishing and isolation? Yes No 6 – Do the products of this family have the same classification, such as degree of protection against electric shock, degree of protection of the applied part, degree of protection against ingress of water? Yes No 7 – Do the products of the family have the same circuits, electrical diagrams and project of mains input? Yes THIS IS NOT A FAMILY OF PRODUCTS THIS IS A FAMILY OF PRODUCTS