BERMAD Waterworks

700 Series

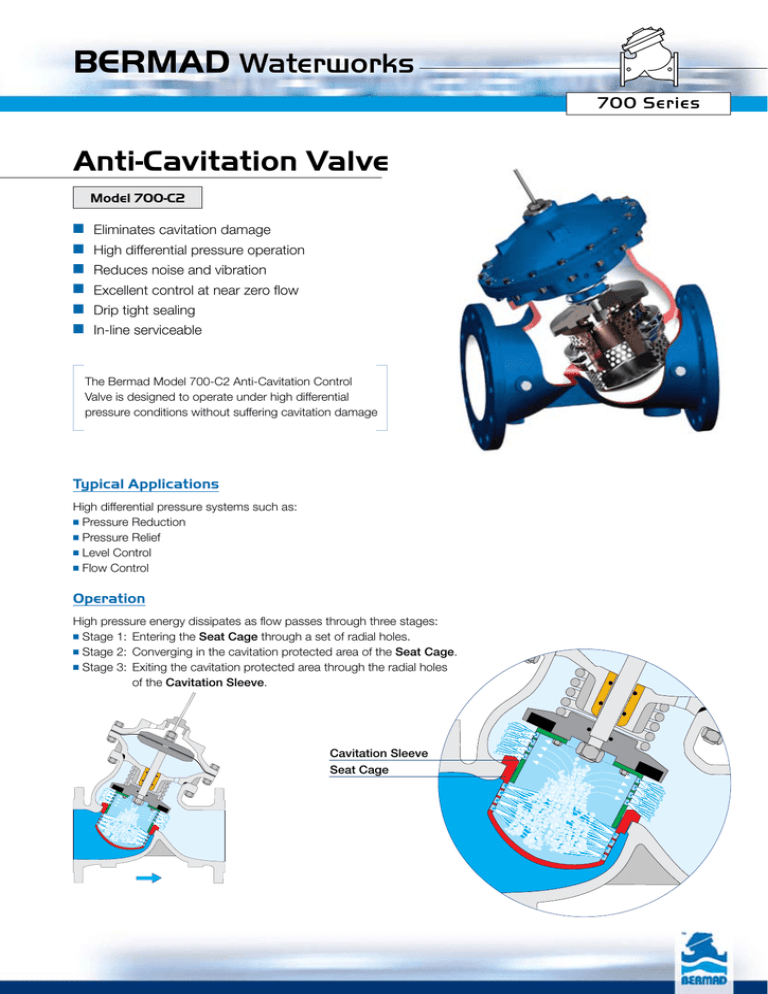

Anti-Cavitation Valve

Model 700-C2

n Eliminates cavitation damage

n High differential pressure operation

n Reduces noise and vibration

n Excellent control at near zero flow

n Drip tight sealing

n In-line serviceable

The Bermad Model 700-C2 Anti-Cavitation Control

Valve is designed to operate under high differential

pressure conditions without suffering cavitation damage

Typical Applications

High differential pressure systems such as:

n Pressure Reduction

n Pressure Relief

n Level Control

n Flow Control

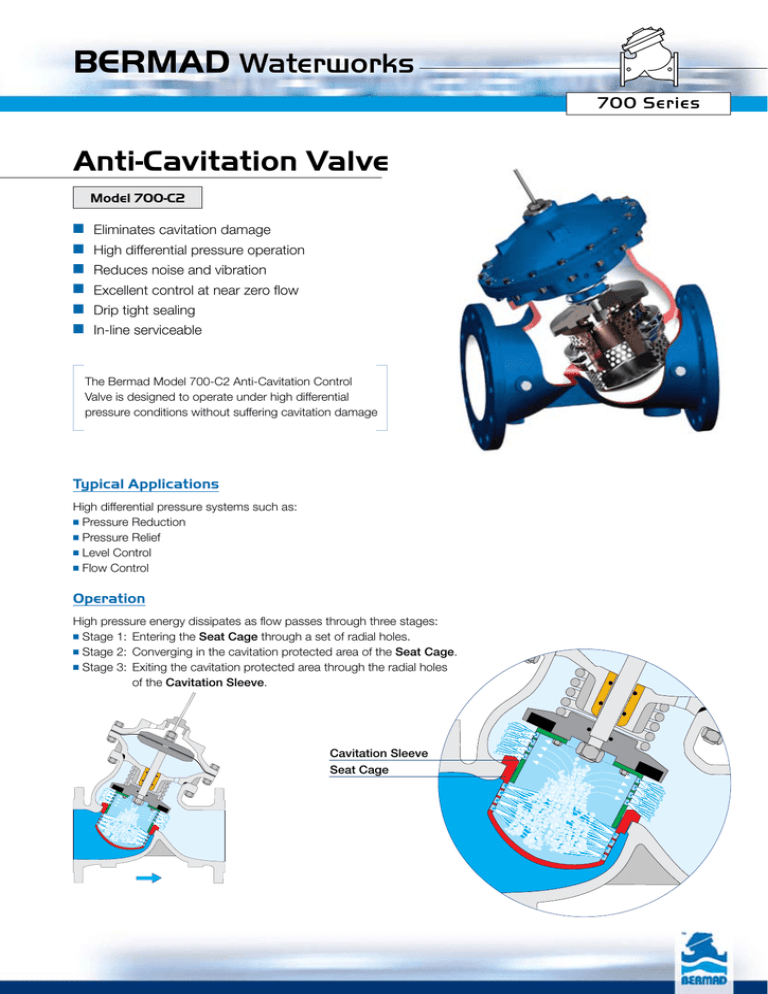

Operation

High pressure energy dissipates as flow passes through three stages:

n Stage 1: Entering the Seat Cage through a set of radial holes.

n Stage 2: Converging in the cavitation protected area of the Seat Cage.

n Stage 3: Exiting the cavitation protected area through the radial holes of the Cavitation Sleeve.

Cavitation Sleeve

Seat Cage

BERMAD Waterworks

700 Series

Model 700-C2 Anti Cavitation Valve

Technical Data

Pressure Ratings According to Body Materials

Patterns, End Connections & Sizes

“Y” Pattern: Flanged - 2”-24”; DN50-600

Grooved - 3”-8”; DN80-200,

Threaded - 1½”-3” ; DN40-80

Angle: Flanged - 2”-18” ; DN50-450,

Threaded - 2”-3” ; DN50-80

Max.

Type Operating

Pressure

PN16 16 bar

Flanged ISO 7005-2

PN25 25 bar

ASTM A536

Ductile Iron

= EN 1563

PN25 25 bar

Grooved

Threaded ISO 7/1-RP (BSP) PN25 25 bar

PN16 16 bar

ASTM A216-WCB

Flanged ISO 7005-2

Cast Steel

= EN 10083-1

PN25 25 bar

PN16 16 bar

ASTM A351 CF8M

Stainless

Flanged ISO 7005-2

Steel 316 = EN 10088-1

PN25 25 bar

Body

Material

End Connection

Standard

Grade

Standard Materials:

Main valve body and cover:

Ductile Iron, Carbon Steel, Stainless Steel

Seat Cage & Cavitation Sleeve:

Stainless Steel 304 or 316 (optional)

Main valve internal parts:

Stainless Steel, Bronze & Epoxy coated steel

Other end connection standards available on request.

Elastomers: Synthetic Rubber

Coating: Fusion Bonded Epoxy NSF-61 approved

Other materials are readily available

Water Temperature: Up to 80˚C

Consult factory for higher temperature.

Flow Properties

Size

700-C2

Y-Pattern

700-C2

Angle

mm

Inch

Kv

K

Leq m

Kv

K

Leq m

40

1½"

16

16

32

17

13

26

50

2"

20

24

68

22

20

56

65

2½"

21

66

230

23

55

190

80

3"

43

35

150

47

29

124

100

4"

75

28

167

83

23

138

150

6"

170

27

282

187

23

233

200

8"

300

28

403

330

23

333

250

10"

410

36

661

451

30

546

300 350 400 450

12" 14" 16" 18"

742 744 1,237 1,282

23

42

26

39

537 1,089 768 1,396

816 818 1,361 1,410

19

35

22

32

444 900 634 1,153

500

20"

1,327

56

2,214

N/A

N/A

N/A

600

24”

1,597

80

3,807

N/A

N/A

N/A

Differential Pressure Calculation

Gf

Valve flow coefficient Kv = Q

ΔP

Where:

Kv =Valve flow coefficient (flow in m3/h at 1bar ∆P)

Q =Flow rate (m3/h)

∆P=Differential pressure (bar)

Gf = Liquid specific gravity (Water = 1.0)

2g

Flow resistance or Head loss coefficient K = ΔH 2

V

Where:

K =Flow resistance or Head loss coefficient (dimensionless)

∆H=Head loss (m)

V =Nominal size flow velocity (m/sec)

g =Acceleration of gravity (9.81 m/sec2)

Practical formulas for water:

Practical formula:

V2

ΔH = K

2g

Q = Kv

ΔP

ΔP =

Q

(Kv

)

2

Equivalent Pipe Length - Leq

In order to simplify system head loss calculation, add the Leq value to the pipe length of the relevant size.

Note:

The Leq values given are for general consideration only. Actual Leq may vary somewhat with each of the valve sizes.

BERMAD Waterworks

700 Series

Model 700-C2 Anti Cavitation Valve

Cavitation Charts

1. Calculate the flow velocity in m/sec according to the required flow

and the estimated valve diameter. Use the formula:

V = Flow velocity (m/sec)

Q= Flow (m3/h)

D= Valve diameter (mm)

V = 354 x Q2

D

15

2. Select the relevant chart according to flow velocity

3. Locate cavitation status according to the relevant upstream

and downstream pressure

4. In order to reduce cavitation damage:

n Increase valve size

n Consider multi stage system

n Use higher grade materials - consult Bermad

5. The charts refer to 700-C2 series valves with double cavitation

cages, Ductile Iron bodies and maximum water temperature at 18°C

Downstream Pressure - bar

10

Low

n

atio

avit

C

Mild

5

Downstream Pressure - bar

Downstream Pressure - bar

10

n

tio

vita

Ca

erate

Mod

ation

Cavit

Severe Cavitation

0

0.5

5

10

15

20

Severe Cavitation

5

10

15

Upstream Pressure - bar

erate

Mod

5

10

15

1

Pressure Loss - bar

0.5

250

100

150

200

400

350

300

450

500

600

0.1

0.05

1

10

100

Flow Rate - m3/h

ation

Cavit

Severe Cavitation

Upstream Pressure - bar

80

n

5

Flow Chart

65

n

atio

avit

C

Mild

10

25

25

atio

avit

C

Low

0

0.5

50

20

Flow Velocity = 5 m/sec

Upstream Pressure - bar

40

tion

e Cavita

Moderat

15

w

Lo

on

Mild C

0

0.5

Flow Velocity = 3 m/sec

n

itatio

Cav

avitati

5

6. For project specific cavitation data, please contact Bermad,

with the design parameters of your application.

15

Flow Velocity = 1.5 m/sec

1,000

10,000

20

25

BERMAD Waterworks

700 Series

Model 700-C2 Anti Cavitation Valve

Dimensions & Weights

BSP

BSP

ISO PN 20; 25

ISO PN 10; 16

ISO PN 20; 25 ISO PN 10; 16

DN 40 50 65

Inch 1½” 2” 2½”

L (mm)

N/A 210 222

700-C2

“Y” Pattern

W (mm)

N/A 165 178

h (mm)

N/A 83 95

H (mm)

N/A 244 257

Weight (Kg) N/A 11.1 13.5

L (mm)

N/A 210 222

W (mm)

N/A 165 185

h (mm)

N/A 83 95

H (mm)

N/A 244 257

Weight (Kg) N/A 12.7 15.5

L (mm)

N/A 124 149

700-C2

Angle Pattern

W (mm)

N/A 155 178

R (mm)

N/A 83 95

h (mm)

N/A 85 109

H (mm)

N/A 227 251

Weight (Kg) N/A 10.5 12.5

L (mm)

N/A 124 149

W (mm)

N/A 165 185

R (mm)

N/A 85 95

h (mm)

N/A 85 109

H (mm)

N/A 227 251

Weight (Kg) N/A 12 14

L (mm)

155 155 212

700-C2

“Y” Pattern

W (mm)

122 122 122

h (mm)

40 40 48

H (mm)

201 202 209

Weight (Kg) 6

6

8.5

L (mm)

N/A 121 140

700-C2

Angle Pattern

W (mm)

N/A 122 122

R (mm)

N/A 40 48

h (mm)

N/A 83 102

H (mm)

N/A 225 242

Weight (Kg) N/A 6

7.5

A (mm)

200 200 200

Pilot system and minimum

service distance

B (mm)

350 350 350

Body ports

C

1/4” NPT

1/4”

1/4”

1/4”

Cover ports

D (NPT)

1/8”

1/8”

1/8”

Lower chamber ports

E (NPT)

1

1

Internal single chamber ports F (NPT)

/8”

/8” 1/8”

Control chamber displacement volume (liter)

0.125 0.125 0.125

Stem travel

(mm)

15 15 15

80

3”

250

200

100

305

23

264

207

105

314

26

152

200

100

102

281

22.5

159

207

105

109

287

24

250

163

56

264

18

159

163

55

115

294

16

250

370

1/4”

1/8”

1/8”

0.3

21

100

4”

320

223

115

366

39

335

250

127

378

45

190

222

115

127

342

37

200

250

127

135

350

43

150

6”

415

320

143

492

79

433

320

159

508

89

225

320

143

152

441

75

234

320

159

165

454

85

200

8”

500

390

172

584

133

524

390

191

602

154

265

390

172

203

545

126

277

390

191

216

558

146

A

250

10”

605

480

204

724

232

637

480

223

742

260

320

480

204

219

633

220

336

480

223

236

649

248

D

E

F

H

C

300

12”

725

550

242

840

392

762

550

261

859

432

396

550

248

273

777

372

415

550

261

294

796

412

350

14”

733

550

268

866

403

767

570

295

893

456

400

550

264

279

781

392

419

550

293

299

801

447

400

16”

990

740

300

1,108

896

1,024

740

325

1,133

950

450

740

299

369

1,082

850

467

740

325

386

1,099

905

450

18”

1,000

740

319

1,127

995

1,030

740

357

1,165

1,017

450

740

320

370

1,082

870

467

740

358

386

1,099

920

500

20”

1,100

740

358

1,167

1,012

1,136

750

389

1,197

1,036

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

A

D

E

H F

C

600

24”

1,450

845

435

1,235

1,123

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

h

h

L

R

B

W

B

320 420 530 620 790 790

400 430 480 520 550 550

3/8” NPT

1/2” NPT

1/4”

1/4”

1/4”

1/2”

1/2”

1/2”

1/8”

1/4”

1/4”

3/8”

3/8”

3/8”

1/8”

1/4”

1/4”

3/8”

3/8”

3/8”

0.45 2.15 4.5 8.5 12.4 12.4

26 35 45 53 72 72

Note: For grooved valves dimensions, refer to flanged valves dimensions

info@bermad.com • www.bermad.com

The information herein is subject to change without notice. BERMAD shall not be held liable for

PC7WE11C2 11

any errors. All rights reserved. © Copyright by BERMAD.

L

B

B

W

B

1000 1000 1000

650 650 650

1” BSPT

3/4”

3/4”

3/4”

3/4”

3/4”

3/4”

3/4”

3/4”

3/4”

29.8 29.8 29.8

100 100 100

1000

650

3/4”

3/4”

3/4”

29.8

100