F/R System Manual

advertisement

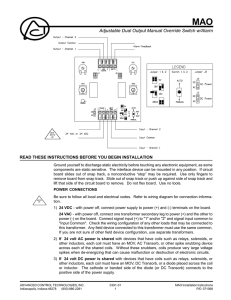

VLA TECHNICAL REPORT NO. 42

F/R SYSTEM MANUAL

D. W. Weber and P. M. Harden

January 1980

CONTENTS

SECTION

TITLE

A

INTRODUCTION SECTION

4

B

FOCUS/ROTATION SYSTEM DESCRIIPTION SECTION

5

C

FOCUS/ROTATION CONTROL UNIT SECTION

145

D

FOCUS/ROTATION CONTROL BIN SECTION

211

E

FOCUS/ROTATION POWER SUPPLY SECTION

236

3

SECTION A

INTRODUCTION

This manual describes the system operation and the electrical

and

mechanical

components

of

the

Focus/Rotation

System.

The

Sections of this manual describe in detail the operation, alignment and

troubleshooting of the system as a whole and of its component parts,

enabling

the

manual

to

be

used as the primary maintenance and

troubleshooting guide for the system.

The Sections (or submanuals) address the following areas:

B - FOCUS/ROTATION SYSTEM

This Section describes the overall system and the associated

components;

ties

together

the

various

components

which

are

distributed throughout the antenna; and includes a troubleshoot­

ing and alignment procedure for the system.

intended for those who are

This Section is

interested in a general functional

description or system troubleshooting.

C - FOCUS/ROTATION CONTROL U N IT, M7

This

Section

describes

the

functional

operation,

bench

alignment and checkout procedure.

D - FOCUS/ROTATION CONTROL BIN

This Section describes the physique and wiring of the F/R

bin (Bin W).

E - FOCUS/ROTATION POWER SUPPLY, M8

This Section describes the F/R power supply used to power

the system electronics.

4

SECTI ON

B

F O C U S /P O T A T IO N

SYSTEM DESCRIPTION

SECTION B

FOCUS/ROTATION SYSTEM DESCRIPTION

TABLE OF CONTENTS

1.0

MANUAL INTRODUCTION AND DESCRIPTION

12

2.0

SYSTEM FUNCTIONAL DESCRIPTION

14

2.1

2.2

2.3

System Specifications

17

2.1.1 Mechanical specifications

17

2 .1 .1 .1 Focus drive

17

2 .1 .1 .2 Rotation drive

18

2 .1 .2 Electrical specifications

18

System Components and Physical Configuration

19

2.2.1 Subreflector

19

2 .2 .2 F/R Mount

19

2 .2 .3 Slo-Syn translators

20

2 .2 .4 Slo-Syn stepper motors

20

2 .2 .5 Brake subsystem

20

2 .2 .6 Limit switches

20

2 .2 .7 M7, F/R Control

20

2 .2 .8 M8, F/R power supply

21

2 .2 .9 M1, Data Set

21

2.2.10 M2, Data Tap

21

2.2.11 Pedestal and apex junction boxes

21

Control Command and Monitor Data Flow

25

2.4

Control Command Execution and Monitor Data Readout

2.5

Telescope O perator/F/R Overlay Considerations

28

and Monitor Data Interpretation

33

2.6

Manual Operation

41

2.7

Calibration Considerations

42

6

2.8

3.0

4.0

2.8.1 Mechanical errors

44

2 .8 .2 Electrical errors

44

2 .8 .3 Transducer errors

45

2 .8 .4 Set point repeatability

45

2 .8 .5 Error calculations

45

2.8 .5 .1 Mechanical errors

45

2 .8 .5 .2 Electrical errors

46

2 .8 .5 .3 Transducer errors

48

49

3.1

Focus/Rotation Mount Assembly

49

3.2

Slo-Syn Translators and Model Variations

53

3.3

Slo-Syn Drive Motors and Model Variations

81

3.4

Brake System

86

3.5

Readout Potentiometers

92

3.6

Limit Switches

95

3.7

F/R Control Unit (M7)

100

3.8

F/R Power Supply (M8)

104

3.9

Junction Boxes and Signals of Interest

105

3.10 F/R System Power Distribution

110

SYSTEM TROUBLESHOOTING AND FAULT DIAGNOSIS

112

4.1

Fault Diagnosis on the Operator's Console

112

4.2

Fault Diagnosis at the Antenna

114

4.3

Typical F/R Control Mount and Translator

Signal Waveforms

126

Junction Box Signals List

129

EQUIPMENT INSTALLATION AND ALIGNMENT

5.1

5.2

6.0

44

DETAILED COMPONENTS DESCRIPTION

4.4

5.0

System Accuracy Discussion

131

F/R Electrical Components Installation and

Initial Tests

131

Electrical Alignment

136

DRAWING REFERENCES

143

6.1

Applicable Antenna Cable Drawings, Antenna 1-20

143

6.2

Applicable Antenna Cable Drawings,

Antenna 21 and Up

144

7

TABLE OF FIGURES

Figure 1:

VLA Antenna Surfaces and Axes

16

Figure 2:

F/R System Physical Configuration

22

Figure 3:

Pedestal Room F/R Components

23

Figure 4:

F/R System CMD/MON Data Flow (Block Diagram)

26

Figure 5:

Data Set Command and Monitor Data and

Data Request Message Formats

27

Figure 6:

Typical Mechanical Calibration Data Sheet

43

Figure 7:

Subreflector Mount and D rive, Isometric Assembly

51

Figure 8:

F/R Mount, Drive and Control Components

52

Figure 9:

HTR-1500/1008/HS-15Q0 Torque vs

Speed Characteristics

57

Figure 10: TM-600/M172-FD306 Torque vs Speed Characteristics

57

Figure 11: HTR-1008/1500 Translator, Block Diagram

58

Figure 12: TM-600 Translator, Block Diagram

58

Figure 13: HTR-1500/1008 Translator Physical Configuration

59

Figure 14: Translator Interconnecting Diagram; Signal

and Power, HTR-1008/1500

60

Figure 15: Translator Interconnecting Diagram; Signal

and Power, TM-600

61

Figure 16: Slo-Syn Motor Switching Sequence States

83

Figure 17: HTR-1500/1008 Translator/HS-1500 Motor, Simplified

Wiring Diagram

84

Figure 18: TM-600 Translator/M172-FD Motor, Simplified

Wiring Diagram

85

Figure 19: Brake and Controller, Physical Description

89

Figure 20: MCS-805-1 Brake Controller, Schematic Diagram

90

Figure 21: Brake and Brake Controller, Simplified

Wiring Diagram

91

Figure 22: Readout Potentiometers, Simplified Wiring Diagram

93

Figure 23: Focus Limit Switches, Physical Arrangement

96

8

Figure 24: Rotation Limit Switches, Physical Arrangement

97

Figure 25: Focus Limit Clearance Adjustments

98

Figure 26: Limit Switches, Simplified Wiring Diagram

99

Figure 27: Simplified F/R Control Unit, Block Diagram

102

Figure 28: Simplified Schematic, Analog C ircuitry

and Error Detector

103

Figure 29: Apex Junction Box, Physical Description

106

Figure 30: Pedestal Room Junction Box, Physical Description

106

Figure 31: AC/DC Power Distribution

111

Figure 32: F/R System Fault Diagnosis via the Overlays

113

Figure 33: (a ) TM-600 Translator Drive Waveforms in

Pedestal Room Junction Box, Antenna 21

Through 28

127

(b ) HTR-1008/1500 Translator Drive Waveforms,

Antenna 1 Through 20

128

Figure 34: F/R System Test Data

139

9

TABLE OF DRAWINGS

Drawing Number

98D19171, Sh. 2

Title

Location in Manual

Cable Diagram-Electronic,

VLA Antenna

B13740S1, Sh. 1

24

HTR-1008, HTR-1500

Translator Schematic

B13740S1, Sh. 2

HTR-1008 Translator

Schematic Assy. A5

B13740S1, Sh. 3

62

63

HTR-1008 Translator

Schematic Assy. A1, A2, A3, A4

10

64

TABLE OF COMPONENT DATA SHEETS

Title

Location in Manual

Instructions for Slo-Syn Translator

Type TM-600, Superior Electric

7600 Series 10 Turn Helipot, Beckman

Signalite Surge Arrester

65

94

107

11

1.0

MANUAL INTRODUCTION AND DESCRIPTION

This manual for the F/R System provides a comprehensive func­

tional and physical description of the system and its components for

the VLA engineers, technicians and telescope operators who may have

occasion to work with or operate the system.

This manual covers all functional components of the F/R Drive

System and addresses the following topics:

1)

System Specifications

2)

System Functional Operations

3)

System Components

4)

Alignment and Calibration

5)

Troubleshooting

6)

Control and Data Flow Formats

and Monitor Data Composition

7)

Telescope Operator Interaction with the F/R

Overlay and Interpretation of Behavior

8)

Equipment Installation and Initial Checkout

9)

Manual Modes of Operation

The emphasis and style of this manual is descriptive - to a detail

level consistent with that required for maintenance and repair opera­

tions.

Simple

functional

electrical

circuit

schematic

diagrams and

mechanical sketches are included to illustrate physical configurations

and functional details.

The description of the mechanical portions of

the system is restricted to functional aspects.

drive

loads,

e tc .,

are not included

Topics such as size,

since they are available from

drawings and specifications.

Mechanical and electrical design considerations and design details

are not included - they are available from the drawings referenced by

the manual and are probably not a primary interest of the average

reader.

This manual also contains a number of drawings, component data

sheets and references other drawings which are relevant to the F/R

System.

12

Salient

features of some of the system components and their

effect on system operation are also described.

13

2.0

SYSTEM FUNCTIONAL DESCRIPTION

The

components

of

the antenna which determine the antenna

beam are the primary surface, secondary surface ( i . e . , subreflector)

and feed horns.

These are illustrated in Figure 1.

The subreflector, an asymmetric hyperboloid, is located at the

apex of the antenna and reflects the antenna beam from the primary

surface into one of the four receiver feed horns located about the

center of the dish.

The asymmetric shape of the subreflector causes

the reflected antenna beam to be offset from the antenna central axis

by about 38 inches.

When the subreflector is rotated, the locus of the antenna beam

(on the surface of the dish) is a 76-inch diameter circle.

The four

feed horns are located on this circle so that band selection is accom­

plished by rotating the subreflector to the appropriate angular posi­

tion to direct the signal into the desired feed horn.

The total range

of rotation motion is 400 degrees, minus a few degrees due to limit

switch inhibit action.

The subreflector is raised or lowered to focus the signal in the

selected feed horn.

The total range of focus motion is 12 inches,

minus about an inch due to limit switch inhibit action.

"CW" and "CCW" motion of the rotation drive is defined in the

clock sense when looking down into the antenna from the sky.

The

"UP" motion of the focus drive is defined as toward the sky (away

from

the

primary

surface)

and

"DOWN"

is

the converse.

These

definitions are illustrated in Figure 1.

The task of the electronics

portion of the

F/R

System is to

position the subreflector at the appropriate position under computer

control.

Wavelength selection commands are automatically directed to

the

System by the observing system in the control computer.

F/R

The computer has four sets of unique command arguments which are

the appropriate set points for the focus and rotation drive mechanism.

The

observing

system outputs

the argument set required

wavelength selected.

14

for the

The

subreflector

position

may

be manually controlled

by the

telescope operator at the control console through the use of the F/R

System overlay on a console CRT terminal.

The subreflector position may also be controlled locally at the

antenna for test or maintenance purposes.

Computer-generated position commands and F/R System monitor

data are routed to/from the F/R System via the Monitor and Control

System as described in paragraph 2.3 of this manual.

15

F /R DRWE.

MECWANJ\5 M S

SECONDARY s u r p a c e

( sue> - RE.PLE C T O R )

a m t e m m a

APEX

S U e> R £F L E C T O R

STRUCTURE

MOVEMENT

PEFlNlTiOMS

* P R IM A R Y

SURFACE

\

SU B R EF LECTOR

\

/

CCW

ANTENNA

VERTEX

FEEDM ORW

(TVP. )

LOCUS OF

AMTEKINA 0 E A M

\

\

1

ONJ T W £ DlSM

S U 8f? £F L E C T O R

AXIS

PR IM A R Y

SUGPACE

AVIO

G E O M E TR IC V IE W

F IG . 1 - VLA

ELECTRICAL VIEW

SILHOUETTE V i e w

AT SUNSET (TYP.)

A N T E N N A SURFACES A N D A XES

16

/

.

2.1

System Specifications

The

following

specifications

have

determined

the

design

characteristics of the F/R System:

1)

Memo - Peter Napier to Bill Horne,

September 4, 1973

2)

RFP - VLA-29, March 15, 1974,

(contains F/R Mount Mech. Specs.)

3)

Memo - Barry Clark to Dave Weber,

May 28, 1975

Because of the bulk of material in these specifications and

the functional description emphasis of this manual, the specifica­

tions of interest have been abstracted and stated below.

specifications

quirements.

do not address

These

important mechanical design

re­

Interested readers are referred to the specifications

above.

2.1.1

Mechanical specifications

2 .1 .1 .1

Focus drive

Mechanism

drive

range

-

12“ excluding

travel

inhibited by limit switch action.

Readout pot drive accuracy - shall be equivalent

to

no

more

than

±.25 mm of

subreflector

travel and shall include effects due to back­

lash, nonlinearity, manufacturing tolerances,

deflection,

This

eccentricity,

accuracy

is

and anything else.

equivalent

to ±0.083% of

range.

Drive accuracy - shall not exceed the equivalent

of

±.5 mm

of

subreflector

travel.

This

accuracy is equivalent to ±.164% of mecha­

nism range.

Drive ratio - one motor step (1 .8 ° shaft rotation

increment)

.01

mm.

shall

T he

move

fu ll

the

12"

requires 30,480 motor steps.

17

of

subreflector

tra v e l

th u s

Drive

rate

-

up to 300 motor steps/second or

180 mm/minute.

Readout pot drive range - 3600° for 12“ of sub­

reflector travel.

2 .1 .1 .2

Rotation drive

Mechanism drive

range -

shall be 400°+10°-0 of

subreflector rotation excluding travel inhib­

ited by limit switch action.

Readout pot drive accuracy - shall not exceed ±.2

degrees of subreflector

rotation when mea­

sured

at the pot shaft input.

shall

include

all

gearing

e rro r,

This error

backlash

linearity, runout e rro r, manufacturing toler­

ances,

eccentricity,

etc.

±0.2

degrees

is

equivalent to ±.055%.

Drive accuracy - shall not exceed ±15 minutes of

arc or ±0.069%.

Drive ratio - one motor step (1 .8 ° shaft rotation

increment)

shall

rotate

the

subreflector

1

arcminute.

The full range of package rota­

tion thus requires 24,000 motor steps.

Readout pot drive range - 3600° for 400° of sub­

reflector rotation.

2 .1 .2

Electrical specifications

Readout potentiometer linearity - ±0.015%, independent

linearity.

Potentiometer - Beckman 7603 series, 20,000 ohms±1%,

10 tu rn , servo mount, flatted shaft, -11300 turns

of resistance wire wiped in 3600° of input shaft

drive.

Resistance temp coefficient <±20 ppm/c°.

Conversion resolution - 1/4096, 12 bits, binary coding.

Conversion accuracy - ±0.05% (±1 b it).

Error null - <±1 LSB.

Temp coefficient of set point error - <±.002%/C°.

18

2.2

System Components and Physical Configuration

Figure 2 depicts the physical

components

of

the

F/R

System.

configuration of the major

Figure

3 depicts

the con­

figuration of the pedestal room components in detail.

Drawing 98D19171, sheet 2, depicts the antenna cable runs

and

the

physical

block

electronics

components.

integrated

into

the

structure

of

The

components and cables are

overall

F/R

the

antenna cabling

antenna

plant.

electrical/

Reference

designators such as "W108" identify cable runs and permit con­

venient reference to the associated cable schematic and assembly

drawings.

Note that ail F/R System power (110 V ac, 22 amps, 60 Hz,

single-phase) is provided by a single ac connector (Hubbel twist

lock) in the lower right side of Rack-C (viewed from the rear)

and comes from a dedicated ac breaker (30 amps) in the pedestal

room breaker box (not shown in Figure 3 ).

This ac connector

should always be disconnected when working in the back of the

rack as there are lethal voltages exposed on uncovered terminal

strips.

The functional

described below.

components of the F/R System are briefly

More detailed descriptions are found in para­

graph 3 of this manual (detailed components description).

2.2.1

Subreflector

The subreflector is an irregular hyperbola 90.5 inches

in diameter and is connected to the F/R Mount via a metal

drum.

2 .2 .2

F/R Mount

This

motors,

axis.

mount

brakes,

This

houses

the

mechanical

rings,

gears,

position pots, and limit switches for both

unit is manufactured

by the Sterling-Detroit

Company, Detroit, Michigan, leading to the secondary name,

"Sterling Mount".

19

2 .2 .3

Slo-Syn translators

Two translators, one for focus and one for rotation,

translate low-level drive pulses to the high voltage,

current two-phase pulses required

motors on the

F/R

Mount.

high

by the Slo-Syn

drive

These translators are special

order units manufactured by the Superior Electric Company.

2 .2 .4

Slo-Syn stepper motors

These motors provide the torque required to move the

focus and rotation drive mechanisms.

These motors are also

manufactured by Superior Electric Company.

2 .2 .5

Brake subsystem

The brake subsystem consists of two induction brakes

(one for each axis) and associated brake controller.

Manu­

factured by the Warner Electric Brake and Clutch Company,

the brakes apply braking torque to the F/R drive to pre­

vent slippage of the subreflector between motion commands.

This is released to permit mechanical movement during the

execution of motor drive commands.

2 .2 .6

Limit switches

The

limit switches

(UPPER/LOWER and CW/CCW) are

activated by their respective drives near the extreme ends

of mechanism motion and

signal to the control logic that

fu rth er drive into the limits is to be inhibited.

2 .2 .7

M7, F/R Control

This single wide module contains the control logic and

circuitry

for

executing

F/R

System

gathering of monitor data which

analog

levels within

the system.

commands

and

the

indicates the states and

The controller contains

two independent controllers which are capable of indepen­

dent

simultaneous

operation.

Section

C of

describes the operation of this unit in detail.

20

this

manual

2 .2 .8

M8, F/R power supply

This

6 wide module contains the +5 V logic,

+5 V

ISOL, +15 V and -15 V power supplies required by the F/R

System electronics.

In addition,

it contains the switching

relays for the brake controllers,

release

voltage and

LED indication of brake

limit switch conditions.

Front panel

push button switches also allow focus and/or rotation to be

driven locally in conjunction with an M7.

Section E of this

manual describes this module in detail.

2 .2 .9

M1, Data Set

This 1 wide Monitor and Control System module pro­

vides the position commands to the F/R Control unit (see

2 .2 .7 ) and gathers monitor data from the control unit which

is

indicative

of

system

performance.

This

unit

is

not

described in this manual, the reader is referred to the Data

Set Manual

(VLA Technical Report 30) for details on the

operation of this unit.

2.2.10

M2, Data Tap

This 4 wide Monitor and Control System module pro­

vides the facilities to trap and display command and monitor

data

messages.

This

enables

System to be observed locally.

used to trap

messages.

the

operation

of the

F/R

This Data Tap may also be

and display any antenna command and data

The operation of this unit is described in the

Data Tap Manual (VLA Technical Report 38) and the in ter­

ested reader is referred to this manual for details on the

operation and use of this unit.

2.2.11

Pedestal and apex junction boxes

These

junction

boxes

are

the terminus for all

F/R

System antenna cables and are very convenient for signal

observations and system maintenance.

21

F /R F E E D -

APEX CAbLE

• RUMS

MOUMT

'

A5 5 EMBLV

sub

-r e f l e c t o

feedhorm

Ct v p . )

ELEVATION! AXtS

CAfcLE W RAP

A Z IM U T H A X IS

CABLE W R A P

BRAKE

POWER

SUPPLl£Sf2)

F /R C O M T RO U

F /R P O W E R 5 U P P L Y

DATA SE T

DATA T A P

v

T R A M S L A T O R S ^)

f

DRW BY*. PAUL HARD€M

adapted pssm

DvOG’s

F IG .

2

- F/R. SYSTEM PHYSICAL

22

CONFIGURATION

njrao

| CABLE, Assy’s

\CA3L£ ASSVk]

1W

iOt, 102,/03.

|104 AM

OW 3 4

I

IW34, vjtoe, to9tno,1

| m, AM

OW//2 |

CABLE R U N S

to apfx

ROT BRAKE

CONTROLLER

PEDESTAL RM

CABLE TRAYS

FOC B R A K E

C O NTRO LLER

AZIMUTH AX/S

CABLE WRAP

"C R A C K

& /N -\ A/

,

F /R SYSTEM

CONTROL E L E C T R O N /C *

200 dba PR

£X M A U S T

FAN

FOC TRANSLATOR

ROT TRANSLATOR

ICABLE.

ASS'/S 1

.\A/f 0 / , / 02 , / 04 , 1

IAM

D WIQ9___|

\~CABLE ASSY'S

1Wfos, foe,/to,

| ///,ANDW//2 |

P £ D ROOM

DOOR A C C E S S

P E D E S T A L RO O M

J U N C T IO N B O X

-Ml F/R CONTROL

M1 DATA S£T /OS 3)

■M2 DATA TAP

W3J2

o

o

© © © O ©

O o C)

o <y o

o @ a s

■r>

cc

C

< j>

i-,

e<> c c

o o

o oo

oo o

F0C (TW

c

a/s

o

/=//? PcweK suPPty

C C A JM S C TC bt

ti

d e t a il

FIG . 3 - P E D E S TA L

1A///2

Sistea

/ ti-C Power

~/ C

c

B i N "\n "

O O

RACK 'C" - PEAR V I£ W

ROOM

F /R

23

COMPONENT'S

. TS-LL" J

! FOCUSSW, j

PDM * 1

50L AR

I

H IV E

*

•OTOR

I

1 LOWER l

J LIMIT j

“ T J

*”

JB3 •

Yr*

r ’ Fs-uL'i

! “PR"

( FOCUS SM/t I

I UPPER I

' LIM IT I

POLAR

D R IV E

L«A

«j

Wr*

V

11

{

I___ r _____I

1____ _ ,_____ I

V

! "PDB*

1

| PO LA R I

REAOOUT I

« (PO T.) !

.

v

Si

H

________r *

st

cable

J66

______ r . A .

J8T } = - - - - J

JB« E------ __ _J

ZO T ®OK*

P R IM E FO CUS

M A N U A L CONTROL

S T A T IO M

*•*

- a

"a i a t

PRIME FEED MOUNT ASSY.

A55Y MO: 98019126-01

w ir e l i s t : 9 6 0 1 9 1 6 0

LQ4* .BAffA.?£T S.9MJP9l.#-Ay?L.kJMfct.

VERTEX ROOM ASSY.

10 5 0*' P S # 3 COMMANDS 4 MCNIT q K DATA

assy n o

jet

r a c k

X

XjL

\

FRONT-END

! '3

ASSY No: 98P19*65-01

1 '4

P«6P.P?*EL

w ir e

TL

r

CRY06CNICS

safety

Switch*

FUSED

ASSY NO:

9<0l»14l-QI

Lis t :

A&SaiMSL

141

j b

VERTEX ROOM

JUNCTION BOX

BLOCK D IA 6R AM J

' ,(L

w ir in g

CRYOGENICS

POWER

D ia g r a m t

98gi> a tja

I.J»

I )9

cRvottwci

CONTROL

PANEL

*AlA4"

CRYOGENICS

PROPOSED

REMOTE

CA»UE

£}9Il__ I

B

oc^ 8«akCAC

compressor

Vf X.

CONTROL

■•fjTENNA

■n t r o l

J N IT

:

cam

_________

" wipe;cbyooi^c compbeispr control.

imti:

JJCJ

FOCUS

BRAKE

CONTROLLER

*« p » 9 te e *< M

SCHEMATIC DIAGRAM!

e d e s ta l r o o m a s s y ,

i L Jt

1

<EEE

a s s y mo:

aS9t

R o t a t io n

Dr a k e

con tro ller

CONTROL

P/R BRAKE CeWTWQt.HR.

ocus

'J L fDRIVE

TRANSL.

ROTATION

DRIVE

TRAMSL.

-R A C K “C; '

SERVO

C o n tro l

O.c. OUTPUTS

UN

LIM

ESIN

S^O

THS

ER

W

O

irN

A

*fISE

INSHW

INCHEiD

S

a ssy mo:

96Dl9ie7-P>

< A N T E N N A S *! i ON

w ir e l is t ;

A1372OWS0

CAflLC Diagram :

.. jg s s m

^

V7

material

SEE 8/M

*

98019171-01

[ NtXT»$S*

<WOEUUOJ^ti

L'SIP 0*

NATIONAL RADIO

ASTRONOMY

OBSERVATORY

sx-or-l.

CA8LE DIAGRAMOTBTELECTRONIC,

BWWWgfl "'

VLA ANTENNA

IfaBL

2.3

Control Command and Monitor Data Flow

Figure

4 depicts the flow of F/R

monitor data

(the

System commands and

balance of the Monitor and Control System

equipment has been omitted for simplicity).

F/R System commands (either position set point or reset)

are issued from MONTY, the computer, by the observing system

at wavelength change time (or manually by the telescope oper­

ator) and are routed to Data Set 3 in the Monitor and Control

System.

The commands and monitor data are digital time sequence

messages with encoded address components which designate, DCS

address, Data Set and Multiplex Channel Address.

The message

information is encoded in 24 bits which follow the address com­

ponents.

The

F/R

position

commands are formatted

least significant twelve of these 24 bits.

into the

Figure 5 depicts the

message format.

Data Set 3 is the control/data interface to the F/R System

and

detects

components

position

F/R

and

System

command messages,

decodes address

causes the command information

set point or drive

reset)

(i.e .,

either

to be loaded into the F/R

Control unit by activation of address, clock, strobe, and infor­

mation

lines to the control

unit.

The Data Set gathers both

digital and analog monitor data from the F/R controller by acti­

vation

of

address,

strobe

and

clock

lines.

These data are

converted to digital values (if analog) and combined with address

components to formulate monitor data messages which describe

the states and analog levels within the F/R System.

Programs in

the control computer decode the messages and provide the infor­

mation to other programs which analyze F/R System performance

and

interact with the telescope operator via

the

F/R

System

overlay.

The Monitor and Control System and command and monitor

data

operations

are

Technical Report 30).

described

in

the

Data Set Manual

(VLA

The reader is referred to this manual for

a more extensive discussion of the system characteristics.

25

£

APEX

VERTEX ROOM

®®®©^ 0

0

0

?£j

tp

£5t" >J* ivSjf U

"to'Q

0 © 0>^

®Tl G» (S>T2 C9

<z»

L.O. S Y S T E M

PEDESTAL

/\

bAA

ANTENNA

BUFFER

ROOM

P

k VD

u

V vn

>41

i

§1

ALL ANTGA/MA

(LMDS AJJDMON

* O'

^

V)

M£SSA<S£S

K$ K p

5 5

S

4m 5i £

o.

i

iir

V7V.

Q © O G )G )

n o c

T 3

V> *

5 0

PR WE

COMMANDS

O*

MB

M&

/

~ F /R S Y S T E M

Om d /M O N

commands

0

/

~

------------»

M7

F/R POWER SUPPLY

F IG . 4

TRANSLATOR

LOCAL

9 f

pfR CONTROL

DATA F L O W

(BLOCK

ROT

TRANSLATORS

D IA G R A M )

I* — 50 11S — ►

5pS/BIT

4 5 0 pS, 45 BITS

lOpS/BIT

010 I I o i oo| I/O

I/O I/O - I/O i/ o| i/ o

I/O i/ o|i/ o

V v-------------- ^ -------------- - V v

MESSAGE

PREFIX, "S"

CHARACTER

ANT ADDR,

5 BITS

DATA

SET

ADDR

3 BITS

MULTIPLEX ADDRESS, 8

BITS

u

PARITY

BIT P9

J

1/0 i/p| IA>

i/o|i/Q 1/ 0 _

l/oll/ol

v................. ............ .......V---------------------^ --------

DATA BYTE # 1 , 8 BITS j

DATA BYTE # 2 , 8 BITS

PARITY

BIT P27

PARITY

BIT P,18

J

V

DATA BYTE # 3 , 8 BITS

36

45

J

MESSAGE ADDRESS COMPONENTS, IDENTIFY

MESSAGE SOURCE OR DESTINATION

MESSAGE INFORMATION

MSB

ANALOG MONITOR DATA FORMAT

12 BITS

V________________

LSB

________________ J

MULTIPLEX ADDRESS + 1 DATA

MSB

BINARY MONITOR DATA FORMAT

H

DATA REQUEST MESSAGE FORMAT, ” q ” CHARACTER

12 BITS

LSB

________________ J

MULTIPLEX ADDRESS DATA

24 BITS

V ____________________________________

MSB

BINARY COMMAND FORMAT

MSB

\ ________________

LSB

_____________________________________ /

24 BITS

LSB

V____________________________________ _ ______________________________________ J

5 0 mS 1 W

||Q I 0 0 I 0 I 0 0 |

FIGURE 5 : DATA SET COMMAND AND MONITOR DATA AND DATA REQUEST MESSAGE FORMATS

2.4

Control Command Execution and Monitor Data Readout

The flow of F/R System control commands and monitor data

has been described in paragraph 2 .3 .

In this process Data Set

3 stores position commands in the F/R Control unit M7.

command

storage

operation

initiates

a command execution

The

se­

quence in either of the two controllers (they are independent

and

capable

of

simultaneous

asynchronous

operation).

The

commands are stored in 12 bit static storage registers as 12 bit

2's

complement values which

represent 4096 possible command

states in the mechanism drive.

The command execution sequence logic firs t energizes the

associated mechanism brake by applying 110 V ac to the brake

controller via a solid state relay in M8.

The dc output of the

brake controller disengages the brake surfaces by electromag­

netic action.

To avoid immediate drive to the mechanism before

the brakes are disengaged the sequencing logic waits 300 milli­

seconds before enabling motor drive.

During this delay, the

analog portions of the controller are allowed to settle (which

takes about 5 milliseconds because of the integration properties

of the error comparators) and the acceleration/deceleration logic

is initialized.

The

error detecting and steering

logic in the controller

performs a continuous comparison between the actual and com­

manded position to produce direction steering terms which enable

either UP/CW or DOWN/CCW drive clocks to the stepper motor

drive

translators.

The

translators

translate

these low-power

logic domain level clock pulses to high-power sequential switch­

ing pulses which cause the motors to drive the mechanisms so as

to null the error.

As the error voltage approaches null it is

tested by analog comparators which switch when the error signal

falls within a reset aperture.

When either comparator switches

the command state is reset and the translator drive clocks are

inhibited.

The comparators reset aperture is « \ bit wide.

28

When the command state is reset by the comparator switch­

ing described above the brake controller ac power is switched

off which causes the brake to reengage (which takes ~200 milli­

seconds) which then applies braking torque to hold the mecha­

nism in the commanded position.

In the halt state ( i . e . ,

in

between motion commands) the stepper motor translator maintains

a constant dc current through two of the four motor windings

which generate a magnetic “motor holding torque".

This motor

torque serves as a fu rth er motion brake (which in the case of

the rotation drive is much greater than the fail safe brake) to

hold the mechanism in position.

The error detector and comparators have integrating pro­

perties which integrate

noise perturbations less than ~5 milli­

seconds

Typical

in

duration.

noise

sources

are

transducer

noise, noise induced in the long cable runs and ac line noise

spikes which pass through the M8 power supplies (despite the

attenuation of the power supplies and an

RFI

filte r ).

Noise

components in excess of this period and greater than 1 bit in

amplitude can cause premature shutdown of the command execu­

tion logic, resulting in faulty command execution.

The position

helical

readout transducer is a wire-wound 10-turn

potentiometer

which

is excited

by the

F/R

controller.

The characteristics of this potentiometer are described in para­

graph 3.5 of this manual.

The

torque

developed

by

the

translators/drive

decreases rapidly as stepping rate is increased.

motors

This phenomena

necessitates starting the mechanism motion at low stepping rates.

If high stepping rate drive is attempted without an initial low

speed

start,

the

motor

will

just growl and slip magnetically

without producing any shaft motion.

The upper bound of suc­

cessful high speed stepping rate starts is in the neighborhood of

300 Hz.

Because of this phenomena, the F/R Control unit time

modulates the stepping rate by starting mechanism drive ~50 Hz,

which is then linearly increased to about 500 Hz in about one

29

second.

This acceleration of stepping rate enables a roughly

constant fraction of motor torque to be used to accelerate the

mechanism mass to the high drive rate which accomplishes most

of the mechanism motion.

As the mechanism approaches error null another phenomena

becomes important - overshoot past null at high motor stepping

rates.

This is the result of two factors - motor overshoot and

motor coupling "wind up".

stepper motor running

When a dead stop is attempted with a

at high

speed,

overshoot the position at which

the motor will tend to

it should have stopped as a

function of stepping rate and load inertia.

be quite

large for

high

inertial

loads.

This overshoot can

The second cause of

overshoot is the elastomer coupling between the drive motor and

the mechanism drive train .

When the mechanism is accelerating

or under heavy frictional or translational workloads the mech­

anism drive can lag behind the motor shaft by quite a few steps

because of the elastomer "wind up".

When the motor is stopped

with the elastomer "wound up" the stored spring energy must be

released.

This

oscillations

release

which

are

is

usually

damped

motor winding/drive circuit.

in the form of mechanical

by the mechanism friction

and

Experimental attempts to execute a

"dead" stop at a high stepping rate ( e . g ., ~500 Hz) have pro­

duced overshoot errors on the order of 1%.

overshoot

phenomena,

rate

~500

from

Hz

the

controller

Because of this

decelerates

the stepping

to ~50 Hz when the mechanism begins to

approach error null.

The deceleration period is ~1 second and

the deceleration sequence is initiated by the controller when the

absolute

value

of

the

error

voltage

decreases

below

preset

bounds.

Although the elastomer coupling is not an ideal (loss­

less) spring, there are stepping rates at which mechanism reso­

nance can be induced by the impulse nature of the stepper motor

torque.

The upper range of realizable stepping rate is somewhere

around 700 to 800 Hz.

d r iv e n

a t r a t e s w h ic h

In some antennas, the mechanisms can be

appro ach

30

1000 H z b u t in o t h e r s ,

th e

upper

realizable drive rate has been found to be about 700 Hz or less.

For this reason the controllers are set up to produce an acceler­

ated stepping rate of ~500 Hz.

When the upper safe drive limit

is exceeded the motors just stop running with the result that the

motion command remains "stuck" in the controller without ever

completing the motion.

For this reason and for other possible

malfunctions the controller has time-out logic which resets the

command and sets a "time-out" fault flip-flop which is read out

as part of the binary monitor data.

The timer period is about

150 seconds, more than enough for the mechanisms to traverse

the full range of motion at a 500-Hz stepping rate.

The next

motion command or a reset command will reset the time-out flip flop and restart the time-out logic.

A stepping rate of 500 Hz will produce a mechanism motion

rate of about 8.3 deg/sec in rotation and 0.2 in/sec in focus.

The

controller

senses

mechanism

limit

switch

and brake

conditions which are used as enable/inhibits in the translator

drive outputs.

If either the UP/CW or DOWN/CCW limit switch

is activated the drive into the limit is inhibited but drive out of

the

limit is permitted

but drive

reverse must be initiated by

another command from the computer.

The controller does not

automatically back the mechanism out of the limit.

The presence

of brake voltage on the brake terminals in the apex junction box

is

sensed

by the controller and enables drive clocks to the

translator.

The normal output of the brake controller is about

70 V

and

the threshold for voltage detection

Note

that

this

is about 30 V.

indication does not necessarily mean that the

brake has disengaged.

There have been occasions when brakes

have not activated even though correctly powered.

These in­

hibit/enable and other states are read out by the binary monitor

data logic in the controller when commanded by the Data Set.

The composition and usage of this data are described in para­

graph 2.5.

31

The F/R position commands loaded into the controller may

be read out as binary monitor data for confirmation of the com­

mand loading process.

The readout process will be left shifted

eight bits and will occur only once as the readout is a destruc­

tive process.

The

controller

contains

a 16 channel

analog

multiplexer

which reads out important analog parameters and the focus and

rotation mechanism positions.

The composition and usage of this

data is described in paragraph 2.5 .

32

2.5

Telescope O perator/F/R Overlay Considerations

and Monitor Data Interpretation

The telescope operator may manually control the F/R System

on the console CRT's.

This display presents F/R analog data,

system states and enables the operator to conveniently interact

with the F/R System.

The

overlay

display

format,

description

of the

display

elements, operator commands and comments on the interpretation

of the overlay data are described below:

FOCUS/ROTATION FOR ANTENNA 12

POSITION

D/A COMMAND

ERROR

XLAT0R PWR

CMD READBACK

REQUESTED

+5V.

4.970

402

0.975

0.030

2.530

0

400

IS0L.

5.010

WORD C-NORM

R=SET ROT

WORD D-MAN

-201

-0.495

0.005

2.580

0

-203

-10V.

+15V.

-15V.

-10.005

7.500

-7.510

Q=QUIT

T=TAKE

G=GIVE

GROUND SACRED+10

0.000

10.005

U=USE

F=SET FOC

S=ST0P

This overlay is called by typing:

routines are running,

FR n.

If the astronomy

n in the overlay call may be either the

DECIMAL value ANTENNA ID#, or the OCTAL value for the DCS

ADDRESS.

If the DCS ADDRESS is used, the octal value must

be preceded by a single quote.

MODE indicates the control mode for the FOCUS/ROTATION

MODULE, it may be in one of the following modes:

COMPUTER for control from control building.

LOCAL for control from antenna pedestal room.

TRAILER for control from checkout trailer.

APEX for control from antenna apex.

33

POSITION is the mechanism position readback in terms of

the REQUESTED units which range over 2047, 0 and -2048 (ig ­

noring limit switch action).

These digital values are 211-1 , 0

and 211 in 2's complement notation.

REQUESTED

Control

is

the

command

argument

unit by the observing system.

sent to

the

F/R

These values are the

decimal equivalent of the command argument.

Note that when

the operator assumes control in the manual mode the value dis­

played is the last one output by the observing system irrespec­

tive of the manually entered POSITION commands.

D /A COMMAND is the analog equivalent of the digital com­

mand sent to the

+4.997,

0 and

F/R

-5.000

controller and has an analog range of

volts which corresponds to the digital

command range of 211-1 , 0 and -2 11 in 2's complement notation.

One DAC bit has the weight of 2.4 41 4+ ... millivolts.

ERROR is the controller servo loop error voltage and is 50

times the difference between the DAC command output and posi­

tion readout potentiometer.

Thus a + or -1 bit error would be

displayed as + or -125 millivolts (+ or -.1 2 5 ) which is 1/8 of the

command units.

F/R Systems with good performance will ty p i­

cally null with less than ±1 bit erro r.

Large values of error

voltage are an indication of a malfunction somewhere.

command

execution

terminates

without

an

error

If the

voltage

null

< 11251 millivolts then either the controller has malfunctioned,

(probably due to noise glitching the analog circu itry) or there is

excessive frictional drag in the drive mechanism.

If the error voltage builds up again after null or fluctuates

erratically in excess of the 125 millivolt value then the pot is

probably getting noisy and must be replaced (they have a short

life in the antennas).

when the antenna

In extreme cases this may happen even

is stowed and there are no antenna drive-

associated vibrations to induce pot noise.

moving the error

voltage

readout will

When the antenna is

usually be higher than

when the antenna is quiescent due to drive vibrations which can

34

stimulate

small

unbalance,

motions in

F/R

drive mechanisms due to load

lost motion and gear train

motions will drive the

noisy output.

backlash.

These small

readout pots and induce an electrically

The focus error voltage is usually much quieter

than the rotation error voltage because there is probably less

lost motion in the focus mechanism because of the heavy vertical

load components borne by the focus mechanism.

The rotation

drive has more evident lost motion (the specs permit up to ±27

minutes worst case) and consequently the error voltage is nois­

ier.

From the above it can be seen that the error voltages are a

sensitive indicator of the F/R System performance but one should

be

cautious

in making judgments about apparent malfunctions

because of fluctuations in these parameters.

XLATOR

PWR is a scaled measurement of the associated

drive translator +14.5 volt power supply voltage.

should be +2.5 volts±200 millivolts.

older model translators

(antennas

The readout

This value applies to the

1 through

20), the readout

values for the newer model translators in antennas 21 through 28

will be ~+2.1 volts±200 millivolts.

If the value is ~0 it means

that the translator is busted or that the translator power fuse

on M8 is blown which

sometimes happens when the ac power

surges as in summer thunderstorms or there is excessive mecha­

nism binding which can overload the translator.

CMD READBACK is the value of the position command sent

to the F/R Control unit in the last system cycle.

The readout is

destructive in that it may be seen only once after each command

output.

The value displayed has been left shifted 8 bits by the

readout logic.

command

was

This feature

actually

provides a confirmation that the

stored

in

the

controller

and

the

left

shifted value should correspond exactly with the command argu­

ment.

the

F/R

If there is some doubt that commands are not reaching

Control

unit this display feature should be checked.

35

FLASHING

ACTION

REPORTS

definitions

are

as follows:

FOCUS DRIVE ACTIVE implies that the focus controller has

had a position command stored and that the command execution

sequence has been initiated.

FOCUS

AT

UPPER

DRIVE

focus limit has been reached.

LIMIT

implies that the upper

Back off the focus by sending a

command of 0 which is the mid-range for focus travel.

FOCUS AT LOWER DRIVE LIM IT implies that the lower focus

limit has been reached.

Move the focus up by sending a com­

mand of 0 which is the mid-range for focus travel.

FOCUS BRAKE RELEASED implies that the focus controller

is sensing a release voltage on the focus brake and the mecha­

nism is (hopefully) free to be driven.

FOCUS

BRAKE

RELEASE

COMMAND

ON implies that the

focus brake controller has been activated.

FOCUS SLEW ACTIVE implies that the focus is being manu­

ally slewed at the antenna in one of the local modes.

ROTATION

DRIVE ACTIVE

implies that the rotation con­

troller has had a position command stored and that the command

execution sequence has been initiated.

ROTATION AT CW LIMIT implies that the clockwise limit has

been reached.

Set a rotation command at 0 which is the mid­

range for rotation to clear the limit.

ROTATION AT CCW LIMIT implies that the counter-clockwise limit has been activated.

Set a rotation command of 0 which

is the mid-range for rotation to clear the limit.

ROTATION

BRAKE

RELEASED

implies

that

the

rotation

controller is sensing a release voltage on the brake and the

mechanism is (hopefully) free to be driven.

ROTATION BRAKE RELEASE COMMAND ON implies that the

rotation brake controller has been activated.

ROTATION SLEW ACTIVE implies that the rotation is being

manually slewed at the antenna in one of the local modes.

36

ACCEPTABLE COMMANDS FOR THE FR n OVERLAY

Q=QUIT

T=TAKE

G=GIVE and U=USE are the same functions as

the ones in the pointing relays.

F=SET FOCUS positions the cursor to accept a focus command.

R=SET ROT positions the cursor to accept a rotation command.

S=STOP

the

current

drive action

in process.

This command

immediately resets the command state in both the focus and

rotation controllers.

The STOP command may be manually issued at any time and

resets the command state in the controller and clears the com­

mand argument previously stored to 0000.

The command argu­

ment for this command is irrelevant as it is not used.

This

command may be used to override one which sends the drive into

the limits.

TIME-OUT fault indicators (not part of the overlay) is set

by the controller if the command execution has not been com­

pleted

within about 150 seconds.

When this fault occurs the

controller logic is reset to the quiescent state and drive clocks

to

the

associated

translator

are

inhibited.

When

TIME-OUT

occurs the drive activate indications are cleared from the dis­

play.

This feature is a malfunction indication and also serves to

protect

the electrical

and mechanical

hardware from incessant

motor drive impulses.

The voltages displayed are vital system voltages which must

be present and correct for proper operation of the F/R System.

SACRED+10 is the precision reference voltage for the con­

troller and

is the DAC reference voltage as well as an offset

current source.

This is a very important parameter and should

be within ±1 millivolt for proper scaling of DAC outputs.

-10 V (-10 volts) is the voltage which excites the position

readout pots and is derived from the SACRED+10 volts.

This

value is also critical and should be within ±1 millivolt for proper

37

operation.

This value will track (with the opposite sign) the

SACRED+10.

The +5 V value is the controller logic power and

should be no more than ±150 millivolts from 5,000.

The ISOL

5 V value is an isolated logic supply which is used in sensing

discrete inputs from limit switches and brake controllers.

This

value should be no more than ±150 millivolts from 5,000.

The

+ and

-15 V values are the analog power supplies

which drive the controller analog circu itry.

These readouts are

from ”2 voltage dividers, thus ±7.500±150 millivolts is indicative

of proper ±15 power supply voltage.

GROUND is literally a grounded input to the F/R Control

unit analog multiplexer and is primarily useful as an indication of

Data Set 3 A /D converter zero d rift.

The 20 volt span of the

SACRED+10 and -10 volts may be used as an indication of Data

Set 3 A /D gain d rift.

Control

unit

which

If there is a component failure in the F/R

will

impact the

SACRED+10 and

-10 volt

supplies the failure will probably cause a dramatic shift in these

values.

Small drifts

in these values should not be cause for

alarm as they are probably due to either A /D gain or zero d rift

which is not a serious problem.

The Data Set A /D converter

least significant bit is 5 millivolts which is more granular than is

desirable for precision measurements of the DAC outputs and the

two critical voltages.

A /D 's typically are accurate to within ±1

LSB (±5 millivolts in the Data Set) when properly calibrated but

may be subject to slow d rift effects.

Because of these drifts the

Data Set A /D 's should be periodically recalibrated.

The F/R Control command multiplex addresses are:

1)

Focus position command - 320^

Focus command reset - 330o

o

2)

Rotation position command - 321g

Rotation command reset - 3310

o

The binary monitor data readout multiplex addresses are:

1)

Focus command readback - 202g

2)

Rotation command readback - 203o

3)

F/R drive status - 204g

o

38

The analog monitor data

readout multiplex addresses and

data are:

Addrg

Parameter

0

+5 volt logic power

1

+5 volt isolated supply

2

-10 volt pot excitation

3

+15 volt power supply (reading = +15/2)

4

-15 volt power supply (reading = -1 5 /2 )

5

Analog ground

6

Focus position

7

Rotation position readout, -10, 0, +10 V

10

Focus

readout,

command

DAC

-10, 0, +10 V

output,

+4.997,

0, -5 V

11

Rotation command DAC output,

+4.997, 0, -5 V

12

Focus command error det output

-1 .2 5 , 0, +1.25

13

Rotation

command

error

det

output

-1 .2 5 , 0, +1.25

14

Focus trans power mon ~+2.5 V

or ~+2.1 V

15

Rotation trans power mon ~+2.5 V

or +2.1 V

16

SACRED+10 reference

17

Not used

20

Anemometer 1 output

21

Anemometer 1 output

40

Anemometer 2 output

41

Anemometer 2 output

All of the above digital and analog monitor data on the MW1

overlay.

An important operational

admonition

is:

DON'T EVER at­

tempt a full-range motion command or try to drive the mechanism

into the

limits.

A large command argument change (from the

39

previous value) will cause the controller to accelerate the drive

rate to a high value which could then cause the motor to drive

the mechanism into the physical stops at high speed.

This could

damage the limit switches ( it has happened) or even damage the

expensive

inside

drive

command

The

some

command values at either end are not physically realizable.

The

controller

argument

limit switches are activated

means that

F/R

the

mechanism.

range

which

does not reject command arguments which are

beyond the limits.

A second reason for this admonition is that

the limit switches may stay stuck on even after the mechanism

switch activator has been backed away from the switch.

The

rotation limit switches are particularly liable to this problem as

they are activated by a spring-loaded lever arm.

Sometimes the

lever sticks and it is necessary to free it by driving to the

other limit (meanwhile hoping that it will not stick in the other

position).

If it sticks you have to climb up to the apex and

reach down and manually unstick it.

short arms.

Drive focus up if you have

Another problem is that 400° of rotation motion

requires that a sliding dog be used to drive the lever arm limit

switch actuator mentioned above.

This dog slides in a circular

groove and normally sits at the most extreme position to which it

was previously driven.

If the groove/dog friction builds up due

to snow or dust clogging the groove the dog may stick if you

attempt to drive into the limit.

In the event that the limits stick

and you elect to manually unstick them, this manual could be

handy as paragraph 3.6 has illustrations which depict the limit

switch locations on the F/R Mount.

If it is really necessary to test the limit switch operation

from

the

F/R

overlay

then

approach them cautiously with

succession of small command arguments.

40

a

2.6

Manual Operation

It is occasionally necessary to drive the subreflector in a

local manual mode for test or alignment purposes.

The local

mode is selected by setting the mode selector switch on the front

panel of the F/R controller to the "prime focus",

"local" positions.

"trailer" or

In the local position the push buttons on the

F/R power supply may be used to manually slew either mecha­

nism at ~100 Hz stepping rate which will rotate the subreflector

at about 1.6 degrees/second and raise or lower the subreflector

at about .040 in/sec.

LED indicators indicate the detection of

brake voltage and actuation of limit switches.

Paragraph 3.9 of

this manual describes the use of these controls more fu lly.

In the trailer mode the subreflector drives can be manually

slewed as described above by the use of a remote F/R power

supply as a control panel.

The LED indicators are illuminated in

the same manner as described above.

This mode of operation is

not presently used but has been used with early antennas for

independent single-dish observations.

The prime focus mode is used to control the subreflector

from the apex by the use of the "Prime Focus Zot Box".

This

mode is used for test purposes at the apex and has LED's to

indicate limit switch activation.

41

2.7

Calibration Considerations

F/R System calibration is a two-fold operation - mechanical

calibration

of the drive mechanism and alignment of the

F/R

Control unit.

Mechanical calibration involves manually rotating the subre­

flector axis to the angular positions which are associated with

the four feed horns.

The resistance between the wiper and the

CCW end of the pot is recorded for each of the four positions.

The total pot resistance is measured and then the ratio of the

four

resistances to the total resistance is then translated into

four command arguments which are then stored in a calibration

table in the computer for access by the observing system.

This

scheme of alignment is quite simple and eliminates the need for

precise adjustment of the position readout pot.

Figure 6 is a

typical resistance calibration data sheet.

The controller alignment consists of bench tests to verify

DAC linearity and data readout gain and zero.

In the antenna a

final gain and zero alignment must be done with the loop closed.

These adjustments are on the order of ~0.1% or less and are

necessary

to adjust the closed loop gain and zero errors to

~±0.025%.

42

FOCUSING FEED MOUNT ANTENNA NO.

1.

FOCUS RATE WITH ZOT BOX

2.

ROTATION RATE WITH ZOT BOX

3.

C W ROTATION CAUSES RESISTANCE DECREASE _

4.

UP MOVEMENT CAUSES RESISTANCE DECREASE

5.

BRAKE GAP SETTING:

_fi/MIN.(>2000fi/min.)

ZOT BOX

__ fi/MIN. (>2500f2/min.)_J*~ SLOW SPEED

*\%

FOCUS

IN.

lA

IN.

7 3 . 3 ^

_VDC

ROTATION

BRAKE VOLTAGE:

FOCUS

ROTATION

7.

FOCUS POTENTIOMETER:

VDC

1 9

TOTAL ft

7 3 3

UP LIMIT n

DN

8.

ROTATION POTENTIOMETER:

TOTAL 0

C W LIMIT n

C C W LIMIT n

2 0 'D X O

1,01b

/*%■

j c f 7/C>

(a )

Q-----------7*---------------------

to

C BAND n

K BAND

KU BAND A

L BAND n

BY:

(3)

7 ^ -7 3

DATE

LMT/mgc

FIGURE 6:

TYPICAL MECHANICAL CALIBRATION DATA SHEET

43

0)

2.8

System Accuracy Discussion

System errors may be considered to consist of the following

components:

1)

Mechanical errors

2)

Electrical errors

3)

Transducer errors

2.8.1

Mechanical errors

Mechanical errors consist of:

1)

Gear train and mechanism slop (o r lost motion),

linkage relationships of concern are: m otor/brake/

readout pot/mech output.

2)

Mechanical

noise

induced

on

the

readout

pot

output by antenna mechanical vibration (the F/R

position

commands

are often

issued during

an­

tenna slew to a new source) and vibration asso­

ciated

train

with

the drive motor impulses and gear

mesh and mechanical

resonance effects at

certain motor stepping rates.

3)

Mechanical drive errors

associated with noncon­

centricity in the gears, and mechanical deforma­

tion induced by mechanical loading and vibration.

2 .8 .2

Electrical errors

Electrical errors consist of:

1)

Controller errors consisting of time, temperature

and supply voltage-induced

errors in the DAC,

precision reference supply, operational amplifiers

and precision analog comparators.

2)

Analog data readout and conversion errors asso­

ciated

with

the

analog

multiplexing

and

A /D

conversion operation performed by the controller

and Data Set.

a positional

Strictly speaking this error is not

error as such but appears so from

t h e m o n it o r d a t a

44

re a d o u t.

2 .8 .3

Transducer errors

The transducer errors consist of wiper noise, nonlin­

earity and noise induced in the potentiometer lines in the

long run between Bin W and the apex.

As the wiper moves

across the resistance windings the transitions are noisy - if

the noise components are large and long enough they can

cause

the

controller

to

prematurely

reset

the

command

state.

The readout potentiometers have a ±0.015% independent

linearity tolerance which is about the best tolerance realiz­

able in this size unit.

Noise induced in the potentiometer lines by ac coupling

mechanisms can cause premature shutdown of the command

state in the controller.

2 .8 .4

Set point repeatability

Set point repeatability is a measure of the servo gain,

and the level of mechanical and electrical ac noise super­

imposed on the readout pot.

for well-behaved

Typical repeatability values

F/R Mounts with good readout pots and

low noise levels (with the antenna stowed) are:

Focus:

±1/2 LSB, ±0.012%

Rotation: ±3/4 LSB, ±.018%

Mechanical noise, binding in the drive, noisy pots or

noisy readout lines can significantly degrade the set point

repeatability.

Note that set point repeatability is not a measure of

the errors due to mechanism slop, DAC errors, mechanical

and electrical nonlinearity and pot nonlinearity.

2 .8 .5

Error calculations

2 .8 .5 .1 Mechanical errors

Focus d riv e :

VLA-29)

the

From the

F/R

Mount specs (RFP

readout pot error may be as large as

±0.083% and drive accuracy error may be as large as

±0.164%.

The worst case sum is ±0.247% or ±0.03 in.

45

Since these errors are (principally) due to mechanism

slop or lost motion which is non-Gaussian the error

probability density function

is a double hump curve

with the peaks near the ±0.25% limits.

Because the

focus mechanism has a significant vertical component

the drive is probably always near the lower peak so

that the error is probably better than the ±0.25 value.

Mechanical ac noise induced on the readout pot

has

been

observed

to

be

(typically)

~±0.0025% or

~±0.0003 in.

Rotation d riv e :

readout

pot

From the

F/R

Mount specs the

error may be as large as ±0.055% and

drive accuracy error may be as high as ±0.069%.

worst case sum is thus ±0.124% or ±0.45°.

The

The error

probability function is again a double hump curve with

the humps near the ±.125% values.

Since the rotation

mechanism is nearly balanced around the drive axis the

mechanism ranges over the whole ±0.124% range as a

function of a subreflector position, load unbalance and

antenna vibration level.

Mechanical ac noise induced on the readout pot

has been observed to be typically ~±0.01% or ~±.036°.

2 .8 .5 .2

Electrical errors

Electrical errors may be caused by time (1 year

assumed),

temperature

change

(a

28°C

temperature

range assumed) and power supply voltage variations,

(±0.1%

line

and

load variations assumed).

Maximum

value error coefficients from manufacturers data sheets

were used in the error calculations.

The error sources are:

1)

Power supply, (+ and -15 volts) - ±0.1% line

and load regulation from LXD-3-152R specifi­

cations.

46

2)

Temperature change - a temperature span of

50° to 100° or ~28°C assumed.

3)

Time - 1 year.

The components which can be affected by these

sources are:

1)

Zeltex

ZD432 D /A

converter which has the

following specs:

Gain

Temp

Coeff:

±0.002%/°C/

% of

RDG

Zero

Temp

Coeff:

±0.002%/°C,

% of

FSR

Linearity Temp Coeff: ±0.002%/°C/ % of FSR

Long

2)

Term

Analog

Stability:

±0.05%/10,000

hours

Devices AD741LN Operational Ampli­

fie r which has the following specs:

Vq s

Temp

Coeff:

5 |JV/°C

max,

2 |JV/°C

typical

I Os Temp Coeff: 0.1 na/°C max, 0.02 na/°C

typical

PSRR:

15 pV/V

CMRR:

90 dB, min

AOL:

50,000 typical

I B ia s Temp Coeff:

1 na/°C max, 0.6 na/°C

typical

3)

National Semiconductor LM299H which has the

following specs:

Output Temp Coeff:

Long Term Stability:

4)

±0.001%/°C

20 ppm/year.

Dale Precision Resistor temperature - induc­

ed

resistance

change.

specified as <20 ppm /°C.

The

temp coeff is

Since the resistors

are custom built in a single batch the tem­

perature

coefficient

was

assumed

within the <20 ppm/°C bounds.

The error calculation results are:

47

constant

RMS E rror, (most probable situation):

±2.74 bits (out of 4096) or ±0.067%.

Worst Case Error (most pessimistic case):

±4.158 bits or ± 0.1%.

2 .8 .5 .3

Transducer errors

AC noise induced on the potentiometer lines has

been observed to be as high as 250 millivolts (due to

malfunctioning brake controllers or improper wire dress

in the junction boxes or conduit ru n s).

F/R

Systems

usually

exhibit

pot

line

order of 1 mV or ~1/2 bit or 0.012%.

Well behaved

noise on the

Integration in

the F/R controller tends to reduce the effect of noise

frequency components above ~500 Hz.

Pot linearity error is ±0.015%.

these two errors is ±0.019%.

48

The rms sum of

3.0

DETAILED COMPONENTS DESCRIPTION

The following descriptions detail the salient physical and func­

tional properties of these units.

3.1

Focus/Rotation Mount Assembly

The VLA F/R Mount is a mechanical package, located at the

antenna apex, and houses the drive motors, induction brakes,

position potentiometers,

and

limit switches for both focus and

rotation.

This

Company,

assembly

is

manufactured

by

the

Sterling-D etroit

Detroit, Michigan, and is similar to the F/R Mounts

used in the antennas at NRAO, Green Bank.

A fter manufacture

of each mount by S terling-D etroit, these mounts are individually

tested

for

mechanical and electrical

soundness by NRAO/VLA

personnel at the Sterling plant in Detroit.

Refer to NRAO Test

Procedure 98S19010 for details on the tests conducted.

A fter

this manufacturing checkout and acceptance testing, the mounts

are shipped to the VLA where they are installed on the antenna

by

E-Systems during

the antenna construction.

This is done

primarily due to the size and weight of this mount and the

inconvenience of mounting the structure without a heavy-duty

crane.

Electrical outfitting and wiring is performed by the electri­

cal and antenna groups when the antenna is on the maintenance

pad.

The F/R Mount consists of three mechanical rings, of which

the top and bottom rings are fixed and the center ring is mov­

able in two axes.

gear train

The drive motors and a portion of the drive

are contained

in the top ring.

Four guide shafts

which extend from the top to the bottom ring pass through the

movable ring and insure a stable vertical (focus) movement of

the movable ring.

Drive lead screws and a splined drive shaft

between the top ring and the movable ring cause the movable

ring to raise or lower (focus motion) and cause the inner posi-

49

tion of the ring to rotate (rotation motion).

The two induction

brakes, mounted on the top ring, provide braking torque for the

top ring gear trains to inhibit motion due to vibration or gravity

loads except during motion commands.

The top ring gears also

drive the focus and rotation readout potentiometers to indicate

the position of the focus and rotation mechanisms.

The focus upper-limit switch

is located on the top

ring

while the focus lower-limit switch is located on the lower ring.

The

rotation

limit switches are

mounted on the movable ring.

located in a weatherproof box

See paragraph 3.6 for illustra­

tions of the switches on the F/R Mount.

A "barrel" is secured to the inner portion of the movable

ring and the subreflector is mounted to the base of this "bar­

rel".

The

barrel

provides

mechanical

strength

between

the

center

ring

and the subreflector, a distance of about 4 feet.

The rotation drive train has a drive ratio of 108:1 so that

one motor step will produce one arcminute of subreflector rota­

tion.

The focus drive

has a drive ratio of 2.54:1 with a lead

screw pitch of .200 so that one motor step will produce 0.01 mm

of subreflector focus motion.

Figure 7 illustrates the configuration of the F/R components

at

the

apex.

Figure

8 illustrates the

location of the drive

motors, readout pots and brakes on the top ring.

NRAO drawing 98D19126 (2 sheets) "VLA Prime Feed Mount

Assembly"

detail

the assembly of the motors, brakes,

pots, and junction box on the Sterling Mount.

are not included in this manual.

50

readout

These drawings

APEX

D1?M BY: PAUL HARDEW

ADAPTED FROM N R A O

D\AJG &&V19062

FIG. 8

-

F /R AfOUAJT,

ORIVB

AND

CONTROL

COMPOAI£fiJTS

3.2

Slo-Syn Translators and Model Variations

Three models of Superior Electric Slo-Syn translators are

used in the F/R System, these are:

Model

Antenna

Associated Motors

HTR-1500

1

2

HS-1500

HTR-1008

3-20

HS-1500

TM-600

-

21 - 28

M172-FD306

The translators and motors must be used in the combina­

tions shown - they are not interchangeable.

Two sets of spare

HTR-1008/HS-1500 translators/motors and spare logic and driver

boards have been purchased to support antennas 1 - 2 0 and two

sets of TM-600/M172-FD306 and spare logic and d river boards

have been purchased to support antennas 21 - 28.

The reason

for the translater/motor change is that Superior Electric discon­

tinued the older special order models in mid-1978 and replaced

them with the standard sized (and lower priced) TM600/M172FD306 series.

The translator/motor cabling requirements differ for these

two sets in that the older set could use a 5 wire cable while the

newer set requires a 6 wire cable.

quirement

is the

The different cabling re­

result of the difference in drive switching

between the older and new designs.

The old design uses simple

switching in the driver circu itry while the newer design dynami­

cally switches off the drive to minimize motor overshoot.

This

difference requires that the center taps of the new motors be

wired independently while the old motors could operate with both

sets of center taps wired commonly.

Although this one wire

difference may sound triv ia l, its impact necessitates two different

antenna F/R System configurations which are not interchangeable

in the area of the motors and translators.

The HTR-1500 translator/HS-1500 motor torque/speed curve

is shown on Figure 9.