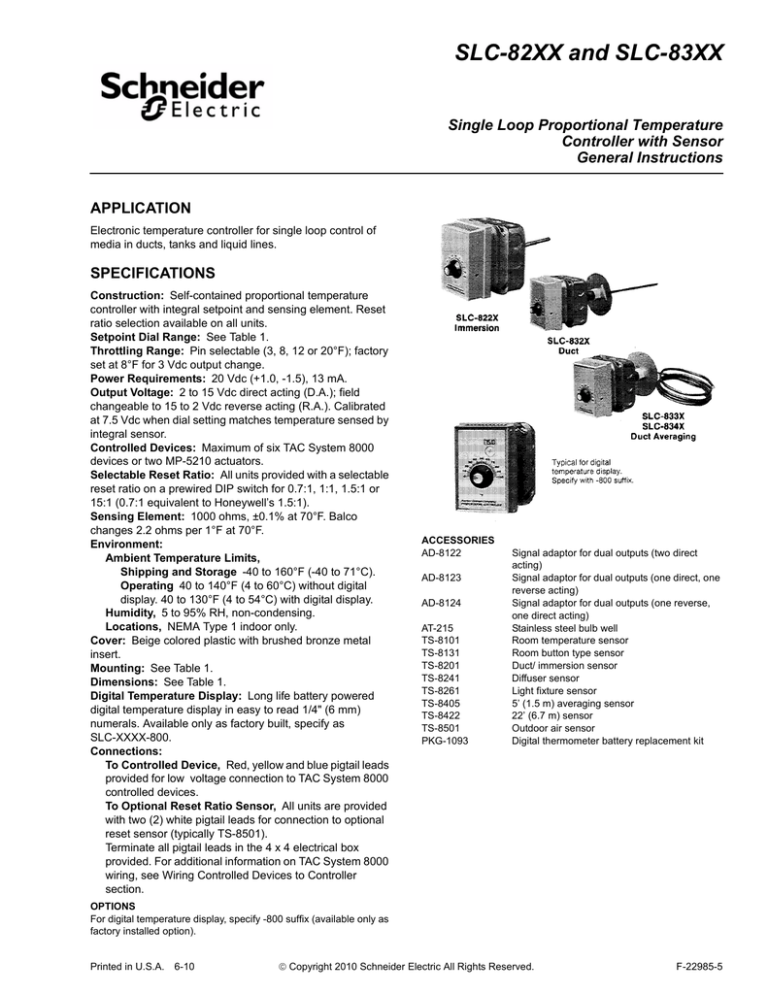

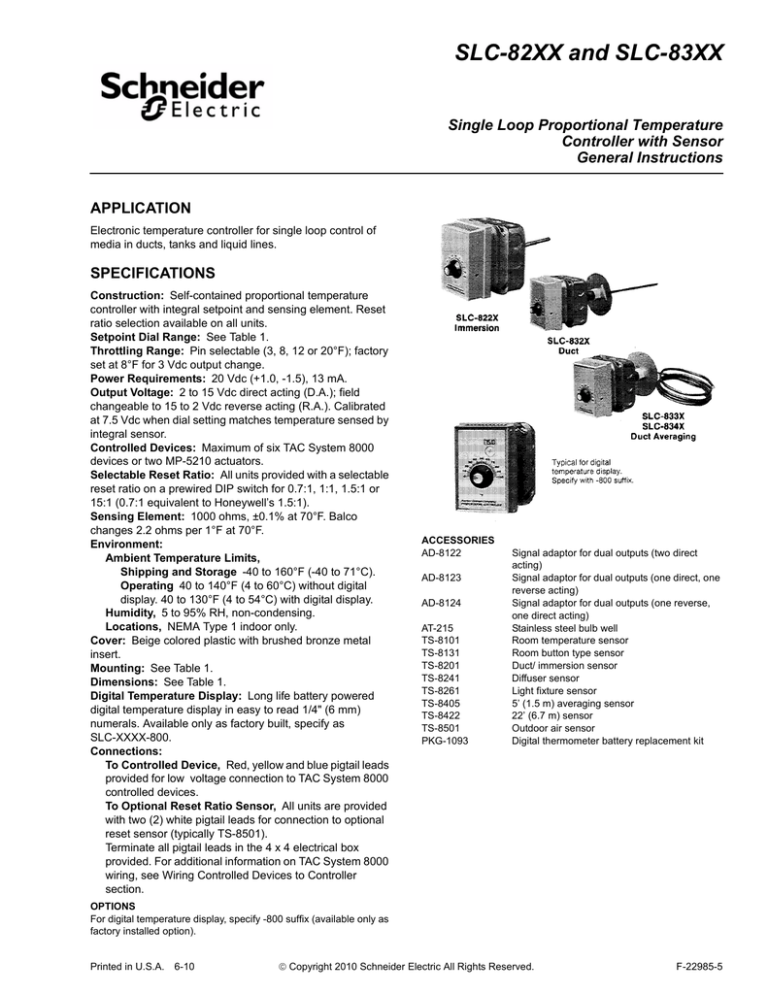

SLC-82XX and SLC-83XX

Single Loop Proportional Temperature

Controller with Sensor

General Instructions

APPLICATION

Electronic temperature controller for single loop control of

media in ducts, tanks and liquid lines.

SPECIFICATIONS

Construction: Self-contained proportional temperature

controller with integral setpoint and sensing element. Reset

ratio selection available on all units.

Setpoint Dial Range: See Table 1.

Throttling Range: Pin selectable (3, 8, 12 or 20°F); factory

set at 8°F for 3 Vdc output change.

Power Requirements: 20 Vdc (+1.0, -1.5), 13 mA.

Output Voltage: 2 to 15 Vdc direct acting (D.A.); field

changeable to 15 to 2 Vdc reverse acting (R.A.). Calibrated

at 7.5 Vdc when dial setting matches temperature sensed by

integral sensor.

Controlled Devices: Maximum of six TAC System 8000

devices or two MP-5210 actuators.

Selectable Reset Ratio: All units provided with a selectable

reset ratio on a prewired DIP switch for 0.7:1, 1:1, 1.5:1 or

15:1 (0.7:1 equivalent to Honeywell’s 1.5:1).

Sensing Element: 1000 ohms, ±0.1% at 70°F. Balco

changes 2.2 ohms per 1°F at 70°F.

Environment:

Ambient Temperature Limits,

Shipping and Storage -40 to 160°F (-40 to 71°C).

Operating 40 to 140°F (4 to 60°C) without digital

display. 40 to 130°F (4 to 54°C) with digital display.

Humidity, 5 to 95% RH, non-condensing.

Locations, NEMA Type 1 indoor only.

Cover: Beige colored plastic with brushed bronze metal

insert.

Mounting: See Table 1.

Dimensions: See Table 1.

Digital Temperature Display: Long life battery powered

digital temperature display in easy to read 1/4" (6 mm)

numerals. Available only as factory built, specify as

SLC-XXXX-800.

Connections:

To Controlled Device, Red, yellow and blue pigtail leads

provided for low voltage connection to TAC System 8000

controlled devices.

To Optional Reset Ratio Sensor, All units are provided

with two (2) white pigtail leads for connection to optional

reset sensor (typically TS-8501).

Terminate all pigtail leads in the 4 x 4 electrical box

provided. For additional information on TAC System 8000

wiring, see Wiring Controlled Devices to Controller

section.

ACCESSORIES

AD-8122

AD-8123

AD-8124

AT-215

TS-8101

TS-8131

TS-8201

TS-8241

TS-8261

TS-8405

TS-8422

TS-8501

PKG-1093

Signal adaptor for dual outputs (two direct

acting)

Signal adaptor for dual outputs (one direct, one

reverse acting)

Signal adaptor for dual outputs (one reverse,

one direct acting)

Stainless steel bulb well

Room temperature sensor

Room button type sensor

Duct/ immersion sensor

Diffuser sensor

Light fixture sensor

5’ (1.5 m) averaging sensor

22’ (6.7 m) sensor

Outdoor air sensor

Digital thermometer battery replacement kit

OPTIONS

For digital temperature display, specify -800 suffix (available only as

factory installed option).

Printed in U.S.A.

6-10

© Copyright 2010 Schneider Electric All Rights Reserved.

F-22985-5

Figure-1 Typical Wiring Diagram.

Table-1 SPECIFICATIONS.

Type

Immersion

Sensor

6" (203 mm) Probe

6" (203 mm) Probe

Duct

5’ (1.5 m) Averaging

22’ (6.7 m)

Averaging

2

Part Number

SLC-8222

SLC-8222-800

SLC-8223

SLC-8223-800

SLC-8224

SLC-8224-800

SLC-8226

SLC-8226-800

SLC-8227

SLC-8227-800

SLC-8228

SLC-8228-800

SLC-8322

SLC-8322-800

SLC-8323

SLC-8323-800

SLC-8324

SLC-8324-800

SLC-8326

SLC-8326-800

SLC-8327

SLC-8327-800

SLC-8328

SLC-8328-800

SLC-8332

SLC-8332-800

SLC-8333

SLC-8333-800

SLC-8334

SLC-8334-800

SLC-8336

SLC-8336-800

SLC-8337

SLC-8337-800

SLC-8338

SLC-8338-800

SLC-8342

SLC-8342-800

SLC-8343

SLC-8343-800

SLC-8344

SLC-8344-800

SLC-8346

SLC-8346-800

SLC-8347

SLC-8347-800

SLC-8348

SLC-8348-800

Setpoint Dial

Range

0 to 100°F

60 to 160°F

120 to 220°F

-20 to 40°C

15 to 70°

50 to 105°

0 to 100°F

60 to 160°F

120 to 220°F

-20 to 40°C

15 to 70°C

50 to 105°C

0 to 100°F

60 to 160°F

120 to 220°F

-20 to 40°C

15 to 70°C

50 to 105°C

0 to 100 °F

60 to 160°F

120 to 220°F

-20 to 40°C

15 to 70°C

50 to 105°C

Digital Display

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Mounting

Install Controller

Directly to an AT-215

Bulb Well (order

separately)

Dimensions

Controller :

4-3/8" high x 4-1/8

wide x 4-1/2" deep

(111 mm x 105 mm x

114 mm)

Sensor:

6" (203 mm) Insertion

Length

Install to Duct by

Means of Duct

Mounting Plate

Provided. A 2-1/2"

(64 mm) Standoff

Provides Clearance

for Duct Insulation if

Present.

Controller:

4-1/8" high x 4-1/8

wide x 4-1/2" deep

(111 mm x 105 mm x

114 mm)

Install to Duct by

Means of Duct

Mounting Plate

Provided. A 2-1/2"

(64 mm) Standoff

Provides Clearance

for Duct Insulation if

Present.

Controller:

4-3/8" high x 4-1/8

wide x 4-1/2" deep

(111 mm x 105 mm x

114 mm)

Install to Duct by

Means of Duct

Mounting Plate

Provided. A 2-1/2"

(64 mm) Standoff

Provides Clearance

for Duct Insulation if

Present.

Controller:

4-3/8" high x 4-1/8

wide x 4-1/2" deep

(111 mm x 105 mm x

114 mm)

© Copyright 2010 Schneider Electric All Rights Reserved.

Sensor: 6" (203 mm)

Insertion Length

Sensor: 5’ (1.5 m)

Insertion Length

Sensor: 22’ (6.7 M)

Insertion Length

F-22985-5

RATIO SELECTION TABLE.

Change in Water Temperature for Different Ratios as Outdoor Temperature Drops from 70°F to

Design Temperature

Outdoor Temp.

(°F)

Ratio

-30

0.7 to 1.0*

1.0 to 1.0

1.5 to 1.0

70 to 220

70 to 170

70 to 137

80 to 230

80 to 180

80 to 127

-20

0.7 to 1.0*

1.0 to 1.0

1.5 to 1.0

70 to 205

70 to 160

70 to 130

-10

0.7 to 1.0*

1.0 to 1.0

1.5 to 1.0

0

Dial Set at

100°F

Dial Set at

110°F

Dial Set at

120°F

90 to 240

90 to 190

90 to 157

100 to 250

100 to 200

100 to 167

110 to 260

110 to 210

-

120 to 270

120 to 220

-

80 to 215

80 to 170

80 to 140

90 to 225

90 to 180

90 to 150

100 to 235

100 to 190

100 to 160

110 to 245

110 to 200

-

120 to 255

120 to 210

-

70 to 190

70 to 150

70 to 123

80 to 200

80 to 160

80 to 133

90 to 210

90 to 170

90 to 143

100 to 220

100 to 180

100 to 153

110 to 230

110 to 190

-

120 to 240

120 to 200

-

0.7 to 1.0*

1.0 to 1.0

1.5 to 1.0

70 to 175

70 to 140

70 to 117

80 to 185

80 to 150

80 to 127

90 to 195

90 to 160

90 to 137

100 to 205

100 to 170

100 to 147

110 to 215

110 to 180

-

120 to 225

120 to 190

-

+10

0.7 to 1.0*

1.0 to 1.0

1.5 to 1.0

70 to 160

70 to 130

70 to 110

80 to 170

80 to 140

80 to 120

90 to 180

90 to 150

90 to 130

100 to 190

100 to 160

100 to 140

110 to 200

110 to 170

-

-

+20

0.7 to 1.0*

1.0 to 1.0

1.5 to 1.0

70 to 145

70 to 120

70 to 103

80 to 155

80 to 130

80 to 113

90 to 165

90 to 140

90 to 123

100 to 175

100 to 150

100 to 133

110 to 185

110 to 160

-

120 to 150

120 to 170

-

+30

0.7 to 1.0*

1.0 to 1.0

1.5 to 1.0

70 to 130

70 to 110

70 to 97

80 to 140

80 to 120

80 to 107

90 to 150

90 to 130

90 to 117

100 to 160

100 to 140

100 to 127

110 to 170

110 to 150

-

120 to 180

120 to 160

-

Dial Set at 70°F Dial Set at 80°F Dial Set at 90°F

*0.7 to 1.0 (Honeywell = 1.5 to 1.0) – 1.0°F O.A. change, hot water changes 1.5°F

Figure-2 Hot Water Control with Outside Air Temperature Reset.

F-22985-5

© Copyright 2010 Schneider Electric All Rights Reserved.

3

PRE-INSTALLATION

Inspection

Visually inspect the carton for damage. If damaged, notify the

appropriate carrier immediately. If undamaged, visually

inspect the device for obvious defects. Return damaged or

defective products.

Required Installation Items

Figure-3 Digital Thermometer Battery Location.

• Wiring diagrams

• Tools (not provided):

Digital Thermometer Theory of Operation

Appropriate screwdriver for mounting screws and terminal connections

3/16" (4.8 mm) or smaller slot screwdriver for digital thermometer battery installation

Appropriate drill and drill bit for mounting screws

• Digital thermometer battery and cover, provided in

separate package for SLC-8XXX-800 models only

• Appropriate accessories

• Mounting screws (2) #10 x 3/4" sheet metal, provided for

SLC-832X, SLC-833X and SLC-834X

INSTALLATION

After installing the battery and battery cover, the display may

flash “LLL” three times. The temperature being sensed should

then be displayed.

If battery becomes low, the display will fade and eventually

disappear. If this condition occurs, replace battery

(PKG-1093).

If the low limit of the digital indicator is exceeded, the display

will continually flash “LLL” until the temperature rises above

the low limit.

If the high limit of the digital indicator is exceeded, the display

will continually flash “HHH” until the temperature lowers below

the high limit.

The display is updated approximately every 10 seconds.

Caution:

1. Installer must be a qualified, experienced technician.

2. Disconnect power supply (line power) before installation

to prevent equipment damage.

3. Make all connections in accordance with the wiring

diagram, and in accordance with national and local

electrical codes. Use copper conductors only.

4. Do not exceed ratings of the device(s).

MOUNTING INSTRUCTIONS

Caution: Avoid locations where excessive vibration,

moisture, corrosive fumes or vapors are present, NEMA Type

1 covers are intended for indoor use primarily to provide a

degree of protection against contact with the enclosed

equipment.

Digital Thermometer Battery & Cover

Figure-4 SLC-822X Immersion Controller’s Dimensions.

SLC-822X Mounting (Requires AT-215 Bulb Well)

1. Mount AT-215 bulb well on the liquid line or tank (see

Figure 5).

2. Thread the controller into AT-215 bulb well that has been

installed in a liquid line or tank.

See Figure 3.

1. Remove battery from package.

2. Remove battery cover. Push down and turn (gently) CCW

1/8 turn with a 3/16" (4.8 mm) or smaller screwdriver.

Note: The AT-215 bulb well should be filled with a

temperature conductive grease, TAC Part Number M-500,

prior to element insertion for optimum medium temperature

sensing.

3. Place battery in the cover compartment with the positive

(+) side up.

4. Place battery cover over the battery. Push down and turn

(gently) CW 1/8 turn with 3/16" (4.8 mm) or smaller

screwdriver.

5. Temperature display should be present. If no display,

repeat steps 2 through 4. If still no display, replace battery

from battery replacement kit (PKG-1093). If no display,

temperature display unit is defective; replace with a

functional display.

4

© Copyright 2010 Schneider Electric All Rights Reserved.

F-22985-5

2. Use the mounting plate supplied as a template (or refer to

Figure 8 for duct mounting dimensions) for mounting hole

location.

3. Mount the sensor enclosure to the duct using the (2) # 10

x 3/4" sheet metal screws provided.

Figure-5 Immersion Mounting.

Figure-6 SLC-832X Duct Controller’s Dimensions.

Figure-8 SLC-833X or SLC-834X Averaging Duct

Controller’s Dimensions.

SLC-832X Mounting

1. Determine the controller mounting location on the duct.

The sensing element is located within 1" of the end of the

sensing probe, and it should be located in the air stream

typical of the temperature requiring sensing.

2. Use the mounting plate supplied as a template (or refer to

Figure 6 for duct mounting dimensions) for mounting hole

location.

3. Mount the sensor to the duct using the (2) #10 x 3/4"

sheet metal screws provided.

Figure-9 SLC-833X or SLC-834X Averaging Duct Controller

Mounting.

DEFINITIONS AND NOMENCLATURE

Mode of Operation

Figure-7 SLC-832X Duct Mounting.

SLC-833X or SLC-834X Mounting

1. Determine the controller enclosure mounting location on

the duct (see Figure 9). The sensor should be serpentined

through the duct in a pattern that will expose it to all areas

where variations of temperature may occur. If duct cannot

be entered, wrap the element around a section of conduit

and place the conduit diagonally in the duct.

Direct Acting Control (DA): Increase in temperature at the

primary sensor causes the controller output (yellow to blue

leads) signal to increase.

Revers Acting Control (RA): Increase in temperature at the

primary sensor causes the controller output (yellow to blue

leads) signal to decrease.

Reverse Reset (RR) Control Only: Decrease in

temperature at resetting element (white leads) Raises the

SLC-8XXX controller’s temperature setpoint upward.

Throttling Range: Throttling Range (T.R.) is defined as the

°F change at the primary temperature sensor in order to cause

a 3 Vdc controller output signal change.

Caution: Do no make sharp bends in the element.

F-22985-5

© Copyright 2010 Schneider Electric All Rights Reserved.

5

2. “Pull” all wires required.

3. Connect all control and optional reset sensing wiring to

the controller leads. The 4 x 4 box cover can be removed

for wiring by loosening the two (2) cover screws.

Note: The 4 x 4 cover plate is permanently attached to the

base by a metal strap to insure that the sensor wires are not

placed under tension.

Figure-10 SLC-8XXX Terminal Nomenclature

Reset DIP Switch Nomenclature

The reset ratio is defined as the temperature change at the

reset sensing element required to reset the SLC control point

1°F (0.5°C) higher. DIP switch ratios of 0.7:1, 1:1, 1.5:1 and

15:1 are provided. A controller with a DIP switch setting of 0.7

will increase the control point temperature 1.5°F (0.8°C) for a

1°F (0.5°C) change at the reset element. See Figure 11 for

DIP switch location.

WIRING OF CONTROLLED DEVICES TO

CONTROLLER

Types of Controlled Devices and Their Power

Supplies

1. Filtered and Regulated Power Supplies:

All TAC System 8000 controlled devices except

MP-52XX and MP-54XX series actuators.

2. Filtered and Unregulated Power Supplies:

MP-54XX series actuators.

3. Unfiltered and Unregulated Power Supplies:

MP-52XX series actuators.

General Rules for Wiring Controllers to Controlled

Devices

1. Never connect red lead (or +20 terminals) of any controlled

device which has a regulated power supply to the red lead

(or +20 terminal) of any other controlled device.

2. Controlled devices with unfiltered and unregulated power

supplies must be filtered. TAC System 8000 controllers

will provide filtering for a maximum of two (2) controlled

devices by connecting the two red leads (+20 terminals)

together at the controller’s red lead (+20 terminal).

3. Controlled devices with filtered and unregulated supplies:

Up to six (6) controlled devices with the red leads (+20

terminals) can be connected together. Number of units

paralleled depends on the current (mAdc) requirements

of the controller or adaptor.

4. See Table 2 for devices and their internal supplies.

Table-2 POWER SUPPLIES.

Figure-11 SLC-8XXX Controller Showing Location of Reset

DIP Switches.

WIRING

Make all electrical connections according to installation wiring

diagrams. Comply with national and local electrical codes.

Use copper conductors only.

To install, proceed as follows:

1. Wiring for the controllers is shown in Figures 12 and 13.

6

Filtered and

Regulated

Filtered and

Unregulated

Unfiltered and

Unregulated

CC-8101

CC-8102

CC-8103

CC-8104

CC-8111 Series

CC-8118 Series

CC-8218 Series

CP-8301 Series*

CP-8161 Series

CP-8425 Series

CP-8502 Series

CP-8511

CP-8513

PP-8121

PP-8516

MP-5XX

MP-54XX

MP-1233

MS-8XXXX

Actuators

MP-52XX

Actuators

*Except CP-8301-101 which does not have a power supply.

© Copyright 2010 Schneider Electric All Rights Reserved.

F-22985-5

ADJUSTMENTS

Table-3 WIRE LENGTH.

Length of Run in Feet

Wire Gauge

Controller to

Controlled

Device

Controller to

Adaptor

Adaptor to

Controlled

Device

22

-

-

-

18

1000

1000

1000

16

2250

2250

2250

14

4000

4000

4000

Caution: Use 18 gauge three-conductor twisted shielded

wire when it becomes necessary to run or install leads in the

same conduit with power wiring or when high RFI/EMI

generating devices are near. Connect the shield to the BLUE

lead at the SLC-8XXX controller only.

Setpoint Dial: Turn the setpoint dial (located on front of

controller) to the desired temperature setting. Normally, no

further adjustments are required.

Throttling Range: Throttling range settings of 3, 8, 12 or

20°F. Factory set at 8°F. Throttling range is determined by

placing the T.R. jumper (BROWN) on the proper T.R. pin. See

Figure 14 for details. For other T.R.’s use the extended T.R.

jumper AD-8969-901. The T.R. will be the sum of the value of

the T.R. pins connected.

Control Action: Factory set for direct acting (D.A.). Reverse

acting (R.A.) can be selected by moving the jumpers as shown

in Figure 14.

Reset Ratio: Reset ratios of 0.7:1, 1:1, 1.5:1 and 15:1. Reset

ratio is determined by positioning a DIP switch on the back

side of the controller (after SLC controller is removed from 4 x

4 handy box). See Figure 15 for details.

Figure-12 Typical Wiring without MP-52XX Actuators.

Figure-13 Typical Wiring with MP-52XX Actuators.

F-22985-5

© Copyright 2010 Schneider Electric All Rights Reserved.

7

CHECKOUT

Note: The SLC-82XX and SLC-83XX have been factory

calibrated to produce a 7.5 Vdc output signal at the YELLOW and

BLUE leads (TO+ AND TS-) when the setpoint and the

temperature at the primary sensor are equal. Optional reset

sensor must be disconnected.

1. Verify wiring per wiring diagram.

2. Measure with a 20,000 ohm per Vdc VOM.

a. Power Supply 20 Vdc: RED (+) to BLUE (-) wires or test

point pins TS- and TS+ (+end of the 47µf. capacitor).

b. Output 2-15 Vdc: YELLOW (+) to BLUE (-) wires to TO+

and TS - test pins. The voltage varies between 2-15 Vdc

as dial knob is rotated.

Figure-14 Throttling Range and Control Action Selection.

3. Replace controller if it is defective.

CALIBRATION

Caution: To assure proper controller operation, if reset is not

used, all DIP switches must be in OFF position and ends of white

wires (auxiliary sensor pigtails) must be taped or protected.

If calibration is necessary, proceed as follows:

1. Connect a 20,000 ohm per Vdc VOM between the YELLOW (+)

and BLUE(-) leads or TO+ and TS- pins on the controller.

2. Place all ratio switches to the OFF position.

3. Measure the temperature at the primary sensor with an

instrument with a ±1°F accuracy or better.

4. Loosen set screw on setpoint knob and remove knob.

5. Adjust setpoint potentiometer until VOM reads 7.5V ±0.1 Vdc.

6. Place setpoint knob over potentiometer shaft and align pointer

with temperature on scale equal to temperature displayed on

instrument at primary sensor. Tighten set screw, taking care

not to turn potentiometer shaft in the process.

7. Controller is calibrated.

MAINTENANCE

Regular maintenance of the total system is needed to assure

sustained optimum performance.

Figure-15 Ratio Reset.

For SLC-8XXX-800 models only, if the battery becomes low, the

display will fade and eventually disappear. Replacement battery kit

(PKG-1093).

FIELD REPAIR

These controllers are not field repairable. Replace a defective

controller with a functional unit.

On October 1st, 2009, TAC became the Buildings business of its parent company Schneider Electric. This document reflects the visual identity of Schneider Electric,

however there remains references to TAC as a corporate brand in the body copy. As each document is updated, the body copy will be changed to reflect appropriate

corporate brand changes.

Copyright 2010, Schneider Electric

All brand names, trademarks and registered

trademarks are the property of their respective

owners. Information contained within this

document is subject to change without notice.

F-22985-5

Schneider Electric

1354 Clifford Avenue

P.O. Box 2940

Loves Park, IL 61132-2940

www.schneider-electric.com/buildings