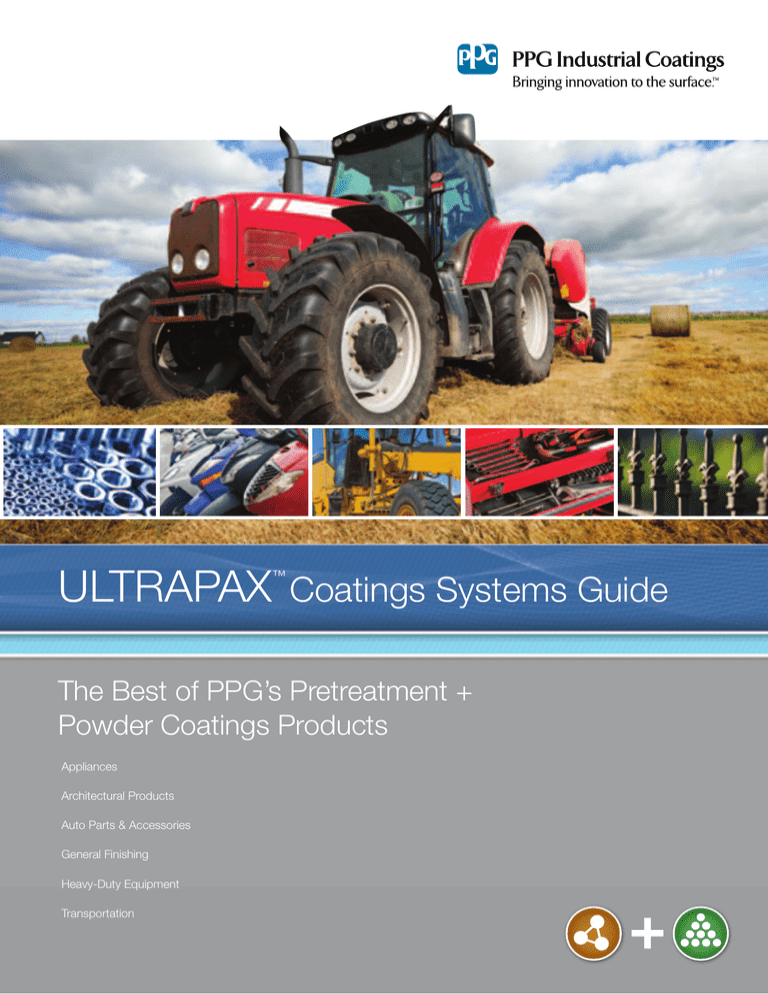

ULTRAPAX™ Coatings Systems Guide

advertisement

ULTRAPAX ™ Coatings Systems Guide The Best of PPG’s Pretreatment + Powder Coatings Products Appliances Architectural Products Auto Parts & Accessories General Finishing Heavy-Duty Equipment Transportation The Very Best of PPG’s Pretreatment + Powder Coatings Products The UltraPax Coatings System starts with the best of PPG’s broad range of pretreatment technologies and matches them to a full compliment of proven, durable powder coatings. These packaged product systems have been engineered together to meet the most stringent performance requirements. As the only manufacturer of both pretreatment and coatings technologies platforms, PPG is uniquely positioned in the marketplace to provide packaged, proven protection – always at the right price. PPG formulates, produces, and tests every pretreatment and powder product together to maximize effectiveness. A Global Coatings Authority As a global company with operations in more than 60 countries, PPG has the unique capability to provide all your coating needs. As a world leader in innovation, sustainability and color, PPG helps customers in transportation, consumer products, construction, and general finishing markets to enhance and protect more surfaces in more ways than any other company. PPG Industrial Coatings has earned a reputation as a leader in the marketplace for innovative, high-performance products, world-class service and color expertise. PPG Industrial Coatings maintains a full portfolio of products and technologies, providing global reach with local service and a commitment to operating sustainably. Color and Styling Through our work in the automotive, architectural, appliance and consumer electronic industries, PPG has built a vast color library with more than 300,000 formulations. More are added every day. PPG also maintains a global staff of color and design experts. Color and styling development laboratories are located around the world, each with a sole focus of monitoring color trends and creating products that keep our customers ahead of the curve. Whether you are designing the bullet train of the future or painting washing machines, we have the services, selection and people you need to get the job done right, and to get the job done fast. Commitment to Sustainability Researchers at PPG laboratories are leading the drive toward more sustainable coatings products and processes. PPG Industrial Coatings are available in formulations designed to exceed global and regional environmental requirements. PPG is deeply committed to working with our customers to improve their manufacturing excellence regarding their sustainability goals. Cutting-Edge Coatings Combos PPG’s UltraPax Pretreatment + Powder Coatings Systems deliver a one-two punch of coatings that protect your substrate from the harshest environments, the toughest weather and the wear and tear of everyday use. The next few pages provide details on technologies that make up PPG’s pretreatment and powder coating product lines. This includes a summary of performance results for a variety of pretreatment and powder coating combinations. The goal: to help you fully explore the options at your disposal and to help you choose a coatings system that meets or exceeds your requirements. UltraPax Pretreatment + Powder Coating System Applications Transportation Auto Parts and Accessories Rail, bus, body builder, trailer, motorcycles, bicycles, scooters and other recreational vehicles Bumpers, wheels, undercarriages, suspension parts, door handles, engine heads, trim, accessories Appliances Architectural Products Washers, dryers, refrigerators, freezers, stoves, ranges Store fronts, railings, accents, trim, flagpoles, windows, doors, ceiling grids General Finishing Plumbing fixtures, faucets, metal and outdoor furniture, fitness equipment, shelving, lighting, tools, toolboxes, racks, bins and displays Tested for Excellence PPG operates two laboratories that support the UltraPax Coatings System: one in Euclid, Ohio for pretreatment products and one in Strongsville, Ohio for powder coatings. These centers of excellence are staffed with experienced professionals using some of the most cutting-edge performance testing equipment available. Each facility can fully replicate realworld application methods used by our customers, allowing PPG to aid them with testing, troubleshooting and making product recommendations. The pretreatment and powder coatings products that form the UltraPax Coatings Systems are tested under harsh, demanding industry and market standards. Our coatings are tested to rigorous ASTM industry standards for corrosion and weather protection, impact resistance, flexibility, UV durability and other critical physical properties. This commitment to excellence in both the lab and in the field has made PPG the coatings provider of choice for brand-name manufacturers around the world. Many PPG pretreatment and powder coatings products are approved by domestic automotive, heavy equipment, agricultural and many other general finishing manufacturers for use on a variety of interior and exterior surfaces. Heavy-Duty Equipment Agricultural equipment, construction machinery, forestry, mining, material handling and lawn & garden PPG Pretreatment Products Surface pretreatment enhances paint adhesion and reduces the rate of substrate corrosion. Effective pretreatment depends on state-of-the-art chemical formulations that provide the highest quality, at the lowest operational costs. PPG offers a full range of effective, economically-efficient pretreatment solutions that includes traditional spray and immersion zinc and iron phosphate systems, multi-metal cleaners, low-temperature cleaners, and low-temperature phosphates. PPG also offers state-of-the-art thin-film zirconium pretreatments. ULTRAX® and Chemkleen Cleaners* Cleaners play an integral role in the surface finishing process by removing unwanted soils such as lubricants, greases, drawing compounds and dirt prior to depositing a pretreatment layer, which ultimately protects against oxidation and promotes paint adhesion. PPG offers a full stable of cleaners designed to remove the toughest soils from the surface of all commonly used metals and alloys. Type Substrate Application Product Description Ultrax 32 Free of inorganic phosphate and alkylphenol ethoxylates (APE surfactants), which makes it waste-treatment friendly. Designed to remove a wide variety of soils including sulfurized and chlorinated oils. The high-detergent package enables heavy soil loading and longer bath life as compared to conventional spray cleaners. Immersion Ultrax 92D A liquid alkaline cleaner designed for immersion or dip-cleaning applications. Capable of high-soil loading for longer bath as compared to conventional immersion cleaners. Excellent all-purpose cleaner for removing industrial grade soils from ferrous substrates. Spray Chemkleen 29LS A low-silicate cleaner for ferrous and non-ferrous metals that was developed to reduce or eliminate silicate dry-on in transfer systems or systems where long dwell times between processing stages may occur. Immersion Ultrax 93D The silicated version of Ultrax 92D, designed for use in mixed metal lines. Spray Ultrax LT8630 A low-temperature cleaner designed for use on ferrous substrates. Immersion Ultrax LT5630D Performs at temperatures as low as 85˚ F and will work well on most soils at 100˚ F. Lower energy usage and lower water consumption (less water evaporation) makes it a cost-effective choice. Because there is less exposure to hot chemicals, it makes for a safer work environment. Other features include: improved parts appearance with less streaking, mottling and dried-on cleaner residue; exceptional rinsing that helps parts stay “wet” longer; and reduced chance of flash rusting between process stages. Spray Ultrax LT8620 A low-temperature cleaner designed for use on ferrous and non-ferrous substrates. Ultrax LT5620D Performs at temperatures as low as 85˚ F and will work well on most soils at 100˚ F. Lower energy usage and lower water consumption (less water evaporation) makes it a cost-effective choice. Because there is less exposure to hot chemicals, it makes for a safer work environment. Other features include: improved parts appearance with less streaking, mottling and dried-on cleaner residue; exceptional rinsing that helps parts stay “wet” longer; and reduced chance of flash rusting between process stages. Spray Traditional Tried and true workhorses, require 130˚ to 160˚ F temperature for optimal performance Steel (Non-Silicated) Range of Metals (Silicated) Steel Only (Non-Silicated) Low Temperature Economical and energyefficient ambient temperature products Range of Metals (Silicated) Immersion * Cleaner selection may need to be modified based on soil load, metal mix, temperature and other factors. Please consult your PPG representative for more details. X-BOND®, CHEMFOS®, CHEMSEAL® and ULTRAGUARD® Pretreatment Products A quality finish depends on how well the substrate surface is prepared prior to painting. The term ‘pretreatment’ describes any deposited film that protects a substrate against oxidation and enhances the adhesion of paints. PPG offers a full complement of surface pretreatments, including 3-stage cleaner-coater iron phosphates, 5-stage iron phosphates and 5-stage zinc phosphates with thin-film zirconium technologies. PPG’s pretreatment product line provides maximum flexibility to meet your most stringent metal finishing requirements. Type Substrate Application Product(s) Description 5-Stage Zirconium Pretreatment Ferrous Metal, Galvanized Steel, Aluminum Spray / Immersion X-Bond 4000 X-Bond 4000 is a zirconium-based conversion coating formulated to provide excellent corrosion resistance for steel, galvanized steel and aluminum substrates. Ferrous Metal Spray / Immersion Chemfos 158 Chemseal 59 5-Stage Iron Phosphate Pretreatment Ferrous Metal, Galvanized Steel, Aluminum Spray / Immersion Ultraguard ATP50F Chemseal 59 Chemfos 158 produces a blue-to-gold coating that can get dusty with higher temperatures. Chemseal 59 eliminates chrome hazard and minimizes waste disposal. By far the most widely used final rinse of the product line. Ultraguard ATP50F is a low-temperature iron phosphate that contains fluoride for use on steel, galvanized steel and aluminum substrates. Chemseal 59 eliminates chrome hazard and minimizes waste disposal. Ferrous Metal Spray Chemfos 51HD Chemfos 51HD is considered one of the premium, organic, accelerated cleaner/coater products in the line. Does not contain fluoride and is best suited to lines running only ferrous metal. Ferrous Metal, Galvanized Steel, Aluminum Spray Ultraguard ATP31F Ultraguard ATP31F is a low-temperature cleaner/coater that contains fluoride for use on ferrous and galvanized steel as well as aluminum substrates. 3-Stage Pretreatment PPG Powder Coatings Powder coatings are a low-VOC solution offering superior performance and costefficiency for applications that require maximum abrasion resistance and hardness. PPG’s outstanding range of powder coating technologies provide answers to just about any application challenge. All of PPG‘s powder coating formulas are economical and backed by years of experience, world-class technology and technical service, and a commitment to sustainability. Envirocron® Powder Coatings The UltraPax Coatings Systems program includes a wide range of premium Envirocron powder coatings. With years of proven experience, this trusted brand utilizes a variety of technologies to offer outstanding protection and beauty for any metal substrate. A Range of Technologies With a full line of polyesters, urethanes, epoxies and hybrids, Envirocron topcoats provide the final step in the protection of your products. Envirocron PCT TGIC polyester powder coatings are available in standard durable and ultradurable formulations. They are tough, attractive and demonstrate outstanding physical properties, enabling them to withstand prolonged exposure and making them the coating of choice for outdoor equipment. Envirocron PCU urethane powder coatings combine outstanding thin-film appearance and toughness with excellent weather resistance. They demonstrate superior chip, mar and scuff resistance and are highly resistant to humidity and salt spray, making them an ideal choice for exterior automotive trim and other highvisibility areas. Envirocron PCM epoxy powder coatings are a great choice for applications requiring the ultimate corrosion resistance in underhood parts and other interior metal surfaces. Epoxies have excellent chemical and mechanical properties, exceptional adhesion and the ability to meet demanding specifications. Finally, Envirocron PCF hybrid powder coatings are a blend of epoxy and polyester resins used primarily for indoor applications. They offer improved penetration into corners and recesses and are less sensitive to overbake on curing than many other chemistries, making them suitable for use on appliances, radiators and other temperature-sensitive applications. Beauty and Durability With a full range of gloss and color solutions, Envirocron powder coatings offer industry-renowned durability that doesn’t sacrifice aesthetic beauty. Choose from one of hundreds of standard colors or work with PPG to develop a custom shade that is all your own. Technology PCT TGIC Polyester Exterior use. Combines high toughness with UV durability. Can deliver energy and cost savings with lower cure temperatures. PCU Urethane Exterior use. Thinner, smoother film and high chemical and corrosion resistance. Thin-film chemical and corrosion, and mar and chip resistance. Product Description PCT Standard Durable Envirocron Polyester Powder Coat (Agricultural) Used in heavy-duty equipment and agricultural applications. Excellent exterior durability, good chemical resistance and virtually zero VOCs. PCT Ultradurable Low-Cure Envirocron Polyester Powder Coat Used in heavy-duty equipment and agricultural applications. Excellent exterior durability, low-cure capability, good chemical resistance and virtually zero VOCs. PCT Ultradurable Envirocron Polyester Powder Coat Used in heavy-duty equipment and agricultural applications. Excellent exterior durability, good chemical resistance and virtually zero VOCs. UL-approved. PCT Standard Durable Envirocron Polyester Powder Coat (Appliance) Used in appliance and household goods applications. Exterior durability, good chemical resistance and essentially zero VOCs. UL-approved. PCU Ultradurable Envirocron Polyester Urethane Powder Coat Widely used in exterior automotive trim and other high-visibility areas. Excellent exterior durability, good chemical resistance and thin-film capabilities. PCM Envirocron Epoxy Powder Coat Workhorse underhood automotive product, also a great fit for interior auto parts and other similar applications. Low-cure capabilities, good chemical resistance and virtually zero VOCs. PCF Envirocron Epoxy-Polyester Hybrid Powder Coat Widely used in interior applications such as office furniture. Good mar and chemical resistance and virtually zero VOCs. UL-approved. PCM Epoxy Interior-grade. Provides lower cure temperatures and high corrosion and chemical resistance. Excellent hardness and abrasion resistance. PCF Hybrid Interior-grade. Good physical and chemical resistance properties with low-bake durability. High flexibility and corrosion resistance. UltraPax Pretreatment + Powder Coatings Systems Testing + PCT TGIC Polyester PCT TGIC Polyester PCT Standard Durable Envirocron Polyester Powder Coat (Agricultural) PCT Ultradurable Low-Cure Envirocron Polyester Powder Coat Cold Rolled Steel 500 hrs. 5-Stage Zirconium Pretreatment 5-Stage Iron Phosphate Pretreatment 1,000 hrs. Cold Rolled Steel 250 hrs. 500 hrs. Hot Rolled Steel 250 hrs. 500 hrs. X-Bond 4000 1.0 mm 2.8 mm 160/160 Pass 0.0 mm 1.7 mm 160/160 N/A 0.0 mm 0.2 mm 100/100 Pass 0.0 mm 0.0 mm 160/140 N/A Chemfos 158 & Chemseal 59 Salt Spray Creep Impact Conical Mandrel 1.0 mm 1.5 mm 140/160 Pass 0.0 mm 0.0 mm 160/160 N/A 0.0 mm 0.5 mm 60/20 N/A 0.0 mm 0.0 mm 160/160 N/A Ultraguard ATP50F & Chemseal 59 Salt Spray Creep Impact Conical Mandrel 2.2 mm N/R 160/160 Pass 0.0 mm 0.0 mm 160/160 N/A 1.0 mm 3.5 mm 160/160 N/A 0.0 mm 0.0 mm 160/160 N/A Chemfos 51HD Salt Spray Creep Impact Conical Mandrel 2.2 mm N/R 160/160 Pass 0.7 mm N/R 160/60 N/A 0.5 mm 3.8 mm 160/160 Pass 0.0 mm 2.2 mm 160/160 N/A Ultraguard ATP31F Salt Spray Creep Impact Conical Mandrel 2.7 mm N/R 160/160 Pass 1.2 mm N/R 160/160 N/A 1.3 mm 3.3 mm 80/20 Pass 0.7 mm 2.3 mm 160/160 N/A PCU Urethane PCM Epoxy PCU Ultradurable Envirocron Polyester Urethane Powder Coat PCM Envirocron Epoxy Powder Coat Cold Rolled Steel 500 hrs. 5-Stage Iron Phosphate Pretreatment 1,000 hrs. Salt Spray Creep Impact Conical Mandrel 3-Stage Pretreatment 5-Stage Zirconium Pretreatment Hot Rolled Steel 500 hrs. 1,000 hrs. Hot Rolled Steel 500 hrs. 1,000 hrs. Cold Rolled Steel 500 hrs. 1,000 hrs. Hot Rolled Steel 500 hrs. 1,000 hrs. X-Bond 4000 Salt Spray Creep Impact Conical Mandrel 1.0 mm N/R 100/20 N/A 0.0 mm 1.0 mm 160/40 N/A 1.0 mm 1.3 mm 160/160 Pass 0.3 mm 0.5 mm 160/160 N/A Chemfos 158 & Chemseal 59 Salt Spray Creep Impact Conical Mandrel 0.5 mm 2.5 mm 140/60 N/A 0.0 mm 0.0 mm 160/160 N/A 1.0 mm 2.0 mm 160/160 Pass 0.0 mm 0.5 mm 160/160 N/A Ultraguard ATP50F & Chemseal 59 Salt Spray Creep Impact Conical Mandrel 1.0 mm 3.0 mm 60/20 N/A 0.5 mm 0.5 mm 160/160 N/A 1.8 mm 2.0 mm 160/160 Pass 0.5 mm 0.3 mm 160/160 N/A Salt Spray Creep Impact 3.0 mm N/R 140/40 2.0 mm N/R 160/60 2.0 mm 2.5 mm 160/160 1.2 mm 3.0 mm 160/160 Pass N/A 1.8 mm 3.0 mm 160/100 Pass 1.5 mm 3.0 mm 160/160 N/A Chemfos 51HD Conical Mandrel 3-Stage Pretreatment Ultraguard ATP31F Salt Spray Creep Impact Conical Mandrel N/A 2.5 mm N/R 120/20 N/A N/A 2.5 mm N/R 160/60 N/A Understanding the Results The chart below details ASTM standard performance results for all UltraPax Pretreatment + Powder Coating System combinations, helping you choose the solution that best fits your needs. Each UltraPax Coatings System is tested on cold- and hot-rolled steel using ASTM standards, ensuring confidence in your finished parts. Each standardized test panel is pretreated with one of our five pretreatment regimens, and topcoated with one of our eight Envirocron powder coatings. PCT TGIC Polyester PCT TGIC Polyester ASTM B-117 Salt Spray – Corrosion Resistance PCT Ultradurable Envirocron Polyester Powder Coat PCT Standard Durable Envirocron Polyester Powder Coat (Appliance) Coated panels are scribed, placed in an enclosed chamber and subjected to salt solution spray. The test measures the amount of subsequent rust formation and paint loss extending from the scribe. Less creep means better protection, and panels are rated accordingly. Cold Rolled Steel 500 hrs. 1,000 hrs. Hot Rolled Steel 500 hrs. 1,000 hrs. Cold Rolled Steel 500 hrs. 1,000 hrs. Hot Rolled Steel 500 hrs. 1,000 hrs. 0.8 mm 2.8 mm 160/140 Pass 0.0 mm 0.5 mm 160/160 N/A 1.0 mm 1.8 mm 160/160 Pass 0.0 mm 1.2 mm 160/160 N/A 0.7 mm 0.5 mm 100/60 Pass 0.0 mm 0.0 mm 160/160 N/A 0.5 mm 0.5 mm 160/160 Pass 0.0 mm 0.0 mm 160/160 N/A 1.5 mm 3.8 mm 100/20 N/A 0.0 mm 0.0 mm 160/160 N/A 1.7 mm N/R 160/160 Pass 0.0 mm 0.0 mm 160/160 N/A 1.0 mm 2.0 mm 160/160 Pass 1.0 mm N/R 160/160 N/A 1.5 mm N/R 160/160 Pass 1.5 mm N/R 160/160 N/A 1.2 mm 3.0 mm 160/120 Pass 0.3 mm 3.5 mm 160/160 N/A 1.8 mm N/R 160/160 Pass 1.5 mm N/R 160/160 N/A PCF Hybrid PCF Envirocron Epoxy-Polyester Hybrid Powder Coat Cold Rolled Steel 500 hrs. 1,000 hrs. 1,000 hrs. 1.0 mm 2.0 mm 160/60 Pass 0.2 mm 0.5 mm 160/60 N/A 2.0 mm 2.0 mm 100/100 Pass 0.0 mm 0.2 mm 160/80 N/A 1.5 mm 1.8 mm 160/40 Pass 0.0 mm 0.3 mm 160/160 N/A 1.7 mm 2.8 mm 160/40 1.0 mm 3.3 mm 160/80 Pass N/A 2.5 mm N/R 160/80 Pass 1.5 mm 2.7 mm 160/120 N/A This test measures a coating system’s resistance to impact. A weight is dropped from a measured height, first directly on the coated side and again on the reverse side. The panel is examined for cracking and other deformities. The value for each side is recorded in inch-pounds, a product of the height multiplied by the weight. A score of 160/160 is considered excellent. UltraPax Coatings Systems offer a range of impact resistance for all applications. ASTM D-522 Conical Mandrel Bend A coated panel is mounted on a test device and bent over a conical apparatus to test the coating’s flexibility. This test applies to cold-rolled steel only. All standard durable powder coatings pass this test, offering a good mix of physical properties and flexibility. Some ultradurable products, however, receive a “Not Applicable” rating. These products are engineered to excel in weathering and chemical resistance instead of flexibility. Hot Rolled Steel 500 hrs. ASTM D-2794 Impact ASTM D-3359 Adhesion Legend Excellent Acceptable Not Recommended Coatings were applied and tested under controlled conditions. Actual results may vary slightly from those obtained here due to surface preparation, part configuration or other factors. Please contact your PPG representative for details. This test measures the coating system’s adhesion to the substrate. Panels are scored with a sharp blade in a crosshatch fashion. Tape is applied to the area and removed. Results are classified by the amount of paint removed, with a 5B indicating that no paint was removed. Adhesion test results are not included in the chart because all UltraPax Coatings System combinations rate a 5B. A Global Partner PPG Industries has manufacturing facilities and equity affiliates in more than 60 countries around the globe, many of them dedicated exclusively to Industrial Coatings. This means our products, knowledge and technical expertise can be delivered to virtually any location on the planet. No matter what challenges your business faces, PPG can fit seamlessly into your product development cycle or global supply chain, providing innovative thinking, engineering expertise and world-class technical support. To make PPG your single-source supplier of pretreatment and powder coatings solutions, contact one of our international sales offices listed below or visit www.ppgindustrialcoatings.com. Regional Headquarters Manufacturing Facility PPG Regional Headquarters PPG Global Headquarters / PPG North America Pittsburgh, PA USA 1.888.774.2001 Notes PPG South America Sumare, Sao Paolo, Brazil + 55.19.3864.6000 PPG Europe Rolle, Switzerland + 41.21.822.30.00 PPG Asia Pacific Hong Kong, China + 852.2861.0918 PPG Industrial Coatings One PPG Place Pittsburgh, PA 15272 USA Chemfos, Chemseal, Envirocron, Powercron, PPG, the PPG logo, X-Bond, Ultraguard and Ultrax are registered trademarks of PPG Industries Ohio, Inc. ©2012 PPG Industries, Inc. 11/12 IC025 Bringing innovation to the surface, Ecological Solutions from PPG and design and UltraPax are trademarks of PPG Industries Ohio, Inc. North America 1.888.774.2001 ic-na@ppg.com www.ppgindustrialcoatings.com