Efficiency of Motor Side Common Mode (CM) Filtering Tech

advertisement

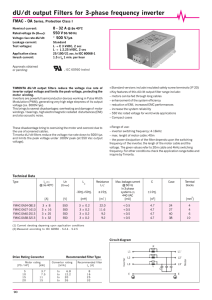

Efficiency of Motor Side Common Mode (CM) Filtering Techniques for PWM Inverters Dennis Kampen, BLOCK Transformatoren-Elektronik GmbH & Co. KG, Germany Nejila Parspour, ILEA- University of Stuttgart, Germany Stefan Beyer & Stefan Laudahn, University of Applied Science Hannover, Germany Abstract In this paper several inverter output CM reduction filters are compared through experimental results. Filters with or without connection to ground and to the DC link are introduced. Quality criteria like leakage current and voltage drop on motor side, conducted emissions and leakage current on line side, power loss and inverter impact are used to compare all filters comprehensively. 1. Introduction When using a PWM inverter to drive a motor there are several problems along with the gain of flexibility. First the inverter is a source of differential mode (DM) disturbances. DM voltage is the voltage between two lines and has a rectangle shape at the output of the inverter. The steeper the slew rate of inverter output DM voltage and the longer the motor leads the higher is the potential for overvoltages at the motor because of reflections [1]. These overvoltages may destroy the motor insulation and are avoided easily with a motor line inductor or better a sineformer, [2] which will be used by default in this paper. Common Mode (CM) disturbances appear because the sum of the inverter output voltages principally is not equal to zero, so that a CM current is driven over the parasitic capacitances of the motor and the leads back through the power supply to the DC link, which is the reference potential of the CM voltage [3], [1], [4], [5]. The analytical expression for the CM voltage is uCM = u1M + u2M + u3M 3 (1) where u1M , u2M and u3M are the voltages between inverter output phases and inverter DC midpoint. The CM voltage can have severe consequences for the System. A voltage between motor shaft and ground potential occurs, which leads to bearing currents and may destroy the motor bearings [6]. If the motor is grounded local with the building ground, the CM leakage current can create a large loop and is then a source of intensive radiated emissions [7]. Expensive shielded conduits normally must be used to avoid the radiation. Fur- thermore the CM leakage current uses the way back through the supply line to the DC link, which leads to conducted emissions and increased leakage currents on line side. Conducted emissions are limited by the EN 61800-3 and leakage currents are limited by the residual current detector (RCD) which is used in the building. 2. Compared filters In this investigation six filter topologies on the inverter output are compared with each other and in relation to a measurement without filter. An overview of the system and the placement of the filters is given in figure 2. Fig. 1: system overview 2.1. DM low pass LC filter Standard DM filter, which consist of a three phase DM inductor Lsin and three DM capacitor Csin connected between the phases to create a sinusoidal voltage waveform between the phases (sine former). With three phase 3UI cores the filter only has little influence on CM disturbances except the damping effect of the leakage inductance of the DM inductor. Fig. 4: additional CM inductor Fig. 2: DM LC low pass filter (sineformer) 2.4. additional CM LC low pass with connection to ground 2.2. galvanic isolating transformers With an isolating transformer the CM path is interrupted, so that CM currents cannot flow, except over parasitic capacitances between the two windings [8]. Fig. 3: additional former galvanic isolating CM low pass LC filters consist of a CM inductor and a further capacitance CPE connected between DM LC filter capacitors star point and ground. The filter shortcuts the CM disturbances before they reach the motor line and the motor [10], [11]. transFig. 5: additional CM LC low pass with connection to ground 2.3. CM inductor 2.5. CM LC low pass with connection to inverter DC link CM inductors Lcom have one magnetic core where all three phases are wound on. They offer inductive damping for CM current while affecting the DM currents only by their leakage inductance [9]. CM LC low pass with connection to inverter DC link have a DC link connection over a capacitance CZK from the DM LC filter capacitors star point. They do not use the ground to shortcut the CM disturbances. They directly offer CM currents a path back to the DC link [12], [13], [14], [15]. frequency. 50m 4G4 motor leads where used. The 15kW motor did not have isolated bearings, so that for estimating bearing currents the motor leakage current and the motor star point to ground voltage were measured which can be done for estimating the bearing currents [16]. All filter prototypes compared here were designed cost effective and as small as possible by the professional filter design department of BLOCK TransformatorenElektronik GmbH & Co. KG. 3.1. motor star point to ground voltage Fig. 6: additional CM LC low pass with connection to inverter DC link 2.6. CM transformer CM transformers are CM inductors with a fourth winding. The CM current is lead from the DM filter capacitors star point through the fourth winding to the DC link. The current in the fourth winding induces the CM voltage to the three phases so that the CM voltage in the motor leads is canceled. This is called voltage cancellation principle [13], [14], [15]. Fig. 7: additional CM transformer The measurement of the motor star point to ground voltage uY−PE shows that the isolating transformer and the CM transformer offer best reduction, although it must be noticed that the isolating transformer only damps the low frequency components while the high frequencies are not damped due to the stray capacitances between the windings. The sine former and especially the CM inductor (CM_ind) boost the low frequency parts of uY−PE which worsens the bearing problems. High frequency components are damped very good with a simple CM inductor. For damping of the lower frequencies, Lcom would have had to be uneconomically high to set the corner frequency low enough. Fig. 8: motor star point to ground voltage comparison 3. Experimental results 3.2. motor leakage current To test the filter comparatively, an invariant drive configuration was built up. The 11kW inverter had an internal class A line filter. The switching frequency fs was set to 8kHz at 50Hz fundamental It can be stated that the motor leakage currents are damped very good with all three CM low pass LC filters, whereas the CM transformer offers the best damping. Fig. 9: motor leakage current comparison Fig. 11: inverter output current comparison 3.5. line leakage current 3.3. filter power loss The power loss in all CM filters in comparison to the single sine former and especially the isolating transformer is significant lower. The isolating transformer losses are high because it was built of laminated iron with a high material insertion. The sine former has higher losses because of the CM currents, which are not damped in contrast to the other filters. CM currents emitted by the inverter output flow partly through the ground to the power line and back to the inverter. The line side leakage current is often monitored by residual current detectors (RCD), which could trigger because of the CM currents. It can be stated that the best damping effect could be reached by the CM transformer and the CM inductor with connection to the DC link. The CM inductor with connection to the ground in opposite increases the leakage current drastically because the ground is used for short circuiting CM disturbances. Fig. 10: filter power loss comparison Fig. 12: line leakage current comparison 3.4. inverter impact 3.6. conducted emissions on line side The inverter output phase current is a degree for the inverter stress. Without filter there are very high inverter output peak currents due to recharging of motor and lead parasitic capacitances. With all filters the inverter stress could be reduced significantly. To comply with EN61800-3 limits, line side filters are used. In this investigation it can be figured out that filtering on the inverter output lead to significant reduction of conducted emissions on line side. All CM filters provide a further reduction in comparison to a simple sine former up to 10MHz. [5] C HEN, S.; L IPO, T.; and F ITZGERALD, D. Modeling of motor bearing currents in PWM inverter drives. Industry Applications, IEEE Transactions on, 1996. [6] B USSE, D.; E RDMAN, J.; K ERKMAN, R.; S CHLEGEL, D.; and S KIBINSKI, G. The effects of PWM voltage source inverters on the mechanical performance of rolling bearings. Applied Power Electronics Conference and Exposition, 1996. APEC ’96. Conference Proceedings 1996., Eleventh Annual, 1996. Fig. 13: conducted emissions on line side comparison 4. Conclusion This paper categorizes and compares motor filters which reduce the CM emissions of PWM inverters. The CM transformer has shown to be the superior solution for a whole system improvement, including bearing currents, line side leakage currents and conducted emissions, power loss and inverter stress. It can also be stated that the CM transformer filter has been the filter with the smallest size. Literature [1] VON J OUANNE, A. and E NJETI, P. Design considerations for an inverter output filter to mitigate the effects of long motor leads in ASD applications. Applied Power Electronics Conference and Exposition, 1996. APEC ’96. Conference Proceedings 1996., Eleventh Annual, 1996. [2] H UPPUNEN, J. Sine wave filter for PWMinverter driven medium speed solid-rotor induction motors. 1999. [3] M ACDONALD, D. and G RAY, W. A practical guide to understanding bearing damage related to PWM drives. Pulp and Paper Industry Technical Conference, 1998. Conference Record of 1998 Annual, 1998. [4] K EMPSKI, A.; S MOLENSKI, R.; and S TRZ ELECKI , R. Common mode current paths and their modeling in PWM inverter-fed drives. Power Electronics Specialists Conference, 2002. pesc 02. 2002 IEEE 33rd Annual, 2002. [7] S KIBINSKI, G.; K ERKMAN, R.; and S CHLEGEL, D. EMI emissions of modern PWM AC drives. Industry Applications Magazine, IEEE, 1999. [8] C HEN, S.; L IPO, T.; and F ITZGERALD, D. Source of induction motor bearing currents caused by PWM inverters. Energy Conversion, IEEE Transaction on, 1996. [9] AG, S. DE 295 06 951 U, 1995. Deutsches Gebrauchsmuster. [10] Z HONG, E. and L IPO, T. Improvements in EMC performance of inverter-fed motor drives. Industry Applications, IEEE Transactions on, 1995. [11] H UPPUNEN, J. and P YRHONEN, J. Filtered PWM-inverter drive for high-speed solid-rotor induction motors. Industry Applications Conference, 2000. Conference Record of the 2000 IEEE, 2000. [12] C HEN, X.; X U, D.; L IU, F.; and Z HANG, J. A Novel Inverter-Output Passive Filter for Reducing Both Differential- and Common-Mode dv/dt at the Motor Terminals in PWM Drive Systems. Industrial Electronics, IEEE Transactions on, 2007. [13] A KAGI, H. and TAMURA, S. A Passive EMI Filter for Eliminating Both Bearing Current and Ground Leakage Current From an Inverter-Driven Motor. Power Electronics, IEEE Transactions on, 2006. [14] R ENDUSARA, D. and E NJETI, P. An improved inverter output filter configuration reduces common and differential modes dv/dt at the motor terminals in PWM drive systems. Power Electronics, IEEE Transactions on, 1998. [15] S WAMY, M. and K UME, T. Common-mode current attenuation techniques for use with PWM drives. Applied Power Electronics Conference and Exposition, 1999. APEC ’99. Fourteenth Annual, 1999. [16] B INDER, A. Abschlussbericht: Elektrische Lagerbeanspruchung bei umrichtergespeisten Maschinen. Tech. rep., TU Darmstadt, 2003.