Adaptive fuzzy robust control of PMSM with smooth inverse based

advertisement

International Journal of Control, Automation and Systems 14(2) (2016) 378-388

http://dx.doi.org/10.1007/s12555-015-0010-6

ISSN:1598-6446 eISSN:2005-4092

http://www.springer.com/12555

Adaptive Fuzzy Robust Control of PMSM with Smooth Inverse Based

Dead-zone Compensation

Xingjian Wang* and Shaoping Wang

Abstract: It is a challenging work to design high precision/high performance motion controller for permanent

magnet synchronous motor (PMSM) due to some difficulties, such as varying operating conditions, parametric

uncertainties and external disturbances. In order to improve tracking control performance of PMSM, this paper

proposes an adaptive fuzzy robust control (AFRC) algorithm with smooth inverse based dead-zone compensation.

Instead of nonsmooth dead-zone inverse which would cause the possible control signal chattering phenomenon, a

new smooth dead-zone inverse is proposed for non-symmetric dead-zone compensation in PMSM system. AFRC

controller is synthesized by combining backstepping technique and small gain theorem. Discontinuous projectionbased parameter adaptive law is used to estimate unknown system parameters. The Takagi-Sugeno fuzzy logic

systems are employed to approximate the unstructured dynamics. Robust control law ensures the robustness of

closed loop control system. The proposed AFRC algorithm with smooth inverse based dead-zone compensation

is verified on a practical PMSM control system. The comparative experimental results indicate that the smooth

inverse for non-symmetric dead-zone nonlinearity can effectively avoid the chattering phenomenon which would

be caused by nonsmooth dead-zone inverse, and the proposed control strategy can improve the PMSM output

tracking performance.

Keywords: Adaptive control, dead-zone, fuzzy logic system, motion control, permanent magnet synchronous motor.

1. INTRODUCTION

In model industry, permanent magnet synchronous motors (PMSMs) are widely used for advanced manufacturing, such as manufacturing robots, assembly robots, etc.

[1], thanks to their known advantages as: compact size,

rapid response, high torque/weight ratio, high efficiency

and high power density [2, 3]. Furthermore, the directdrive PMSM can also avoid some mechanical transmission problems, such as backlash and vibration, due to

elimination of gearbox. Based on these advantages, it is

believed that PMSM has the potential to achieve high precision/high bandwidth motion. However, the high performance controller design for PMSM is still a challenging

work, because numerous issues still need to be addressed,

such as varying operating conditions, parametric uncertainties, unknown modeling errors, unstructured system

dynamics and external disturbances.

During the past decades, extensive control theories and

techniques have been proposed for PMSM, including classical and robust control laws. The field orientation vec-

tor control technique for PMSM has been widely studied due to its simplicity [2, 4]. In order to achieve faster

torque dynamic response, direct torque control technique

was applied to PMSM driving system [5, 6], but the problems of torque ripple and current distortion needed attentions. Fortunately, these problems have been settled

in [7] and the coordinating relationship between switching frequency and torque ripple has been analyzed for

PMSM under direct torque control [8]. In addition, many

researchers investigated nonlinear tracking control algorithms for PMSM control [4, 9, 10]. Specially, adaptive

approaches based controllers were proposed for PMSM

to achieve better tracking performance [11–13]. However, the common feature of the aforementioned adaptive

approaches require a precise mathematical system model

and deal with parametric uncertainties or structured dynamics only. But in fact, in practical industrial applications, uncertainties or nonlinearities of one system cannot

always be precisely structured or modeled, thus the control performance may be degrade in the presence of unstructured dynamics, varying operating conditions or un-

Manuscript received January 7, 2015; revised March 30, 2015; accepted May 2, 2015. Recommended by Associate Editor Sung Jin Yoo

under the direction of Editor Euntai Kim. This work was supported by the National Natural Science Foundation of China under Grant No.

51305011, National Basic Research Program of China (973 Program) under Grant No. 2014CB046402 and the Fundamental Research Funds

for the Central Universities under Grant No. YWF-14-FGC-016, YWF-13-T-RSC-064.

Xingjian Wang and Shaoping Wang are with the School of Automation Science and Electrical Engineering, Beihang University, Beijing

100191, China (e-mails: wangxj@buaa.edu.cn, shaopingwang@vip.sina.com).

* Corresponding author.

c

⃝ICROS,

KIEE and Springer 2016

Adaptive Fuzzy Robust Control of PMSM with Smooth Inverse Based Dead-zone Compensation

known external disturbances. In order to deal with these

nonlinearities, many researchers paid their great attention

to approximator-based approaches [14–17] of nonlinear

systems with unstructured uncertainties or nonlinearities.

Some advanced approximators, such as fuzzy logic [18]

and neural network [19,20], were utilized to solve the nonlinear control problem of PMSM.

On another aspect, in order to achieve further improved

tracking control performance, better compensation need

to be designed for some specific nonlinearities in PMSM

system, for example dead-zone. Dead-zone is ubiquitous in mechanical systems and electrical components, including PMSM of cause [21]. It is a non-smooth/nondifferentiable nonlinearity that characterizes certain nonsensitivity for small control input signals [22, 23]. Especially, when the mechanical systems are operated with a

small input, the deadzone nonlinearity becomes particularly evident. Under this condition, it would result in undesired control performance, such as instability and limit

cycles [24].

To cope with this inherent problem, many researchers

devoted their effort to design controller for nonlinear systems preceded by dead-zone nonlinearity and convergence

performance were realized [25–27]. Adaptive techniques

with fuzzy systems or neural networks were utilized to

solve the tracking control problem of nonlinear systems

with unknown dead zones [28–30]. Robust practical stabilization was also studied for nonlinear uncertain systems

with dead-zone nonlinearity [31, 32]. However, in real

precision control systems, the imperfect knowledge of the

dead-zone nonlinearity would cause a serious problem in

high precision control. Thus it is a challenging work to

deal with the dead-zone nonlinearity by using aforementioned adaptive or robust control approaches [33]. Therefore, many researchers tried to describe the characteristic of dead-zone and model it by some techniques. Without explicitly exploring the detailed dead-zone characteristics, some researchers formulated the dead-zone nonlinearity as a combination of linear input with either a

constant coefficient for symmetric dead-zone or a timevarying coefficient for nonsymmetric one and an external

disturbance that depends on the dead-zone characteristics

[23, 33]. Moreover, the nonsmooth inverse based deadzone compensation and integrated direct/indirect adaptive

robust control were proposed for nonlinear systems preceded by nonsymmetric dead-zone [24]. These methods

provide alternative solutions to deal with dead-zone nonlinearity, but the possible control signal chattering phenomenon may be brought in by such nonsmooth methods,

because the errors of dead-zone modeling and identification are unable to be avoided.

In this study, in order to solve these difficult issues in

PMSM control, we propose a novel adaptive fuzzy robust control (AFRC) algorithm with smooth inverse based

dead-zone compensation for high precision motion con-

379

trol of PMSM. In order to avoid the possible signal chattering problem caused by nonsmooth dead-zone compensation method, we design a smooth inverse based deadzone compensation for dead-zone nonlinearity. In the proposed algorithm, discontinuous projection based adaptive

control law can online estimate unknown system parameters and compensate the linearizable system dynamics,

and Takagi-Sugeno fuzzy logic system are used to approximate unknown and unstructured system dynamics.

The robustness and stability of closed-loop control system are also guaranteed by robust control law. The proposed algorithm is tested on a PMSM motion control system and comparative experiments are carried out. The

comparative experimental results show that our proposed

algorithm can achieve more precise motion control and

the chattering phenomenon can be avoided. The results

also verify that dead-zone compensation is necessary for

high performance tracking control. Overall, the high precision motion control results obtained from experiments

validate the effectiveness of the propose algorithm in practical PMSM control system.

The reminder of this paper is organized as follows: Section 2 outlines the PMSM dynamic mathematical model

and the proposed smooth inverse for non-symmetric deadzone is also presented in this section. The proposed adaptive fuzzy robust control algorithm is detailed in Section 3.

In Section 4, comparative experiments are presented to illustrate the effectiveness of the proposed algorithm. Conclusions are given in Section 5.

2.

PMSM MODELING AND SMOOTH INVERSE

BASED DEAD-ZONE COMPENSATION

2.1. PMSM dynamic model

In most PMSM applications, the motor amplifier with

current-feedback vector control strategy drives PMSM to

generate electromagnetic torque. Usually, the amplifier

has a current loop with a bandwidth higher than 1 kHz.

Frequency responses for system identification also show

that only the mechanical dynamics of the PMSM system

need to be considered within the frequency of 100 Hz [24],

thus its electrical dynamics can be ignored. In addition,

input saturation can be also ignored when torque motor

operates in normal condition. With these simplifications,

considering the input dead-zone nonlinearity, the relationship of electro-magnetic torque Tem and input control voltage Vin to motor amplifier can be represented as follows:

Tem = DZ(Vin ).

(1)

The dead-zone nonlinearity DZ(Vin ) will be defined in

next subsection.

Considering unstructured dynamics and external disturbances, the PMSM system dynamics can be described as

Tem + Tun (θm , ωm ,t) + Td (t) = Jm ω̇m + Bm ωm ,

(2)

Xingjian Wang and Shaoping Wang

380

Vin

mp

bn

Tem

bp

mn

Vin

1 / mp

bp

u (t )

bn

1/ mn

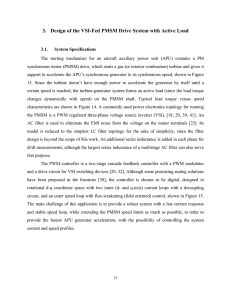

Fig. 1. The ideal dead-zone nonlinearity and its inverse

functions.

where θm and ωm represent angular displacement and velocity of PMSM, respectively. Jm is inertia of PMSM rotator and Bm is combined coefficient of damping and viscous

friction. Tun (θm , ωm ,t) represents unstructured dynamics, such as unknown nonlinear friction, cogging torque

and unknown electromagnetic nonlinearity. Td (t) is the

lumped effect of external disturbances.

2.2. Dead-zone and smooth inverse

As shown in Fig. 1(a), the ideal non-symmetric deadzone nonlinearity DZ(Vin ) in input channel can be described as [25]

m p v − m p b p , for v ≥ b p ,

0,

for bn < v < b p ,

Tem = DZ(Vin ) =

mn v − mn bn , for v ≤ bn ,

(3)

where the parameters m p > 0 and b p > 0 are slope and

break-point in positive direction while mn > 0 and bn < 0

in negative direction. Generally speaking, for nonsymmetric dead-zone nonlinearity, m p ̸= mn and |b p | ̸= |bn |.

The most obvious choice to compensating dead-zone

nonlinearity is to adopt a pre-designed dead-zone inverse

function. The nonsmooth inverse, which is given as the

dashed one in Fig. 1(b), was used to compensate the

dead-zone nonlinearity [24], but the possibly chattering

phenomenon caused by nonsmooth inverse has been ignored. Thus, a new smooth inverse function Vin = SI(u)

(the solid one in Fig. 1(b)) for non-symmetric dead-zone

compensation is proposed as follows

[

]

2b̂ p u(t)

arctan(kdz u) +

SI(u) =η p (u) π m̂ p

[

]

(4)

2b̂n u(t)

+ ηn (u) ,

arctan(kdz u) +

π m̂n

where m̂ p , m̂n , b̂ p and b̂n are the offline identified deadzone parameters of m p , mn , b p and bn , respectively. u(t) is

the desired control signal that would achieve the desired

control performance when there is no dead-zone nonlinearity. kdz ∈ R is a positive constant to adjust the shape of

inverse function. Then η p (u) and ηn (u) are defined as

{

1, if u ≥ 0,

η p (u) =

(5)

0, else,

{

1, if u < 0,

ηn (u) =

(6)

0, else.

By using this smooth dead-zone inverse function SI(u),

the possibly chattering problem can be avoided. Then the

resulting error between actual input control voltage Vin and

the desired control signal u(t) can be given as:

ũ(t) = Vin − u(t) ≤ Bu ,

(7)

where Bu is the bound of compensation error ũ(t) and it

decreases as constant kdz in (4) increases.

2.3. Design models and assumptions

If we use the smooth inverse based dead-zone compensation (4) into the PMSM control system, the PMSM system dynamics (2) can be rewritten as

Jm ω̇m = u(t) − Bm ωm + Tun (θm , ωm ,t) + ũ(t) + Td (t). (8)

Define the states variables as x = [x1 , x2 ]T = [θm , ωm ]T , the

state-space form of system (8) is

ẋ1 =x2 ,

θ1 ẋ2 =u(t) − θ2 x2 + θ3 + Tun (x1 , x2 ,t) + ũ(t) + T̃d (t),

(9)

where the unknown paramenter set is defined as θ = [θ1 ,

θ2 , θ3 ]T ∈ R4 , in which θ1 = Jm , θ2 = Bm , and θ3 can be

thought as nominal value of the lumped external disturbance Td (t). T̃d (t) = Td (t)− θ3 represents the time-varying

uncompensated external disturbances.

Adaptive Fuzzy Robust Control of PMSM with Smooth Inverse Based Dead-zone Compensation

Assumption 1: The extents of parametric uncertainties are assumed to be known, i.e., uncertain parameter

vector θ are within a known bounded convex set Ωθ as

[34, 35]

∆

θ ∈ Ωθ = {θ : θmin ≤ θ ≤ θmax } ,

(10)

where θmax = [θ1max , θ2max , θ3max ]T and θmin = [θ1min ,

θ2min , θ3min ]T are known upper and lower bound constant

vectors of θ .

Assumption 2: The uncompensated disturbances

T̃d (t) is assumed to be bounded by a known function,

i.e., T̃d (t) satisfies [34, 35]

}

∆ {

|T̃d (t)| ∈ ΩT̃d (t) = T̃d (t) : |T̃d (t)| ≤ BT̃d ,

(11)

where BT̃d is a known and bounded positive function.

Notation 1: In this paper, •i represents the ith component of vector •, •max for the maximum value of • and •min

for the minimum value of •. The operation < or ≤ for two

vectors is performed in terms of corresponding elements

of the vectors.

For the PMSM system (9) under Assumptions 1 and 2,

the control objective is to design a control law u(t) with

smooth inverse based dead-zone compensation (4), such

that all closed-loop signals are bounded and the PMSM

position output x1 tracks its time-dependent desired trajectory xd (t), i.e., x1 → xd asymptotically as t → ∞, with

certain guaranteed transient responses.

Assumption 3: The desired trajectory xd (t) is assumed to be bounded with bounded at least derivatives

second-order, i.e., ẋd (t), ẍd (t).

3.

ADAPTIVE FUZZY ROBUST CONTROLLER

DESIGN

In this section, the AFRC strategy will be synthesized

for control law u(t). Discontinuous projection based adaptive law is used to estimate the unknown parameters while

fuzzy logic system is utilized to approximate the unknown

unstructured system dynamics. Then a guaranteed transient and steady-state control performance is attained by

using robust law. Finally, asymptotic output tracking

can be achieved in the absence of dead-zone nonlinearity,

parameter uncertainties, uncertain nonlinearities unstructured dynamics and unknown external disturbances.

3.1. Discontinuous projection based adaptive law

Instead of smooth projection, the widely used discontinuous projection method will be used to update parameters in AFRC controller. Let θ̂ denotes the estimate

of θ and θ̃ denotes estimation error (i.e., θ̃ = θ̂ − θ ).

Specifically, viewing (9), parameter estimate θ̂ is updated

through a discontinuous parameter adaptation law [34,35]

381

in the form

θ̂˙ = Projθ̂ (Γτ ),

(12)

where Γ > 0 is a diagonal matrix of adaptation rate and

τ is any adaptation function to be designed according

to system model. The discontinuous projection mapping

Projθ̂ (•) can be defined as

0, if θ̂ = θmax and • > 0,

Projθ̂ (•) =

(13)

0, if θ̂ = θmin and • < 0,

•, otherwise.

For any adaptation function τ , the projection mapping

used in (13) has the following properties [34, 35]

}

∆ {

(P1) θ̂ ∈ Ωθ = θ̂ : θmin ≤ θ̂ ≤ θmax ,

(14)

[

]

(P2) θ̃ T Γ−1 Projθ̂ (Γτ ) − τ ≤ 0, ∀τ .

3.2. Fuzzy logic system

During the past several years, fuzzy logic system has

been attracting the attention of many researchers [36, 37],

because it has the capacity to uniformly approximating

any nonlinear function which cannot be linearly parameterized or structured. In this paper, the widely used

Takagi-Sugeno (T-S) fuzzy system [38] will be applied to

approximate the unknown or unstructured system dynamics in PMSM control system.

If we choose singleton fuzzifier, product inference engine and center average defuzzifier, the output of T-S

fuzzy system can be given as

q

y f = ∑ y f i ξ f i (x),

(15)

i=1

where q is the total number of fuzzy rules, x =

[x1 , x2 , · · · , xn ]T is the vector of fuzzy variables,

n

ξ f i (x) =

∏ µxi j (x j )

j=1

(

)

m

n

∑ ∏ µxi j (x j )

i=1

is fuzzy basis function, and y f i

j=1

is the output of the ith rule which can be described as

y f i = ai0 + ai1 x1 + ai2 x2 + · · · + ain xn ,

(16)

where ai0 , ai1 , ai2 , · · · , ain are constant parameters. Let

x̄ = [1, xT ]T , then (15) can be rewritten as

y f = ξ f (x)A f x̄,

where ξ f (x) = [ξ f 1 (x), ξ f 2 (x),

a10 a11

a20 a21

sis vector and A f = .

..

..

.

(17)

· · · , ξ f q (x)] is fuzzy ba

· · · a1n

· · · a2n

.. . Usually, the

···

.

aq0 aq1 · · · aqn

membership function can be described as

[

]

i

i 2

(g

x

−

b

)

j

j

j

µxi j (x j ) = exp −

,

2 ∗ (hij )2

(18)

Xingjian Wang and Shaoping Wang

382

10

16

=(52

36

30

,QSXW

3%

2XWSXW

1%

Fig. 2. Fuzzy logic system membership functions µxi j (x j ).

where gij ∈ R, bij ∈ R and hij > 0 are adjustable parameters of membership function µxi j (x j ), i = 1, 2, · · · , q, and

j = 1, 2, · · · , n. The gaussian function-based fuzzy membership functions µxi j (x j ) are shown in Fig. 2, in which

m = 7.

Lemma 1: For any continuous function f (x) defined

in a compact set x ∈ Ωx and ∀B f > 0, there exist an ideal

fuzzy logic y f such that [39]

|y f − f (x)| ≤ B f ,

∀x ∈ Ωx .

a11

a21

..

.

Tun (x1 , x2 ,t) = c f ξ f (x)ω f + ξ f (x)A f 2 [1, x1 , xeq ]T + δ f .

(24)

Then substitute (24) into (22), we have

θ1 ż = u + θ T φ (x̄,t) + c f ξ f (x)ω f + d,

(25)

where

d = ξ f (x)A f 2 [1, x1 , xeq ]T + δ f + ũ(t) + T̃d (t),

(26)

and

For the PMSM system (9), define position output tracking error as

(20)

Then define a switching-function-like quantity z as

z = ė + kz e = x2 − x2eq ,

a12

a12

a22

a22

where A f = A f 2

.. , A f 1 = .. ,

.

.

aq0 aq1 aq2

aq2

ξ f (x) = [ξ f 1 (x), ξ f 2 (x), · · · , ξ f q (x)], δ f represents fuzzy

approximating error and |δ f | ≤ B f , here B f is unknown

but bounded positive constant.

∗

Let c f = ∥A f 1 ∥, A∗f = c−1

f A f 1 . It is clear that A f ≤ 1,

then let ω f = A∗f z, (24) can be rewritten as

(19)

3.3. AFRC controller design

e = x1 − xd .

a10

a20

= .

..

(21)

where kz > 0 is a positive gain and x2eq = ẋd − kz e. Since

1

Gz (s) = e(s)

z(s) = s+kz is a stable transfer function, e will

asymptotically tend to zero along with z asymptotically

tending to zero. Thus, the rest work of AFRC controller

design is to design an ideal control law u which can make

z as small as possible.

Differentiating z and noting (9), we can rewritten the

system dynamics as

θ1 ż =u − θ1 ẋ2eq − θ2 x2 + θ3 + Tun (x1 , x2 ,t) + ũ(t) + T̃d (t)

=u + θ T φ (x̄,t) + Tun (x1 , x2 ,t) + ũ(t) + T̃d (t),

(22)

where φ (x̄,t) = [−ẋ2eq , −x2 , 1]T and x̄ = [x1 , x2 , xd ]T .

Noting that unstructured system dynamics Tun (x1 , x2 ,t)

is assumed to be an unknown continuous function, hence,

according to fuzzy logic theorem as mentioned in Lemma

1, Tun (x1 , x2 ,t) can be expressed as

Tun (x1 , x2 ,t) = ξ f (x)A f [1, x1 , x2 ]T + δ f

= ξ f (x)A f 1 z + ξ f (x)A f 2 [1, x1 , xeq ]T + δ f ,

(23)

|d| ≤ Bd md ,

(27)

{

}

where Bd = max ∥A f 2 ∥ , Bf , Bu (t), BT̃d is an positive

constant and md = ∥ξ f (x)∥ · [1, x1 , xeq ]T + 1.

The desired AFRC control law u consists of three parts

as

u = ua + u f + ur .

(28)

At first, we design the adaptive control item as

ua = −ka z − θ̂ T φ (x̄,t).

(29)

Substituting (28) and (29) into (25) leads to

θ1 ż = (u f + ur ) − ka z − θ̃ T φ (x̄,t) + c f ξ f (x)ω f + d. (30)

Then, we design the fuzzy control item u f as

u f = −λ̂ f ψ f z,

(31)

where λ̂ f is an online estimate of parameter λ f with estimate error λ̃ f = λ f − λ̂ f , and λ f = c2f . Then the online

adaptation law for λ̂ f can be designed as

[

]

˙

λ̂ f = k f ψ f z2 − γ f (λ̂ f − λ f ) ,

(32)

where k f > 0 and γ f > 0 are two positive parameters for

online adaptation law (32). ψ f = ∥ξ f (x)∥2 /(4β f2 ) and

β f > 0 is a positive design parameter.

Define a positive semi-definite (p.s.d.) function V as

1

1

V = θ1 z2 + k−1

λ̃ 2 .

2

2 f f

(33)

Adaptive Fuzzy Robust Control of PMSM with Smooth Inverse Based Dead-zone Compensation

383

˙

Considering λ̃˙ f = −λ̂ f and (28), the time derivative of V

can be given as:

˙

V̇ =θ1 zż − k−1

f λ̃ f λ̂ f

(34)

[

]

˙

=z u + θ T φ (x̄,t) + c f ξ f (x)ω f + d − k−1

λ̃

λ̂

.

f

f

f

Considering (28) and substituting adaptive control item ua

(29) and fuzzy control item u f (31) into (34), we can get

the following equation

V̇

˙

2

=zc f ξ f (x)ω f − k−1

f λ̃ f λ̂ f − λ̂ f ψ f z

− ka z2 + z{ur − θ̃ T φ (x̄,t) + d}.

Fig. 3. Experimental setup of PMSM control system.

∥ξ f (x)∥2

+ β f2 ∥ω f ∥2 .

4β f2

(36)

Considering that λ f = c2f , ψ f = ∥ξ f (x)∥2 /(4β f2 ) and λ̃ f =

λ̂ f − λ f , from (36), the following inequality is holding

zc f ξ f (x)ω f ≤ z2 λ̂ f ψ f + z2 λ̃ f ψ f + β f2 ∥ω f ∥2 .

(37)

Substituting (32) and (37) into (35) leads to

V̇ ≤ −ka z2 − γ f λ̃ f2 + β f2 ∥ω f ∥2 + z{ur − θ̃ T φ (x̄,t) + d}.

(38)

Now we can get the following robust performance conditions for robust control item ur as

condition (1) z{ur − θ̃ T φ (x̄,t) + d} ≤ ε ,

condition (2) zur ≤ 0.

(39)

Notation 2: One smooth example of robust control

item ur satisfying (39) can be found as follows. Let hr

be any smooth function satisfying hr ≥ ∥θM ∥ · ∥φ (x̄,t)∥ +

Bd md where θM = θmax − θmin . ε > 0 is positive design

parameter.

Then we can design a robust control law ur as

ur = −

1 2

h z.

4ε r

Rotary

Encoder

(35)

According to Young’s inequality, the following inequality

holds

zc f ξ f (x)ω f ≤ |zc f ξ f (x)ω f | ≤ z2 c2f

Torque

Sensor

PMSM

(40)

approximated by T-S fuzzy logic systems. If we design an adaptive fuzzy robust control law u (28) with the

smooth inverse based dead-zone compensation (4), all signals in this system are bounded. If control parameters are

chosen suitably, the tracking error can be smaller than a

prescribed error bound, and it means the tracking error

asymptotically converges zero.

Proof: See Appendix A.

4.

□

EXPERIMENTAL RESULTS

4.1. Experimental setup

To demonstrate the performance of the proposed algorithm, a set of comparative experiments is carried out on a

PMSM system. The experimental setup for PMSM precision motion control is showed in Fig. 3. The tested

PMSM is a Direct-Drive Rotary torque motor D143M

by Danaher and it is driven by a Danaher digital servo

amplifier S620. A Heidenhain high-resolution rotary encoder ECN113 with Heidenhain PC counter card IK220

are used to measure the rotary displacement of PMSM

and the velocity signal is obtained by the difference of rotary displacement. A high-precision torque sensor AKC17 is installed to measure the output torque of PMSM for

dead-zone identification. A 16-bit AD/DA multi-function

card PCI-1716 by Advantech is used to sample torque signal and to send out control voltage to the motor amplifier. Original designed real-time control program based

on RTX real-time operating system and Labwindows/CVI

is applied to control and monitor the PMSM system and

its sampling frequency is selected as fs = 2KHz.

Thus, (39) can be given as

V̇ ≤ −ka z2 − γ f λ̃ f2 + β f2 ∥ω f ∥2 + ε .

(41)

3.4. The closed-loop system stability analysis

Theorem 1: Consider the PMSM system (2) which

is subjected to dead-zone nonlinearity, parameter uncertainties, unstructured dynamics and external disturbances,

and suppose that the unknown system dynamics can be

4.2. System parameters and sead-zone identification

Without considering nonlinear effects and unstructured

dynamics, offline parameter identification is performed to

get the nominal values of PMSM system parameters. The

nominal values of PMSM system parameters are: Jm =

0.045Kg · m2 , Bm = 2.16Nm/rad/s.

For dead-zone identification, the amplifier S620 working model is chosen as current feedback control with PI

Xingjian Wang and Shaoping Wang

384

Fig. 5. The desired trajectory.

Fig. 4. Fitting result of PMSM input dead-zone identification.

controller and the output shaft of PMSM is blocked. Under such condition, the mechanical dynamics can be neglecting, then the system functions (1) and (2) can described as follows:

Tem ≈ DZ(Vin ) ≈ Tts ,

(42)

where Tts is the torque output of PMSM and it can be measured by torque sensor. Thus, the dead-zone nonlinearity

DZ(Vin ) can be described by the relationship between a

set of input voltages Vin and a set of consequential output torques Tts . Accurate fitting result of PMSM deadzone nonlinearity between input voltage Vin and electromagnetic torque Tem is shown in Fig. 4. The identified

dead-zone parameters in (3) are: m p = 36.65, b p = 0.082

mn = 38.54 and bn = −0.063.

4.3. Comparative experimental results

We select the desired trajectory as xd = 0.27 + 0.1sin

(0.8π t −0.5π )+0.09sin(1.0π t −0.5π )+0.08sin(1.2π t −

0.5π ) which is shown in Fig. 5. The control objective is

to guarantee that (a) all signals in the closed-loop PMSM

system are bounded and (b) the output x1 follows the desired trajectory xd as close as possible.

According to the AFRC algorithm proposed in the last

section, the control function u can be given as

u = ua + u f + ur

= −0.5z − θ̂ T φ (x̄,t) − λ̂ ψ f z − 0.25h2r z,

(43)

where z = ė + 1000e, ψ f = ∥ξ f (x)∥2 /(4 ∗ 0.52 ), and hr =

∥θM ∥ · ∥φ (x̄,t)∥ + Bd md .

The discontinuous projection-based parameter adaptation laws are designed as:

[

]

θ̂˙ = Projθ̂ Γφ (x̄,t)z ,

(44)

where Γ is a diagonal matrix of the adaptation rates and

it is given as: Γ = diag {0.1, 3.5, 0.2}. The upper and

lower bounds of the parameters variations for θ are chosen as θmin = [0.02, 1.0, 0.1]T , θmax = [0.06, 3.0, −0.1]T .

Then the initial values of parameter estimates are chosen

as θ (0) = [0.04, 1.5, 0]T

As shown in Fig. 2, the fuzzy membership function is

defined as

[

]

(0.1 ∗ z − (i − 4))2

i

µz (z) = exp −

,

(45)

2 ∗ 0.42472

where i = 1, 2, · · · , 7.

The adaptation laws of fuzzy parameter λ is given as

[

]

˙

λ̂ f = 5.0 ∗ ψ f z2 − 1.0 ∗ (λ̂ f − 1.5) .

(46)

In order to better illustrate the effectiveness of the proposed AFRC algorithm with smooth inverse based deadzone compensation, the following four algorithms will be

implemented on PMSM motion control system and compared:

C1: Adaptive fuzzy robust controller without any deadzone compensation;

C2: Adaptive fuzzy robust controller with nonsmooth

inverse-based dead-zone compensation;

C3: Adaptive robust controller with smooth inverse based

dead-zone compensation;

C4: The proposed adaptive fuzzy robust controller with

smooth inverse based dead-zone compensation.

Among the above four algorithms, C1, C2 and C4 use

the same AFRC controllers (the same control laws and the

same control parameters) but different dead-zone compensation strategies. In C2, the nonsmooth inverse shown in

Fig. 1(b) is used for dead-zone compensation. Both of

C3 and C4 use the smooth inverse based dead-zone compensation (4) which is proposed in this paper, but their

controller are different. In C3, adaptive robust controller

proposed in [24, 34, 35] is used for comparison. The different between ARC and AFRC compared in this paper

is that AFRC utilizes fuzzy logic system to approximate

the unknown or unstructured system dynamics while ARC

does not use any approximator or compensator, that means

ARC controller is designed as u = ua + ur . For a fair comparison, all the four algorithms use the same controller

parameters when they have the same physical meanings.

The experimental results of above four compared algorithms are shown on Figs. 6-10.

Adaptive Fuzzy Robust Control of PMSM with Smooth Inverse Based Dead-zone Compensation

385

Fig. 7. The desired control signal and actual input control

voltage in C2.

Fig. 6. PMSM position output tracking errors of the 4

compared algorithm.

Fig. 6 shows the output tracking errors of all four algorithms. It can be seen from these error plots that all

four algorithms achieve good steady-state tracking performances with very small tracking errors. However, C4 get

the best tracking control performance among the four algorithms.

Remark 1: Comparing with C2 and C4, it is obviously

that the control performance of C4 is better than C2 and

the tracking errors of C2 are very noisy. This result validates the advantage of the proposed smooth inverse based

dead-zone compensation. Furthermore, comparing with

C3 and C4, C4 have much better tracking performance

than C3 thanks to the apply of fuzzy logic system. This

result strongly demonstrates the advantages of T-S fuzzy

logic system in approximating unknown or unstructured

system dynamics, such as unknown nonlinear dynamic

friction.

Fig. 7 shows the desired control signal and actual input

control signal of C2 in PMSM system, while Fig. 8 shows

the ones of C4.

Remark 2: The chattering of control signal is a very

serious problem for practical servo control system, it

would severely affect the control performance, resulting in

undesired control performance or even causing the practical system unstable. Comparing with these two figure, it

is easy to find that the actual input control signal Vin (the

output signal of nonsmooth inverse) in C2 is chattering

fiercely when the desired signal u (the input signal of nonsmooth inverse) is in the vicinity of zero. Fortunately, this

chattering phenomenon can avoided by applying our proposed smooth inverse based dead-zone compensation. As

Fig. 8. The desired control signal and actual input control

voltage in C4.

shown in Fig. 8, the control output signal Vin (the output

signal of smooth inverse) in C4 is quite smooth and without chattering phenomenon.

Fig. 9 shows the the online adaptive parameter estimations θ̂ of uncertain system parameters. Fig. 10 shows the

online updated fuzzy parameter λ̂ . Figs. 9 and 10 indicate

that both of θ̂ and λ̂ are all bounded.

Remark 3: To sum up, all these experimental results

confirm that the proposed algorithm C4 can achieve excellent tracking performance in practical PMSM motion

control system and T-S fuzzy logic system with online

updated parameter can effectively compensate unknown

or unstructured system dynamics. Moreover, the welldesigned smooth inverse based compensation for nonsymmetric dead-zone can eliminate the influence of such

nonlinearity, without bringing in additional chartering

problem of control signal.

Xingjian Wang and Shaoping Wang

386

tems, viz. Sz̄ω f and Sω f z̄ . Subsystem Sz̄ω f is given as

ż = u + θ T φ (x̄,t) + c f ξ f (x)ω f + d,

[

]

˙

λ̂ f = k f ψ f z2 − γ f (λ̂ f − λ f ) ,

(A.1)

Z̄ = H(Z) = Z,

where ω f is considered as input of subsystem Sz̄ω f and Z̄

[

]T

is the output. Z = z, λ̃ f .

Design a Lyapunov function as (33), and according to

(41), its time derivative can be obtained as:

V̇ ≤ − ∥Z∥2 + β f2 ∥ω f ∥2 + ε .

Fig. 9. The online parameter estimates of AFRC in C4.

(A.2)

According to small gain theorem [40, 41], the subsystem Sz̄ω f satisfies ISpS, so there exist class K∞ functions

fK1 (s), fK2 (s), such that fK1 (∥Z∥) ≤ V (Z) ≤ fK2 (∥Z∥),

fK3 (s) = s2 , fK4 (s) = γ 2 s2 , then the gain of subsystem Sz̄ω f

can be obtained as

−1

−1

γZ̄ (s) = fK1

· fK2 · fK3

· fK4 (s), ∀s > 0.

(A.3)

Consider subsystem Sω f z̄ as

ω f = ĀZ̄,

Fig. 10. The online updated fuzzy parameters of AFRC in

C4.

5. CONCLUSION

This paper provides a precision motion control algorithm for PMSM. In order to eliminate the adverse effects

of dead-zone nonlinearity, at the same time, to overcome

the possible chartering problem, this paper investigates a

smooth inverse for dead-zone compensation. Considering

parameter uncertainties, unstructured dynamics and external disturbances in PMSM control system, adaptive fuzzy

robust control law is synthesized by combining backstepping technique and small gain theorem. Discontinuous

projection-based parameter adaptive law is employed to

estimate unknown system parameters. The Takagi-Sugeno

fuzzy logic system are used to approximate the unknown

/unstructured dynamics. The robustness of closed-loop

PMSM control system is guaranteed by robust law. The

AFRC algorithm with smooth inverse based dead-zone

compensation is implemented on a practical PMSM motion control system. The comparative experimental results

indicate the proposed control strategy is effective and the

output tracking performance can be improved.

APPENDIX A

Proof: At first, we rewrite the closed-loop PMSM system with AFRC algorithm into two composited subsys-

(A.4)

where Z̄ is the

ωf is subsystem

[ input

] of this subsystem,

output, Ā = A∗f , 0 . Considering that A∗f ≤ 1, we have

[ ∗ ] ∗ Ā = A f , 0 = A f ≤ 1.

(A.5)

Let γ ′ = Ā,

∥ω f ∥ ≤ Ā ∥Z̄∥ = γ ′ ∥Z̄∥ .

(A.6)

Therefore γ ′ ≤ 1, the gain of subsystem Sω f z̄ can be given

as γω f = γ ′ ≤ 1.

According to small gain theorem, if γZ̄ (γω f (s)) < s, then

the closed-loop system is ISpS. We have

γZ̄ (γω f (s)) < s

⇒

γγ ′ < 1.

(A.7)

Because 0 < γ ′ ≤ 1, if choose 0 < γ < 1, the closed-loop

system satisfies ISpS conditions. Therefore, there exist a

class KL function and a positive condition δ0 such that

[

([

)

]T ]T z(t), λ̃ f (t) ≤ fKL z(0), λ̃ f (0) ,t + δ0 .

(A.8)

Therefore, z(t) ∈ L∞ , x(t) ∈ L∞ . There exist σ0 > 0 and

T > 0, such that ∥x∥ < σ0 , ∀t ≥ T , i.e. the closed-loop

system is uniformly ultimately bounded.

Furthermore, according to small gain theorem [40, 41],

if ε = 0, the subsystem Sz̄ω f is ISS and the closed-loop system is also ISS. Therefore, there exists a class KL function

such that

[

([

)

]T ]T z(t), λ̃ f (t) ≤ fKL z(0), λ̃ f (0) ,t . (A.9)

That means limt→∞ e(t) = 0, i.e., the asymptotic output

tracking is achieved.

□

Adaptive Fuzzy Robust Control of PMSM with Smooth Inverse Based Dead-zone Compensation

REFERENCES

[1] H. X. Liu and S. H. Li, “Speed control for PMSM servo

system using predictive functional control and extended

state observer,” IEEE Trans. on Industrial Electronics, vol.

59, no. 2, pp. 1171-1183, February 2012. [click]

[2] M. Rashed, P. F. A. MacConnell, A. F. Stronach, and

P. Acarnley, “Sensorless indirect-rotor-field-orientation

speed control of a permanent-magnet synchronous motor

with stator-resistance estimation,” IEEE Trans. on Industrial Electronics, vol. 54, no. 3, pp. 1664-1675, June 2007.

[click]

[3] H. G. Li, C. F. Li, R. J. Zhao, D. L. Liu, and H. H. Zhu,

“Analysis of the sensorless PMSM control technique in the

full speed section,” Applied Mechanics and Materials, vol.

672, pp. 1191-1196, November 2014. [click]

[4] Y. S. Kung and M. H. Tsai, “FPGA-based speed control

IC for PMSM drive with adaptive fuzzy control,” IEEE

Trans. on Power Electronics, vol. 22, no. 6, pp. 2476-2486,

November 2007. [click]

[5] L. Zhong, M. F. Rahman, W. Y. Hu, and K. W. Lim, “Analysis of direct torque control in permanent magnet synchronous motor drives,” IEEE Trans. on Power Electronics,

vol. 12, no. 3, pp. 528-536, May 1997. [click]

[6] C. Ortega, A. Arias, C. Caruana, J. Balcells, and G.

M. Asher, “Improved waveform quality in the direct

torque control of matrix-converter-fed PMSM drives,”

IEEE Trans. on Industrial Electronics, vol. 57, no. 6, pp.

2101-2110, June 2010. [click]

[7] C. L. Xia, J. X. Zhao, Y. Yan, and T. N. Shi, “A novel

direct torque control of matrix converter-fed PMSM drives

using duty cycle control for torque ripple reduction,” IEEE

Trans. on Industrial Electronics, vol. 61, no. 6, pp. 27002713, June 2014. [click]

[8] K. Gulez, A. A. Adam, and H. Pastaci, “A novel direct

torque control algorithm for IPMSM with minimum harmonics and torque ripples,” IEEE/ASME Trans. on Mechatronics, vol. 12, no. 2, pp. 223-227, April 2007. [click]

[9] T. Orlowska-Kowalska and M. Dybkowski, “Statorcurrent-based MRAS estimator for a wide range speedsensorless induction-motor drive,” IEEE Trans. on Industrial Electronics, vol. 57, no. 4, pp. 1296-1308, April 2010.

[click]

[10] M. Morawiec, “The adaptive backstepping control of permanent magnet synchronous motor supplied by current

source inverter,” IEEE Trans. on Industrial Informatics,

vol. 9, no. 2, pp. 1047-1055, May 2013. [click]

[11] Z. Chen, B. Yao, and Q. Wang, “Accurate motion control

of linear motors with adaptive robust compensation of nonlinear electromagnetic field effect,” IEEE/ASME Trans. on

Mechatronics, vol. 18, no. 3, pp. 1122-1129, June 2013.

[click]

[12] Y.-R. Mohamed, “Adaptive self-tuning speed control for

permanent magnet synchronous motor drive with dead

time,” IEEE Trans. on Energy Conversion, vol. 21, no. 4,

pp. 855-862, December 2006. [click]

387

[13] C. H. Lin, “Novel adaptive recurrent Legendre neural network control for PMSM servo-drive electric scooter,” Journal of Dynamic Systems, Measurement, and Control, vol.

137, no. 1, 011010, August 2014. [click]

[14] Y. S. Yang and J. S. Ren, “Adaptive fuzzy robust tracking

controller design via small gain approach and its application,” IEEE Trans. on Fuzzy Systems, vol. 11, no. 6, pp.

783-795, December 2003. [click]

[15] B. B. Ren, S. S. Ge, K. P. Tee, and T. H. Lee, “Adaptive

neural control for output feedback nonlinear systems using

a barrier Lyapunov function,” IEEE Trans. on Neural Networks, vol. 21, no. 8, pp. 1339-1345, August 2010. [click]

[16] D. Saifia, M. Chadli, S. Labiod, and T. M. Guerra, “Robust H∞ static output feedback stabilization of TS fuzzy

systems subject to actuator saturation,” International Journal of Control, Automation and Systems, vol. 10, no. 3, pp.

613-622, Jun 2012. [click]

[17] H. C. Sung, J. B. Park, and Y. H. Joo, “Observer-based

sampled-data control for nonlinear systems: Robust intelligent digital redesign approach,” International Journal of

Control, Automation and Systems, vol. 12, no. 3 pp. 486496, May 2014. [click]

[18] S. Barkat, A. Tlemçani, and H. Nouri, “Noninteracting

adaptive control of PMSM using interval type-2 fuzzy logic

systems,” IEEE Trans. on Fuzzy Systems, vol. 19, no. 5, pp.

925-936, October 2011. [click]

[19] C. H. Lin, “Hybrid recurrent wavelet neural network control of PMSM servo-drive system for electric scooter,” International Journal of Control, Automation and Systems

vol. 12, no. 1 pp. 177-187, February 2014. [click]

[20] F. El-Sousy, “Robust wavelet-neural-network sliding-mode

control system for permanent magnet synchronous motor

drive,” IET Electric Power Applications, vol. 5, no. 1, pp.

113-132, January 2011. [click]

[21] J. Na, X. M. Ren, G. Herrmann, and Z. Qiao, “Adaptive

neural dynamic surface control for servo systems with unknown dead-zone,” Control Engineering Practice, vol. 19,

no. 11, pp. 1328-1343, November 2011. [click]

[22] J. Zhou, C. Wen, and Y. Zhang, “Adaptive output control of

nonlinear systems with uncertain dead-zone nonlinearity,”

IEEE Trans. on Automatic Control, vol. 51, no. 3, pp. 504511, March 2006. [click]

[23] T. P. Zhang and S. S. Ge, “Adaptive dynamic surface control of nonlinear systems with unknown dead zone in pure

feedback form,” Automatica, vol. 44, no. 7, pp. 1895-1903,

July 2008.[click]

[24] C. X. Hu, B. Yao, and Q. F. Wang, “Adaptive robust precision motion control of systems with unknown input deadzones: a case study with comparative experiments,” IEEE

Trans. on Industrial Electronics, vol. 58, no. 6, pp. 24542464, June 2011. [click]

[25] G. Tao and P. V. Kokotovic, “Adaptive control of plants

with unknown dead-zones,” IEEE Trans. on Automatic

Control, vol. 39, no. 1, pp. 59-68, 1994. [click]

388

Xingjian Wang and Shaoping Wang

[26] Q. K. Shen and T. P. Zhang, “Adaptive variable structure

control for large scale time-delayed systems with unknown

nonlinear dead-zone,” Journal of Systems Engineering and

Electronics, vol. 18, no. 4, pp. 865-870, December 2007.

[click]

[27] H. J. Ma and G. H. Yang, “Adaptive output control of uncertain nonlinear systems with non-symmetric dead-zone

input,” Automatica, vol. 46, no. 2, pp. 413-420, February

2010. [click]

[28] S. C. Tong and Y. M. Li, “Adaptive fuzzy output feedback

tracking backstepping control of strict-feedback nonlinear

systems with unknown dead zones,” IEEE Trans. on Fuzzy

Systems, vol. 20, no. 1, pp. 168-180, February 2012. [click]

[29] S. C. Tong and Y. M. Li, “Adaptive fuzzy output feedback

control of MIMO nonlinear systems with unknown deadzone inputs,” IEEE Trans. on Fuzzy Systems, vol. 21, no. 1,

pp. 134-146, February 2013. [click]

[30] Y. J. Liu and S. C. Tong, “Adaptive NN tracking control

of uncertain nonlinear discrete-time systems with nonaffine

dead-Zone input,” IEEE Trans. on Cybernetics, vol. 45, no.

3, pp. 497-505, March 2015. [click]

[31] M. L. Corradini and G. Orlando, “Robust practical stabilization of nonlinear uncertain plants with input and output

nonsmooth nonlinearities,” IEEE Trans. on Control Systems Technology, vol. 11, no. 2, pp. 196-203, March 2003.

[click]

[32] M. L. Corradini, G. Orlando, and G. Parlangeli, “A VSC

approach for the robust stabilization of nonlinear plants

with uncertain nonsmooth actuator nonlinearities-a unified

framework,” IEEE Trans. on Automatic Control, vol. 49,

no. 5, pp. 807-813, May 2004. [click]

[33] S. Ibrir, W. F. Xie, and C. Y. Su, “Adaptive tracking of

nonlinear systems with non-symmetric dead-zone input,”

Automatica, vol. 43, pp. 522-530, March 2007. [click]

[34] B. Yao and M. Tomizuka, “Adaptive robust control of SISO

nonlinear systems in a semi-strict feedback form,” Automatica, vol. 33, no. 5, pp. 893-900, May 1997. [click]

[35] B. Yao and M. Tomizuka, “Adaptive robust control of

MIMO nonlinear systems in semi-strict feedback forms,”

Automatica, vol. 37, no. 9, pp. 1305-1321, September

2001. [click]

[36] Y. S. Yang and C. J. Zhou, “Adaptive fuzzy H∞ stabilization for strict-feedback canonical nonlinear systems via

backstepping and small gain approach,” IEEE Trans. on

Fuzzy Systems, vol. 13, no. 1, pp. 104-114, February 2005.

[click]

[37] H. Chaoui and P. Sicard, “Adaptive fuzzy logic control of

permanent magnet synchronous machines with nonlinear

friction,” IEEE Trans. on Industrial Electronics, vol. 59,

no. 2, pp. 1123-1133, February 2012. [click]

[38] T. Takagi and M. Sugeno, “Fuzzy identification of systems

and its applications to modeling and control,” IEEE Trans.

on Systems, Man, and Cybernetics, vol. 15, no. 1, pp. 116132, January-February 1985. [click]

[39] L. Wang, A Course in Fuzzy Systems and Control, PrenticeHall, New York, 1997.

[40] E. D. Sontag, “Smooth stabilization implies coprime factorization,” IEEE Trans. on Automatic Control, vol. 34, no.

4, pp. 435-443, April 1989. [click]

[41] E. D. Sontag, “Further facts about input to state stabilization,” IEEE Trans. on Automatic Control, vol. 35, no. 4, pp.

473-476, April 1990. [click]

Xingjian Wang received the Ph.D. and

B.Eng. degrees in mechatronics engineering from Beihang University, China, in

2012 and 2006. From 2009 to 2010, he

was a visiting scholar in the School of Mechanical Engineering, Purdue University,

West Lafayette, IN, U.S.. He is currently

with the School of Automation Science

and Electrical Engineering, Beihang University, Beijing, China. His research interests include adaptive

and nonlinear control, fault diagnostic, prognostic and health

management, active fault tolerant control.

Shaoping Wang received the Ph.D.,

M.Eng. and B.Eng. degrees in mechatronics engineering from Beihang University,

China, in 1994, 1991 and 1988. She has

been with the Automation Science and

Electrical Engineering at Beihang University since 1994 and promoted to the rank

of professor in 2000. She was honoured as

a "Changjiang Scholar Professor" by the

Ministry of Education of China in 2013. Her research interests

include engineering reliability, fault diagnostic, prognostic and

health management, active fault tolerant control.