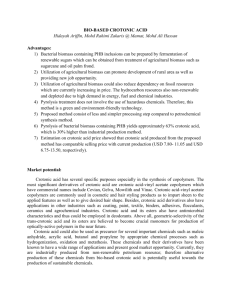

NNFCC Market Review: Bio-based Products, April 2013

advertisement

NNFCC Market Review Bio-based Products E Issue Thirteen, April 2013 ach month we review the latest news from across the global biobased chemicals and materials sector for NNFCC members. Pirelli are far from being the first to look at biobased alternatives to existing sources of rubber. Last year Cooper Tire announced they would be working with Yulex to develop tyres made from guayule-based polymers. Foreword Guayule isn’t the only alternative either. Nearly a dozen companies are working with tyre manufacturers to develop rubber from biobased isoprene. This includes the three largest tyre manufacturers. In March 2010, Goodyear announced they would be working with Genencor (now DuPont) to develop tyres from isoprene. Then a little over a year later in October 2011 Michelin teamed up with Amyris to develop tyres from isoprene and just last year the world’s largest tyre manufacturer Bridgestone announced they were working with Ajinomoto to develop isoprene-based tyres. Welcome to the April 2013 issue of our biobased products market review. This month Pirelli announced it had signed an agreement with Versalis to research the potential of guayulebased rubber. Guayule is a desert shrub and natural alternative to existing sources of rubber. Global demand for rubber is predicted to grow to around 36 million metric tons by 2020, from 26 million metric tons in 2011. But the price of rubber has fluctuated dramatically over the past decade, with natural rubber reaching a peak in the summer of 2011 at $2.81/pound. Prices have since decreased but they are still three times higher than they were a decade ago. In the past, most rubber used in tyres has been made from the latex-bearing Pará rubber tree or synthesised from petroleum. But continued restraints on the geographic area suitable for natural rubber production and pressure on the long-term supply of synthetic rubber is causing value chain concerns. This is making bio-based alternatives an attractive area for investment as tyre makers look for a way of controlling volatile raw material costs. Continue reading for the full story, as well as the rest of the market news. Highlights Page 2 Markets Page 3 Platform Chemicals Page 5 Speciality Chemicals Page 7 Bioplastics Page 9 Research Page 11 Price Information Page 12 Events NNFCC Market Review, April 2013, Page 1 of 12 meaning that bio-based production capacity will grow faster than overall production. Markets Source: nova-institut Bio-based polymers production capacity could triple by 2020 New study finds that bio-based polymers production capacity could triple from 3.5 million tonnes in 2011 to nearly 12 million tonnes in 2020. Bio-based drop-in PET and PE/PP polymers and the new polymers PLA and PHA show the fastest rates of market growth. The lion’s share of capital investment is expected to take place in Asia and South America. The study was carried out by nova-Institute in collaboration with renow ned international experts from the field of bio-based polymers. It is the first time that a study has looked at every kind of bio-based polymer produced by 247 companies at 363 locations around the world and it examines in detail 114 companies in 135 locations. Considerably higher production capacit y was found than in previous studies. The bio-based pol ymers market represent ed around 1.5 per cent of the total polymer market in 2011. However, current producers of bio-based polym ers estimate that production capacity will reach nearly 12 million tonnes by 2020. With an expected total polymer production of about 400 million tonnes in 2020, the bio-based share should increase from 1.5 per cent in 2011 to 3 per cent in 2020, The most dynamic development is foreseen for drop-in biopolymers, which are chemically identical to their petrochemical counterparts but at least partially derived from biomass. This group is spearheaded by partl y biobased PET (Bio-PET) whose production capacity will reach about 5 million tonnes by the year 2020, using bioethanol from sugar cane. The second in this group are bio-based polyolefins like PE and PP, also based on bioethanol. But the capacit y for “new in the market” bio-based polymers PLA and PHA is expect ed to at least quadruple between 2011 and 2020. Most investment in new bio-based polymer capacities will take place in Asia and South America because of better access to feedstock and a favourable political framework. Europe’s share will decrease from 20 per cent to 14 per cent and North America’s share from 15 per cent to 13 per cent, whereas Asia’s will increase from 52 per cent to 55 per cent and South America’s from 13 per cent to 18 per cent. Click here for more information. US could replace 20 per cent of petrochemical consumption with biobased products over the next decade The United States could replace 20 per cent of petrochemical consumption with biobased products over the next decade – while creating jobs and capturing a large share of the global renewable chemical market. The key is acting soon, before the current technological and agricultural edge is lost to other nations. The findings came from a report by the Milken Institute, in collaboration with the US Department of Agriculture. According to their report, "Unleashing the Power of the BioEconomy," experts from finance, policy and NNFCC Market Review, April 2013, Page 2 of 12 industry identified three major barriers to the development of new biotechnology in the US: Financing new projects and bringing them to scale: The development timetable for bio-based chemicals is five to ten years, longer than most new tech investors will tolerate before seeing returns. Perceived market uncertainties: The relative cost difference of bio-chemicals is largely dependent on the cost of oil. Policy uncertainty and complexity: The regulation of bio-based chemicals is complex and sometimes seemingly more onerous than the rules for petrochemicals, which are subject to a number of longstanding exemptions. Click here for more information. Platform Chemicals First commercial-scale lignin plant in 25 years opens in US A commercial-scale lignin separation plant has been installed by Domtar at its mill in North Carolina, US. The company claims this is the first facility of its type in the country in over 25 years. The production of lignin began in February, with a targeted rate of 75 tonnes a day, for industrial applications such as a bio based alternative to the use of petroleum and other fossil fuels. The project was helped to fruition by a grant through the Biomass Research and Development Initiative awarded by the US Department of Agriculture and the US Department of Energy. Click here for more information. Source: ZeaChem ZeaChem financial troubles cut work at Ore cellulosic biorefinery Just weeks after announcing that it made ethanol from sawdust at a demonstration plant in Eastern Oregon, ZeaChem has been forced to reduce its workforce while it tries to raise capital. ZeaChem is trying to build a $400 million refinery to create biofuels in Boardman, along the Columbia River. However, the company has failed to close on a bridge loan, leading to layoffs at the Oregon plant as well as a lab in California and the Colorado headquarters, the East Oregonian reported. CEO Jim Imbler said the Boardman facility remains staffed at a muchreduced capacity but the company hopes to have financing lined up in a few weeks. "These are the kinds of things that can happen when you're running a startup. Our team is very excited, and business is going to work. There's a reason this isn't for the faint of heart," said Imbler. Click here for more information. Myriant and Bayegan partner to commercialise bio-based chemicals Myriant Corporation, a global renewable chemicals company located in the US, and Bayegan Group, an international chemical production and trading company based in NNFCC Market Review, April 2013, Page 3 of 12 Turkey, have announced a collaboration agreem ent to commercialise Myriant's biosuccinic acid in markets across the Middl e East, Eastern Europe and Afri ca. acid from lignocellulose. Up until now, there has not been any known consolidated bioprocess for producing lactic acid from lignocellulose, the company said. Under the terms of the agreement, Bayegan has committed to annually purchase a predetermined amount of Myriant's bio-succinic acid for supply to customers in the Middle East, Eastern Europe and Afri ca. In addition, Myriant has granted exclusive distribution rights of bio-succinic acid to Bayegan in these areas. The two companies have also agreed to negotiate a potential joint venture to build a bio-succinic acid plant in Turkey subj ect to certain commercial milestones being met. Using pre-treated Miscanthus grass, Direvo fermented lactic acid on pilot scale in a single-step-synthesis. Direvo was further able to show that the important step of downstream processing of free lactic acid in the fermentation matrix can be realised effici ently by standardised procedures. On the basis of this proof-of-concept, the next development stage to raise competitiveness in a commercial environment will be to increase the yield of lactic acid. Click here for more information. Click here for more information. Purac to acquire BIRD Engineering Purac, a subsidiary of CSM, has announced that it has entered into an agreement to acquire Dutch company BIRD Engineering. BIRD Engineering is a biotech contract research company, specifi cally in the field of industrial microbiology. BIRD has experi ence with various micro-organisms, mostly bacteria and yeasts, and has expertise in the field of the development of new strains, and development of fermentation processes. The acquisition will include the intellectual property and 7 k ey employees of BIRD Engineering. BIRD Recruitment, a division of BIRD Engineering B.V. will not be part of the acquisition. Click here for more information. Direvo reaches milestone in consolidated bioprocessing of lignocellulose to lactic acid Industrial biotechnology company Direvo has announced that it has successfull y built up a processing chain from pre-treatment through fermentation to downstream processing for a consolidated bioprocess for making lactic Source: SEKAB Davy Process Technology Ltd and SEKAB E-Technology AB Form Strategic Partnership British-based Dav y Process Technology Limited, a Johnson Matthey company, and SEK AB, a leading player in the field of the ethanol based chemicals and biofuels, have announced that they are embarking on a collaboration to develop and market CelluTech™, SEKAB’s lignocellulosic based biorefinery technology. The technologies that constitute CelluTech™ were developed by SEKAB E-Technology in collaboration with Swedish universities. International experts have rated the CelluTechTM process among the most advanced methods to treat lignocellulosic biomass in the world. The platform is flexible NNFCC Market Review, April 2013, Page 4 of 12 and can be adapted to a variety of raw materials such as wood, straw, corn residues and bagasse. Click here for more information. Bio-XCell and METabolic EXplorer review progress on plan to build a PDO plant in Malaysia METabolic EXplorer, a green chemistry company that specialises in the development of bioprocesses for the production of chemical compounds used in a wide range of everyday products, and Malaysian BioXCell, the developer of the Bio-XCell biotechnology park and ecosystem in the Iskandar region of Malaysia, have reviewed the progress made so far on plans to build a PDO plant in Malaysia. An anal ysis of the issues addressed over the past two months has prompted Bio-XCell and METabolic EXplorer to agree on the conditions in which the project can be resumed and pursued. The issues in question mainly concern the reorganisation of the engineering aspects. Accordingl y, the two partners are determined to press ahead with plans to open a METabolic EXplorer plant in Malaysia and will do everything necessary to adjust the contractual framework before end of May 2013, in order to resume operations by Sept ember 2013. Click here for more information. Anellotech announces ability to produce large volume samples of bioderived benzene and toluene Anellotech, a technology-based company focusing on producing low -cost green drop-in versions of widely used petrochemicals directly from non-food biomass such as wood, bagasse and corn stover, has announced that it plans to make available large quantities of green benzene and toluene to strategic partners for downstream product development purposes before the end of 2013. Anellotech is the developer of a thermochemical catal ytic fast pyrol ysis (CFPTM) process for making aromatics directly from non-food biomass. By pyrolyzing biomass in the presence of a catalyst, the volatiles produced during the pyrolysis process can be converted into aromatic hydro carbons such as benz en e, toluene, and xylenes (BTX). Click here for more information. Speciality Chemicals Versalis signs agreement with Pirelli for joint research project on guayulebased natural rubber Versalis and Pirelli have entered into a Memorandum of Understanding to kick off a joint research project for the use of guayule based natural rubber in tyre production. The project will run over a period of three years. On an exclusivity basis, Versalis will prov ide an innovative range of guayule-based natural rubber materials, while Pirelli will carry out trial tests to validate the performance of the materials for tire production. As soon as new industrial quantities become available, Versalis will supply Pirelli with guayule-based natural rubber to complement the current set NNFCC Market Review, April 2013, Page 5 of 12 of synthetic rubber that Versalis is already supplying to Pirelli for the production of conventional tyres. three flavours and fragrances ingredi ents, with an initial fragrance oil targeted for commercialisation in early 2014. The agreement with Pirelli follows the partnership between Versalis and Yulex for guayul e production and for the construction of an industrial complex to be based in Southern Europe. The new collaboration agreement provides Firmenich with exclusive access to the Amyris technology platform for the flavours and fragrances market in exchange for significant funding over the next six years. Under the new agreem ent, Amyris and Firmeni ch will jointly select additional target flavours and fragrances ingredi ents that Amyris will develop and manufacture. Firmenich will market and distribute any ingredi ents resulting from the collaboration exclusively in the flavours and fragrances market. Both parties will share in the economic value derived from the sale of these ingredi ents. Click here for more information. Akzo Nobel and Solvay cooperate on renewable solvents Solvay and Akzo Nobel have announced a partnership for the usage of bio-based chemicals within AkzoNobel formulations of paints and coatings. "This partnership demonstrates that sustainable development is not only an ethical attitude from companies but also a means of doing business and creating value for our customers and our businesses.” said Solvay Coatis President Vincent Kamel. The agreement concerns widely used oxygenated solvents, specifically bio-Butanol and bio-Acetone and their derivatives, and the Solvay Coatis Augeo family of solvents. Solvent volumes of up to 10 kiloton per year are targeted by 2017. Click here for more information. Amyris and Firmenich announce expansion of collaboration in flavours & fragrances Am yris and flavours and fragrances company Firmenich have announced a ‘significant’ expansion of their collaboration to develop and commercialise renewable ingredients for the flavours and fragrances market. Under a previous agreement established in November 2010, Firmenich funded Am yris’s research and development to produce up to Click here for more information. Start-up to use University of Minnesota technology to manufacture bio-based methylmethacrylate Start-up Ascenix BioTechnologies have announced plans to commercialise production methods to synthesise chemicals from renewable feedstocks. The start-up predicts this new bio-based process, developed by University of Minnesota researchers, will be more economical and environmentally friendl y. The pro cess yi elds drop-in chemicals comparable in performance to those created using petroleum-based materials. Although the process could be applied to the production of biofuels and myriad chemicals, the start-up’s initial focus is on methylmethacrylate (MMA), a chemical used to make acrylic glass, paints and coatings, automotive parts and electronics. Global production of the chemical is more than 6 billion pounds per year. Click here for more information. NNFCC Market Review, April 2013, Page 6 of 12 Codexis announces next generation CodeXyme® cellulase enzymes Codexis, a developer of engineered enz ymes for pharmaceutical, biofuel and chemical production, has announced the launch of CodeXyme® 4 and CodeXym e® 4X cellulase enz yme packages for use in producing cellulosic sugar for production of biofuels and bio-based chemicals. Codexis’ latest generation of advanced cellulase enz ymes, CodeXyme® 4 for dilute acid pretreatments and CodeXyme® 4X for hydrothermal pretreatments, exhibits excellent performance, converting up to 85 per cent of available fermentable sugars at high biomass and low enzyme loads. Combined with high strain productivity using the CodeXporter® enz yme production system, this allows for a cost-in-use that the company believes will be among the lowest available once in full-scale commercial production. Click here for more information. expertise in the functional modification of PHA plastics to generate high-performance, cost-effective, sustainable PHA materials. Click here for more information. Perstorp and Purac in partnership to develop caprolactone lactide copolymers Purac, a leader in natural food preservation and bio-based chemicals, has announced a partnership with Perstorp to develop caprolactone lactide co -polymers for plastic, coatings and adhesive markets. Combining the complementary strengths of Perstorp in specialty products for coatings and plastics with Purac in renewable lactic acid based chemicals has already resulted in partly renewable caprolactone lactide coproducts. Possible uses for this new caprolactone lactide co -polymer include polyols for coatings, adhesives, sealants and elastomers, and for biodegradable plastics and hot-melt adhesives. The new co-pol ymer will be launched to the market in 2013. Bioplastics Click here for more information. Polymers Packaging Newlight partners with Biomer to expand sales of ‘greenhouse gasderived’ PHA plastics Metabolix signs distribution and PHA supply agreements with Tianjin GreenBio Materials Co. Ltd Newlight Technologies and Biomer have announced that the two companies have execut ed a partnership to expand sales of ‘greenhouse gas-derived’ PHA plastics. Under the terms of the partnership, Newlight has acquired the rights to Biomer's intellectual property, including for the functional modification of PHA’s. Newlight will combine the company's high yield greenhouse gas -to-PHA conversion and functionalisation technologies with Biomer's Bioscience company Metabolix have announced they have ent ered into a distribution agreement with Tianjin GreenBio Mat erials, a biomaterials company based in Tianjin, China. Under the terms of the agreement, Metabolix will distribute GreenBio's SoGreen™ heat shrink film in Europe and will be the exclusive distributor in the Americas. In addition to a distribution relationship, Metabolix and GreenBio have also signed a supply agreem ent for PHA biopolymers. Under the NNFCC Market Review, April 2013, Page 7 of 12 arrangement, GreenBio will supply PHA resins to Metabolix, which will extend the range and availability of the Company's PHA products. Click here for more information. Bags newly issued FTC Green Guidelines and laws being enacted in California. Click here for more information. Breville goes green with Cardia compostable juicer bags Cardia has announced that Breville Group Limited, a global designer and manufacturer of small kitchen appliances will purchase and market Cardia’s compostable “juicer bags” as part of its Juicer accessory offering to consumers. The 100 per cent compostable “Clean & Green™” juicer pulp bags are part of Breville’s campaign to encourage environmentally-friendl y waste disposal practices. The agreement is expected to generate strong sales for Cardia. Click here for more information. Health Source: Bio-buddy Custom Bioplastics to market the new Bio-buddy dog waste bag using Cardia’s biohybrid technology US-based Custom Bioplastics have launched the new “Bio-buddy™ dog waste bag” developed using Cardia’s Biohybrid™ technology. The new “Bio-buddy™ dog waste bag” is now being manufactured and marketed into the US and online by Custom Bioplastics, a US manufacturer of blown and cast film plastic packaging located in the Pacific Northwest. Custom Bioplastics new Biohybrid™ Bio-buddy dog waste bag are made with a combination of recycl ed resin and Cardia’s Biohybrid technology. The plant starch in Biohybrid lessens the total carbon footprint of the bag along with creating a bag that is soft and silky to the touch. This introduction is the result of a desire of Custom Bioplastics to provide a dog waste bag that follows the Source: Etavonni Etavonni Products launches FrozenPeaz® hot and cold therapy packs Etavonni Products has launched its FrozenPeaz® hot and cold therapy packs made with DuPont Tate & Lyle’s Zemea® propanediol. FrozenPeaz® products deliver flexible hot and cold therapy to relieve pain and assist in recovery from minor injuries or post-surgery rehabilitation. Benefits of this product include safe and non-toxic delivery NNFCC Market Review, April 2013, Page 8 of 12 of long-lasting hot and cold therapy, with flexibility like a bag of frozen vegetables. The Clear Ice™ Solution (made from Zemea®) is a natural, 100 per cent plant-based alternative competitive Technology Strategy Board (TSB) award, ‘Rapid Engineering of Cellular Factories’, in collaboration with University College London and University of to petroleum and glycerin-based gels. Manchester. Zemea® propanediol is made from corn sugar through fermentation and developed for use in the cosmetics and personal care market. It is a high-performance, environmentally sustainable alternative to petroleum-based glycols and glycerin, where the product’s lack of skin irritation, improved moisturisation and excellent aesthetic properties are benefits. Zemea® is approved as a natural ingredient by Eco cert and the Natural Products Association; is certified 100 per cent bio-based by the US D epartment of The Synthace project will integrate several novel technologies as reusable components, including the highly controlled import and export of chemicals from a cell, and the ability to rapidly tune the amount of each part used to assist in the production of a Agriculture. Click here for more information. chemical inside of a cell. Together with the other technologies in the Synthace platform, it enables the engineering of a cell which can convert low value feedstocks such as vegetable oils into much higher value chemicals such as pharmaceutical ingredi ents, fragrances, and pigments. Click here for more information. Research Green Biologics is awarded grant funding to advance the industrial application of synthetic biology Green Biologics, a British industrial biotechnology company focused on the production of biobutanol and other C4 chemicals from a range of sustainable and renewable feedstocks, has announced it has been awarded grant funding from the TSB, the UK’s innovation agency, to engineer a novel bacterial host for biobutanol production. UK Minister for Universities and Sci ence David Willets with Synthace CEO Sean Ward at the UCL Advanced Center for Biochemical Engineering, Source: Synthace Synthace awarded £500,000 TSB Synthetic Biology Grant University College London spin-out Synthace has announced the receipt of a highly The project is in collaboration with the Clostridia Research Group (CRG) at the University of Nottingham which is funded by the Biotechnology and Biological Sciences Research Council (BBSRC). The total project costs are £492k made up from contributions by Green Biologics (£62k ), TSB (£185k) and BBSRC (£245k ). The project duration is 18 months and due to commence on 1st May 2013. The partners aim to develop a novel bacterial host for the production of 1-butanol from NNFCC Market Review, April 2013, Page 9 of 12 renewable feedstocks. The strategy focuses on the modification of a clostridium species (Clostridium pasteurianum) for the fast growing renewable chemicals market. This microbe has many desirable features that make it an attractive fermentation host (fast growth rates, robustness and good butanol tolerance) but suffers from technical limitations. In this project, the partners will deploy advanced molecular biology tools for clostridia and introduce synthetic metabolic pathways that increase the range of feedstocks and also improve butanol production. Click here for more information. New Paper: Current progress on biobased polymers and their future trends, in Progress in Biomaterials This article reviews the recent trends, developments, and future applications of bio based pol ymers produced from renewable resources. Bio-based pol ymers are attracting increased attention due to environmental concerns and the realisation that global petroleum resources are finite. Bio-based polymers not only replace existing polymers in a number of applications but also provide new combinations of properties for new applications. A range of bio-based polymers are presented in this review, focusing on general methods of production, properties, and commercial applications. The review examines the technological and future challenges discussed in bringing these materials to a wide range of applications, together with potential solutions, as well as discusses the major industry players who are bringing these materials to the market. Click here for more information. Source: Resources, Conservation & Recycling New paper: Critical aspects in the life cycle assessment (LCA) of bio-based materials – Reviewing methodologies and deriving recommendations, in Resources, Conservation & Recycling Concerns over non-renewable fossil fuel supply and climate change have been driving the Renaissance of bio-based materials. To substantiate environmental claims, the impacts of bio-based materials are typi cally quantified by appl ying life cycle assessm ent (LCA). The internationally agreed LC A standards provide generic recommendations on how to evaluate the environmental impacts of products and services but do not address details that are specifically relevant for the life cycl es of bio-based materials. This paper provides an overview of key issues and methodologies explicitly pertinent to the LCA of bio-based materials. The authors argue that the treatment of biogenic carbon storage is critical for quantifying the greenhouse gas emissions of bio-based materials in comparison with petrochemical materials. Click here for more information. New Book Chapter: The Transition to a Bio-Based Chemical Industry Transition Management from a Geographical Point of View Management Principles of Sustainable Industrial Chemistry: Theories, Concepts and Industrial Examples for Achieving Sustainable Chemical Products and Processes from a Non-Technological Viewpoint. Click here for more information. NNFCC Market Review, April 2013, Page 10 of 12 Price Information Item Crude oil (petroleum, barrel) Maize (corn, metric ton) Sugar (pound) Rapeseed oil (metric ton) Soybean oil (metric ton) Ethanol (gallon) Price, US$ (Mar 08) 101.84 233.85 0.1288 1640.50 1321.27 2.31 Price, US$ (Mar 13) ↑ 107.66 ↓ 302.50 ↓ 0.1821 ↑ 1217.64 ↑ 1131.98 ↓ 2.45 % Price I ncrease 5.71 29.36 41.38 -25.78 -14.33 0.61 For details on indexes please see www.indexmundi.com/commodities Crude Oil (petroleum), simple average of three spot prices; Dated Brent, West Texas Intermediate, and the Dubai Fateh. Historic ethanol prices available at www.neo.ne.gov/statshtml/66.html Arrows indicate rise ( ↑ ), constant (–) or fall (↓ ) from previous month. Comparison of Price Indexes (2005 = 100) Price index (relative terms) 300 250 200 Agricultural Raw Materials 150 Food 100 Crude Oil (Petroleum) 50 Feb-98 Feb-99 Feb-00 Feb-01 Feb-02 Feb-03 Feb-04 Feb-05 Feb-06 Feb-07 Feb-08 Feb-09 Feb-10 Feb-11 Feb-12 Feb-13 0 For details on the nature of these commodities please see www.indexmundi.com/commodities NNFCC Market Review, April 2013, Page 11 of 12 Events *NEW* Life Cycle Assessment Workshops, 10-11 Apr 2013 in York, UK www.nnfcc.co.uk/events/new -partnershipproviding-lca-workshops Following the success of our previous Life Cycle Assessment (LCA) workshops, NNFCC and North Energy bring you two new training workshops providing you with insight into how LCA’s work and their applications. Renewable Plastics Conference, 16-17 Apr 2013 in Amsterdam, The Netherlands NNFCC members receive a 15 per cent discount off the usual delegate rates. Email enquiries@nnfcc.co.uk to receive the special promotional code. Biochemicals and Bioplastics 2013, 19-20 Jun 2013 in Frankfurt, Germany www.wplgroup.com/aci/conferences/ eucbc1.asp Biochemicals & Bioplastics 2013 summit will be valuable to anyone who needs a comprehensive overview of progress in the biochemical industry and what are the latest technological advancements and which Biorenew able market segment are the most promising in the next 10 years. www.renewable-plastics.com Now in its 4th year, the Renewable Plastics Conference will examine how the renewable plastics industry will evolve in the future. Over the two days, we will provide you with current essential information on the key issues surrounding this area and an update on recent technological developments. Dr John Williams, Head of Materials at NNFCC, will be speaking on bio-based feedstock opportunities and biomass process innovations. NNFCC members receive a 15 per cent discount off the usual delegate rates. Email enquiries@nnfcc.co.uk to receive the special promotional code. Dr John Williams, Head of Materials at NNFCC, will be chairing the conference and also speaking about "Bioplastics in an economically challenging climate”. Credits and Disclaimer NNFCC Market Review is edited by Dr Matthew Aylott for NNFCC members. Feedback is welcome. The Review has been compiled in good faith and NNFCC does not accept responsibility for any inaccuracies or the products or services shown. NNFCC The Bioeconomy Consultants NNFCC, Biocentre, York Science Park, Innovation Way, Heslington, York, YO10 5DG. Phone: +44 (0)1904 435182 Fax: +44 (0)1904 435345 E: enquiries@nnfcc.co.uk Web: www.nnfcc.co.uk NNFCC Market Review, April 2013, Page 12 of 12