Categorisation of Safety Functions and Classification of Structures

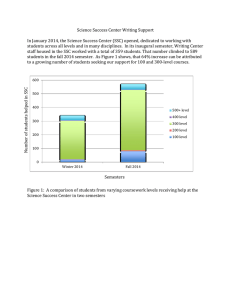

advertisement