as a PDF

advertisement

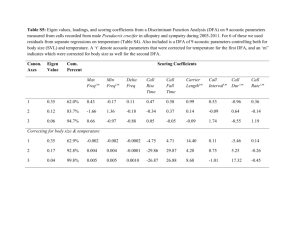

IMPLEMENTATION OF DFA IN CONCEPTUAL AND EMBODIMENT DESIGN USING DECISION SUPPORT PROBLEMS Timothy W. Simpson, Matthew D. Bauer, Janet K. Allen, and Farrokh Mistree Systems Realization Laboratory George W. Woodruff School of Mechanical Engineering Georgia Institute of Technology Atlanta, Georgia ABSTRACT How can Design for Assembly be implemented when the conceptual form of a product being designed is known but the information defining its physical form is vague and incomplete? In this paper, we answer the preceding question from a decisionbased perspective. Specifically, we adapt Boothroyd and Dewhurst’s Design for Assembly method for use in conceptual and embodiment design. We achieve this adaptation through the use of Decision Support Problems, and we illustrate our adaptation through an example, namely, the design of an aircraft evacuation system. Our emphasis in this paper is on presenting the conceptual framework used to make suitable Boothroyd and Dewhurst’s Design for Assembly to conceptual design and not the numerical results per se. 1 OUR FRAME OF REFERENCE It is well known that Design for Assembly (DFA) analyses such Boothroyd and Dewhurst's DFA (Boothroyd and Dewhurst, 1989) are applicable and useful once the design (geometric and material features) of a component is known, i.e., late in the embodiment design phase. But what if we want to address the issue of design for assembly very early on a time-line, for example, when only concepts are known? Eight governing principles provide the foundation for Boothroyd and Dewhurst's work which is used to facilitate assembly and reduce costs of existing products. It is difficult, however, to apply these criteria as written during conceptual and embodiment design when the information defining a concept’s physical form is vague and incomplete. Several methods have been developed for incorporating DFA in the early stages of design. At Sony, they have developed a set of rules for product design which includes design for assembly (Yamigiwa, 1988) . Computer advisory systems such as those described by (Onwubiko and Bekey, 1993; Jakiela, et al., 1985; Mantÿlä, 1990; Kroll, et al., 1988) have been developed to aid designers in the incorporation of DFA early in the design process. Several CAD applications have also been developed in addition to computer advisory systems, (Sturges and Yang, 1992; Henson, et al., 1993) . Moreover, Sturges and Kilani, 1992) , describe the development of an Integrated Design for Assembly Evaluation Reasoning System which utilizes existing solid-modeling packages to evaluate the assemblability of a design and makes design for assembly recommendations at component, system, and process levels. In this paper, we develop an extension to the Boothroyd and Dewhurst DFA approach using a decision-based perspective and selection Decision Support Problems (DSPs) which incorporates abstracted DFA principles for use during conceptual and embodiment design. Review of various methods used for selection are presented in (De Boer, 1987; De Boer, 1989; Vadde, et al., 1992). We therefore do not review other methods in this paper. Suffice it to say that we create and solve • a preliminary selection DSP using abstracted DFA principles as criteria for use during conceptual design, and • a selection DSP for use during embodiment design again using abstracted DFA principles for our selection criteria. The conceptual framework of our approach is shown in Figure 1. In the left hand column of Figure 1, we show the Pahl and Beitz, 1988, design process within which our approach is implemented. We incorporate our abstracted DFA principles into conceptual and embodiment design through the use of preliminary selection and selection DSPs (Mistree, et al., 1994) . Our approach consists of developing a design process which incorporates product design for assembly both qualitatively1 and 1 qualitative method - an approach which provides a set of rules or guidelines for designers to follow. quantitatively2. By transforming Boothroyd and Dewhurst’s eight governing DFA principles into abstracted DFA principles for use during conceptual and embodiment design as shown in the right hand column of Figure 1, we create a qualitative approach for guiding designers through the product realization process. By incorporating abstracted DFA principles in preliminary selection and selection DSPs as shown in the middle column of Figure 1, we provide a quantitative DFA evaluation method. In this paper, we detail our approach in the following sequence. In Section 2, we discuss how we extend Boothroyd and Dewhurst’s DFA principles, and in Section 3, we present our aircraft evacuation example and the formulation of our selection Decision Support Problems. Finally in Section 4, we discuss the results of our example and expound on the ramifications of extending Boothroyd and Dewhurst’s Design for Assembly principles. In this paper, we are concerned with the implementation of abstracted DFA principles through the DSPs rather than the detailed results of our example per se. Process Evaluation DFA Criteria Pahl & Beitz Need DSPs Figure 4 Section 3 Clarification Section 3.1 Conceptua Preliminary Selection DSP ? Embodimen Selection DSP ? Figure 2 Section 2.1 Section 3.2 Detail Boothroyd & Dewhurst Product FIGURE 1. CONCEPTUAL FRAMEWORK OF OUR APPROACH TO THE EXTENSION OF DFA 2 EXTENDING THE USE OF BOOTHROYD AND DEWHURST’S DESIGN FOR ASSEMBLY The overall concurrency of DFA with Pahl and Beitz’s design process is an important step in designing for assembly, Figure 1. Boothroyd and Dewhurst’s DFA analysis is applicable to detailed designs and existing products, but the importance of DFA in conceptual design cannot be neglected. In conceptual design, information governing a product’s geometric form is unavailable and incomplete, making the application of DFA principles a very subjective or qualitative procedure. As we proceed through conceptual design and into embodiment design, applying DFA becomes increasingly more objective or quantitative as more information becomes available. Ideally, improvements in the design process will be realized by eliminating or minimizing the need for secondary DFA analysis and redesign after detail design. Improvements in products will be apparent in their decreased cost of assembly and increased reliability. Neglecting the principles of DFA in the conceptual design phase makes revisions unavoidable. In embodiment design, DFA provides a means to improve the final product’s manufacturability and assembly. Moreover, product information, i.e., geometric form, material features, etc., is available in the embodiment design phase, making the application of DFA a more objective process. As embodiment design leads into detail design, DFA becomes an integral process 2 quantitative method - an approach which requires quantitative information to provide an objective evaluation or comparison (Kroll, et. al., 1988) in designing for manufacturability. In detail design, components’ positions, types of fasteners, and number of sub-assemblies, for example, can be optimized in accordance with DFA principles. In conceptual design, shown in the left hand column of Figure 1, little is known about the geometry or form of solution concepts, making the application of DFA during this phase very subjective because we cannot readily apply Boothroyd and Dewhurst’s eight DFA principles to a concept. In order to use DFA in conceptual design, it is essential to understand the characteristics of a concept which will cause later assembly and manufacturing difficulties. With this understanding, we can map Boothroyd and Dewhurst’s DFA principles into conceptual design as abstracted DFA principles as depicted in Figure 2. These abstracted DFA principles can be implemented in preliminary selection DSPs as selection criteria as illustrated in Figure 1. We present the results of our extension of DFA pictorially in Figure 2 and discuss below. The DFA principles we have abstracted are intended to help designers determine which concepts, when realized, will be designed better for assembly. We illustrate several different abstractions in Figure 2 as we outline below. 1. Design evolution progresses from left to right. Since Boothroyd and Dewhurst’s DFA principles apply to existing designs and designs in the detail design phase, they are located on the right side of the diagram. The abstracted DFA principles we create are located on the left hand side of the diagram since they are applicable earlier in the design evolution. 2. As designs evolve from a concept to the final detail solution, we assert that the abstraction of the design decreases. From the way they are structured, Boothroyd and Dewhurst’s DFA principles are very concrete and apply to designs which are concrete. In order to apply the DFA principles in the early stages in design, particularly during conceptual design, we must abstract these DFA principles so that they can be applied to concepts which are less concrete, i.e., more abstract, than finalized designs. The abstraction occurs in two ways: • the boundaries of the principles become less solid, and • the principles themselves become less concrete. We represent these two abstractions in Figure 2 through amorphisizing shapes and decaying borders. The change from a solid border to a dotted one symbolizes the abstraction of the bounds of our abstracted DFA principles in conceptual design, and the amorphisizing shapes symbolizes the abstraction of Boothroyd and Dewhurst's principles. The arrows indicate our mapping of Boothroyd and Dewhurst's principles into the abstracted DFA principles for conceptual design. 3. By integrating Boothroyd and Dewhurst's eight principles, we create the following abstracted DFA principles for use in conceptual design. • Relax Constraints - A solution concept which has fewer constraints and tight fittings may be easier to assembly. • Proper Material Selection - Some materials are easier to use in certain applications and some materials are better suited for manufacturing and precision equipment. Choosing the right material will help simplify the assembly process. • Minimize Solution Complexity - We feel that a more complex solution concept requires more parts and components and thus is more difficult and costly to assemble. • Minimize Relative Motion of Parts - If there is no need for relative motion between two parts, then there is no functional need to make two parts, unless they must be made of different materials. By minimizing necessary relative motion and number of different materials, we can decrease the number of parts hence decreasing the complexity of the solution and thereby facilitate assembly. • Maximize Solution Symmetry - A more symmetric concept will lend itself to having more components/parts which are the same, thus minimizing the number of parts which can be assembled incorrectly and reorientations needed during assembly. We assert that by incorporating DFA considerations into conceptual design, designers will be able to produce significantly better products in terms of design for assembly. By accomplishing this, we assert that the cost of the product will be reduced two fold. First, the product will be easier to assemble, and second, the product will require minimal redesign. concept which is more symmetric is likely to have fewer dissimilar parts and more parts which are similar in geometry and function. This will help minimize solution complexity. The same holds true in reverse; if a concept is less symmetric, then the solution is likely to be more complex. Minimize Solution Complexity Maximize Solution Symmetry Relax Constraints Minimize Relative Motion Acessible and Visible Eliminate Adjustments Ease of Handling Proper Material Selection Prevent Improper Installation Minimize Solution Complexity Reduce Parts Minimize Relative Motion Relax Constraints Self-Aligning and Locating Minimize Reorientations Maximize Solution Symmetry Maximize Symmetry DESIGN EVOLUTION INCREASING ABSTRACTION FIGURE 2. MAPPING DFA INTO CONCEPTUAL DESIGN Many abstracted DFA principles interact each other, Figure 3. These interactions stem from the translation of Boothroyd and Dewhurst’s principles into more abstract DFA principles. The overlap occurs because the translated DFA principles are more abstract than Boothroyd and Dewhurst’s eight principles. The interactions illustrated in Figure 3 are: • Constraints inversely affect complexity and vice versa. Complex concepts often require smaller tolerances, and concepts which need smaller tolerances can be more complex when realized. • Constraints inversely affect relative motion and vice versa. Systems requiring relative motion of parts often require them to be very accurately fitted together, increasing the need for tight tolerances. Similarly, if large tolerances are used, relative motion between parts becomes less possible. • Complexity inversely affects relative motion and vice versa. A concept which has more relative motion between its parts is likely to be more complex than a concept which does not. Similarly, a concept which has many parts moving relative to one another is likely to be more complex than a concept which does not have many moving parts. • Symmetry inversely affects complexity and vice versa. A FIGURE 3. INTERACTIONS BETWEEN ABSTRACTED DFA PRINCIPLES While we recognize the inherent interactions which exist among our abstracted DFA principles, it is perferable to have the abstracted DFA principles uncoupled for use in the preliminary selection DSPs. However, we are more concerned with the implementation of DFA in conceptual design than in the abstracted DFA principles themselves. During embodiment design, the use of DFA has the greatest impact on the product's final design and layout. In embodiment design, as shown in the left hand column of Figure 1, we begin to create preliminary form and layout designs for our solution concepts. By having abstracted DFA principles which apply during embodiment design, we can select designs which require minimal redesign for assembly in the final product design. Since both layout and form are created during embodiment design, all eight of Boothroyd and Dewhurst's DFA principles are applicable to some extent. However, we must translate each principle into a slightly more abstract form in order to apply it more easily in embodiment design and to utilize it as a selection criterion in a selection DSP as indicated in the middle column of Figure 1. As depicted in Figure 4, this abstraction is done on a one-to-one basis as we map Boothroyd and Dewhurst's eight principles directly into eight abstracted DFA principles for embodiment design. The abstracted DFA principles are illustrated in Figure 4 and explained as follows. • Reduce Part Count - Decreasing the number of parts in a design will reduce material costs and reduce assembly time. • Eliminate Adjustments - Designs which require fewer adjustments increase the assemblability of a design. • Self-Aligning and Self-Locating Parts - Parts and subassemblies which are self-aligning and self-locating will reduce assembly time and assembly costs. • Adequate Access and Visibility - Designing parts and subassemblies which are easy to access and easy to see will ensure better design for assembly. • Ease of Handling of Parts - Parts that are easier to move and manipulate ease assembly. • Minimize Reorientations - Minimizing the number of necessary reorientations of parts or sub-assemblies in a design will reduce assembly time and ensure the final product is more suited for assembly. • Prevent Improper Installation - Keeping a design simple and avoiding complex fittings and connections will facilitate a final product’s assembly. In addition, creating obstructions which prevent improper installation and otherwise anticipating and avoiding characteristics of a design which will make installation difficult and will facilitate assembly. • Maximize Symmetry - Maximizing symmetry or emphasizing the asymmetry will facilitate final product assembly. Abstracted DFA Principles for Conceptual Design Relax Constraints Proper Material Selection Minimize Solution Complexity Minimize Relative Motion Abstracted DFA Principles for Embodiment Design Acessible and Visible Boothroyd & Dewhurst’s DFA Principles for Existing and Detail Design Eliminate Adjustments Ease of Handling Prevent Improper Installation Reduce Parts Self-Aligning and Locating Minimize Reorient. Maximize Solution Symmetry Acessible & Visible Eliminate Adjust. Ease of Handling Prevent Improper Install. Reduce Parts Self Align. & Locating polygons in the DFA column of Figure 1 have been embodied in the form of abstracted DFA principles illustrated in Figure 4. It is these DFA principles that we will incorporate in our preliminary selection and selection DSPs for the original design of an aircraft evacuation system. We use the abstracted DFA principles shown in the left column of Figure 4 as criteria in a preliminary selection DSP during conceptual design. The criteria are not absolute, most of them require a relative basis for comparison. Therefore, we feel that we can incorporate these criteria very nicely into a preliminary selection DSP, middle column of Figure 1. Preliminary selection involves the selection of the most-likely-tosucceed concepts for further development (Mistree, et al., 1994) . The word formulation of the Decision Support Problem representing preliminary selection DSP is given in Table 1. TABLE 1. WORD FORMULATION OF PRELIMINARY SELECTION DSP (MISTREE, ET AL., 1994) Given A set of concepts. Identify The principal criteria influencing selection. The relative importance of the criteria. Capture Experience-based knowledge about the concepts with respect to a datum and the established criteria. Rank The concepts in order of preference based on multiple criteria and their relative importance. Minimize Reorient. Maximize Symmetry Maximize Symmetry DESIGN EVOLUTION INCREASING ABSTRACTION FIGURE 4. ABSTRACTION OF BOOTHROYD AND DEWHURST’S DFA PRINCIPLES FOR CONCEPTUAL AND EMBODIMENT DESIGN Similarly to our approach in conceptual design, the abstracted DFA principles for embodiment design are developed for use as attributes in a selection DSP. Since physical form and quantitative information becomes more available in embodiment design, the application of the abstracted DFA principles in selection DSPs is more objective. 3 AN AIRCRAFT EVACUATION SYSTEM DESIGN To demonstrate the efficacy of incorporating DFA in the early stages of design, we offer an example, the design of an aircraft evacuation system. Assume that our goal is the original design of an aircraft evacuation system which is versatile and can be used on a variety of passenger aircraft. In keeping with the Pahl and Beitz approach, our design work begins with the clarification of the task and concludes upon completion of embodiment design. We use the example to illustrate a quantitative approach for incorporating DFA considerations into conceptual and embodiment design. We do not discuss the actual design of the aircraft evacuation system in detail but concentrate on the incorporation of the abstracted DFA principles into preliminary selection and selection DSPs in conceptual and embodiment design. We combine the abstracted DFA principles in one picture, Figure 4, which spans the entire design time-line. Referring to Figure 1, we can see that our physical representation of the dashed TABLE 2. SOLUTION CONCEPT ACRONYMS NDIS NDRR NDIC ND3S NDSC FDIS FDRR FDIC FD3S FDSC EDIS EDRR EDIC ED3S EDSC - Normal door, inflatable slide - Normal door, rigid ramp - Normal door, padded cushion - Normal door, 360° slide - Normal door, Inflatable slide/cushion - Fold open door, inflatable slide - Fold open door, rigid ramp - Fold open door, padded cushion - Fold open door, 360° slide - Fold open door, Inflatable slide/cushion - Explosive bolt door, inflatable slide - Explosive bolt door, rigid ramp - Explosive bolt door, padded cushion - Explosive bolt door, 360° slide - Explosive bolt door, Inflatable slide/cushion The method of Pugh (Pugh, 1981) forms the basis of the algorithm developed for solving the preliminary selection DSP (Mistree, et al., 1988; Kuppuraju, et al., 1985) . The solution steps are as follows. Step 1 Describe the concepts and provide acronyms Step 2 Describe each generalized criteria, provide acronyms and weighting constants for the specific criteria. Step 3 Choose a datum with which all other concepts will be compared. Step 4 Compare the concepts rating concepts as either better than (+1), the same as (0), or worse than (-1) the datum Step 5 Evaluate the merit function for each concept within each generalized criterion. Step 6 Include interactions between generalized criteria. Step 7 Post-solution analysis: determine the most-likely-to succeed concepts. Step 1 Describe the concepts and provide acronyms. We present the results of the first two steps of our design process, i.e., clarification of the task and conceptual design, Table 2 and Figure 5. Explosive Door (ED) Normal Door (ND) TABLE 3. DFA PRINCIPLES FOR CONCEPTUAL DESIGN Abstracted DFA Principles for Conceptual Design • Minimize sol'n complexity • Relax tolerances • Use materials which simplify manufacturing & assembly • Minimize relative motion of parts • Maximize concept symmetry • • • • • Abstracted DFA Criteria for Conceptual Design Selection Solution complexity Required tolerance characteristics Required material characteristics Amount of relative motion of parts Concept symmetry TABLE 4. PRELIMINARY SELECTION CRITERIA General Criteria Assemblage Fold Open Door (FD) Rigid Ramp (RR) Safety Performance Economics 360° Inflatable Slide (3S) Specific Criteria Solution Complexity Required Tolerance Req. Material Characteristics Amt. of Relative Motion Solution. Symmetry Hazardous to People Partial Deploy. Safety Amt. of Impact Reliability Flow Rate Deployment Rate Aircraft Compatibility Cost Technology Inflatable Cushion (IC) TABLE 5. PRELIMINARY SELECTION WEIGHTINGS Inflatable Slide (IS) General Criteria Weighting Scenario Assemblage Safety Performance Economics 0.3 0.22 0.28 0.2 Inflatable Slide Cushion (SC) FIGURE 5. SOLUTION CONCEPTS Step 2 Describe each generalized criterion, provide acronyms We outline our abstracted DFA principles and preliminary selection criteria for the conceptual design of our aircraft evacuation system in Table 3. The left hand column contains the abstracted DFA principles from Figure 4 and the right hand column contains the corresponding criteria. The remaining selection criteria for the preliminary selection DSP are listed in Table 4. The Assemblage criteria are the result of mapping the principles for manual assembly into conceptual design as detailed in Figure 4 and Table 3. The Safety, Performance, and Economics criteria in Table 4 reflect customer requirements. We recommend varying the weights for the preliminary selection DSP to identify concepts which are consistent performers. However, as we are concerned with selecting concepts based on their design for assemblability, we use the weighting scenario listed in Table 5 when performing preliminary selection. The weights were determined using a prioritization matrix (Allard, et al., 1994) . Step 3 Choose a datum We choose the Normal Door Inflating Slide (NDIS), Exploding Bolt Door 3-D Slide (ED3S), and Folding Door Inflatable Slide/Cushion Hybrid (FDSC) to serve as datums. We have chosen NDIS because it constitutes current practice, the ED3S because it is the most controversial of our concepts, and the FDSC because it has potential to be the mostlikely-to succeed. Step 7 Determine the most-likely-to succeed concepts The results of preliminary selection are shown in Figure 6. The comparisons of each concept against each datum (Step 4), the calculation of merit functions for each concept (Step 5), and the creation of different weighting scenarios (Step 6) have been omitted due to space constraints but can be found in (Allard, et al., 1994) . As shown in Figure 6, the NDIS, NDIC, and NDSC (Normal Door with Inflatable Slide, Inflatable Cushion, and Inflatable Slide/Cushion, respectively) concepts consistently rank higher and therefore are determined to be the most-likely-to succeed concepts for further development. Use of the preliminary selection DSP enables us to narrow the large list of concepts (15) to a few most-likely-to succeed concepts (3). We now proceed to develop more quantitative information about each concept through further engineering analysis. Once sufficient information is generated, a selection DSP can be formulated and solved to help the designer determine the best concept for detail development. In the process of ana- lyzing the concepts, we eliminated the inflatable cushion concept since it is unsafe and does not meet performance requirements. The completion of embodiment design consists of determining the best concept by formulation and solution of a selection DSP, Figure 1. 1 NDIS as datum EDSC as datum FDSC as datum 0.9 0.8 0.7 0.6 0.5 engineering analysis and develop additional quantitative data for each concept for use in the selection DSP. Applying the selection DSP Criteria to the Partially Inflated Slide Concept: • Number of Parts: 10 • Number of Adjustments: 11 (based on one possible assembly sequence) • Self Aligning and Locating Parts: 1 (the valve stem) • Visibility: 100% • Ease of Handling: 4 of 10 parts bad (the long side pieces are awkward to handle) • Installation Difficulties: 0% • Symmetry: 9 out of 10 (all parts but valve stem symmetric) • Number of Reorientations: 0 (all activities top down and in one workspace) 0.4 0.3 0.2 0.1 L A A 0 Concept Acronyms Top View t2 t2 TABLE 6. WORD FORMULATION OF SELECTION DSP (MISTREE, ET AL., 1994) Given A set of concept variants. Identify The principal attributes influencing the selection. The relative importance of the attributes. Rate The alternatives with respect to each attribute. Rank The concept variants in order of preference based on attributes and their relative importance. The steps for solving the selection DSP are as follows. Step 1 Describe the alternatives and provide acronyms Step 2 Describe each attribute, specify the relative importance of the attributes and provide acronyms. Step 3 Specify scales, rate the alternatives with respect to each attribute. Step 4 Normalize ratings. Step 5 Evaluate the merit function for each alternative. Step 6 Post-solution sensitivity analysis. Further details on formulating and solving selection DSPs is provided in (Mistree, et al., 1988) . Step 1 Describe alternatives and provide acronyms The selection DSP is to determine the ordinal ranking of the two slide concepts using nine selection criteria. We perform further wi Section AA A Top View wo t1 FIGURE 6. PRELIMINARY SELECTION RESULTS After further development of the two concepts, a selection DSP is formulated for the analysis, Table 6. As discussed in (Mistree, et al., 1994) , the selection DSP facilitates the ranking of alternatives based on multiple attributes of varying importance. Use of the selection DSP helps the designer rate the alternatives, allowing not only the rank of the alternatives to be determined but also by how much one alternative is preferred to another. L A D FIGURE 7. PARTIALLY INFLATED SLIDE CONCEPT wo t1 wi D Section AA FIGURE 8. FULLY INFLATED SLIDE CONCEPT The selection DSP Criteria for the Fully Inflated Slide are: • Number of Parts: 7 • Number of Adjustments: 9 (based on one possible assembly sequence) • Self Aligning and Locating Parts: 1 (the valve stem) • Visibility: 5 of 7 parts easily visible (two mesh strips obscured) • Ease of Handling: 4 of 7 parts bad (the long topside, underside, and meshes are awkward to handle) • Installation Difficulties: 3 of 7 parts bad (the two meshes and the last endcap) • Symmetry: 4 out of 7 (Only endcaps and meshes symmetric) • Number of Reorientations: 1 (must remove assembly from mandrel during process) Steps 2 and 3 Describe each attribute, provide acronyms, specify scales Using the abstracted DFA principles from the middle column of Figure 4, eight of our selection criteria are DFA oriented while the last criterion, material volume, is chosen to quantify the weight of the slides. The selection criteria for use in evaluation are given in Table 7. The different scales used in selection DSPs are described in (Bascaran, et al., 1989; Mistree, et al., 1988) . Explanation of the selection criteria listed and the corresponding scales is as follows. • Number of Parts - We use a ratio scale with low preference to rate designs based on the number of parts or sub-assemblies they contain. • Number of Adjustments - We use a ratio scale with a low preference to rate designs based on the number of adjustments that a design will require. • Self-Aligning and Self-Locating - We use an interval scale with a high preference for designs with high percentages of selfaligning and self-locating parts or sub-assemblies. • Accessible and Visible - We use an interval scale with a high preference to rate designs based on the percentage of parts or sub-assemblies which are accessible and visible. • Ease of Handling - We use an interval scale with a preference for designs with high percentages of easy to handle parts. • Number of Reorientations - We use a ratio scale with low preference to rate designs based on the number of reorientations of parts or sub-assemblies that a design will require. • Installation Problems - We use an interval scale with a high preference to rate designs based on the percentage of parts or sub-assemblies without anticipated installation problems. • Symmetry - We use an interval scale with a high preference to rate designs based on percentage of symmetric parts. In the selection DSP, each criterion is weighted by its relative importance, Table 8. Assuming that both concepts perform equally, then we want DFA considerations and material volume to be our only selection criteria. Therefore, we weight each of our eight DFA criteria equally and place additional emphasis on the material volume which characterizes the cost of our slide. Then, the concept variants are evaluated in terms of the nine selection criteria using the information in Figures 8 and 9 utilizing the selection DSP in Table 9. TABLE 7. DFA SELECTION CRITERIA Criteria Acronym Scale High/ Low Pref. High Value Low Value PART Ratio Low 100 0 ADJT Ratio Low 100 0 Number of Parts Number of Adjustments Self-Aligning and Locating Accessible and Visible Ease of Handling Number of Reorientations Installation Problems Symmetry SAAL Interval High 1 0 ACVS Interval High 1 0 HAND Interval High 1 0 REOR Ratio Low 100 0 INST Interval High 1 0 Interval High 1 0 SYM M TABLE 8. WEIGHTING FACTORS FOR SELECTION DSP Criteria # Parts # Adjustments Align/Locate Access/Visible Ease of Handling # Reorientations Inst. Problems Symmetry Volume Attributes PART ADJT SAAL ACVS HAND REOR INST SYMM VOLM Weights 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.2 We show in bold print the differences in DFA considerations for our two designs in Table 9. Based on the desired preferences, Table 7, the fully inflated slide has fewer parts/sub-assemblies (PART), more self-aligning parts (SAAL), and fewer adjustments (ADJT) than the partially inflated slide; however, the remaining design for assembly considerations favor the partially inflated slide. The partially inflated slide will require fewer reorientations (REOR), has more parts which easy to handle (HAND), has more symmetric parts (SYMM), fewer installation problems (INST) and allows for easy access and visibility (ACVS) during assembly. Based on the weighting factors in Table 8, we would expect the partially inflated slide to be better than the fully inflated slide in terms of DFA considerations, and the solution to the selection DSP, shown in Table 10, verifies this. TABLE 9. ATTRIBUTE RATINGS FOR SELECTION DSP Criteria # Parts # Adjustments Align/Locate Access/Visible Ease of Handling # Reorientations Inst. Problems Symmetry Volume Selection Criteria PART ADJT SAAL ACVS HAND REOR INST SYMM VOLM Partially Inflated Slide Fully Inflated Slide 10 11 0.10 1.00 0.60 0.00 1.00 0.90 0.038 7 9 0.11 0.71 0.43 1.00 0.57 0.43 0.050 Step 5 Evaluate the merit function for each alternative. The selection DSP is solved and the merit values are computed for each concept variant, Table 10. From this analysis, we validate that the partially inflated slide concept is better than the fully inflated slide concept. Using a selection DSP on two alternatives is overkill. The selection DSP is designed to be used for several concepts, when it is difficult to rank order them and choose the best one. We chose to go ahead with the selection DSP, however, to verify that the partially inflatable slide is better than the fully inflatable slide . TABLE 10. MERIT FUNCTIONS FROM SELECTION DSP Concepts Partially Inflated Slide Fully Inflated Slide Acronym Merit Values Overall Rank PISL 0.838 1 FISL 0.707 2 4 CLOSURE We recognize that there are many ways to incorporate DFA considerations into a design process. In this paper, we create Decision Support Problems with DFA principles as selection criteria to incorporate DFA into conceptual and embodiment design. By translating Boothroyd and Dewhurst's eight governing DFA principles backwards along the design evolution timeline at levels of increasing abstraction to create general DFA principles for use during conceptual and embodiment design, we create a qualitative approach for guiding designers through the product realization process, minimizing the need for redesign for ease of assembly. By incorporating DFA considerations in preliminary selection and selection DSPs, we provide a quantitative evaluation method for fostering the development of designs with favorable assembly characteristics. Use of the preliminary selection DSP in conceptual design narrowed our concepts from 15 to 3, and use of the selection DSP in embodiment design narrowed our concept variants from 2 to 1 based on design for assembly considerations. The improved conceptual and embodiment design for an aircraft evacuation system means not only will manufacturers save money through reduced assembly costs, but human life will be improved. As the reliability of the aircraft evacuation system increases, fewer people will have to suffer. We have tried to abstract DFA principles which are domain independent. We have applied these DFA criteria to the design of an aircraft evacuation system, but recognize that they could be expanded, pending the examination of other designs and more rigorous examples. As stated earlier our intent is to illustrate our application of DFA in conceptual and embodiment design through Decision Support Problems and provide a new starting point for applying DFA earlier in the design process to minimize later redesign for assembly. As it exists, Boothroyd and Dewhurst’s systematic approach is applicable to detailed designs or existing products, when information defining its physical form and shape is known and available. Our extension of DFA into conceptual and embodiment design is driven by the current formulation of DFA for redesign or use in detail design. We assert that the incorporation of DFA in conceptual and embodiment design will have the same effect as using DFA late in the design process or during product redesign. Moreover, we assert that incorporating DFA throughout the design process minimizes the amount of redesign necessary and produces better conceptual designs for development in embodiment design. This follows from the premise that earlier incorporation allows selection of conceptual designs that truly embody the principles of DFA thereby realizing the benefits of DFA analysis while reducing time to market and minimizing the secondary cost of redesign for assembly. Application of abstracted DFA principles during conceptual and embodiment design through Decision Support Problems will facilitate assembly, reduce assembly cost, and minimize the need for redesign for assembly of a final product. By raising design for assembly issues in the early stages of design through the implementation of abstracted DFA principles in selection DSPs, we have not only created a design process which affects how engineers design but also what they design. ACKNOWLEDGMENTS Drs. J.A. Shupe and Sudhir Hublikar of B.F. Goodrich posed this problem. Financial support from NSF Grant DDM 93-96052 is gratefully acknowledged. We appreciate the support received from J. Peplinski and P. Koch, and the guidance of Dr. D. Rosen. We acknowledge the participation of C. Allard, J. Elliot, and M. Marston in the development of this approach. M. Bauer and T. Simpson are funded by The G.W. Woodruff School of Mechanical Engineering, Georgia Tech. REFERENCES Allard, C., Bauer, M., Elliot, J., Marston, M. and Simpson, T., 1994, "Incorporating Design for Assembly in the Design of an Aircraft Evacuation System," Georgia Tech. Bascaran, E., Bannerot, R.B. and Mistree, F., 1989, "Hierarchical Selection Decision Support Problems in Conceptual Design," Engineering Optimization, Vol. 14, pp. 207-238. Boothroyd, G. and Dewhurst, P., 1989, Product Design for Assembly, Boothroyd Dewhurst, Inc., Wakefield, RI. De Boer, S. J., 1987, "Selection Techniques in Methodical Design," Proceedings 1987 International Conference on Engineering Design, (Eder, W. E., ed.), Boston, ASME, pp. 303310. De Boer, S. J., 1989, Decision Methods and Techniques in Methodical Engineering Design, Academisch Boeken Centrum, De Lier, The Netherlands. Henson, B. W., Baxter, J. E. and Juster, N. P., 1993, "Assembly Representation Within a Product Data Framework," Advances in Design Automation, ASME, Vol. 65, No. 1, pp. 195205. Jakiela, M., Papalambros, P. and Ulsoy, A. G., 1985, "Programming Optimal Suggestions in the Design Concept Phase: Application to the Boothroyd Assembly Charts," Journal of Mechanisms, Transmissions, and Automation in Design, Vol. 107, No. 2, pp. 285-291. Also available in Design Engineering Technology Conference Proceedings, 1984, ASME, Cambridge, MA., pp. 1007-1012. Kroll, E., Lenz, E. and Wolberg, J. R., 1988, "A KnowledgeBased Solution to the Design for Assembly Problem," Manufacturing Review, Vol. 1, No. 2, pp. 104-108. Kuppuraju, N., Ittimakin, P. and Mistree, F., 1985, "Design through Selection ... A Method that Works," Design Studies, Vol. 6, No. 2, pp. 91-106. Mantÿlä, M., 1990, "A modeling system for top-down design of assembled products," IBM Journal of Research and Development, Vol. 34, No. 5, pp. 636-659. Mistree, F., Lewis, K. and Stonis, L., 1994, "Selection in the Design of Aircraft," 5th AIAA/UASF/NASA/ISSMO Symposium on Multidisciplinary Analysis and Optimization, ed., Panama City, Florida, pp. 1153-1166. Mistree, F., Marinopoulos, S., Jackson, D. and Shupe, J.A., 1988, "The Design of Aircraft using the Decision Support Problem Technique," NASA Contract Report #4134. Onwubiko, C. and Bekey, G.A., 1993, "Group Technology for DFA - An Intermediate Step for DFA Advisory System," 1993 NSF Design and Manufacturing System Conference, Charlotte, NC, Society of Manufacturing Engineers, Dearborn, MI, pp. 641648. Pahl, G. and Beitz, W., 1988, Engineering Design, The Design Council/Springer-Verlag, London/Berlin. Pugh, S., 1981, "Concept Selection: A Method that Works," Proceedings of the International Conference on Engineering Design, Rome, March 9-13. Sturges, R.H. and Kilani, M.I., 1992, "Towards an integrated design for an assembly evaluation and reasoning system," Journal of Computer-Aided Design, Vol. 24, No. 2, pp. 67-79. Sturges, R.H. and Yang, J., 1992, "Design for Assembly Evaluation of Orientation Difficulty Features," Advances in Design Automation, ASME, Vol. 44, No. 1, pp. 59-65. Vadde, S., Allen, J.K. and Mistree, F., 1992, "Catalog Design: Design Using Available Assets," Advances in Design Automation, (Hoeltzel, D.A., ed.), ASME, NY, pp. 345-354. Yamigiwa, Y., 1988, "An Assembly Ease Evaluation Method for Product Designers: DAC," Techno Japan, Vol. 21, No. 12, December.