Mechanically Generated Square Wave for Demonstrative Purposes

advertisement

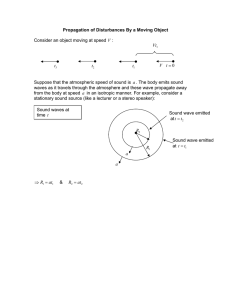

Mechanically Generated Square Wave for Demonstrative Purposes Nicholas Stankovich Over the course of studying physics, one of the concepts that arises on several occasions is that of Fourier Synthesis. As a means for generating exotic wave types using simpler waves, it is invaluable in fields such as electronics, where it is used to generate electronic signals. As important as this concept is, it can be difficult for some people to visualize exactly how it works. It is for this purpose of instruction that I have designed a physical, visual demonstration of Fourier Synthesis. The device uses additive sine waves, made by a system of rotating parts, to generate an approximate square wave. In designing this device, I created several computer simulations of its operation, using the equations for generating a square wave. The device itself uses gears to rotate separate levels at proper rates to simulate a square wave at its top most point. In this paper I will detail the design and operation of this device. Fourier Analysis is a very important concept of the fields of physics, with many applications, particularly in the field of Electronics. In particular, the idea of Fourier Synthesis is that any periodic wave form can be produced by adding a series of other wave forms. Physically or visually speaking, waves are added by adding their amplitudes at any given position or time. In two dimensions, waves may add constructively, that is their amplitudes are in the same direction and the added amplitude is larger, or they can add destructively, where their amplitudes are in opposite directions and the added amplitude is smaller or even zero. Utilizing these two features, we can add waves to shape the resultant wave form to whatever form we want. This is useful for creating unique and rather useful wave forms such as triangle waves, sawtooth waves, or our focus, the square wave. Square waves are waves with the feature that they switch instantly between a maximum and minimum value at regular intervals. While at those values, the wave amplitude remains constant in time. This can be visualized as the turn signal on a car, switching back and forth between its “On” and “Off” positions. When this wave is plotted it has a distinct square shape, giving the wave its name. Figure 1. A plotted square wave, displaying its characteristic shape The Fourier series summation that gives a square wave is given by the sum of an infinite number of sine waves. In this formula, f is the frequency of the resultant square wave and t is the time variable. In designing the machine itself, it became necessary to choose not only a method to generate simple harmonic motion but to easily and realistically add multiple waves. The two easiest ways to create SHM are with springs or with rotating discs. The only one of these that can easily be added is the discs. When a reference point on a rotating disc is observed from the side, projecting its position onto a single axis, its motion follows SHM. If a second rotating disc is centered at this reference point, a new reference point on it will follow the sum of the two rotations. This makes it the ideal method for producing a mechanical square wave. The ultimate design of the machine is shown in the figure below. Figure 2. Two levels of the apparatus in a side-on view This figure shows a side-on view of two levels of the apparatus. At each level, there is a larger base disc mounted on a hollow outer pipe that is free to rotate around a solid inner shaft. This inner shaft goes through a hole in the lower disc, and mounted to the top of it is a gear. Mounted to a point near the edge of the outer disc is another solid inner shaft around which is the freely rotating outer pipe connected to the upper disc and outer gear. As the base disc rotates, it carries the upper shafts, gear, and disc around in a circle. As they go around, the outer gear runs along the outside of the inner gear, causing it to rotate. This rotates the upper disc, where the whole process is repeated with another version of this apparatus set up on top of it. This system will consist of ten total discs. By controlling the disc sizes and gear ratios, it is possible to very precisely generate and add the specific sine waves, with the specific phase relationship, needed for the Fourier series. The disc sizes are relatively simple to calculate. The radii at which the upper disc of each level must be mounted is related to the amplitude of the corresponding iteration of the Fourier sum. This amplitude is given by given by 1/(2k-1) for the kth term of the formula. For instance, the disc second from the bottom must be mounted at 1/(1*2-1)R0 , or simply 1*R0 from the center of the bottom disc, where R0 is some base radius. R0 can be arbitrarily chosen to determine the scale of the device. A table of the radii of all levels with respect to R0 is shown below. 1st Disc 2nd Disc 3rd Disc 4th Disc 5th Disc 6th Disc 7th Disc 8th Disc 9th Disc 10th Disc 1 R0 1/3 R0 1/5 R0 1/7 R0 1/9 R0 1/11 R0 1/13 R0 1/15 R0 1/17 R0 1/19 R0 st th Table 1. The radius of each disc in the system. Numbered from 1 disc (bottom) to 10 disc (top). Calculating the gear ratios uses the other important part of a sinusoidal wave, the rotational frequency. In our formula, this is given by the part inside the sine wave, . Normally a gear ratio is equal to the ratio of rotational frequencies. However, since each level contributes rotation to the levels above it, the ultimate ratio is (Ftop - Fbottom)/Fbottom, where F is the roational frequency of a given disc. For the first level, the ratio is given by 1 st Level 2 nd or 2/1. The full list 3rd Level 4 th Level 5 th Level 6 th Level 7 th Level 8 th Level 9 th Level 2/5 2/7 2/9 2/11 2/13 2/15 2/17 Level 2/1 2/3 of ratios is tabulated below. Table 2. List of gear ratios for each level. Each level contains two disc levels, the first with discs 1 and 2, discs 2 and 3 in the second, etc. In order to demonstrate how the system will behave, I created a number of simulations in Maple that demonstrate the motion of the discs as well as that of the top reference point. This was done by animating a series of circles, where each circle moves in such a way that it’s center follows the edge of the circle before it. The Maple Code for this is as follows: The way this code works is that is creates a series of circles whose centers move in such a way that they follow the edge of the last circle. This is done by making the center of each circle follow the path of a successive iteration of the Fourier sum, where the x value of the center is given by the Fourier sum and the y value is given by the sum with cos() replacing sin(). When executed, an animation is generated, the first frame of which is shown below. Figure 3. First frame of animated simulation of the device’s operation This is a top down view of the system. The top circle represents the reference point that is observed. When it is viewed from the side (either from the top or the bottom of this simulation), the motion of that reference point on top is projected on a single axis and approximates a square wave with its side to side motion. To further show this, I plot the horizontal position of the reference point in the simulation above (now on the vertical axis) versus time in the following graph. Figure 4. The square wave path of the top reference point potted versus time. In this graph, we can clearly see the square shape of the wave. It is not a perfect square because this approximation is only adding ten waves, and to get a perfect square you need an infinite number of them. To demonstrate this, below are waves generated from 3 and 20 discs. Figure 5. Waves from 3 and 20 discs. More discs produce a better square wave. We can see that more discs produce a cleaner square wave, as expected. The 3 disc wave has only the most vague of square shapes, where as the 20 disc wave is even better than our 10 discs. From what I’ve seen, 10 is about the minimum in order to have a good square shape. Once all the calculations were complete, the next step is acquiring parts. There are only a handful of companies that offer gears in the custom sizes needed for this apparatus, and only one responded to my request for a quote. This company was Rush Gears Inc. The prices they quoted me ranged from $300 to nearly $2000 per gear, depending on size and quantity of each. Unable to acquire such funding, I was unable to continue to the construction and testing of the device. However, with the simulations and calculations detailed here, it can be concluded that this design should work as I have predicted to approximate a square wave. Using my calculated ratios and radii, it is theoretically possible to construct my design, the operation of which is simple enough to conclude that it should match the operation of my simulations. If completed, this device can be used to visually demonstrate an important concept, the understanding of which is essential in numerous fields of physics.