Product & Instruction Bulletin RPF

Release B, Effective October 2008

See Bulletin Change Summary on last page.

Vikuiti™ Rear Projection Film

Preparing the Application Surface and Installing the

Film

Recommended Use

Vikuiti rear projection film is designed to be applied to transparent surfaces

for use as a rear projection screen. The film provides excellent contrast

and color at all viewing angles under a variety of lighting conditions. The

film is self-adhesive and is easy to apply and remove. The film can be cut

into any shape or integrated with other graphics for a compelling visual

display.

Limitations of End

Uses

• Each user must determine if this product meets the specific needs of

their particular application.

• Rear projection film is not designed or recommended for application to

vehicles, compound curves, textured, rough or ribbed surfaces or to any

outdoor surfaces.

• Although rear projection film is removable, it cannot be removed from a

surface and reapplied.

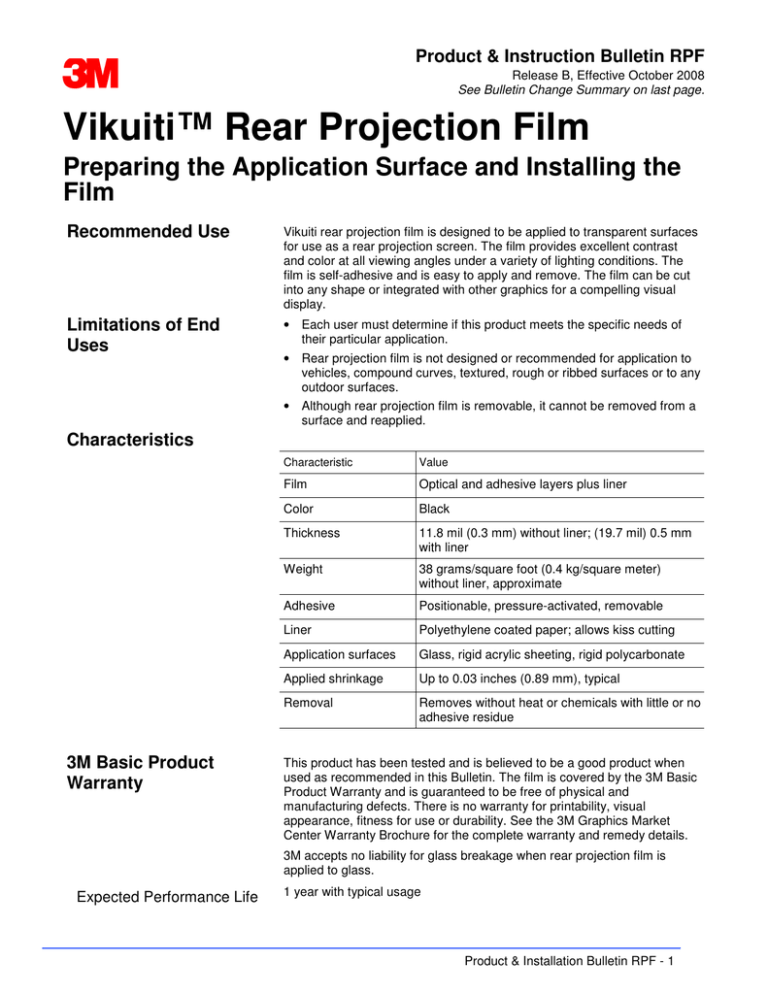

Characteristics

3M Basic Product

Warranty

Characteristic

Value

Film

Optical and adhesive layers plus liner

Color

Black

Thickness

11.8 mil (0.3 mm) without liner; (19.7 mil) 0.5 mm

with liner

Weight

38 grams/square foot (0.4 kg/square meter)

without liner, approximate

Adhesive

Positionable, pressure-activated, removable

Liner

Polyethylene coated paper; allows kiss cutting

Application surfaces

Glass, rigid acrylic sheeting, rigid polycarbonate

Applied shrinkage

Up to 0.03 inches (0.89 mm), typical

Removal

Removes without heat or chemicals with little or no

adhesive residue

This product has been tested and is believed to be a good product when

used as recommended in this Bulletin. The film is covered by the 3M Basic

Product Warranty and is guaranteed to be free of physical and

manufacturing defects. There is no warranty for printability, visual

appearance, fitness for use or durability. See the 3M Graphics Market

Center Warranty Brochure for the complete warranty and remedy details.

3M accepts no liability for glass breakage when rear projection film is

applied to glass.

Expected Performance Life

1 year with typical usage

Product & Installation Bulletin RPF - 1

Health and Safety

!

Read, understand and follow all information contained in this Bulletin prior

to installation of this product.

CAUTION When handling any chemical products, read the manufacturers' container

labels and the Material Safety Data Sheets (MSDS) for important health,

safety and environmental information. To obtain MSDS sheets for 3M

products go to 3M.com/MSDS, or by mail or in case of an emergency, call

1-800-364-3577 or 1-651-737-6501.

When using any equipment, always follow the manufacturers' instructions

for safe operation.

!

CAUTION To reduce the risk of injury, be aware that heat generated by direct sunlight

on dark areas of film can cause thermal expansion that may result in glass

breakage. See Location of Rear Projection Film, below, for more

information.

Product & Installation Bulletin RPF - 2

Installation

In sizes larger than 60 inch diagonal, rear projection film should be

professionally applied by an experienced film applicator.

Tools

• 3M™ Prespacing Tape SCPS-55

• 3M™ Application PA-1, Gold, free of nicks or burrs

• 3M™ Low Friction Sleeve SA-1, new and clean

• Scotch™ Blue Masking Tape 2090

• Spray bottle or plastic garden sprayer with tap water

• Mild, non-concentrated detergent (such as Dawn) containing no

lotions, soaps, oils, waxes or enzymes.

• 3M™ Micro-Fiber Cleaning Cloth or lint-free cleaning cloths

• 3Mt Prep Solvent 70, may be optional

• Bon Ami Glass Cleaner or Soft Scrub€Cleaner, may be optional

• Tri-sodium phosphate (TSP), may be optional

• Laser level or plumb-bob, optional

Location of Rear Projection

Film

For the best performance, apply the rear projection film on a recommended

surface where it is out of direct sunlight. Glare from sunlight makes the

image hard to view and will heat the film, increasing shrinkage and edge

lifting.

If the application surface is glass, the heat generated by direct sunlight on

dark areas of film may cause the glass to break due to thermal expansion.

Glass size, thickness, quality of cut, edge treatment, tinting and frame

design also influence the risk of breakage. 3M accepts no liability for glass

breakage when rear projection film is applied to glass.

For complete details, refer to 3M System Design Bulletin RPF.

Window Seams and Panes

Do not install the rear projection film as one piece on or across a window

seam. Instead, install the film as separate pieces between seams or on

each pane.

How to Cut Shapes

Also refer to 3M Creating Shapes with RPF for additional information on

designing and using shapes for special effects.

• Use an electronic cutter such as a flatbed or friction fed plotter.

• The black side of the rear projection film is the side onto which the

image is projected. The side with the adhesive and liner is the viewing

side.

• Cut all shapes in reverse on the black rear projection film side for

correct viewing.

• Use the cutter's standard set procedures for the knife blade. Make sure

that the cut goes completely through the rear projection film and lightly

scores the liner. This allows for clean removal (weeding) of the rear

projection film that will be discarded.

• Use premasking tape SCPS-55 to hold cut shapes in registration while

applying them to the application surface.

Product & Installation Bulletin RPF - 3

How to Apply

Premasking Tape

1. Unroll the premasking tape adhesive-side-up and place the cut rear

projection film on it so the liner is facing up.

2. Lightly squeegee the rear projection film on the liner side to adhere the

shapes to the premasking tape's adhesive.

3. Flip the rear projection film package over and re-squeegee from the

front side.

4. Cut the premask to the edge of the rear projection film liner.

5. If practical, use vacuum and heat after applying the premasking tape.

6. The graphic is now ready to apply.

Temperature

The air and application surface must be at least 60°F (16°C).

If rear projection film is applied at or near the minimum temperature, the

adhesive bond will develop more slowly. Thorough squeegeeing will assist

in creating a good bond.

Clean the Work Area

Be sure any work surface where you will lay or apply the rear projection

film is clean and free of dust and contaminants.

If applying the rear projection film to a permanent surface, be sure you

know exactly where it will be located so the correct application area is

cleaned.

Prepare the Application

Surface

Test Glass for Coatings

Clean the application surface immediately before applying the film. Dust

and other contaminants can collect quickly on the application surface and

prevent the film from adhering properly.

Many architectural glasses have coatings that could prevent rear projection

film from adhering well, functioning as intended, or removing it without

damaging or removing the coating. The user must test and approve an

application surface. Always check with the building maintenance

supervisor before testing or cleaning a surface.

The following test and method for cleaning is commonly used.

1. Place drops of water on several areas of the glass.

2. If the water forms into beads, there is a coating that must be removed.

• Use a cleaner such as Bon Ami Glass cleaner or Soft Scrub cleaner

to remove the coating. Follow the manufacturer's instructions.

• Repeat the test again to ensure a clean surface.

Glass Cleaning Procedure

1. Saturate a clean paper towel with a solvent such as low solvent

content, 3M prep solvent 70.

2. Wipe with a lint-free paper towel before the solvent evaporates from the

application surface. As the paper towel becomes dirty, discard it.

3. Make sure the application surface is completely dry. If necessary, use a

heat gun to dry any retained moisture.

4. Apply the rear projection film immediately.

Test Polycarbonate for

Outgassing

Polycarbonate sheet may outgas, which can create bubbles under applied

rear projection film. This test determines if the entire sheet needs to be

dried before the film is applied.

1. Apply a 5 x 5 inch (135 x 135 cm) piece of rear projection film used to a

piece of the same type polycarbonate you will be using.

2. Wait for 24 hours or, if possible, oven bake for 2 hours at 150°F (65°C)

or 5 minutes at 350°F (176°C).

3. If bubbles appear under the rear projection film, the polycarbonate is

outgassing: repeat the test daily until bubbles do not appear. If

outgassing continues after repeated tests, contact the sheeting

manufacturer for assistance.

4. If no bubbles appear, the sheeting is not outgassing.

Product & Installation Bulletin RPF - 4

Polycarbonate or Acrylic

Cleaning Procedure

1. Typical cleaning method: Wash the application surface with 1 ounce

of synthetic detergent per gallon of lukewarm water. Avoid soaps or

preparations that contain waxes, oils or lotions. Be aware that some

window cleaners contain waxes. Dry thoroughly with clean, lint-free

cloths or paper towels.

2. If grease or oil is present on the surface: Wash the application

surface with a solution of trisodium phosphate (TSP) and lukewarm

water. Prepare the solution according to the manufacturer's written

instructions. Dry thoroughly with clean, lint-free cloths or paper towels.

3. Apply the rear projection film immediately.

Registration Marks

Mark the horizontal and vertical alignment of all outer corners of the

projection area using Scotch blue masking tape.

Mark the horizontal center line. If possible, place this mark on the the

outside of the application surface so it can remain in place during

installation and then removed. If this is not possible, place the marks just

outside the rear projection film application area. A laser level may be useful

during alignment.

Prepare a Detergent

and Water Solution

Prepare a solution of 1/3 teaspoon (2 ml) of non-concentrated detergent,

containing no lotions, soaps, oils, waxes or enzymes, for each 1 quart (1

liter) of clean, cool water. One quart of solution is usually enough to

complete a single small- or medium-sized graphic.

After mixing the solution, pour some into a spray bottle.

Installation Procedure

Note: If your application surface is portable, application is easiest if you

are able to lay the application surface flat on a clean work surface.

1. Spray the application surface with the detergent and water solution.

2. Lay the rear projection film liner-side-up on a clean, dry, work surface

near the application surface.

3. Lift one corner of the liner and spray water onto the exposed adhesive.

Try to keep the liner dry; a wet liner is more difficult to remove. See

FIGURE 1.

FIGURE 1

Lift Corner of Liner; Spray with

Water

Rear Projection Film Liner

4. Continue to remove the liner and spray the solution. By the time the

liner is completely removed, the entire adhesive surface should be wet.

Spray on more solution, if necessary.

Note: Depending upon the size of the graphic, you may need another

person to help you complete the next step.

5. Lift and turn the rear projection film over so the adhesive side faces the

wetted application surface. Align the registration marks. See FIGURE 2.

FIGURE 2

Lift and Turn Rear Projection

Film

Product & Installation Bulletin RPF - 5

6. To smooth out wrinkles and bubbles:

a. Use a gold squeegee and very light pressure to smooth out the

entire graphic. Start at the center and work toward the edge, using

overlapping strokes and the order shown in FIGURE 3. When you

finish this step, the rear projection film should be flat on the

application surface and most of the water pushed out.

FIGURE 3

Squeegee from the Center to

the Edge, Overlapping Strokes

3 1 5

4 2 6

b. Use a gold squeegee and firm, overlapping strokes to re-squeegee

from the center of the graphic to the edges. When you finish this

step, all of the water and as many bubbles as possible should be

removed.

c. Wipe the entire surface dry, paying particular attention to the edges.

7. If an application tape was used, remove it now by pulling down at an

angle as close as possible to 180 degrees and immediately re–

squeegee the rear projection film.

8. Remove any remaining bubbles from the rear projection film:

a. Puncture the rear projection film at one end of the bubble with the air

release tool or a pin. Do not use a razor or blade.

b. Use your thumb to push the trapped air or wetting solution toward

the puncture. See FIGURE 4.

FIGURE 4

Removing Trapped Air

9. Keep the newly applied graphic out of direct sunlight for 24 hours.

10. After 24 hours, use a gold squeegee with a low friction sleeve to resqueegee the rear projection film edges. This important step helps seal

the edges and reduce lifting.

11. Clean the rear projection film before projecting the image onto it for the

best viewing.

Tiling on Large Surfaces

Glass Application Surfaces

You can tile pieces of the rear projection film on large surfaces. Seams will

be visible but are typically not distracting. To maximize overall appearance,

try to use film from the same lot and alternate the direction of the film to

keep left edges to left edges and right edges to right edges.

1. Apply the rear projection film to the application surface using the water

application method (see page 4).

2. Overlap the next panel by about 1/2 inch (1.25 cm) and apply it.

3. Using a straight edge and sharp blade, cut between the overlap.

Remove the excess margin of rear projection film from each side and re

squeegee the seam.

Product & Installation Bulletin RPF - 6

Plastic Application Surfaces

1. On a clean work surface, use a straight edge and a sharp blade to cut a

small margin of rear projection film off each side of the rear projection

film that will butt up to another piece.

2. Apply the rear projection film to the application surface using the water

application method (see page 4). Fully apply one panel and then butt up

the next one and apply it, making sure the seams are as tight as

possible.

Projector Set Up

Care and Maintenance

Rear Projection Film

Cleaning Procedure

For complete details, refer to 3M System Design Bulletin RPF.

Avoid touching the rear projection film or placing it where observers can

touch it. Skin oil and other contaminants can stain the film.

1. General cleaning.

a. Wash the application surface with 1 ounce (28 grams) of synthetic

detergent per gallon of lukewarm water. Avoid soaps or preparations

that contain waxes, oils or lotions. Be aware that some window

cleaners contain waxes.

b. Dry thoroughly with a clean, soft cloth such as 3M micro-fiber

cleaning cloths, applying only light pressure.

c. Rinse with clean water and dry by blotting with a clean dry cloth of

chamois.

2. For stubborn fingerprints or oily contamination on the bead side of the

rear projection film (non-adhesive side), isopropyl alcohol can be used.

a. Saturate a clean paper towel with isopropyl alcohol (IPA).

• If you are using industrial grade IPA, mix it in a ratio of 2 parts

water to 1 part IPA.

• If you are using rubbing alcohol, do not dilute it.

b. Wipe with a lint-free paper towel before the IPA evaporates from the

application surface. The evaporation rate increases in warm and/or

windy environments. As the paper towel becomes dirty, discard it.

Product & Installation Bulletin RPF - 7

Portable Application

Surfaces

Repairing Damaged Rear

Projection Film

If the rear projection film is applied to a portable surface, use care to

protect it from contaminants, scratching, gouging or other damage during

transport and storage.

It is possible to patch in a piece of rear projection film if an area has been

damaged. Although it will look better than a gouged screen, it will not be an

invisible repair.

• Using a straight edge and sharp blade, cut out the damaged area,

being careful not to damage the application surface.

• Carefully remove the damaged piece. Any stress or pulling on the

rear projection film that is to remain on the application surface could

distort it.

• Apply a new, slightly larger piece of rear projection film over the cut

out area using the water application method (see page 4), but do not

work quite out to the edges of the patch.

• Again using the straight edge and sharp blade, carefully align and

cut the patch piece to fit.

• Finish the installation, making sure to squeegee all edges well and

mop up any excess water. Squeegee again after 24 hours.

Shelf Life and Storage

Shelf Life

Storage Conditions

Total shelf life: 2 years from the date on the original box

Up to 2 years unprocessed, OR process within 1 year and apply within 1

year of processing

• 40° to 100°F (4° to 38°C)

• Out of sunlight

• Clean dry area

• Original container

• Bring the rear projection film to room temperature before using

Disclaimers

The information contained and techniques described herein are believed to

be reliable, but 3M makes no warranties, express or implied, including but

not limited to any implied warranty of merchantability or fitness for a

particular purpose. 3M shall not be liable for any loss or damages, whether

direct, indirect, special, incidental or consequential, in any way related to

the techniques or information described herein.

Product & Installation Bulletin RPF - 8

3M™ Vikuiti™ Rear Projection Film Product Warranty

Individual Product Limited

Warranty

Defect Coverage

3M warrants to the Distributor, Graphics Manufacturer and End User that

Vikuiti™ Rear Projection Film (Product) will be free of the defects listed

below, be manufactured to the specifications described, and adhere and

perform as intended for a period of one (1) year from the date of

installation when the product is used as described in the Product &

Instruction Bulletin RPF that is in effect at the time of purchase.

• Physical Defects. Defects incurred during manufacturing, packaging or

shipment.

• Manufacturing Defects. Visual and adhesive defects.

Warranty Limitations

• Defined End Uses Limitation. This warranty only applies to Product that

is used in a responsible manner for the end uses described in the

applicable 3M Product & Instruction Bulletin. For any other use, the

user is responsible for determining the suitability of the Product and for

any and all risk or liability associated with that use or application.

• Product Misuse Limitation. This warranty does not cover Product that is

modified or damaged through improper storage, misuse, abuse,

accident, vandalism, neglect or mishandling of processed or

unprocessed products by any person.

• Glass Breakage Limitation. This warranty does not cover glass

breakage.

• Adhesion to Application Surfaces Limitation. This warranty does not

cover the Product or damage to any surface coating applied to the

substrate prior to applying the Product.

Remedies and Limitations of

Liability

• Materials. If the Product does not meet the above warranty terms (for

approved warranty claims), upon timely notification, 3M’s sole

responsibility, and the Distributor, Graphics Manufacturer and End

User’s exclusive remedy shall be at 3M’s option: (A) Credit the full

purchase price of the Product or (B) Replace the Product, only in the

quantity shown to not meet the warranty terms.

• No Extension of Warranty. In the case of an approved warranty claim,

the replacement graphic or materials carry only the remaining term of

the original graphic or materials’ warranty period as stated in the

applicable 3M Product Bulletin.

• No Other Liability. Other than as set out in this limited warranty, 3M

shall not be liable for any loss or damages, whether non-specified

direct, indirect, special, incidental or consequential (including downtime,

loss or profits or good will) in any way related to the Product regardless

of the legal theory asserted.

Claims Procedure

End Users

Distributors and Graphics

Manufacturers

Contact your graphics manufacturer who may submit a claim on your

behalf.

If you purchase direct from 3M, the required method for initiating a claim is

to use the on-line product quality complaint form, which provides complete

details. Go to www.3mgraphics/qualitydirect or call toll-free,

1-800-511-3705 in the U.S. To be eligible for adjustment, 3M must receive

notice within sixty (60) days after the reason for the claim was discovered.

3M and Vikuiti are trademarks and/or logos of 3M Company.

Bon Ami is a registered trademark of Faultless Starch/Bon Ami Company. Soft Scrub is a registered

trademark of The Clorox Company. All other trademarks are the property of their respective owners.

Bulletin Change

Summary

The 3M™ Vikuiti™ Rear Projection Film Product Warranty has been added

to this bulletin.

Product & Installation Bulletin RPF - 9

Commercial Graphics

Division

3M Center, Building 22012E-04

PO Box 33220

St. Paul, MN 55144-3220

USA

General Info. 1-800-3746772

Technical Info. 1-800-3283908

Fax 1-651-736-4233

www.3Mgraphics.com/rpf

3M Canada

P.O. Box 5757

London, Ontario

Canada N6A 4T1

1-800-265-1840

Fax 519-452-6245

3M México, S.A. de C.V

Av. Santa Fe No. 55

Col. Santa Fe, Del. Alvaro

Obregón

México, D.F. 01210

52-55-52-70-04-00

Fax 52-55-52-70-22-77

3M Puerto Rico, Inc.

Puerto Rico Industrial Park

P.O. Box 100

Carolina, PR 00986-0100

787-620-3000

Fax 787-750-3035

E3M 2008. All rights reserved.

Product & Installation Bulletin RPF - 10