Freescale Semiconductor

Application Note

AN1907

Rev. 1, 6/2006

Solder Reflow Attach Method for

High Power RF Devices in Plastic Packages

By: Wendi Stemmons, Jerry Mason, Rich Wetz, Tom Woods, Mahesh Shah and David Runton

INTRODUCTION

This application note describes a process to solder attach

the TO - 270 - 2 (Case 1265) as well as the TO - 270 WB - 4

(Case 1486) RF power plastic packages to a printed circuit

board and heatsink assembly. There are several issues that

are of concern that will be addressed here:

semiconductor packages. The technology and material used

(such as lead frame, die attach, wire bond and mold

compounds) have been used in many applications and are

known to provide robust semiconductor packages. These

plastic packages have been used for power devices in harsh

environments such as under - the - hood applications, without

any reliability degradation.

1. Establishing a good thermal path between the device

and heatsink by providing high quality solder joint

between the device heat spreader and the power

amplifier (PA) heatsink.

2. Obtaining a high quality solder joint between the device

leads and the pads on the printed circuit board (PCB).

3. Maintaining the package integrity so that the leads or

molded plastic are not overstressed.

DISCUSSION

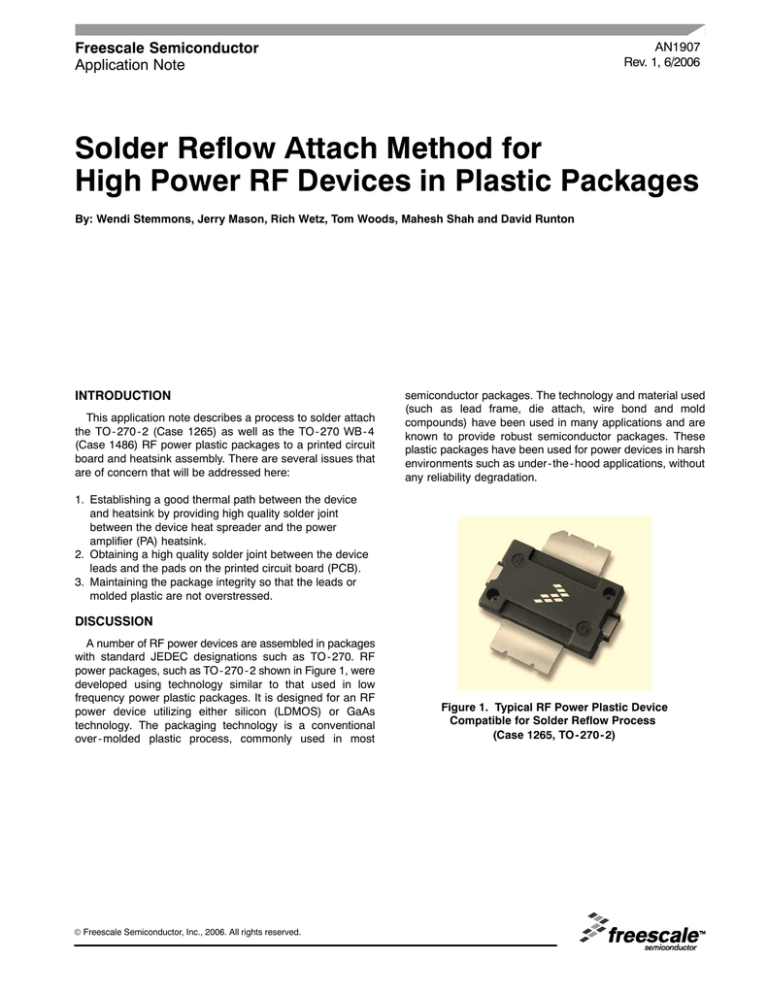

A number of RF power devices are assembled in packages

with standard JEDEC designations such as TO - 270. RF

power packages, such as TO - 270 - 2 shown in Figure 1, were

developed using technology similar to that used in low

frequency power plastic packages. It is designed for an RF

power device utilizing either silicon (LDMOS) or GaAs

technology. The packaging technology is a conventional

over - molded plastic process, commonly used in most

© Freescale Semiconductor, Inc., 2006. All rights reserved.

RF Application Information

Freescale Semiconductor

Figure 1. Typical RF Power Plastic Device

Compatible for Solder Reflow Process

(Case 1265, TO - 270 - 2)

AN1907

1

PCB ASSEMBLY PROCESS

For better electrical and thermal performance, Freescale

highly recommends that the RF power device should be

soldered to a PCB and the heatsink, as shown in Figure 2. The

soldered interface at the heat spreader or the source contact

provides a better heat dissipation path from the device to the

heat spreader and then to the power amplifier (PA) heatsink,

resulting in a lower junction temperature. The reduction in

junction temperature typically is associated with an increased

Mean - Time - to - Failure (MTTF) for the semiconductor

devices. In addition, a soldered interface tends to provide

improved grounding for the RF power device and, thus,

improved electrical performance. For this kind of assembly

process, two types of special PCB technologies are available.

Figure 2. Reflow Pallet Assembly with Components and Soldering Fixture

In one type of PCB assembly, the conventional PCB is

attached to a full metal carrier or pallet that is the same size

or slightly larger than the PCB. This is known as an Integrated

Metal Carrier (IMC). The metal carrier is made from mostly

copper or aluminum material. The metal is plated to provide a

solderable surface. A copper pallet is typically plated with Ni

followed by Au. The Au thickness is fairly small and is

commonly known as Au flash. The aluminum material is

typically plated with some type of zinc, followed by a Ni and Au

top layer to prevent the Ni from oxidizing.

The second type of PCB assembly is a forged or machined

copper coin that is also plated with Ni and Au. The coin is

usually designed to be larger than the RF power device and

has two bolt holes on each side of the RF power device to bolt

the coin to the PA heatsink.

Both the coin and the pallet are attached to the under side

of the PCB using either a high temperature solder or a

conductive epoxy such as Ag- filled epoxy. If solder is used to

attach the coin or the pallet to the PCB, the solder selected

must have a higher melting temperature than the solder used

for the components on the PCB. In either case, the PCB

supplier will provide the PCB with either the IMC or coin

already attached to it. The typical process flow is shown in

Figure 3.

The assembly shown in Figure 2 was created using the

typical mounting process flow for a solder reflow process

described in Figure 3. The gate and drain leads of the device

are soldered to the pads on the top of the printed circuit board.

The heat spreader of the device (source contact for an

LDMOS device) is soldered to a machined cavity in the copper

plate through a hole in the PCB. The bottom of the PCB is tin

lead plated and attached to the copper plate.

The biggest challenge in assembling any device is to

overcome the accumulated tolerances in the stack - up

between the device, PCB and copper plate and to maintain

good thermal and electrical contact where necessary. If the

device leads are too high above the PCB surface, they may

not contact the solder paste, resulting in a weak or possibly

non - existent solder joint. If the device is placed too low, the

leads can be bent in an upward direction, resulting in possible

delamination in the device.

AN1907

2

RF Application Information

Freescale Semiconductor

PROCURE PCB WITH COIN OR

PALLET ALREADY ATTACHED.

ALTERNATIVELY, PROCURE PCB,

PALLET OR COIN AND ATTACH TO PCB.

SIZE THE CAVITY DEPTH

OR PEDESTAL HEIGHT.

INCORPORATE IT IN THE

PALLET OR COIN DESIGN.

SCREEN PRINT SOLDER PASTE ON

THE PCB SOLDER PADS.

(SCREEN PRINT)

PLACE SOLDER PREFORM(S) IN THE

CAVITY THROUGH PCB SLOTS.

DISPENSE FLUX IF NECESSARY.

(PICK AND PLACE)

PLACE RF POWER DEVICE IN THE

PCB SLOT, WHILE POPULATING

THE PCB.

(PICK AND PLACE)

ADD THE FIXTURE TO KEEP THE RF

DEVICE IN PLACE WHILE SOLDERING.

(PICK AND PLACE)

REFLOW THE SOLDER IN A

CONVECTION REFLOW FURNACE.

(REFLOW)

REMOVE THE REFLOW FIXTURE AND

EXAMINE THE SOLDER JOINTS.

Figure 3. Process Flow for Board Assembly

Mechanical tolerances for this device are tightly controlled.

The manufacturing process results in a seating plane height

of 0.041 ± 0.001″ (1.04 ± 0.03 mm). The seating plane height

is defined as the distance from the bottom of the device lead

to the bottom of the package case. There is also a co- planarity

specification on these devices that indicates how level the

leads must be with respect to the flange. The co- planarity limit

is typically 0.041 ± 0.003″ (1.04 ± 0.07 mm). These tolerances

are much tighter than those for any of the metal ceramic

devices common in the industry for RF power application. It is

also important to note that the leads of the plastic packages

are made from 8 mil (0.20 mm) thick Cu- alloy rather than the

5 mil (0.13 mm) thick Fe- Ni alloy used in most metal ceramic

packages. The increased thickness makes the leads for

TO - 270 packages slightly stiffer than metal ceramic package

leads.

Typical tolerances of the PCB manufacturing process are

±10% of the PCB thickness. The tolerances of the machined

cavity in the copper plate can be kept to ±0.003″ (0.08 mm) or

better. The recess in the copper plate must be designed so

that the device leads are not assembled in a bent- up position.

We recommend using the square root of sum of squares

method to define the cavity depth rather than using the

worst - case tolerance stack - up analysis. Care should be

taken in the design of the heatsink so that the leads are not

bent to the point where this can contribute to delamination of

the plastic mold compound from the leads. Tests were

conducted to show that 0.015″ (0.38 mm) of lead tip deflection

during three solder reflow operations will not cause any

delamination of the mold compound from the lead frame.

In addition to the cavity depth, the next important

consideration is to ensure that the device is held in place with

the device heat spreader in contact with the solder preform in

the cavity and the leads are in contact with the solder paste on

the PCB solder pads. The PCB solder pads are designed to

be a minimum of 0.010″ (0.25 mm) larger than the

corresponding lead sizes as shown in Figure 4. In multi - lead

packages, where the lead spacing is very close, this distance

may have to be reduced to ensure that the device leads can

be soldered without getting shorted by solder bridging

between two pads.

AN1907

RF Application Information

Freescale Semiconductor

3

Device Lead

ÍÍÍÍÍÍÍÍÍ

ÍÍÍÍÍÍÍÍÍ

ÍÍÍÍÍÍÍÍÍ

ÍÍÍÍÍÍÍÍÍ

Solder Pad

3X

10 mils minimum

Figure 4. Pad Size and Spacing for Gate and

Drain Leads

For the solder reflow process, a fixture is usually needed to

(a) keep the device in place while running though the reflow

furnace, (b) prevent the device from lifting off due to buoyancy

forces when the solder melts and (c) keep the leads in contact

with the solder paste so it forms a good solder joint. The fixture

may also be required to apply force on the device to hold it in

place and to prevent it from lifting off. The amount of force

needed depends on the amount and type of solder used and

the soldering process.

RF power packages with the suffix “M” in the device part

number are provided with SnPb plating on all of the exposed

metal surfaces (source pad and gate and drain leads).

Packages with the suffix “N” in the device part number are

provided with matte- Sn finish on all exposed metal surfaces.

These devices are RoHS compliant.

RF power devices can be soldered using either

SnPb - based solder or most of the Pb - free solders in use. In

general, Freescale’s RF power devices are all being qualified

to meet the JEDEC J - STD - 20 requirements of MSL 3 at

260°C package peak temperature. Each device data sheet

identifies the package peak temperature and corresponding

MSL rating of the device. Devices with an MSL rating below

1 are normally shipped in a vacuum pack. The handling,

storage and use of such devices on the customer’s assembly

floor should strictly adhere to JEDEC J - STD - 33. This

standard defines the shelf life of the devices after they are

removed from their vacuum pack. It also defines the

conditions for drying such devices to reset the floor life after

moisture exposure. It should be noted that the drying is

typically specified at either 40°C, 90°C or 125°C. The baking

time for an MSL 3 rated part at 40°C is in months, which is not

very practical. In addition, the tape and the reel material in

which RF power devices are shipped cannot withstand

temperatures higher than 70°C. If such devices must be dried

to reset the floor life, they should be removed from the tape

and reel and dried in a tray that can handle a drying

temperature of 125°C.

In our experiment, we designed a PCB capable of powering

the device in DC mode. In addition, we also machined a

copper pallet with a cavity to accommodate the power

transistor. The copper pallets were plated with approximately

1,000 to 1,500 micro - inches (25 to 38 micrometers) of

electroless nickel. The pallets contain a recessed cavity that

is overplated with 0.0003″ to 0.0005″ (8 to 13 micrometers) of

tin plating to promote solder reflow. We used Sn plating

because the pallets were going to be soldered very quickly

after being received from the plating shop. For long - term

storage and use, we recommend using Au plating over

electroless Ni instead of Sn plating. In addition, we used a

special fixture to push the leads down at the tips so that the

lead tips were at a fixed distance above the top surface of the

PCB and the leads were in contact with the solder paste during

the reflow process. The cross-section of the assembly through

the fixture and the TO-270-2 device is shown in Figure 5. To

solder multiple components at one time, a simple fixture can be

designed to secure all of the components during the reflow

operation.

In the soldering process, the PCB was first attached to the

pallet. After that, the PCB was screen printed with Sn/Pb/Ag

solder paste using a 0.006″ (0.15 mm) - thick stainless steel

stencil. Prior to placing the device, two 0.002″ (0.05 mm)- thick

solder preforms and two drops of no clean flux were set into

the cavity. The device was then placed in the cavity through

the slot in the PCB. The solder reflow fixture was then attached

over the part. Finally, the entire assembly was placed in a

convection reflow furnace.

Clamp

Deformed

Copper Lead TO−270−2 Device

Solder Paste

Solder Preform

PCB

Figure 5. Concept of Fixture Holding the Leads Down on the PCB

AN1907

4

RF Application Information

Freescale Semiconductor

In the reflow step, the board is preheated to 150_C and held

constant for a minimum of one minute to stabilize the board

temperature. A “spike” above the 183_C liquidus temperature

achieves the best reflow characteristics. In order to achieve

the appropriate temperature profile, the peak temperature and

belt speed of the reflow furnace are determined based on the

total mass of the assembly going through soldering.

Maximum time above the liquidus temperature is 90 seconds

with 30 to 60 seconds typical. Maximum time above 150_C

is 5.5 minutes. Figure 6 shows a typical reflow profile used in

the reflow of SnPb eutectic or similar solder. Similarly, Figure

7 shows the typical reflow profile for Pb- free solder. We want

to emphasize that these profiles are shown here only as an

example. The solder supplier should specify the required

profile. After the reflow operation, the fixture is removed. The

fixture can then be reused. An actual board assembly is shown

in Figure 8.

250

Temperature ( C)

200

° 150

100

50

0

0

100

200

300

Time (seconds)

Figure 6. Typical Solder Reflow Profile for Sn63 or

Similar Solder

Figure 7. Typical Solder Reflow Profile for Pb - free (SnAgCu) Solder

AN1907

RF Application Information

Freescale Semiconductor

5

Figure 8. Complete PCB Assembly with TO - 270 - 2 (Case 1265) Package on a Cu Pallet

RESULTS

As mentioned earlier, the lead tips can be pushed down by

0.015″ (0.38 mm) maximum to provide a good solder joint. An

evaluation was performed to determine whether bending the

lead and then reflowing the components caused any

delamination on the lead to plastic interface. The leads to

plastic interface of several TO - 270 packages were examined

using acoustic microscopy. The leads were then pushed down

at the tips by 0.015″ (0.38 mm) using a fixture similar to the one

used for the soldering operation. The assembly was then

exposed to the standard reflow temperature profile three

times. Figures 9 and 10 show sonoscan images of the

interface on two typical parts before the reflow exposure.

Figures 11 and 12 show sonoscan images of the interface on

the same parts after three reflow exposures. There is no

evidence of delamination in the parts caused by combined

stresses of the soldering temperature exposure (a maximum

of three times) and lead deflection of 0.015″ (0.38 mm).

The device MRF9045NR1 in the TO - 270 - 2 package

has a typical junction to case resistance (θ JC ) of 0.85_C/W.

For the installation described here, the device is soldered

down in the cavity of a copper pallet. The difference

between the maximum temperature in the solder joint at

the source contact and the maximum temperature in the

die will be equal to 0.8 times the dissipated power (in

watts). Once the ambient temperature in the base station

is known, the system design can be evaluated to determine

the temperature at the solder joint at the source contact of

the device. The temperature rise, calculated above based

on the power dissipation, can be added to determine the

junction temperature.

AN1907

6

RF Application Information

Freescale Semiconductor

Figure 9. Lead to Plastic Interface of Part A Prior

to Lead Bending and Reflow as Viewed Using an

Acoustic Microscope

Figure 10. Lead to Plastic Interface of Part B Prior

to Lead Bending and Reflow as Viewed Using an

Acoustic Microscope

Figure 11. Lead to Plastic Interface of Part A After

Bending and Reflow (Three Times) as Viewed

Using an Acoustic Microscope

Figure 12. Lead to Plastic Interface of Part B After

Bending and Reflow (Three Times) as Viewed

Using an Acoustic Microscope

AN1907

RF Application Information

Freescale Semiconductor

7

How to Reach Us:

Home Page:

www.freescale.com

E - mail:

support@freescale.com

USA/Europe or Locations Not Listed:

Freescale Semiconductor

Technical Information Center, CH370

1300 N. Alma School Road

Chandler, Arizona 85224

+1 - 800 - 521 - 6274 or +1 - 480 - 768 - 2130

support@freescale.com

Europe, Middle East, and Africa:

Freescale Halbleiter Deutschland GmbH

Technical Information Center

Schatzbogen 7

81829 Muenchen, Germany

+44 1296 380 456 (English)

+46 8 52200080 (English)

+49 89 92103 559 (German)

+33 1 69 35 48 48 (French)

support@freescale.com

Japan:

Freescale Semiconductor Japan Ltd.

Headquarters

ARCO Tower 15F

1 - 8 - 1, Shimo - Meguro, Meguro - ku,

Tokyo 153 - 0064

Japan

0120 191014 or +81 3 5437 9125

support.japan@freescale.com

Asia/Pacific:

Freescale Semiconductor Hong Kong Ltd.

Technical Information Center

2 Dai King Street

Tai Po Industrial Estate

Tai Po, N.T., Hong Kong

+800 2666 8080

support.asia@freescale.com

For Literature Requests Only:

Freescale Semiconductor Literature Distribution Center

P.O. Box 5405

Denver, Colorado 80217

1 - 800 - 441 - 2447 or 303 - 675 - 2140

Fax: 303 - 675 - 2150

LDCForFreescaleSemiconductor@hibbertgroup.com

Information in this document is provided solely to enable system and software

implementers to use Freescale Semiconductor products. There are no express or

implied copyright licenses granted hereunder to design or fabricate any integrated

circuits or integrated circuits based on the information in this document.

Freescale Semiconductor reserves the right to make changes without further notice to

any products herein. Freescale Semiconductor makes no warranty, representation or

guarantee regarding the suitability of its products for any particular purpose, nor does

Freescale Semiconductor assume any liability arising out of the application or use of

any product or circuit, and specifically disclaims any and all liability, including without

limitation consequential or incidental damages. “Typical” parameters that may be

provided in Freescale Semiconductor data sheets and/or specifications can and do

vary in different applications and actual performance may vary over time. All operating

parameters, including “Typicals”, must be validated for each customer application by

customer’s technical experts. Freescale Semiconductor does not convey any license

under its patent rights nor the rights of others. Freescale Semiconductor products are

not designed, intended, or authorized for use as components in systems intended for

surgical implant into the body, or other applications intended to support or sustain life,

or for any other application in which the failure of the Freescale Semiconductor product

could create a situation where personal injury or death may occur. Should Buyer

purchase or use Freescale Semiconductor products for any such unintended or

unauthorized application, Buyer shall indemnify and hold Freescale Semiconductor

and its officers, employees, subsidiaries, affiliates, and distributors harmless against all

claims, costs, damages, and expenses, and reasonable attorney fees arising out of,

directly or indirectly, any claim of personal injury or death associated with such

unintended or unauthorized use, even if such claim alleges that Freescale

Semiconductor was negligent regarding the design or manufacture of the part.

Freescalet and the Freescale logo are trademarks of Freescale Semiconductor, Inc.

All other product or service names are the property of their respective owners.

© Freescale Semiconductor, Inc. 2006. All rights reserved.

AN1907

AN1907

8Rev. 1, 6/2006

RF Application Information

Freescale Semiconductor