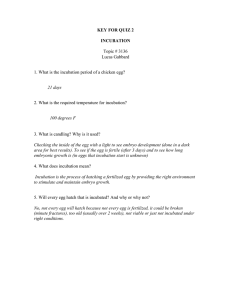

Incubation Guide

advertisement