Surface Mount Technology (SMT) 0.64mm

Generation Y

(LAC),

Hand Mate,

Application Specification

114-13230

(GET),

and USCAR-Approved Header Assemblies

07 MAY 09

Rev A

USCAR is the United States Council for Automotive Research

NOTE

i

All numerical values are in metric units [with U.S. customary units in brackets]. Dimensions are in millimeters [and

inches]. Unless otherwise specified, dimensions have a tolerance of +0.13 [+.005] and angles have a tolerance of +2 .

Figures and illustrations are for identification only and are not drawn to scale.

_

1. INTRODUCTION

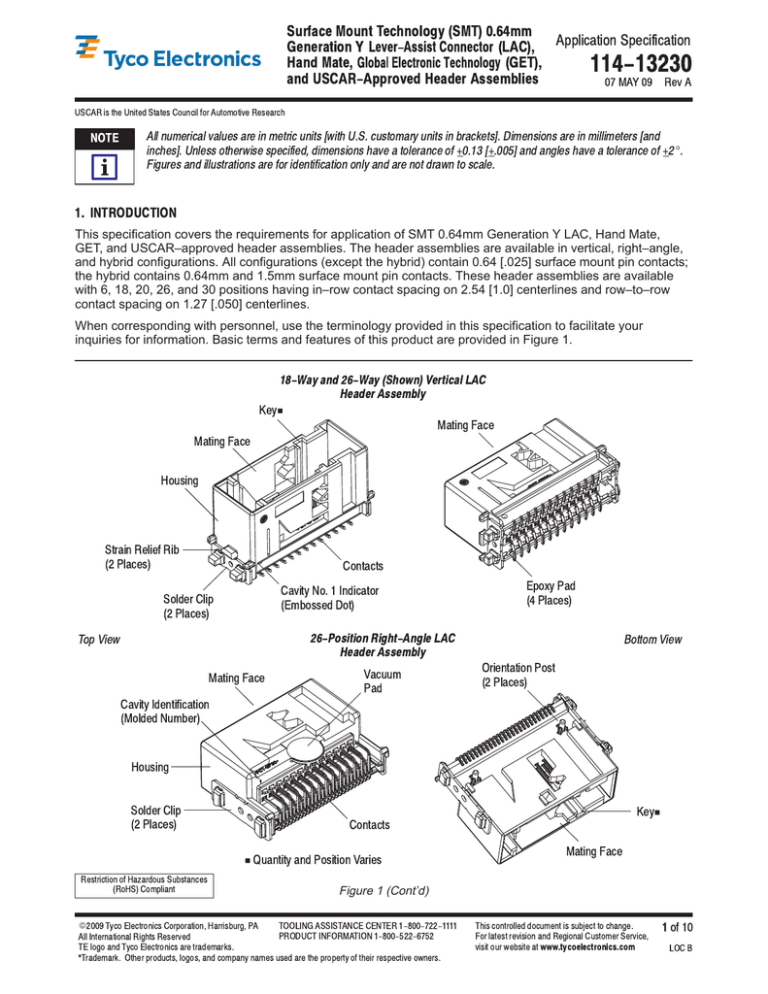

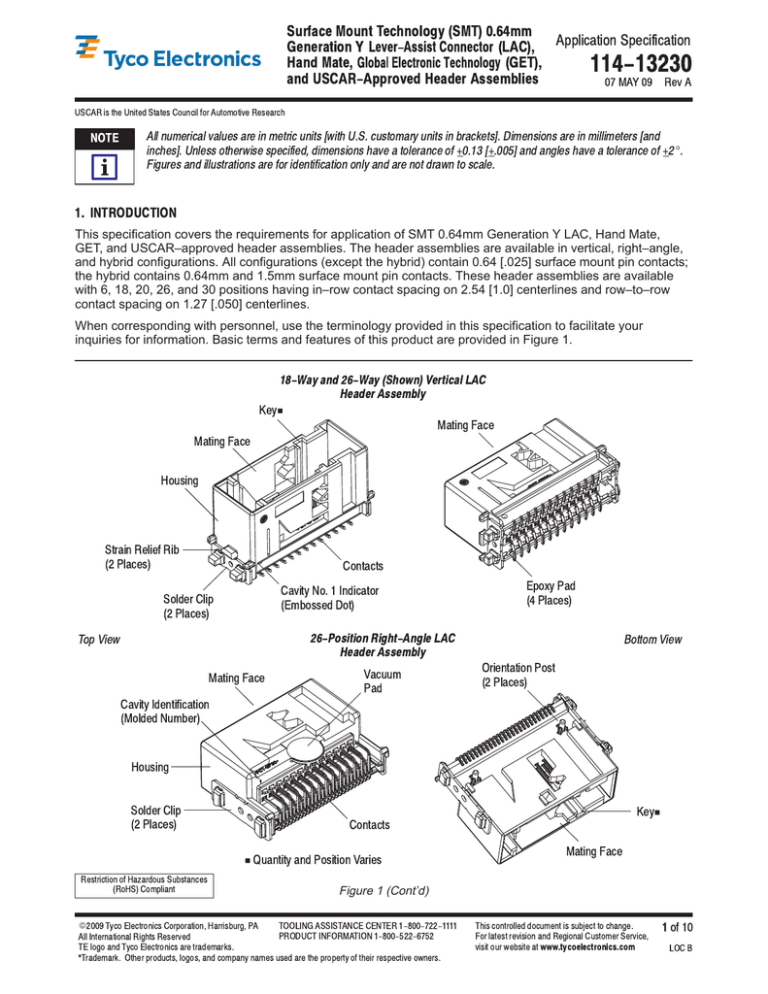

This specification covers the requirements for application of SMT 0.64mm Generation Y LAC, Hand Mate,

GET, and USCAR–approved header assemblies. The header assemblies are available in vertical, right–angle,

and hybrid configurations. All configurations (except the hybrid) contain 0.64 [.025] surface mount pin contacts;

the hybrid contains 0.64mm and 1.5mm surface mount pin contacts. These header assemblies are available

with 6, 18, 20, 26, and 30 positions having in–row contact spacing on 2.54 [1.0] centerlines and row–to–row

contact spacing on 1.27 [.050] centerlines.

When corresponding with personnel, use the terminology provided in this specification to facilitate your

inquiries for information. Basic terms and features of this product are provided in Figure 1.

18-Way and 26-Way (Shown) Vertical LAC

H

Header Assembly

Key

Mating Face

Mating Face

Housing

Strain Relief Rib

(2 Places)

Contacts

Cavity No. 1 Indicator

Solder Clip

(4 Places)

(Embossed Dot)

(2 Places)

Top View

Epoxy Pad

Bottom View

26-Position Right-Angle LAC

Header Assembly

Mating Face

Vacuum

Pad

Orientation Post

(2 Places)

Cavity Identification

(Molded Number)

Housing

H

Solder Clip

Key

(2 Places)

Contacts

H

Quantity and Position Varies

Mating Face

Restriction of Hazardous Substances

(RoHS) Compliant

E

2009 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

Figure 1 (Cont’d)

TOOLING ASSISTANCE CENTER 1-800-722-1111

This controlled document is subject to change.

PRODUCT INFORMATION 1-800-522-6752

For latest revision and Regional Customer Service,

TE logo and Tyco Electronics are trademarks.

*Trademark. Other products, logos, and company names used are the property of their respective owners.

visit our website at www.tycoelectronics.com

1 of 10

LOC B

SMT 0.64mm Generation Y LAC, Hand Mate, GET, and USCAR-Approved Header Assemblies

114-13230

18- and 26-Position (Shown) Vertical Hand Mate

30-Position Vertical Hybrid Hand Mate

Header Assembly

Header Assembly

H

H

Key

Key

Mating Face

Mating Face

Housing

Housing

Strain Relief Rib

Strain Relief Rib

(2 Places)

(2 Places)

Contacts

Contacts

Cavity No. 1 Indicator

Solder Clip

Solder Clip

(Embossed Dot)

(2 Places)

(2 Places)

1

H

20-Position Vertical USCAR-Approved

6 Right-Angle GET

Header Assembly

Header Assembly

Key

H

Key

Cavity No. 1 Indicator

Mating Face

(Molded Number)

Mating Face

Housing

Housing

Strain Relief Rib

Contacts

(2 Places)

Strain Relief Rib

(2 Places)

Solder Clip

(2 Places)

H Quantity and Position Varies

Contacts

Orientation

Solder Clip

Post (2 Places)

(2 Places)

Figure 1 (End)

These header assemblies are available with features that provide proper orientation and strain relief.

Orientation features include a cavity No. 1 indicator (embossed dot) or cavity identification (molded numbers)

and/or orientation posts. For header assemblies without an orientation feature, silkscreen can be used to mark

the silhouette of the header assembly on the pc board to aid in proper orientation during hand placement.

After the header assembly is soldered on the pc board, the solder clips prevent any undue stress from being

transferred onto the contact solder tails. In addition, the header assemblies are designed to accept a

customer–supplied module (cover) to protect the contact solder tails from outside stress. The strain relief ribs

are provided as support points for the module.

The header assemblies can be placed on the pc board by hand or using an automatic machine. The

right–angle LAC header assembly features a vacuum pad for pick–and–place applications. Any of the header

assemblies can be held in place during the soldering process (for example, when using two–sided pc board

application or the pc board is held upside down) by using the epoxy pads. The epoxy pads are designed to

contact epoxy applied to the pc board without compromising the coplanarity of the header assembly.

All of these header assemblies (except the hybrid) mate with cable plug assemblies having 0.64mm terminals;

the hybrid mates with cable plug assemblies having 0.64mm and 1.5mm terminals. The header assemblies are

designed with keys to match the correct mating cable plug assembly and ensure proper orientation during

mating. The cored area on the surface of the housing varies depending on the key. Some keys also have a

color code.

2

of 10

Tyco Electronics Corporation

Rev A

SMT 0.64mm Generation Y LAC, Hand Mate, GET, and USCAR-Approved Header Assemblies

114-13230

2. REFERENCE MATERIAL

2.1. Revision Summary

S Initial release of application specification

2.2. Customer Assistance

Reference Product Base Part Number 1488956 and Product Code K806 are representative of SMT 0.64mm

Generation Y LAC, Hand Mate, GET, and USCAR–approved header assemblies. Use of these numbers will

identify the product line and expedite your inquiries through a service network established to help you obtain

product and tooling information. Such information can be obtained through a local Representative or, after

purchase, by calling PRODUCT INFORMATION at the number at the bottom of page 1.

2.3. Drawings

Customer Drawings for product part numbers are available from the service network. If there is a conflict

between the information contained in the Customer Drawings and this specification or with any other technical

documentation supplied, call PRODUCT INFORMATION at the number at the bottom of page 1.

2.4. Manuals

Manual 402–40 can be used as a guide to soldering. This manual provides information on various flux types

and characteristics with the commercial designation and flux removal procedures. A checklist is included in the

manual as a guide for information on soldering problems.

2.5. Specifications

Product Specification (108–series) provides product performance and test information. There are no

documents available that pertain to this product.

2.6. Instructional Material

Instruction Sheets (408–series) provide product assembly instructions or tooling setup and operation

procedures. There are no documents available that pertain to this product.

2.7. Standards and Publications

Standards and publications developed by the Institute for Interconnecting and Packaging Electronic Circuits

(IPC) provide industry test and performance requirements. Documents available which pertain to this product

are:

IPC–A–610, “Acceptability of Electronic Assemblies”

3. REQUIREMENTS

3.1. Safety

Do not stack product shipping containers so high that the containers buckle or deform.

3.2. Storage

A. Ultraviolet Light

Prolonged exposure to ultraviolet light may deteriorate the chemical composition used in the header

assembly material.

B. Shelf Life

The header assemblies should remain in the shipping containers until ready for use to prevent deformation

to the contacts. The header assemblies should be used on a first in, first out basis to avoid storage

contamination that could adversely affect performance.

C. Chemical Exposure

Do not store header assemblies near any chemical listed below as they may cause stress corrosion

cracking in the contacts.

Alkalies

Amines

Rev A

Ammonia

Carbonates

Citrates

Nitrites

Phosphates Citrates

Sulfur Nitrites

Tyco Electronics Corporation

Sulfur Compounds

Tartrates

3

of 10

SMT 0.64mm Generation Y LAC, Hand Mate, GET, and USCAR-Approved Header Assemblies

114-13230

3.3. PC Board

A. Material and Thickness

The pc board material shall be glass epoxy (FR–4 or G–10). There is no required thickness for the pc

board.

B. Coplanarity of Contact Solder Tails

The respective customer drawing gives the maximum coplanarity of the contact solder tails.

C. Allowable Bow of PC Board

Maximum allowable bow of the pc board over the length of the header assembly is dependent on the

solder paste thickness, coplanarity of the pc board solder pads, and coplanarity of the contact solder tails.

For example, if:

solder paste thickness is 0.20 [.008]

coplanarity of the contact solder tails is 0.13 [.005]

coplanarity of the solder pads is 0.03 [.001]

then: maximum allowable bow of the pc board over the length of the header assembly is 0.04 [.0015]

(0.20 [.008] – 0.13 [.005] – 0.03 [.001] = 0.04 [.0015])

NOTE

Contact must be maintained between the contact solder tails and the solder paste during reflow.

i

D. Solder Pads

The pc board solder pads and solder clip pads must be solderable in accordance with Test Specification

109–11. Maximum allowable coplanarity of the solder pads to the pc board is dependent upon the solder

paste thickness, coplanarity of the contact solder tails, and the bow of the pc board over the length of the

header assembly.

For example, if:

solder paste thickness is 0.20 [.008]

coplanarity of the contact solder tails is 0.13 [.005]

maximum allowable bow of the pc board over the length of the header assembly is 0.04 [.0015]

then: coplanarity of the solder pads is 0.03 [.001]

(0.20 [.008] – 0.13 [.005] – 0.04 [.0015] = 0.03 [.001])

NOTE

Contact must be maintained between the contact solder tails and the solder paste during reflow.

i

E. Holes

The holes for orientation posts must be drilled through to specific dimensions to prevent stubbing during

placement of the header assemblies on the pc board. Hole diameters are provided in the pc board layout

on the customer drawing for the specific header assembly.

F.

Layout

The pads and, if applicable, holes in the pc board must be precisely located to ensure proper placement

and optimum performance of the header assembly. The pc board layout must be designed using the

dimensions provided on the customer drawing for the specific header assembly. A sample of

recommended pc board layouts are shown in Figure 2.

If the epoxy pads are used, a dot of epoxy (for each epoxy pad) must be applied to the pc board before

the header assembly is placed on the pc board. Size and height of epoxy dot is epoxy specific. PC board

location of epoxy dots are provided upon request.

If a silkscreen profile or text is used, space must be allowed for over–printing on the pc board.

4

of 10

Tyco Electronics Corporation

Rev A

SMT 0.64mm Generation Y LAC, Hand Mate, GET, and USCAR-Approved Header Assemblies

114-13230

Sample Recommended PC Board Layout

26-Position Right-Angle LAC

Header Assembly

4X 4.45

0.15

0.1

26X 0.90

0.15

0.05

0.05

X Y

X

25X 1.27

POSN NO REF

5

13 12 11 10 9 8

26X 5.945

0.05

X Y

X

7 6 5 4

5

26X 5.95

26X 5.20

0.15

0.05

3 2 1

0.05

X Y

X

2X 5.47

26 25 24 23 22 21 20 19 18 17 16 15 14

2X 11.33

1.85

0.15

0.1

2X

2X 16.98

4

-X-

4X 8.50

0.15

0.1

0.90

4

-Y-

B

4.855

4

XXX

0.05

X Y

X

0.05

X Y

X

36.055

20-Position Vertical USCAR-Approved

Header Assembly

2X 31.98

4

XXX

2X 4.56

20X

20X

4.35

0.15

0.05

0.05

X Y

X

1.27

0.15

0.05

0.05

X Y

X

-Y-

4.90

55 TYP

4

0.60

TYP

4X 6.00

2X 10.55

XXX

4X 5.00

0.15

0.1

0.05

X Y

X

4

4

-X-

2.54

TYP

5

5

4X 3.00

4X 2.50

0.15

0.1

0.05

X Y

X

4 Datums and Basic Dimensions Established by Customer

5 Allow for Over-Printing on PC Board

Figure 2

Rev A

Tyco Electronics Corporation

5

of 10

SMT 0.64mm Generation Y LAC, Hand Mate, GET, and USCAR-Approved Header Assemblies

114-13230

3.4. Soldering

A. Solder Paste Thickness

The recommended minimum lead or lead–free solder paste thickness is 0.15 when considering coplanarity

of the header assembly only. The thickness can be greater depending on the design of the pc board,

warpage, and solder pad coplanarity.

B. Solder Paste Characteristics

— Alloy type shall be 63 Sn/37 Pb, 60 Sn/40 Pb, or 62 Sn/36 Pb/2 Ag

— Flux incorporated in the paste shall be rosin, mildly active (RMA) type.

— Paste shall be at least 80% solids by volume.

C. Process

The header assembly is compatible with the soldering technique, temperature, and time specified in

Figure 3.

SOLDERING PROCESS

TEMPERATURE (Max)

Non-Focused Infrared (IR) Reflow

Forced Convection Only

_

_

260 C [500 F]

TIME (Max)

30 Seconds

Figure 3

3.5. Silkscreen

Properties of the silkscreen must be customer determined.

3.6. Epoxy

Type and thickness of epoxy and method of application must be customer determined.

3.7. Header Assembly Spacing

Care must be used to avoid interference between adjacent header assemblies and other components to

ensure proper mating. If robotic equipment is used, other space allowances will be required for the grippers.

3.8. Header Assembly Placement

A. Position

It is imperative that the contact solder tines and contact surface of the solder clips are sufficiently pressed

into the solder paste. Optimally, the contact solder tine should be centered on the solder pads; however,

misalignments are permissible as shown in Figure 4. The same requirements apply to the surface of the

solder clips.

PC Board

Contact Solder Tine Centered

on Solder Pad is Optimal

Misalignments of Contact Solder Tine

Permissible Within Limitations Stated in

IPC-A-610

Note: Same Requirements Apply to Contact Surface of Solder Clips

Figure 4

6 of 10

Tyco Electronics Corporation

Rev A

SMT 0.64mm Generation Y LAC, Hand Mate, GET, and USCAR-Approved Header Assemblies

114-13230

3.9. Checking Installed Header Assembly

The installed header assembly must conform to the following (refer to Figure 5):

— the housing must not be bottomed on the pc board

— solder fillets are evenly formed around each contact solder tine and contact surface of the solder clip

— for header assemblies with orientation posts, each orientation post must enter the pc board (amount of

protrusion from the other side of the board depends on the thickness of the board)

— if used, the header assembly epoxy pads must contact the epoxy dot

(epoxy pads must not touch the pc board)

Placement and Inspection

Vertical Header Assemblies

Detail A

Housing Not Bottomed

ÏÏÏÏ

ÏÏÏÏ

on PC Board

ÏÏÏÏ

See Detail C

Contact

See Detail A

Solder Fillet Evenly Formed

With No Visible Cracks

Right-Angle Header Assemblies

Detail B

Housing Not Bottomed

See Detail C

on PC Board

ÏÏ

ÏÏ

See Detail B

ÏÏÏÏ

Contact

Orientation Post (2 Places)

Solder Fillet Evenly Formed

(Shown Through PC Board; Protrusion

With No Visible Cracks

Depends on Thickness of Board)

Detail C

ÏÏÏ

ÏÏÏ

ÏÏÏ ÏÏÏ

ÏÏÏÏÏÏ

Solder Clip

(2 Places)

Solder Fillet Evenly Formed

With No Visible Cracks

Figure 5

Rev A

Tyco Electronics Corporation

7

of 10

SMT 0.64mm Generation Y LAC, Hand Mate, GET, and USCAR-Approved Header Assemblies

114-13230

3.10. Special Assembly Consideration

The header assemblies MUST NOT support the weight of the pc board.

Where applicable, a customer–supplied module (cover) should be installed over the header assemblies. When

installed, the module should contact the header assembly housing and strain relief ribs. Refer to the customer

drawing of the specific header assembly for position and height of the strain relief ribs.

3.11. Keying

Description of keying codes and coordinating housing colors are shown on the customer drawing for the

specific header assembly. Available keying codes and coordinating housing colors are given and samples of

keying codes are shown in Figure 6.

Sample Keying Codes

26-Way Vertical LAC Header Assembly

1

(Ref)

6 Right-Angle GET Header Assembly

(Ref)

A

AE

Keyed Area

Keyed Area

Keyed Area

B

Keyed Area

BE

Keyed Area

Keyed Area

Keyed Area

C

Keyed Area

Keyed Area

BF

Keyed Area

Keyed Area

D

Keyed Area

Keyed Area

Keyed Area

KEYING CODE

COLOR

HEADER ASSEMBLY

AE

Black

BE

Gray or Natural

BF

Blue, Natural, or Purple

CE

Green

CF

Black

A, B, C, D

Black

USCAR-Approved, Hybrid Hand Mate, GET

E, F

Black

USCAR-Approved

LAC, Hand Mate

Vertical LAC

Figure 6

8 of 10

Tyco Electronics Corporation

Rev A

SMT 0.64mm Generation Y LAC, Hand Mate, GET, and USCAR-Approved Header Assemblies

114-13230

3.12. Repair

Defective or damaged header assemblies MUST NOT be used. These header assemblies are not repairable.

The header assembly may be removed from the pc board by standard de–soldering methods and replaced.

4. QUALIFICATION

These header assemblies do not require agency approval.

5. TOOLING

No tooling is required for manual placement of the header assemblies. For automatic machine placement, the

robotic equipment must have a true position accuracy to properly locate the header assemblies. This includes

gripper and fixture tolerances as well as equipment repeatability. It must use the datum surfaces detailed on

the customer drawing to ensure reliable placement.

Rev A

Tyco Electronics Corporation

9

of 10

SMT 0.64mm Generation Y LAC, Hand Mate, GET, and USCAR-Approved Header Assemblies

114-13230

6. VISUAL AID

The illustration below shows a typical application of SMT 0.64mm Generation Y LAC, Hand Mate, GET, and

USCAR–approved header assemblies. This illustration should be used by production personnel to ensure a

correctly applied product. Applications which DO NOT appear correct should be inspected using the

information in the preceding pages of this specification and in the instructional material shipped with the

product or tooling.

VERTICAL HAND MATE

HEADER ASSEMBLY

SHOWN

HOUSING MUST NOT

BE DEFORMED OR

DAMAGED IN ANY WAY

HOUSING MUST NOT BE

BOTTOMED ON PC BOARD

CONTACT SOLDER TINE

MUST NOT BE DEFORMED

SOLDER FILLET FOR SOLDER

CLIPS MUST BE EVENLY FORMED

WITH NO VISIBLE CRACKS

EACH CONTACT SOLDER TINE

MUST BE CENTERED ON PC

CONTACT SURFACE OF

BOARD PAD OR MISALIGNED

SOLDER CLIPS MUST

WITHIN LIMITATIONS STATED

BE ON PC BOARD PAD

IN IPC-A-610

SOLDER FILLET MUST BE EVENLY

RIGHT-ANGLE LAC

HEADER ASSEMBLY

SHOWN

FORMED WITH NO VISIBLE CRACKS

CONTACTS MUST

NOT BE DEFORMED

ORIENTATION POSTS MUST ENTER

PC BOARD (PROTRUSION DEPENDS

ON THICKNESS OF BOARD)

FIGURE 7. VISUAL AID

10

of 10

Tyco Electronics Corporation

Rev A