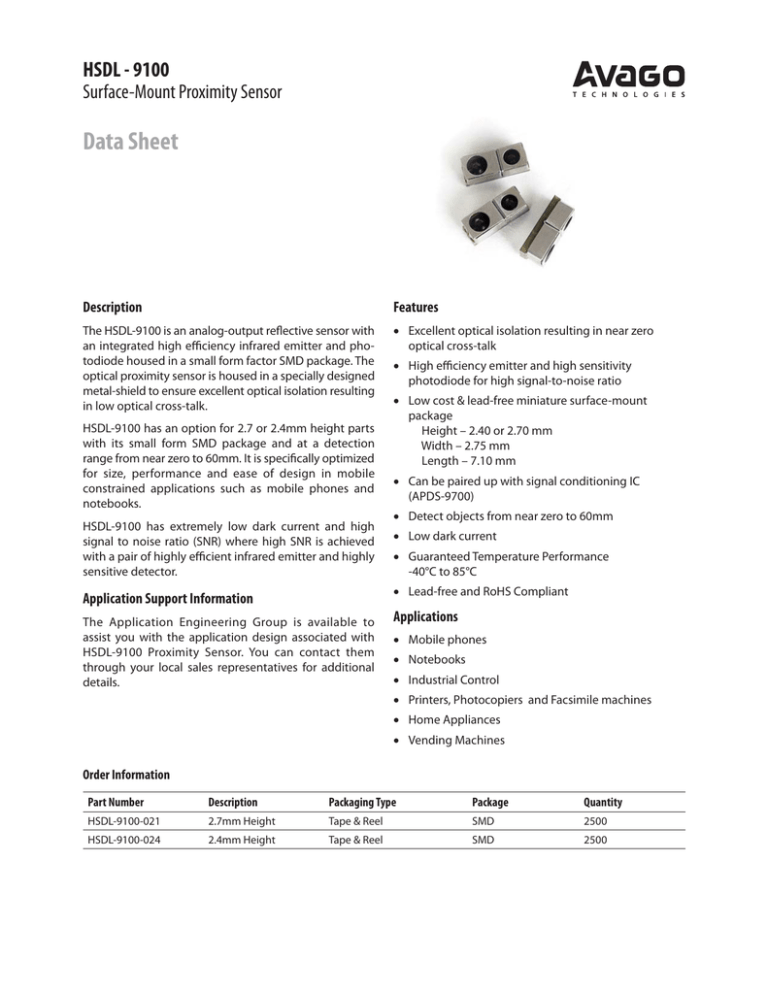

HSDL - 9100

Surface-Mount Proximity Sensor

Data Sheet

Description

Features

The HSDL-9100 is an analog-output reflective sensor with

an integrated high efficiency infrared emitter and photodiode housed in a small form factor SMD package. The

optical proximity sensor is housed in a specially designed

metal-shield to ensure excellent optical isolation resulting

in low optical cross-talk.

x Excellent optical isolation resulting in near zero

optical cross-talk

HSDL-9100 has an option for 2.7 or 2.4mm height parts

with its small form SMD package and at a detection

range from near zero to 60mm. It is specifically optimized

for size, performance and ease of design in mobile

constrained applications such as mobile phones and

notebooks.

HSDL-9100 has extremely low dark current and high

signal to noise ratio (SNR) where high SNR is achieved

with a pair of highly efficient infrared emitter and highly

sensitive detector.

x High efficiency emitter and high sensitivity

photodiode for high signal-to-noise ratio

x Low cost & lead-free miniature surface-mount

package

Height – 2.40 or 2.70 mm

Width – 2.75 mm

Length – 7.10 mm

x Can be paired up with signal conditioning IC

(APDS-9700)

x Detect objects from near zero to 60mm

x Low dark current

x Guaranteed Temperature Performance

-40°C to 85°C

x Lead-free and RoHS Compliant

Application Support Information

The Application Engineering Group is available to

assist you with the application design associated with

HSDL-9100 Proximity Sensor. You can contact them

through your local sales representatives for additional

details.

Applications

x Mobile phones

x Notebooks

x Industrial Control

x Printers, Photocopiers and Facsimile machines

x Home Appliances

x Vending Machines

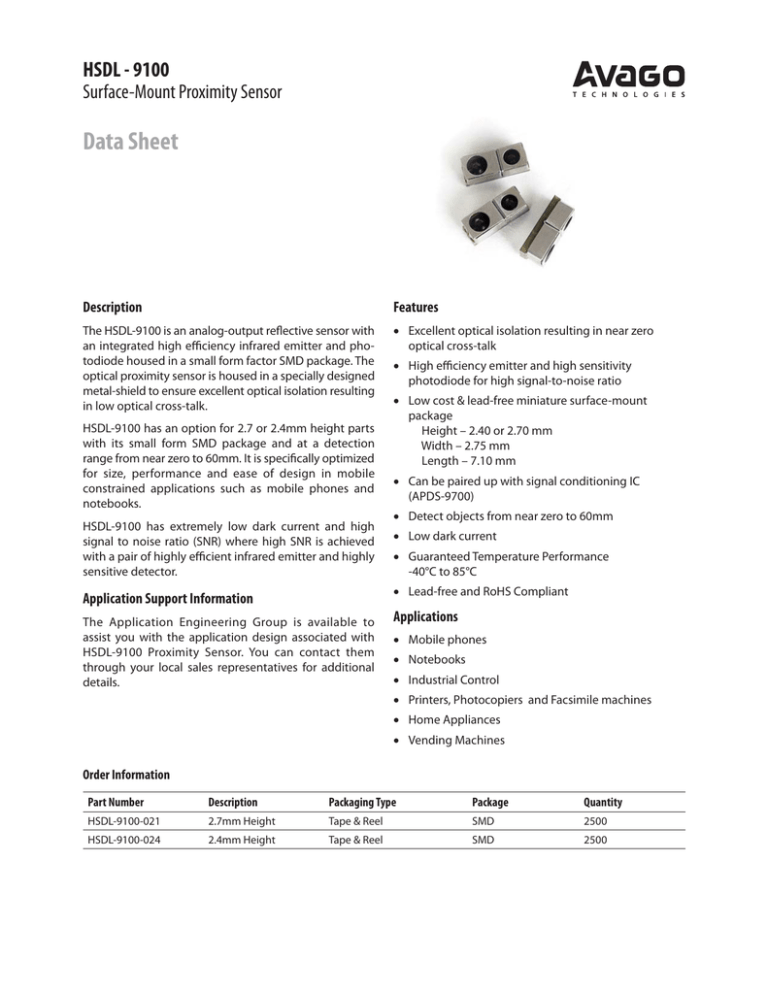

Order Information

Part Number

Description

Packaging Type

Package

Quantity

HSDL-9100-021

2.7mm Height

Tape & Reel

SMD

2500

HSDL-9100-024

2.4mm Height

Tape & Reel

SMD

2500

Block Layout

Pins Configuration Table

Photodiode

LED

1

LED_A

4

DET_K

2

LED_K

3

DET_A

Pin

Symbol

Description

Notes

1

LED_A

LED Anode

1

2

LED_K

LED Cathode

-

3

DET_A

Photodiode Anode

-

4

DET_K

Photodiode Cathode

-

TOP VIEW

Notes:

Voltage to supply across the LED; VLED

Figure 1. Block Layout of HSDL-9100

Absolute Maximum Ratings (Ta=25°C)

Ratings

Parameter

Emitter

Continuous Forward Current

Coupled

Total Power Dissipation (refer to Figure 1)

Operating Temperature

Storage Temperature

Reflow Soldering Temperature

Symbol

Min.

Max

Units

IDC

-

100

mA

PTOT

TOP

TSTG

TSOL

-40

-40

-

165

+85

+100

260

mW

°C

°C

°C

Electrical-Optical Characteristics (Ta=25°C)

Ratings

Parameter

Symbol

Test Condition

Min

Typ

Max

Units

VF

VR

lp

Dp

IF = 100mA

IR = 10PA

IF = 20mA

IF = 20mA

5

-

1.50

940

50

1.65

-

V

V

nm

nm

Detector

Dark Current

Forward Voltage

Reverse Breakdown Voltage

IDark

VF

VBR

VR = 10V, L** = 0

IF = 10mA , L=0

IR = 100uA, L = 0

0.5

-

2

-

10

1.3

35

nA

V

V

Coupled

Output Current

Peak Output Distance

Operating Cross Talk Current

Rise Time (LED)

Fall Time (LED)

Rise Time (Photodiode)

Fall Time (Photodiode)

IO

DO

IFD

TRL

TFL

TRD

TFD

Refer to Fig 2

Refer Note 1

Refer to Fig 3

RL = 50:

RL = 50:

RL = 5.1K:

RL = 5.1K:

-

10

5

50

50

6

6

200

-

PA

mm

nA

ns

ns

Ps

Ps

Emitter

Forward Voltage

Reverse Voltage

Peak Wavelength

Spectrum Width of Half Value

** L = 0 (zero light condition)

Note:

1. ILed = 300mA Pulse, 5% Duty Cycle (Kodak 18% Reflectance Gray Card)

2

Output Current Test Condition (Ta=25°C)

Dark Current Test Condition (Ta=25°C)

LIGHT SEALED DARK BOX

D

KODAK GRAY CARD

18% REFLECTION

PHOTODIODE

LED

PHOTODIODE

LED

IF

IO

IF

IDARK

Figure 2.

Test Condition used are D = 5mm 18% Gray Card,

ILED = 300mA Pulse, 5% Duty Cycle

Figure 3.

Test Condition used are ILED = 300mA Pulse, 5% Duty Cycle

Response Time Test Condition (Ta=25°C)

5mm

KODAK GRAY CARD

18% REFLECTION

INPUT

LED

PHOTODIODE

90%

IF

IO

R LED

PULSE

GENERATOR

RL

OUTPUT

10%

SCOPE

TR

TF

Figure 4. Response Time Test Condition

Typical Radiation Profile for HSDL-9100

1.2

1.1

1.0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0.0

-90 -80 -70 -60 -50 -40 -30 -20 -10 0 10 20 30 40 50 60 70 80 90

Angle (degree)

1.1

1.0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0.0

-90 -80 -70 -60 -50 -40 -30 -20 -10 0 10 20 30 40 50 60 70 80 90

3

Normalized Responsivity

HSDL-9100 Typical Photodiode Angular Responsivity Profile

Normalized radiant intensity

HSDL-9100 Typical LED Angular Emitting Profile

Angle (degree)

Typical Characteristics

Power Dissipation Vs Temperature

200

90

180

80

160

70

140

60

120

Power (mW)

Forward Current

LED Forward Current Vs Temperature

100

50

40

100

80

30

60

20

40

10

20

0

0

0

10

20

30

40

50

60

70

80

0

90

10

20

30

Temperature (˚C)

LED Forward Current Vs Forward Voltage @ Across Temperature

60

70

80

90

(Photodiode) Forward Current Vs Forward Voltage@Across Temp

E-3

0.12

.0

20

25

-25

85

0.1

25

-25

85

1

-3

.0E

0

10

0.08

Forward Current (A)

Forward Current (A)

40

50

Temperature (˚C)

0.06

0.04

-3

.0E

80

-3

.0E

60

-3

.0E

40

0.02

-3

.0E

20

0

0

0.2

0.4

0.6

0.8

1

1.2

1.4

+0

.0E

1.6

0

00

Forward Voltage (V)

0

Forward Current (A) Vs Temperature (degC) @Vcc=1V and 1.3V

0.1

+3

0.09

0.08

0.06

1V

0.05

1.3V

0.04

0.03

0.02

0.01

0

-40

-20

0

20

40

Temperature (˚C)

4

60

80

100

Response Time (us)

Forward Current (A)

0.07

E

1.0 0

+

.0 0E 0

90 E+

0.0

80 E+0

0.0

70 E+0

0.0

60 E+0

0.0

50 E+0

0.0

40 E+0

0.0

30 E+0

0.0

20 E+0

0.0

10 E+0 0.1

0.0

00

0.2

0.4

0.6

0.8

1

Forward Voltage (V)

1.2

1.4

1.6

(Photodiode) Rise/Fall Time Vs Load Resistance@Room Temp,

ILED=300mA Pulse

(Rise

(Fall)

Mean

(Fall)

1

10

100

Load Resistance (kohm)

1000

10000

Output Voltage vs Distance @ Room Temp and RL = 100K

Ohm ILED = 100mA, 200mA and 300mA Pulse

1.0

E-6

(Photodiode) Dark Current Vdet = 3/6/9V vs Across Temperature

3

E+

1.0

3V

300mA

200mA

100mA

6V

1.0

E-9

Dark Current (A)

10

10

0.0

.0E

E-9

-9

Output Voltage (mV)

9V

0

E+

0.0

10

90

+0

.0E

10

0

-40

-20

0

20

40

60

80

100

E+

1.0

2

3

Temperature (˚C)

3mm

4mm

5mm

900

Output Voltage (mV)

800

10 20 30 40 50 60 80 100 120 300 400 450

Distance (mm)

The diagram below illustrates the explanation of edge

distance. Edge detection is labeled as D in the diagram

below.

Output Voltage Vs Edge Distance @ Room Temp

and RL=100K Ohm ILED=300mA, D=3/4/5mm

1000

5

700

600

500

400

300

18% Reflection

Gray Card

200

100

0

-10

-8

-6

-4

-2

0

Edge Distance (mm)

2

4

6

Distance = D(mm)

LED

Distance = -D(mm)

PIN

5mm

5

HSDL-9100 Package Outlines

3.88

2.75

2.35

1.375

R0

R1

.9 0

Mounting Centre

2.48

3.55

Tx

0.10

Rx

0.10

0.8

2.7

6.9

0.05

0.05

7.10

0.625

2.35

3

1

4

Pin 1 - LED Anode

Pin 2 - LED Cathode

Pin 3 - Photodiode Anode

Pin 4 - Photodiode Cathode

0.6

1.1

2.35

2

2

Photodiode

direction mark

Figure 5a. HSDL-9100-021 Package dimensions

3.88

2.75

2.35

1.375

R1

R0

.9

Mounting Centre

2.48

Rx

3.55

Tx

0.1

0.1

0.8

2.4

6.9

0.05

0.05

2.35

0.625

7.10

3

1

4

Photodiode

direction mark

Figure 5b. HSDL-9100-024 Package dimensions

6

2

0.6

1.1

2.35

2

Pin 1 - LED Anode

Pin 2 - LED Cathode

Pin 3 - Photodiode Anode

Pin 4 - Photodiode Cathode

1.55±0.05

1.75

Rx Anode

Tx Cathode

2±0.1

4±0.1

B

7.5

Rx Cathode

Tx Anode

1.5

2.78±0.07

16

7.35±0.1

B-B Section

0.35

5˚ (MAX)

HSDL-9100-021/024 Tape and Reel Dimensions

8±0.1

A

A

2.95±0.1

B

PROGRESSIVE DIRECTION

UNIT: MM

EMPTY

PARTS MOUNTED

LEADER

(400 mm MIN.)

(40 mm MIN.)

EMPTY

(40 mm MIN.)

OPTION #

"B"

"C"

QUANTITY

001

178

60

500

021

330

80

2500

UNIT: mm

DETAIL A

2.0 ± 0.5

B

C

16.4

+2

0

13.0 ± 0.5

R 1.0

LABEL

21 ± 0.8

DETAIL A

2.0 ± 0.5

Figure 6. Tape and Reel Dimensions

7

HSDL-9100 Moisture Proof Packaging

Baking Conditions Chart

All HSDL-9100 options are shipped in moisture proof

package. Once opened, moisture absorption begins.

Units in A Sealed

Moisture-Proof

Package

This part is compliant to JEDEC Level 3.

Baking Conditions

If the parts are not stored in dry conditions, they must

be baked before reflow to prevent damage to the parts.

Package

Temp

Time

In reels

60 °C

t 48hours

100 °C

t4hours

125 °C

t 2 hours

In bulk

Package Is

Opened (Unsealed)

Environment

less than 30 deg C,

and less than

60% RH

Baking should only be done once.

Yes

Recommended Storage Conditions

Storage Temperature

10°C to 30°C

Relative Humidity

below 60% RH

No Baking

Is Necessary

Yes

Time from unsealing to soldering

No

After removal from the bag, the parts should be soldered

within seven days if stored at the recommended storage

conditions.

No

Perform Recommended

Baking Conditions

Figure 7. Baking conditions chart

8

Package Is

Opened less

Than 168 hours

Recommended Reflow Profile

MAX 260°C

T - TEMPERATURE (°C)

255

R3

230

217

200

180

150

120

R2

R4

60 sec to 120 sec

Above 217°C

R5

R1

80

25

0

50

P1

HEAT

UP

Process Zone

100

150

P2

SOLDER PASTE DRY

Symbol

200

P3

SOLDER

REFLOW

'T

250

300

t-TIME

(SECONDS)

P4

COOL DOWN

Maximum 'T/'time

or Duration

Heat Up

P1, R1

25°C to 150°C

3°C/s

Solder Paste Dry

P2, R2

150°C to 200°C

100s to 180s

Solder Reflow

P3, R3

P3, R4

200°C to 260°C

260°C to 200°C

3°C/s

-6°C/s

Cool Down

P4, R5

200°C to 25°C

-6°C/s

> 217°C

60s to 120s

Time maintained above liquidus point , 217°C

Peak Temperature

Time within 5°C of actual Peak Temperature

Time 25°C to Peak Temperature

The reflow profile is a straight-line representation of

a nominal temperature profile for a convective reflow

solder process. The temperature profile is divided into

four process zones, each with different 'T/'time temperature change rates or duration. The 'T/'time rates or

duration are detailed in the above table. The temperatures are measured at the component to printed circuit

board connections.

In process zone P1, the PC board and component pins are

heated to a temperature of 150°C to activate the flux in

the solder paste. The temperature ramp up rate, R1, is

limited to 3°C per second to allow for even heating of

both the PC board and component pins.

Process zone P2 should be of sufficient time duration (100

to 180 seconds) to dry the solder paste. The temperature

is raised to a level just below the liquidus point of the

solder.

260°C

-

> 255°C

20s to 40s

25°C to 260°C

8mins

Process zone P3 is the solder reflow zone. In zone P3, the

temperature is quickly raised above the liquidus point

of solder to 260°C (500°F) for optimum results. The

dwell time above the liquidus point of solder should be

between 60 and 120 seconds. This is to assure proper

coalescing of the solder paste into liquid solder and the

formation of good solder connections. Beyond the recommended dwell time the intermetallic growth within

the solder connections becomes excessive, resulting in

the formation of weak and unreliable connections. The

temperature is then rapidly reduced to a point below

the solidus temperature of the solder to allow the solder

within the connections to freeze solid.

Process zone P4 is the cool down after solder freeze.

The cool down rate, R5, from the liquidus point of the

solder to 25°C (77°F) should not exceed 6°C per second

maximum. This limitation is necessary to allow the PC

board and component pins to change dimensions evenly,

putting minimal stresses on the component.

It is recommended to perform reflow soldering no more

than twice.

9

Appendix A: HSDL-9100 SMT Assembly Application Note

Recommended Metal solder Stencil Aperture

Table 1. Combinations of metal stencil aperture and metal

stencil thickness

0.6

2.75

0.5

0.6

7.7

7.1

0.6

It is recommended that only a 0.152 mm (0.006 inch) or

a 0.127 mm (0.005 inch) thick stencil be used for solder

paste printing. This is to ensure adequate printed solder

paste volume and no shorting. See Table 1 below the

drawing for combinations of metal stencil aperture and

metal stencil thickness that should be used. Aperture

opening for shield pad is 3.05 mm x 1.1 mm as per land

pattern.

0.525

Recommended land pattern

2.1

2.4

Solder / stencil opening for each pad is 2.4mm x0.6mm

Figure 10. Land Pattern

Stencil

Aperture size (mm)

thickness,

t (mm)

Length,

l

Width,

w

0.152

1.60+/-0.05

0.55+/-0.05

0.127

1.92

0.55+/-0.05

Apertures as per

Land Dimensions

t

l

w

Adjacent Land Keep out and Solder Mask Areas

Adjacent land keep out is the maximum space occupied

by the unit relative to the land pattern. There should be

no other SMD components within this area. The minimum

solder resist strip width required to avoid solder bridging

adjacent pads is 0.2mm.It is recommended that two

fiducial crosses be placed at mid length of the pads for

unit alignment. Also do take note that there should not

be any electrical routing with the component placement

compartment.

Figure 11. Solder stencil aperture

k

Component placement

j

h

Note:

Wet/Liquid Photo-imaginable solder resist/mask is recommended

Mounting Center

Solder Mask

Solder Pad, Mask and Metal Stencil

l

Metal stencil for

solder paste printing

Stencil Aperture

Land Pattern

Dim.

mm

h

4.15

l

11

k

5.5

j

3.5

Figure 12. Keep-out area

Solder Mask

PCBA

Figure 9. Stencil and PCBA

10

Appendix B: General Application Guide for the HSDL-9100

Description

Interface to the Recommended I/O chip

The Proximity sensor has several possible applications for

multimedia product, Automation, and Personal handled.

The proximity sensor is basically made up of the emitter

(infrared LED) and detector (photodiode). The block

diagram of the sensor is shown in Figure 13. The emitter

will emit IR light pulse. This light travels out in the field

of view and will either hit an object or continue. No light

will be reflected when no object is detected. On the other

hand, the detector will detect the reflected IR light when

it hits the object.

The HSDL-9100 is general interface with the GPIO pin of

the controller chipset. The LED_A, pin1 is connected to

the PWM port alternatively the external timer circuitry

can be used to drive the LED. The DET_K, pin 4 is interface

to the signal conditioning before driving the GPIO port.

Figure 14 shows the hardware reference design with

HSDL-9100.

Photodiode

3

4

Photodiode

anode

Photodiode

cathode

2

1

LED

anode

LED

cathode

LED

Figure 13. Proximity sensor block diagram

(refer to Pins Configuration Table)

Key Pad

STN/TFT LCD Panel

LCD Control

Touch Panel

Peripherial

interface

A/D

IrDA

interface

Mobile Application

chipset

Memory Expansion

Logic Bus Driver

Memory I/F

Baseband

controller

ROM

Power Management

IR Transceiver

GPIO

AC97

sound

PCM Sound

I2S

Audio Input

PWM

Antenna

FLASH

*IR LED driver

SDRAM

Signal Conditional

*

The LED can be driven by the PWM output or the external timer circuitry.

Figure 14. Mobile Application Platform

11

HSDL-9100

The next section discusses interfacing configuration with

general processor including the recommended signal

conditional circuitry.

The DET_A pin of HSDL-9100 is connected to the filter

circuit then to the comparator before interfacing with

the GPIO pin. The filter circuit is implement to provide

the ambient light filter. The PWM is pulse to drive the

LED_K pin alternative the external timer 555 can also be

replaced. The detector distance can be varies with the

increase/decrease of the LED current supply.

Interfacing circuitry with signal conditional circuitry

VCC

HSDL-9100

DETK

DETA

LEDA

LEDK

PWM

VCC

220 Ω

VCC

36 KΩ

BC848

22 KΩ

220 pf

10 Ω

BC846B

24 KΩ

GND

GND

1 MΩ

VCC

GND

47 kΩ

GPIO

300 Ω

controller chipset

GND

Signal conditioning circuitry

Figure 15. HSDL9100 configuration with controller chipset

12

Appendix C: Recommended window and light guide for HSDL-9100

x Using opaque material of light pipes with two holes as

light path. The structure need to be carefully designed

to minimize the signal loss and crosstalk. (See option 3)

Close to the window

Material #

Light

Transmission

Haze

Refractive

Index

Lexan 141

88%

1%

1.586

Lexan 920A

85%

1%

1.586

Lexan 940A

85%

1%

1.586

Note:

920A and 940A are more flame retardant than 141.

Recommended Dye: Violet #21051 (IR transmissant above 625 nm)

For product information and a complete list of distributors, please go to our web site: www.avagotech.com

Avago, Avago Technologies, and the A logo are trademarks of Avago Technologies in the United States and other countries.

Data subject to change. Copyright © 2005-2009 Avago Technologies. All rights reserved. Obsoletes AV02-0779EN

AV02-2259EN - November 26, 2009

Flat Window (Transmission rate >85%)

Recommended Plastic Materials:

Photodiode

Photodiode

Option 3

LED

Flat Window (Transmission rate >85%)

Recommended Window Material

Almost any plastic material will work as a window material. Polycarbonate is recommended. The surface finish

of the plastic should be smooth, without any texture.

The thickness of the window material is recommended

to be less than 0.5mm. An IR filter dye may be used in

the window to make it look black to the eye but the total

optical loss of the window should be 10% or less for best

optical performance. Light loss should be measured at

875nm. The recommended plastic materials for use as a

cosmetic window are available for General Electric Plastics.

Option 2

Option 1

LED

x Using separate pieces of light guide bonded together

for emitter and photo sensor respectively. Insert a baffle

in between the two light guides. (See option 4)

Photodiode

Photodiode

x Using baffle in between emitter and detector will

reduce the crosstalk caused by bottom surface. It is recommended to extend the baffle into the flat window as

to reduce the crosstalk caused by top surface too. (See

option 2)

Flat Window (Transmission rate >85%)

x Put the optical sensor close to the window material.

(See option 1)

LED

Flat Window (Transmission rate >85%)

LED

Some constraints on the design and position of the window are required so that the cross talk from the emitter

to the photodiode is minimized. Four recommendations

of window design are suggested as below:

Option 4