Determining the Time Constant of Buildings

advertisement

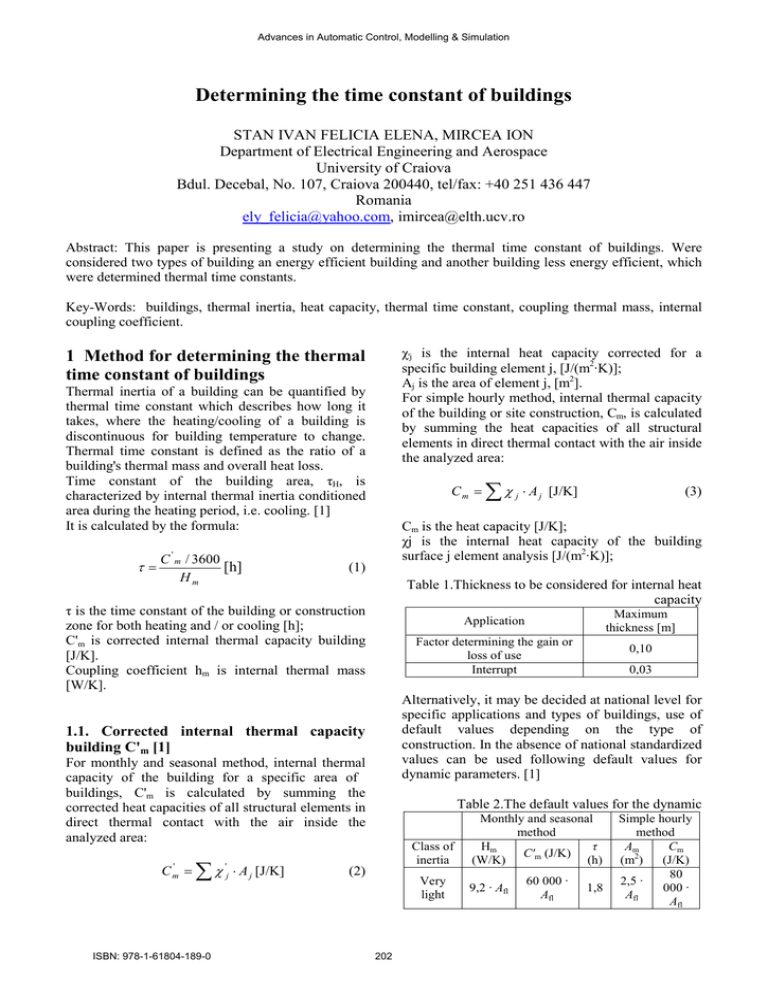

Advances in Automatic Control, Modelling & Simulation Determining the time constant of buildings STAN IVAN FELICIA ELENA, MIRCEA ION Department of Electrical Engineering and Aerospace University of Craiova Bdul. Decebal, No. 107, Craiova 200440, tel/fax: +40 251 436 447 Romania ely_felicia@yahoo.com, imircea@elth.ucv.ro Abstract: This paper is presenting a study on determining the thermal time constant of buildings. Were considered two types of building an energy efficient building and another building less energy efficient, which were determined thermal time constants. Key-Words: buildings, thermal inertia, heat capacity, thermal time constant, coupling thermal mass, internal coupling coefficient. χ'j is the internal heat capacity corrected for a specific building element j, [J/(m2·K)]; Aj is the area of element j, [m2]. For simple hourly method, internal thermal capacity of the building or site construction, Cm, is calculated by summing the heat capacities of all structural elements in direct thermal contact with the air inside the analyzed area: 1 Method for determining the thermal time constant of buildings Thermal inertia of a building can be quantified by thermal time constant which describes how long it takes, where the heating/cooling of a building is discontinuous for building temperature to change. Thermal time constant is defined as the ratio of a building's thermal mass and overall heat loss. Time constant of the building area, τH, is characterized by internal thermal inertia conditioned area during the heating period, i.e. cooling. [1] It is calculated by the formula: τ= C ' m / 3600 [h] Hm Cm = (1) ISBN: 978-1-61804-189-0 ⋅ A j [J/K] (3) Maximum thickness [m] Application Factor determining the gain or loss of use Interrupt 0,10 0,03 Alternatively, it may be decided at national level for specific applications and types of buildings, use of default values depending on the type of construction. In the absence of national standardized values can be used following default values for dynamic parameters. [1] For monthly and seasonal method, internal thermal capacity of the building for a specific area of buildings, C'm is calculated by summing the corrected heat capacities of all structural elements in direct thermal contact with the air inside the analyzed area: ' j ⋅ A j [J/K] Table 1.Thickness to be considered for internal heat capacity 1.1. Corrected internal thermal capacity building C'm [1] ∑χ j Cm is the heat capacity [J/K]; χj is the internal heat capacity of the building surface j element analysis [J/(m2·K)]; τ is the time constant of the building or construction zone for both heating and / or cooling [h]; C'm is corrected internal thermal capacity building [J/K]. Coupling coefficient hm is internal thermal mass [W/K]. C m' = ∑χ Table 2.The default values for the dynamic Class of inertia (2) Very light 202 Monthly and seasonal method Hm τ C'm (J/K) (W/K) (h) 9,2 · Afl 60 000 · Afl 1,8 Simple hourly method Am Cm (m2) (J/K) 80 2,5 · 000 · Afl Afl Advances in Automatic Control, Modelling & Simulation Class of inertia Monthly and seasonal method Hm τ C'm (J/K) (W/K) (h) Light 9,2 · Afl 83 000 · Afl 2,5 Average 9,2 · Afl 124 000 · Afl 3,7 Heavy 9,9 · Afl 195 000 · Afl 5,5 Very heavy 10,4 · Afl 278 000 · Afl 7,4 annual values of heat transfer coefficients of transmission and ventilation. Simple hourly method Am Cm (m2) (J/K) 110 2,5 · 000 · Afl Afl 165 2,5 · 000 · Afl Afl 260 3,0 · 000 · Afl Afl 370 3,5 · 000 · Afl Afl 2.2. Simplified hourly method [2] The model is a simplification of dynamic simulation, taking into account the following considerations: - Same level of transparency, reproducibility and robustness as monthly method; - Be clearly specified a limited set of equations, allowing calculation traceability process; - Reduce as much as possible of the input data; - Unambiguous calculation procedure; - The main advantage it has is monthly intervals method that allows direct input of hourly models. Afl is useful surface room [m2]; 2 Simplified method Coupling thermal mass [1] schedule. 2.1. Simplified method and data on the dynamic Internal coupling coefficient of thermal mass of the building area is obtained using the following equation for calculating: H m = (H tr + H ve ) [W/K] (4) Htr - heat transfer coefficient by transmission [W/K]; The values for the coefficient of heat transmission, Htr,k of k element is calculated in accordance with ISO/ DIS 13789:2005, taking into account standards for specific, such as windows (ISO/DIS 100771:2004) walls and roofs (ISO/DIS 6946:2005) curtain wall (prEN 13947), etc.. Heat transfer coefficient of heat transmission Htr,k takes into account the temperature θe,k is the temperature θe for outdoor use. For simple hourly method requires a distinction between structural elements glazing (windows, doors, curtain walls, glazed elements provided) and compact elements. H ve ,k = ρ a ⋅ c a ⋅ q ve ,k [W/K] Fig.1. Electrical model of a wall with five resistance and capacity [2] Internal coupling coefficient of thermal mass of the building area is obtained using the following equation for calculating: Hm = (5) 1 1 + H is H ms [W/K] (6) His and Hms coupling coefficients, calculated for simple hourly method: Hve,k is the coefficient of heat transfer by ventilation air circulation element k in the temperature θs,k [W/K]; qve,k is the flow of air in the conditioned space, determined in accordance with standards, [m3/s]; ρa·ca that is heat capacity of air volume=1200[J/ (m3·K)], or ρa·ca = 0, 34 Wh/(m3K); Htr and Hve values can be calculated as the average ISBN: 978-1-61804-189-0 1 His = his ⋅ At [W/K] (7) At = Rat ⋅ A fl (8) With: 203 Advances in Automatic Control, Modelling & Simulation opaque building elements, Hop, and divided into Hem and Hms; - Hv ventilation and process characteristics θsup air; - His coupling conductance [W/K]; - Cm internal heat capacity [J/K]. His is the coupling conductance between nodes i and s [W/K]; At is the total area of the room surfaces [m2]; Afl is useful surface room [m2]; His is the heat transfer coefficient between nodes i and s, with fixed value hsi = 3, 45 [W/ (m2K)]; Rat is the dimensionless ratio of surface areas and internal floor area, Rat can be assumed to be equal to 4, 5. Sizing system used to calculate Afl (internal dimensions, external dimensions or size) may be set nationally, but must be specified. [3] If necessary, useful surface area of a building is determined in a similar manner for each building area calculation. Sum of all the useful surface area equals the usable area of the building. Coupling coefficient table, monthly and seasonal Hm methods: Table 3. Heat storage materials and their physical properties [4] clay brick sand wood concrete glass aluminum iron steel earth magnet water His = 3, 45·At, At = 4,5·Afl, Hms = 9,1·Am; Internal heat capacity corrected for monthly and seasonal method: Split transmission heat transfer coefficient, Htr, for opaque elements Hop in Hem and Hms is obtained as follows: 1 [W/K] 1 1 − H op H ms C m2 ∑A j ⋅ χ 2j [m2] Material d [cm] m [kg/m³] cs [kJ/(kgK)] λ [W/(mK)] Afl [m2] (9) Coating 2 Concrete 20 2400 1,08 2,1 1800 1,08 0,87 10,04 U-value: 2, 6439 W/ (m²K) Heat capacity: 557, 28 kJ/ (m²K) Exterior wall Material d [cm] m [kg/m³] cs[kJ/(kgK)] λ[W/(mK)] Afl [m2] (10) Exterior plaster Polystyrene Concrete Interior plaster 1 10 20 2,5 1800 1,08 0,87 30 1,8 0,04 2400 1,08 2,1 1800 1,08 0,87 10,04 U-value: 0, 35645 W/ (m²K) Heat capacity: 591, 84 kJ/ (m²K) 2.3. Determine the main variables of the method: Foundation plate The main variables of the model are: -heat transfer coefficients at the doors, windows, curtain walls and walls made of glass Hw and ISBN: 978-1-61804-189-0 Volumetric heat capacity [106J/m3K] 1,28 1,51 1,57 1,67 1,76 2,27 2,43 3,57 3,68 3,77 3,89 4,17 Less energy efficient building [5] Interior wall And Hms = hms · Am; Hms is the coupling conductance between nodes m and s [W/K]; hms is the heat transfer coefficient between nodes m and with a fixed value hms = 9,1 [W/(m2·K)]; Am is the effective mass area [m2]. Effective mass area Am, is calculated by the formula: Am = Specific heat [J/kgK] 879 837 712 2390 880 837 896 452 465 1840 752 4182 We will determine the value of thermal constant for a less energy efficient building and energy efficient building having walls composed of the following structures: C'm = 0, 75·Cm H em = Material density [kg/m3] 1458 1800 2200 700 2000 2710 2710 7900 7840 2050 5177 988 Material 204 Material Concrete d 20 Mineral wool 10 Sound insulation 2 Plast er 4 Advances in Automatic Control, Modelling & Simulation Material Concrete Mineral wool Sound insulation Plast er 2400 45 20 1080 [cm] m [kg/m³] U-value: 0, 11893 W/ (m²K) Heat capacity: 920, 67 kJ/ (m²K) Roof Material cs [kJ/(kgK)] λ [W/(mK)] Afl [m2] 1,08 1,8 1 1,8 2,1 0,04 0,035 0,87 d [cm] m [kg/m³] cs[kJ/(kgK)] λ[W/(mK)] Afl [m2] 67,60 Mineral wool 10 45 1,8 0,04 80,93 OSB 15 600 1,98 0,13 U-value: 0, 26073 W/ (m²K) Heat capacity: 205, 74 kJ/ (m²K) Table 4.Determine the main variables of simplified hourly method less energy efficient building Energy efficient building Interior wall Material d [cm] m [kg/m³] cs [kJ/(kgK)] λ [W/(mK)] Afl [m2] Plaster 2 1800 2400 0,35 Concrete 20 2400 1,08 2,1 χ [j/m2K] Aj [m2] Cm [J/K] 10,4 C'm [J/K] U-value: 2, 4249 W/ (m²K) Heat capacity: 557, 28 kJ/ (m²K) His[W/K] Hms[W/K] At[m2] Am[m2] Hm [W/K] Exterior wall Material Concrete d [cm] m [kg/m³] c s[kJ/(kgK)] λ [W/(mK)] Afl [m2] 20 2400 Mineral wool 15 45 1,08 2,1 20 30 Plast er 5 1800 0,504 1,8 1,8 1,8 0,35 0,35 Polystyrene Foundation plate d [cm] m [kg/m³] cs[kJ/(kgK)] λ[W/(mK)] Afl [m2] 35 2400 1,08 2,1 Extruded polystyrene ISBN: 978-1-61804-189-0 20 30 1,8 0,04 67,60 Mineral wool 10 45 0,504 0,04 Exterio r wall Foundation plate 591840 604660 10,40 615513 6 461635 2 35,88 9,877 10,4 1,08 45,75 67,60 40875016 30656262 233,22 435,61 67,6 47,87 668,83 Roof 2057 40 80,93 1665 0538 1248 7904 279,2 72,28 80,93 7,94 351,4 Building type Less energetically Energetically efficient efficient building building Afl Structur Afl τ1 Structure τ2 [h] [m2] e [m2] [h] Interior 26,4 Interior 28,93 10.4 10.4 wall 6 wall 9 Exterior 28,0 Exterior 10.4 10.4 32,54 wall 2 wall Foundati 12,7 Foundat 67.6 67.60 16,64 on plate 3 ion plate 0 80.9 Roof 80.93 9,86 Roof 1,72 3 77,0 Total 79,83 7 10,4 Concrete Interio r wall 55728 0 10,04 55950 91 41963 18 35,88 8,162 10,4 0,89 44,047 Table 5. Thermal time constant values,τ for the analyzed buildings U-value: 0,096079 W/ (m²K) Heat capacity: 629, 8 kJ/ (m²K) Material Sound insulation 1 20 1 0,035 We will determine building thermal constant for the two types of buildings analyzed using computer relationship (1). To determine the thermal constant of the building,τ, for both types of buildings analyzed, using equation (1) calculation, we determine the main variables used in the simplified hourly method using relations (2) and (6). Roof Plaster 1 1800 1,08 0,87 Mineral Mineral wool wool 20 20 45 45 0,504 0,504 0,04 0,04 80,93 U-value: 0,095511 W/ (m²K) Heat capacity: 28,712 kJ/ (m²K) U-value: 0, 29563 W/ (m²K) Heat capacity: 604, 66 kJ/ (m²K) Material d [cm] m [kg/m³] cs [kJ/(kgK)] λ [W/(mK)] Afl [m2] Gypsum plaster 1 1800 1,08 0,7 Sound insulat ion 2 20 1 0,035 205 Advances in Automatic Control, Modelling & Simulation Table 6.Determine the main variables of the simplified hourly method for building energy efficient χ [j/m2K] Aj [m2] Cm [J/K] C'm [J/K] His [W/K] Hms [W/K] At [m2] Am [m2] Hm [W/K] 35 Interior wall Exterio r wall Foundatio n plate Roof 557280 629800 920670 28712 10,04 10,40 67,60 80,93 5595091 4196318 654992 0 491244 0 3 Conclusions This paper presents a study regarding a comparation for the thermal constant of buildings for two different buildings: an energy efficient building and another building less energy efficient From the analysis it can be seen that the time constant of less energy-efficient building is smaller than the time constant for energy efficient buildings, the total value of τ1 = 77,07 compared with τ2 = 79,83, so that the higher the time constant value is the inside temperature is more stable to external temperature variations. Intermittent heating saves energy even higher as the room (building) has a smaller time constant, the higher the temperature is higher and the more usage time is less. So if you subtract heat transfer coefficient of the building envelope insulation, high performance windows that are used in terms of thermal resistance, energy savings through lower intermittent heating. 23236 62 17427 47 279,20 85 62237292 46677969 35,88 35,88 233,22 4,40 6,04 545,56 0,760 10,4 10,4 67,6 80,93 0,48 0,66 59,95 0,08 40,29 41,92 778,78 279,97 References: [1]. ISO TC 163/SC 2/N02, Energy performance of buildings - Calculation of energy use for space heating and cooling 2006, pg. 58 -60. [2]. ISO TC 163/SC 2/N02, „Energy performance of buildings - Calculation of energy use for space heating and cooling”, 2006, Annex C, Full set of equations for simple hourly method pg. 82. [3]. ISO TC 163/SC 2/N02, „Energy performance of buildings - Calculation of energy use for space heating and cooling”, 2006, pg. 23, 24. [4]. Tuohy et al, „Masa termică, izolaŃie şi ventilaŃie în locuinŃe durabile” - 2004 . [5]. Stan Ivan Felicia E., „Studiul eficienŃei energetice şi economice a clădirilor”, Anexa 2.1. Caracteristici structuri pereŃi pentru cele două tipuri de clădiri analizate, 2009. Thermal time constant for the two buildings analyzed t1 [h] 30 t2 [h] V a l u e [h ] 25 20 15 10 5 0 1 2 3 4 Fig. 2. Comparisons between time constants of the two buildings analyzed ISBN: 978-1-61804-189-0 206