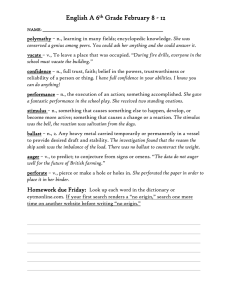

Application of axiomatic design, TRIZ, and mixed integer

advertisement

Int J Adv Manuf Technol (2012) 61:827–842

DOI 10.1007/s00170-011-3752-1

ORIGINAL ARTICLE

Application of axiomatic design, TRIZ, and mixed integer

programming to develop innovative designs: a locomotive

ballast arrangement case study

Gül Okudan Kremer & Ming-Chuan Chiu &

Chun-Yu Lin & Saraj Gupta & David Claudio &

Henri Thevenot

Received: 1 September 2010 / Accepted: 7 November 2011 / Published online: 5 January 2012

# Springer-Verlag London Limited 2011

Abstract In this paper, we present a method incorporating

axiomatic design, TRIZ, and mixed integer programming

(MIP) to solve engineering design problems. Axiomatic

design decomposes the problem into several mutually

G. O. Kremer (*)

School of Engineering Design, The Pennsylvania State University,

213T Hammond Building,

University Park, PA 16802, USA

e-mail: gkremer@psu.edu

G. O. Kremer : C.-Y. Lin : S. Gupta

Department of Industrial and Manufacturing Engineering,

The Pennsylvania State University,

310 Leonhard Building,

University Park, PA 16802, USA

C.-Y. Lin

e-mail: czl134@psu.edu

S. Gupta

e-mail: sgupta@dresser-rand.com

M.-C. Chiu

Department of Industrial Engineering and Engineering

Management, National Tsing Hua University,

Hsinchu, Taiwan 30013, Republic of China

e-mail: mcchiu@ie.nthu.edu.tw

D. Claudio

Department of Mechanical and Industrial Engineering,

Montana State University,

Bozeman, MT 59717-3800, USA

e-mail: david.claudio@ie.montana.edu

H. Thevenot

GE Transportation,

2901 East Lake Road,

Erie, PA 16531, USA

e-mail: henri.thevenot@ge.com

independent sub-problems, TRIZ generates all feasible

design concepts, and MIP optimizes cost and the numerical

configuration among available design options. The method

is illustrated on a locomotive ballast arrangement case

study. Ballast arrangement is a key process for a locomotive

assembly, which determines the carrying capacity. Due to

the unsophisticated technology requirements, the ballast

arrangement process has received little attention. The trend

of mass customization, however, demands locomotive manufacturers to provide diverse products with affordable cost and

reduced time. Thus, a flexible and easy to implement ballast

arrangement process design is sought. The proposed method

determines what material combinations, in what quantity, and

where in the limited cavities should the ballast be allocated to

minimize cost. Using the case study, we demonstrate the

advantages in cost reduction and time savings. The synergy of

these improvements not only can enhance productivity and

agility but also competitive advantage.

Keywords Axiomatic design . TRIZ . MIP .

Design for manufacturability

Notations

Index sets

f

g

h

i

J={1,…, Nj}

K={1,…, Nk}

The ballast located in center front area of

the locomotive

The ballast located in center back area of

the locomotive

The ballast located in front end area of

the locomotive

The ballast located in back-end area of

the locomotive

The different locomotive models, j ∈J

Different types of ballast materials, k ∈K

828

Decision variables

Wkfj Total weight of ballast type k in the center front

center area f of model j

Wkgj Total weight of ballast type k in the center back area

g of model j

Wkhj Total weight of ballast type k in the front end area

h of model j

Wkij Total weight of ballast type k in the back-end area i

of model j

C

Total cost which is the summary of all models

BPj Binary variable that controls the balance percentage.

It will be 1 when front end is heavier than back-end,

otherwise 0.

BNj Binary variable that controls the balance percentage.

It will be 1 when back-end is heavier that front end,

otherwise 0.

PXj Number of standard X weight box in the center area

of f and g of model j

PYj Number of standard Y weight box in the center area

of f and g of model j

PZj

Number of standard Z weight box in the center area

of f and g of model j

Parameters

Density of ballast type k

Dk

VF

Available volume in front end of all models

VE

Available volume in back-end of all models

VC Available volume in center end of all models

Ck

Unit cost of ballast type k

TWj Total weight requirement of model j

BI

Balance index of the weight difference between

frond-end and back-end of locomotive

WX Unit weight of the standard ballast type X

WY Unit weight of the standard ballast type Y

WZ Unit weight of the standard ballast type Z

1 Introduction

As global technology competition becomes fiercer, an

ability to solve engineering and technology problems

expeditiously becomes critical for the survival of individual

businesses and entire industries [1]. As such, numerous

problem solving techniques have been devised to solve a

variety of industrial problems. However, every tool does

not suit every application, and hence, it is essential that the

right tool be selected for the application at hand. Based on

their review of the state of the art, Shirwaiker and Okudan

[2] have proposed and demonstrated the effective use of

TRIZ and axiomatic design as appropriate tools for

engineering design problems in general (e.g., product

design and manufacturing process design problems). In this

paper, we append to the synergistic use of TRIZ and

Int J Adv Manuf Technol (2012) 61:827–842

axiomatic design (AD) by showing the need for optimization, and then illustrate the use of the modified method on a

locomotive ballast arrangement case study.

Ballast to a locomotive is a “sweet loading.” It aims to

provide sufficient force so that a locomotive can pull the

cars by increasing its weight. Extra weight will waste

energy, while insufficient weight will reduce the capacity of

a locomotive. Hence, the precise weight control of the

ballast is important. In addition to weight, balance is

another critical concern in ballast arrangement. The weight

difference between the front half and the back half, as well

as the left-hand side and the right-hand side of a locomotive

should be less than 1%.

Traditional ballast construction process is completed

through stacking both metal scrap and slab into specific

ballast cavities inside the locomotive platform. The space is

limited and metal slab is expensive, so the metal scrap is

allocated as much as possible during the construction process.

However, there are several drawbacks in the current process.

First of all, the metal scrap, which is purchased from recycling

facilities, has a variant density. Accordingly, the operators

have to measure weight and balance of locomotive body using

huge scales several times during the stacking process.

Furthermore, unsteady market demand pressures the

manufacturers to produce locomotives in various weights for

diverse purposes, bringing chaos to the shop floor when

shipping schedules change. The ballast construction departments have high work in process (WIP) and very long cycle

times. Finally, the rising cost of metal slab and metal scrap

compresses the revenue. Survey of cheaper alternatives is

necessary. Based on the above mentioned reasons, the need for

the development of a flexible ballast loading process design is

deemed important, and hence is the focus. In the paper, we

present a synergistic approach, which utilizes axiomatic

design (AD), theory of inventive problem solving (TRIZ),

and mixed integer programming model, to solve this problem.

The paper is organized in the following manner:

Section 2 presents a literature review and the rational for

the proposed method. In Sections 3 and 4, we present the

proposed methodology, and then provide its illustration on

the ballast arrangement case study. Finally, conclusions are

provided in Section 5.

2 Literature review

Theory of inventive problem solving technique (TRIZ),

developed by Genrich Altshuller in 1946, is a systematic

ideation technique. After studying more than one million

patents, Altshuller found that problems and their solutions

tend to be repeated across a range of industrial and

scientific situations, and that the patterns of technological

evolution incline to repeat both in industrial applications

Int J Adv Manuf Technol (2012) 61:827–842

and sciences. Accordingly, inventions often made use of

scientific effects that were developed in unrelated areas.

Therefore, the problem solving ways may be repeatable and

predictable. From viewpoint of TRIZ, every factor that

affects a system can be defined as a parameter. There is a

dependency relationship between the parameters of the

system. While improving some parameters with positive

effects to system, some of the other parameters might have

negative effects. This results in a contradiction. Altshuller

asserts that an invention occurs when a contradiction

between parameters is solved. Based on this hypothesis,

TRIZ structures a problem into a “contradiction statement”

and derives solutions that address the problem statement

both from technical and system perspectives. Hence, the

ideality of the design increases while a parameter is

improved without worsening the other parameter [3–5]. In

this manner, TRIZ demonstrates the capability as a support

tool for original idea creation. In this study, we applied the 39

engineering parameters, 40 innovative principles, and the

contradiction matrix to generate new ballast design concepts.

TRIZ has been used in synergistic ways with other

methods (e.g., QFD [5], AHP [6, 7], DFMA [8], and

function-based design [9]). Its effectiveness in idea generation has also been demonstrated in classroom settings [10,

11]. Despite its success in aiding idea generation, however,

TRIZ (implemented alone) falls short in selecting the most

appropriate idea, and hence, using it in unison with

appropriate tools is recommended.

Axiomatic design has been implemented in tandem with

TRIZ. Developed by Suh [12], AD method interrelates four

domains: customer needs (CNs), functional requirements

(FRs), design parameters (DPs), and process variables

(PVs). It first transfers the customer needs (CNs) to

functional requirements (FRs) of a product. The functional

requirements are further mapped to design parameters

(DPs). Each design parameter connects to a process

variable (PV). Each customer need is viewed as a function,

which can be further decomposed into subfunctions. Accordingly, every subproblem again decomposes to one or more

lower level subproblems until it reaches the “axiomatic” level.

Therefore, the problem forms a hierarchical structure. In the

same way, functional requirements (FRs), design parameters

(DPs), and process variables PVs have a corresponding

hierarchical structure. In axiomatic design, every subfunction

of these domains has one on one mapping and this organizes a

“zigzagging” relationship between two architectures.

Two major axioms of AD are independence axiom and

information axiom. The independence axiom maintains the

independence of the functional requirements where each

functional requirement (FR) is satisfied without affecting

the other FRs. The information axiom aims to minimize the

information content of the design. The design that satisfies

both independence and information axioms will be the

829

optimal concept. Independence axiom first screens out the

solutions which are “not good.” Then, the information

axiom will analyze the remaining solutions to pick the best

one. The role of axiomatic design in this study is to begin at

the system level and decompose the design problem into

smaller design objects until all design objects are clearly

represented. The details are provided in Section 4.

2.1 Compatibility of AD and TRIZ

In a review of the manufacturing related applications of

TRIZ and AD from literature, Shirwaiker and Okudan [2]

pointed out the major strengths of these tools as: (1) TRIZ

has the capability of generating innovative solutions, and

(2) AD has the capability to analyze effectiveness of

solutions in terms of satisfying the two axioms. Similarly,

Mann [13] discusses the effectiveness of applying TRIZ

and AD concurrently to solve a problem. From the AD

perspective, TRIZ fits very elegantly into the “Ideate and

Create” element of Suh’s design process map. From a TRIZ

perspective, AD offers the potential for improving the

problem definition and problem solving processes through

axioms offering means of assessing the effectiveness of a

design concept, and new perspectives on the specification

of functional requirements and the handling of multilayered

problems [13]. Consequently, a synergistic problem solving

approach using TRIZ and AD has been proposed by

Shirwaiker and Okudan [2].

Ruihong et al. [14] have also proposed an approach

combining AD and TRIZ and explained it using the case

study of a paper machine. However, the synergistic problem

solving approach is a more robust and enhanced approach.

While the Ruihong et al. [14] approach employs TRIZ only

in cases where the design matrix of AD is coupled, the

synergistic approach utilizes TRIZ more effectively in that

TRIZ is used not only for decoupling in case of a coupled

design matrix but is also used for the mapping and

zigzagging processes between the functional domain and

physical domain of the AD hierarchy. This brings efficiency

into the problem solving process.

However, neither the synergistic approach [2] nor Ruihong

et al.’s way of using TRIZ and AD together tackles the

quantitative issues in a design problem. Accordingly, we

expand the synergistic approach to include an optimization

module. Below, we present the modified method and then

show its implementation on the case study.

3 Methodology

The synergistic approach uses TRIZ and AD in concert by

assigning specific functions to the two tools. By applying

TRIZ within an AD framework, we try to capitalize on the

830

strengths of both tools. The synergistic approach primarily

uses AD in order to analyze the problem and decompose the

main problem into a hierarchy of basic level problems. TRIZ

is applied to separate functional requirements (FRs) (if they

are coupled) and to generate innovative solutions to the basic

problems in the AD hierarchy. Thus, the framework attempts

to synergistically use detailed analysis capability of AD with

the innovative idea generation prowess of TRIZ.

As indicated before, however, the adopted synergistic

approach does not tackle the quantitative issues in a design

problem. Quantitative issues mostly arise during material

selection and form design phases in a design problem.

Various material properties impact the design in either

positive or negative way, or positively and negatively both

at the same time; hence, material search requires specific

attention. Likewise, form issues in design problems amplify

the complexities in design scenarios, and should be

considered. Accordingly, we expand the synergistic method

to include specific steps for material search and form

ideation in order to expand the design space, and use

optimization to make a final design alternative selection.

The flow of the methodology is provided below.

To solve the locomotive ballast arrangement problem,

we implement the above presented method. Axiomatic

design first decomposes the ballast arrangement problem

into several mutually independent subproblems. Then TRIZ

serves as a systematic ideation technique that generates

all feasible design concepts according to contradictions

of 39 parameters. With different combinations of these

conflicting situations, some among 40 inventive principles

are suggested as generic solutions. Designers can create

specific solutions by interpreting these principles. Finally, a

mixed integer mathematical programming model is developed to optimize total cost and generate a standardized

ballast allocation model for various locomotive platforms.

We present the details of our implementation below.

Int J Adv Manuf Technol (2012) 61:827–842

standard ballast arrangement models can enable quick

reaction to changing customer needs, alternating market

demands, and better utilization of ballast and workforce

resources, and hence a reduction in the long process

time under existing manufacturing conditions.

2. Cost consideration: The company currently uses two

types of ballast materials—metal scrap and metal slab.

Metal scrap is the major ballast material in use, and it is

much cheaper than slab. However, due to the increasing

raw material cost, finding replacement low-cost materials with relatively more stable market prices can benefit

the company in huge savings and prevent it from losing

market competitiveness. Moreover, the transportation

cost for acquiring ballast materials also need to be

taken into account.

3. Complex ballast loading process: The existing ballast

loading process is complex and inefficient. A better

way is required to simplify current ballast loading

process in order to eliminate redundant procedures and

increase the overall efficiency.

Above are the on-going problems that force the company

management to consider ways to improve from the current

status. To solve this problem, we applied the proposed

methodology incorporating axiomatic design, TRIZ and

optimization, and followed the steps closely that were

outlined in Fig. 1.

Problem Definition

Functional Requirements

Design Parameters (DP)

Yes

Can DPs be

decomposed

further?

4 Case study

Company A is a locomotive manufacturing company that

seeks to redesign its existing platform ballast arrangement

system. In their current system, two different types of ballast

are loaded to the locomotive platform to reach five specific

weight requirements requested by customers. However, their

current system lacks efficiency in addition to several

manufacturing problems. These problems include:

1. Lack of standardization: Company A currently uses numerous ballast arrangement models to reach the five

weight requirements from multiple customers. Those

models are mostly acquired either by trial and error or by

past experience, and thus lack standardization. However,

No

Express DPs as Technical

Contradictions (TC)

Utilize 40 Inventive Principles

Materials Search

Form Ideation

Optimization

Fig. 1 Proposed method

Int J Adv Manuf Technol (2012) 61:827–842

4.1 Ballast functional requirements structure

To begin with, AD is introduced to analyze the problem. AD

hierarchically decomposes the problem into independent

functional requirements (FRs) in a top-down manner. In each

hierarchy, brainstorming is used to generate numerous

possible functional requirements, and then group-thinking is

adopted to eliminate inappropriate or dependent ones. For our

problem, we first divided all platforms to be produced based

on the type of the motor: AC-motor platforms and DC-motor

platforms. This consideration is based on the two main types

of product lines that company A produces. In fact, both motorbased platforms can share the same set of hierarchical

structures. For the next lower level hierarchy, the selection

of ballast arrangement methods is considered. Two functional

requirements are built: the standard ballast and the variant

ballast. In our case study, we only focus on the variant ballast

condition, which is the more complex part of the problem. For

the next lower level, the available ballast loading cavities are

enumerated (front, back, and center). Some constraints need to

be taken into account, such as weight constraints and required

air flow capacity. Lastly, for the lowest hierarchy level,

different material alternatives are considered. Figure 2

presents the entire functional requirements structure for the

AC-based platform.

4.2 TRIZ contradictions

After defining all the hierarchical functional requirements

using the AD approach, we introduce TRIZ to determine the

selection of materials with the consideration of their physical

(e.g., density, state, etc.) and other (e.g., cost, availability,

manufacturability, etc.) features. TRIZ is a systematic tool that

can focus idea generation. It enables users to resolve

sophisticated problems in a systematic fashion by relating

the 40 inventive principles to the problem context.

TRIZ starts with the identification of technical contradictions, which are conflicting engineering parameter pairs.

To determine technical contradictions, the first step is to

Fig. 2 Hierarchy of ballast functional requirements structure

831

inspect the problem, find out potential improvement directions

and replace them with specific TRIZ parameters. Indeed,

improving from one parameter usually may conflict with one

or more other parameters. To clarify the problem more

thoroughly, it is important to define all the technical contradictions by indicating all the possible conflicts. For our case,

we have 10 improvable engineering parameters potentially

conflicting with 12 unique parameters. These result in 16 pairs

of technical contradictions as shown in Table 1.

In the platform design, the standard ballast will remain fixed

irrespective of the weight requirements of the particular model,

and variant ballast will be adjusted to meet particular requirements. As a result, our team decided to work on the design of

the variant ballast only after finalizing the “form design” and

“total weight” of the standard ballast. Once the FRs hierarchy

was determined, our team proceeded to determine the material

and its attributes (e.g., cost, availability, manufacturability, and

human factors) by using TRIZ. Therefore, the next step was to

formulate different contradictions and their corresponding

TRIZ principles from TRIZ matrix. After achieving all the

solutions for each pair of technical contradictions from the

TRIZ principles, we organized the most commonly applied

recurring principles in Table 2. In this table, we can see that

most suggested principles related to finding better ballast

materials and more appropriate ballast arrangement methods.

Accordingly, we decided to focus our solution efforts around:

(1) ballast material research, (2) concept generation, and (3)

optimization.

After investigating a variety of materials, we proposed

two categories of materials: (1) metals and metal alloys and

(2) non-metal materials.

1. Metals and metal alloys: Table 3 shows the density and

cost information for a number of materials in this

category. After careful consideration of design criteria,

we decided to use cast iron and steel as our major

materials for the metals and metal alloys category. Cast

iron is the material of metal scrap, and steel is the

material of metal slab.

2. Non-metal materials: For non-metal materials, initially,

we selected four candidates: (a) concrete, (b) stone, (c)

brick, and (d) sand. Table 4 shows the density and cost

information for the four non-metal materials. However,

after acquiring detailed information for these materials,

we found that all of the four non-metal materials have

low-density levels. Density is a critical determinant that

excludes alternatives from being potential replacements

to steel-based ballast. However, non-metal materials all

have cost advantages in comparison to metals or metal

alloys. Thus, mixing non-metal materials with metals or

metal allows might be a good way to reduce total

ballast cost. Nevertheless, concrete, brick, and stone are

still not suitable as auxiliary ballast since they have

832

Int J Adv Manuf Technol (2012) 61:827–842

Table 1 Contradiction matrix and corresponding TRIZ principles

No.

Feature to improve

Conflicting feature

TRIZ principles

1

Manufacturability (32)

Waste of time (25)

35 Physical or chemical properties

28 Replace a mechanical system

34 Recycling (rejecting and regenerating)

4 Asymmetry

2

Weight of stationary object (2)

Manufacturability (32)

1 Segmentation

27 Cheap disposable

36 Use phase changes

13 Other way around

3

Manufacturability (32)

Waste of energy (22)

4

Volume of stationary object (8)

Shape (12)

19 Periodic action

35 Physical or chemical properties

7 Nesting dolls

2 Separation or extraction

35 Physical or chemical properties

5

Weight of stationary object (2)

Volume of stationary object (8)

35 Physical or chemical properties

10 Preliminary action

19 Periodic action

14 Spherical shapes

6

Stability of object (13)

Amount of substance (26)

15 Dynamism

32 Optical changes

35 Physical or chemical properties

7

Durability of stationary object (16)

Amount of substance (26)

3 Local quality

35 Physical or chemical properties

31 Porous materials

8

Level of automation (38)

Complexity of device (36)

15 Dynamism

24 Intermediary

10 Preliminary action

9

Durability of stationary object (16)

Manufacturability (32)

35 Physical or chemical properties

10 Preliminary action

10

Force (10)

Weight of moving object (1)

8 Counter-weight

1 Segmentation

37 Thermal expansion

18 Mechanical vibration

11

Accuracy of measurement (28)

Manufacturability (32)

6 Universality

35 Physical or chemical properties

25 Self-service

18 Mechanical vibration

12

Accuracy of measurement (28)

Convenience of use (33)

1 Segmentation

13 Other way around

17 Moving to another dimension

34 Recycling (rejecting and regenerating)

13

Weight of stationary object (2)

Harmful side effects (31)

35 Physical or chemical properties

22 Blessing in disguise (harm to benefit)

1 Segmentation

39 Inert environment

14

Convenience of use (33)

Harmful side effects (31)

All

15

Reliability (27)

Productivity (39)

1 Segmentation

35 Physical or chemical properties

29 Pneumatics or hydraulics

38 Strong oxidants

additional drawbacks. Brick and stone cost a lot to

transport while concrete has the manufacturability

problem. Therefore, sand is decided as the only nonmetal material that will be further considered.

Int J Adv Manuf Technol (2012) 61:827–842

833

Table 2 Recurring TRIZ principles

TRIZ principles

Number of

occurrences

Description of principle

35 Parameter changes

8

Change concentration or consistency

3 Local quality

6

Enable each part of the system to function in a locally optimized

condition

10 Preliminary action

4

13 “The other way around”

4

Pre-arrange objects or system such that they can come into action at the

most convenient time and place

Make movable objects fixed, and fixed objects movable

15 Dynamization

4

31 Porous materials

4

40 Composite materials

4

Allow a system or object to change to achieve optimal operation under

different conditions

Make an object porous or add porous element OR if an object is already

porous, add something useful into the pores

Change from uniform to composite (multiple) materials where each

material is optimized to a particular function requirement

4.3 Form ideation

Before acquiring the standardized ballast loading model for all

different platform types, we needed to consider a standard

process to load the ballast. In this section, we apply TRIZ to

assist in generating different ways to load ballast by either

Table 3 List of materials with their density and cost

Metal

Density (lb/cu ft)

Cost ($/lb)

Aluminum bronze (3–10% A1)

480.7

0.74–0.97

Antimony, cast

Arsenic

Beryllium

418.0

354.0

505.7

1.25–2.50

0.72

160.00

Bismuth

Cadmium

Cast iron

611.0

540.0

424.5

3.60–4.05

1.84

0.03–0.11

Chromium

Cobalt

Copper

Gold

Iridium

Lead

Manganese

Mercury

428.0

546.0

557.5

1,206.1

1,383.0

711.0

475.0

848.6

0.33–0.43

27.37–31.74

1.33

5,598.00

874.00

0.23–0.35

0.60

800.00

Molybdenum

Nickel

Platinum

Silver

Steel

Tin

Tungsten

Uranium

Vanadium

Zinc

636.0

541.0

1,336.0

654.9

467.0

454.0

1,223.6

1,179.9

343.0

445.4

7.03

2.50–4.73

5,850.00

65.00

0.40

2.90

12.50

9.65–12.20

3.90–5.00

0.43–0.52

redesigning the cavity or redesign the shape of ballast. We

generated a variety of concepts for company A to enable it to

select from after reviewing pros and cons.

4.3.1 Conceptual designs incorporating variability

in the front and back-end cavities

Concept A. Ice cube tray design

In this conceptual design, an ice-cube tray

frame is designed to accommodate the variable weights in the front and back-end

cavities. Therefore, the first step would

involve fabricating the ice-cube tray frame,

which could be made of steel/sheet metal and

should be of the size of the two end cavities

with adequate tolerances for easy insertion

and retrieval. The cavities would first be filled

with the standard quantity of loose ballast as

shown in Fig. 3a. The next step would require

putting the ice-cube tray frame on top of the

loose ballast, and welding it with the platform

base (though welding may not be necessary

for a properly dimensioned tray). This might

also be a part of the standard platform

fabrication process as illustrated in Fig. 3b.

Depending on the variable ballast to be added

to a particular platform model, removable

Table 4 Density and cost of non-metal materials

Non-metal

Sand, dry

Concrete, limestone

Stone (common, generic)

Brick, common red

Density (lb/cu ft)

Cost ($/lb)

111.1

148.0

168.5

120.0

0.03–0.04

0.03–0.04

0.08–0.16

0.12

834

Int J Adv Manuf Technol (2012) 61:827–842

Fig. 3 Ice-cube tray design

weights can be added into the ice-cube

cavities either as boxes or slabs, as shown in

Fig. 3c. The ballast hopper may also be

directly used in order to fill the loose ballast

onto the ice-cube tray frame, which is much

similar to filling of a regular ice-cube tray

under a running water tap. One possible

disadvantage of this design would be the

potential over-utilization of the overhead

crane for transporting individual removable

weights to the ice-cube cavities on the

standard platform in shop floor.

Concept B. Stacked ice-cube tray design

This design utilizes an ice-cube tray frame

similar to concept A but differs in the way that it

stacks ice-cube trays in order to add variability.

The ice-cube tray is pre-filled with a standard

quantity of loose ballast, which is densely

packed. In the cavities, they are placed one over

the other in order to add variability. Therefore,

the number of trays determines the variable

Fig. 4 Stacked ice-cube trays

design

weight. Figure 4a shows a standard ice-cube

tray, while Fig. 4b shows the conceptual

design. One disadvantage may be the change

in compactness of the loose ballast in the trays

after the platform is turned upside down,

thereby displacing all the densely packed loose

ballast from the ice-cube trays.

Concept C. Stacked boxes design

This idea is an extension of abovementioned

concept B. The main purpose of this design is to

design a standard box (either variable loose

ballast or slab) to increase the manufacturability

and flexibility. As Fig. 5 shows, these standard

boxes can be assembled in both vertical and

horizontal directions depending on the variable

weight requirements. In order to horizontally

join two boxes, a jig-saw puzzle connection is

proposed.

Concept D. Sliding plates design

This conceptual design is quite similar to

the first ice-cube tray design (concept A), but

Int J Adv Manuf Technol (2012) 61:827–842

835

Fig. 5 Stacked boxes design

instead of the cubic-shaped cavities in the icecube tray frame, this design utilizes thin

rectangular plates that slide into the slots.

The slots are fabricated on the ice-cube tray

frame, which is welded on to the platform

after the fixed quantity of loose ballast is

poured into the end cavity. Depending on the

variable weight needed for that particular

model, the required number of plates may be

inserted in the slots. Figure 6 shows the

platform design utilizing the sliding plates

design. One disadvantage of this design may

be the high precision and time required by the

operator to accurately position the thin rectangular slabs into their respective slots. The

overhead crane would be utilized to pick up

the plates, which may also lead to its overutilization.

Concept E. Tetris design

This design utilizes the combination of

three standard components in different ways

to achieve different weights. As shown in

Fig. 7a–d, four rectangular shapes are possible

by welding the standard components in

different ways and each resultant shape has

the same width. Figure 7e shows that once the

standard loose ballast quantity is put, these

Fig. 6 Sliding plates design

weights can be put in the slot on the side of

the end cavity. The advantage here is the easy

control of variable weight.

Concept F. Weight training slab design

In this design, the end cavity is first filled

with the standard quantity of loose ballast.

After that, a lid is placed over the loose

ballast, which contains five cylindrical rods

that are equidistant from each other. Figure 8

illustrates the standard slabs, which may be

put over the cylindrical rods in order to

constrain them from any translatory motion.

Figure 9 shows an alternative concept for the

weight training design, where the standard

slabs are fabricated in a slightly different

manner than in Fig. 8.

Concept G. Ice-tray frame design

Figure 10 shows the ice-cube tray frame,

whose total height extends to the base of the

cavity. A number of cavities may be filled up

to the standard quantity with the loose ballast

and the remaining cavities may be filled with

the slabs in order to individually balance each

end cavity. The major difference of this

conceptual design from the previous icecube tray designs is that in this design, the

length of the frame extends the whole height

836

Int J Adv Manuf Technol (2012) 61:827–842

Fig. 7 Tetris design

of the cavity. The ice-cube tray frame is first

welded on to the end cavity, and then the

standard quantity of loose ballast is poured in

the standard cavity as shown in the following

figure.

Concept H. Box with spring-loaded chamber

The purpose of the big box is to reduce the

process time while providing flexibility to add

and remove variable weight (Fig. 11). There are

two cabins in this box. The left side of the

cabin is for loose ballast which accommodates

the standard weight. The right side of the cabin

has a spring-controlled adjustable volume. We

Fig. 8 Weight training slab

design – I

can put slabs in this spring-loaded chamber

depending on the weight requirements. The

main advantage of the spring is to clamp, and

therefore, constrain the variable slabs from

moving inside the chamber.

4.3.2 Conceptual designs incorporating variability

in the central cavity

A. Nesting dolls design

This design is mainly for the central cavity, and it

utilizes the nested doll principle by keeping the airflow

Int J Adv Manuf Technol (2012) 61:827–842

837

Fig. 9 Weight training slab

design – II

considerations in mind. The cavity frame (Fig. 12) is to

be welded on to the central cavity, and is designed

similar to the ice-cube tray (concept A in Section 4.3.1). The shape of the frame provides a path

for the airflow travel (similar to a virtual pipe). This

design can be used for AC platforms as well as DC

platforms since the ice-tray like cavities at the two ends

are symmetric along the central axis, and only one side

may be filled with loose/box/slab as per the variable

weight requirements.

4.3.3 Conceptual designs incorporating variability

on the lid of the front/back-end cavities

A. Folder design

This folder design is based on the principle of

rotation along the hinges (i.e., like a door). However,

the hinged frame consists of slots for accommodating

variable weights in the form of slabs. There are four

different slabs as shown in Fig. 13. In Fig. 13a, the

cavity is filled with the standard quantity of the loose

ballast. Figure 13b–c shows the standard frame, which

has slots for inserting the four different slabs. The

Fig. 10 Conceptual ice-tray

frame design

standard frame is then hinged along with the cavity and

can be swiveled between 0° and 90° because of its pinhole system for hinging (Fig. 13d). After hinging both

the frames on to the cavity, the cavity is closed. This

action also compresses the loose ballast material,

thereby increasing the density. The rotating standard

frame can also be substituted as the cover for the end

cavities.

B. Deck-plate design

In this design, the variable weight is added to the

existing deck plate instead of placing it over the fixed

quantity of standard ballast in the end cavities. The

deck plate is lifted using the overhead crane, and an

outer frame containing the variable weights is welded

to the bottom of the deck plate as shown in Fig. 14b.

The operator then utilizes the overhead crane, and

loads the slab ballasts into the horizontal slots

(Fig. 14e). Finally, the whole deck plate is lowered

on to the standard platform. There are several benefits

of this design. Firstly, the outer frame for the variable

weight compresses the loose ballast material. Another

major advantage is that this design allows two or more

operators to simultaneously load variable weights (in

the form of slabs) in to the frame. At the same time, the

838

Int J Adv Manuf Technol (2012) 61:827–842

Fig. 11 Box with spring-loaded

chamber

other operators can fill the front/back-end cavities with

the loose ballast material. This decreases the overall

cycle time. This design is also ergonomically beneficial

to the technicians as the crane height can control the

height of the deck plate (from the ground) based on the

operator height.

C. Cavity lid design

Alternatively, instead of adding weight to the whole

deck plate (as in concept B in Section 4.3.3), separate

lids can be manufactured for both the front and backend cavities. These lids contain the slots for placing the

variable weights and can be lowered on to the

individual cavities with the help of the overhead crane.

Figure 15 shows this design concept.

D. Cavity lid design–2

This design concept is another alternative to the

cavity lid design, and offers an additional advantage of

the ice-cube tray design. It comprises of standard slots

below the lid (Fig. 16), where the operators can place

the variable weights after the standard weight has been

poured in the cavity. The lid is then placed on to the

cavity and perhaps welded. However, if further weight

needs to be added, it can be added on to the sliding ice

tray, which is placed in the center of the top of the lid.

There are slots on top of the ice tray so that a sliding

lid can seal the ice tray. The main advantage of this

design is that it allows flexibility at the shop floor as

the weight can be removed from the top (ice tray).

Fig. 12 Central cavity frame

design

4.3.4 Conceptual ideas for densely packing the loose

ballast material into the front/back-end cavities

A. Pneumatic hydraulic press

Figure 17 shows the use of a pneumatic/hydraulic

(pulsating) press for densely packing the loose ballast into

the two end cavities. A (portable press) might be

integrated to the overhead crane actions, particularly right

after lifting the loose ballast hopper to fill the end cavities.

B. Vacuum suction compression

The purpose of this idea is to compress the volume

of loose materials to increase its density, and meanwhile, the compressed materials can keep a united

rectangle shape so as to efficiently stock them in the

cavity or a cell in the ice-cube frame. As illustrated in

Fig. 18, this idea needs a heat sealer, plastic bag, a steel

container, a filter, and an air compressor.

4.4 Optimization module

After determining the appropriate ballast materials and

potential forms of ballast arrangement, we built optimization models to find out the best ballast arrangement

solutions. In this step, we used integer programming

technique to build two optimization models. For both

models, the objectives are the same, which is to minimize

total material costs. In addition, we also want to achieve a

standardized ballast arrangement scenario from both opti-

Int J Adv Manuf Technol (2012) 61:827–842

839

Fig. 13 Folder design

mization models. The two models are referred to as the

“base model,” and the “material-mix model.”

Following are the four major constraints considered in

the model.

4.5 Mathematical formulation

Volume constraint: In a locomotive platform, ballast can be

loaded in four locations: the front cavity, center front path,

center back path, and rear cavity. We rename these areas as

front end h, front center f, back center g, and back-end i.

Both front end and back-end cavities have unique volumetric constraints. Front center (f) and back center (g) are

physically connected. It is divided into two sections

because of the balance requirement. Equations 3–6 represent the relationships that satisfy the weight requirement

under volume limitations. Front center f and back center g

have airflow constraints. The center path is reserved for the

air flow to reduce the engine temperature. Thus, the

minimum air flow requirement is considered to be the

maximum ballast loading constraint.

The objective function of the MIP model, as shown in

Eqs. 1 and 2 is to achieve the minimum material cost while

satisfying all the constraints. Here, the total material cost is

the summary of all types of unit material cost multiplied by

the allocated weight.

ð1Þ

Min C

Where

C¼

K

X

k¼1

Ck »Wkfj þ Ck »

K

X

Ck »Wkgj þ

k¼1

K

X

k¼1

Ck »Wkhj þ

K

X

Ck »Wkij

k¼1

ð2Þ

Fig. 14 Variability with the deck plate

840

Int J Adv Manuf Technol (2012) 61:827–842

Fig. 15 Cavity lid design

K

X

Wkfj þ

k¼1

Dk

K

X

Wkij

k¼1

Wkgj þ

k¼1

K

X

Wkhj

k¼1

K

X

Dk

K

X

k¼1

Wkhj þ

K

X

Wkij TWj

ð3Þ

k¼1

VF

ð4Þ

VE

ð5Þ

Balance: The balance of the platform is very important to

maintain the stability; accordingly, ballast loadings should

not lead to big changes in center of gravity of the platform.

An imbalance coefficient is adopted to verify the balance.

After loading all the ballast onto the platform, the

difference of total weights from both sides of the modified

center of gravity should be limited to be lower than a

balance index, BI. Equations 7 and 8 represent this

relationship.

ð

K

P

k¼1

K

X

ðWkfj þ Wkgj Þ

k¼1

Dk

Wkfj þ

K

P

k¼1

Wkhj Þ ð

K

P

Wkgj þ

k¼1

TWj ðBPj BNj Þ

VC

Fig. 16 Cavity lid design – 2

ð6Þ

BPj þ BNj ¼ 1

K

P

k¼1

Wkij Þ

BI

ð7Þ

ð8Þ

Int J Adv Manuf Technol (2012) 61:827–842

841

Table 5 Cost savings for the base model

Cost

Model

Current ballast

cost (%)

Cost from the

base model (%)

Cost saving

(%)

Model 1

100.00

71.29

28.71

Model 2

134.87

97.10

37.77

Model 3

Model 4

112.90

137.10

110.00

122.90

2.90

14.19

Model 5

216.13

253.47

−37.34

Total Cost

701.00

654.76

46.24

TWj K

X

Wkij k¼1

K

X

Wkhj WX »PXj < WX

ð12Þ

k¼1

Fig. 17 Pneumatic/hydraulic press

Standardized ballast: All the possible types of ballast

loaded to the different models are standardized ballast with

standardized weights. We also try to limit the number of

different weights of ballast used in the models. In our

model, we use three different weights of standard ballast,

which are included in the model with WX, WY, and WZ

notations. This scenario is formulated in Eqs. 9–13.

WZ < WY

ð9Þ

WY < WX

ð10Þ

TWj K

X

k¼1

Wkij K

X

TWj K

X

Wkij k¼1

K

X

Wkhj WX »PXj WY »PYj < WY

k¼1

ð13Þ

Variable-type constraints There are three different types of

variables in the MIP, which are shown in Eqs. 14–16.

Wkfj ; Wkgj ; Wkhj ; Wkij ; C 0

ð14Þ

BPj ; BNj 2 f0; 1g

ð15Þ

PXj ; PYj ; PZj ; 0; Integer

ð16Þ

Wkhj WX »PXj WY »PYj WZ »PZj ¼ 0

4.6 The base model

k¼1

ð11Þ

For this model, we generated a standardized ballast arrangement model based on currently used ballast, metal slab and

metal scrap. Company A currently produces five types of

locomotive platforms with different total weight requirements.

Table 6 Cost comparisons of material-mix model, current model, and

the base model

Cost

Model

Fig. 18 Vacuum suction compression technique

Model 1

Model 2

Model 3

Model 4

Model 5

Total Cost

Current ballast Base model Material-mix Cost saving

cost (%)

(%)

model (%)

(%)

100.00

134.87

112.90

137.10

216.13

701.00

71.29

97.10

110.00

122.90

253.47

654.76

55.94

77.26

84.12

93.19

252.14

562.64

44.06

57.61

28.79

43.91

−36.01

138.36

842

Other factors also need to be considered during the model

construction process. For example, after loading all the ballast

to the platform, the difference across two halves of the

locomotive weight should be less than 0.5%. Three types of

standardized ballast are 2,000, 3,000, and 4,000 lbs. Metal slab

costs $0.41 per pound, and metal scrap costs $0.21 per pound.

Based on the information above, we formulated and

solved the base model in the mathematical optimization

software, Lingo. Results are provided in Table 5, where the

solution is provided for one locomotive platform per model.

We can see that, despite the fact that we do not consider the

adoption of additional ballast materials in the base model,

using standardized model can still benefit company A with

a total cost saving of 46.24%. Note that cost values are

provided in percentage terms taking the current ballast for

model 1 as the nominal value (100%). However, adopting

standardized ballast arrangement model can increase the

cost for the highest weight requirement platform. The

reason is that standardized model reduces the ballast

loading flexibility. The standardized model can simplify

the ballast loading process, improve WIP, and better react to

the changing demand.

4.7 The material-mix model

For the material-mix model, while we apply all the

constraints used in the base model, we also consider the

possible combination of three types of ballast—metal slab,

metal scrap, and sand. The cost information used in the

material-mix model for metal slab and meal scrap are the

same. For sand, the unit cost is assumed to be $0.02 per

pound. The total cost of material-mix model, the current

ballast model, and the base model are shown in Table 6. We

can see that the material-mix model has huge cost savings

in comparison to the base model (138.36%).

5 Discussion and conclusions

In its essence, design for manufacturability is the goal of

this case study. We investigated the current ballast process

and constructed a MIP model to optimize the ballast

material cost. The rough estimates indicate considerable

savings in the material cost for the case study company. In

addition, we developed several platform-based ballast

design concepts that fit the current shop floor environment.

Hence, investment on migration to new ballast process is

trivial. With the modular design perspective, ballast sizes

and types are classified as several different standardized

weights. In the meantime, the whole ballast construction

process will be simple. This design can be modified into

different weight specifications within a short time. The

benefit of these new designs is obvious and significant. The

Int J Adv Manuf Technol (2012) 61:827–842

simplicity of the ballast construction process can decrease

the process time and enhance shop floor capacity. High

flexibility in achieving different weight configurations will

also reduce the WIP level and keep the production schedule

robust under dynamic demand conditions. Hence, the shop

floor space can be saved. The synergy of these improvements not only enhances the productivity and responsiveness but also competitive advantage.

More importantly, the actual industrial case study presented

in this paper, not only shows that TRIZ and AD usage in

unison is a powerful tool for solving complex industrial

problems, but also blends the power of optimization.

Acknowledgements We acknowledge contributions from our

colleagues Mr. Teahyun Kim and Dr. Denise Bauer.

References

1. Jugulum R, Sefik M (1998) Building a robust manufacturing

strategy. Comput Ind Eng 35(1/2):225–228

2. Shirwaiker RA, Okudan GE (2008) TRIZ and axiomatic design: a

review of case-studies and a proposed synergistic use. J Intell

Manuf 19(1):33–47

3. Low MK, Lamvik T, Walsh K, Myklebust O (2001) Manufacturing a green service: engaging the TRIZ model of innovation. IEEE

Trans Electron Packag Manuf 24(1):10–17

4. Akay D, Demiray A, Kurt M (2008) Collaborative tool for solving

human factors problems in the manufacturing environment: the

theory of inventive problem solving technique (TRIZ) method. Int

J Prod Res 46(11):2913–2925

5. Yamashina H, Ito T, Kawada H (2002) Innovative product

development process by integrating QFD and TRIZ. Int J Prod

Res 40(5):1031–1050

6. Li T-S, Huang H-H (2009) Applying TRIZ and Fuzzy AHP to

develop innovative design for automated manufacturing systems.

Expert Syst Appl 36(4):8302–8312

7. Li T (2010) Applying TRIZ and AHP to develop innovative

design for automated assembly systems. Int J Adv Manuf Technol

46:301–313

8. Bariani PF, Berti GA, Lucchetta G (2004) A combined DFMA

and TRIZ approach to the simplification of product structure. Proc

Ins Mech Eng Part B: J Eng Manuf 218(8):1023–1027

9. Nix, A.A., Sherrett, B. and Stone, R.B. 2011. A function based

approach to TRIZ. Proceedings of ASME International Design

Engineering Technical Conferences, August 29–31, Washington, D.C

10. Okudan GE, Ogot M, Shirwaiker R (2002) An Investigation on

the Effectiveness Design Ideation Using TRIZ. Proceedings of

IDETC/CIE 2006 Design Education Conference, September 10–

13, 2006, Philadelphia, PA

11. Okudan G.E., Chiu M-C, Lin C., Schmidt L., Vargas N, and

Linsey J. "A pilot exploration of systematic ideation methods and

tools on design learning" Information Technology Based Higher

Education and Training (ITHET), April 29th - May 1 2010

12. Suh NP (1995) Designing-in of quality through axiomatic design.

IEEE Trans Reliab 44(2):256–264

13. Mann, D., 1999. Axiomatic design and TRIZ: compatibilities and

contradictions. The TRIZ Journal (http://www.triz-journal.com)

14. Ruihong, Z., Runhua, T.,and Guozhong, C., 2004. Case study in

AD and TRIZ:A papermachine. TRIZ Journal (http://www.

trizjournal.com)