cross-industry innovation in the health care sector

advertisement

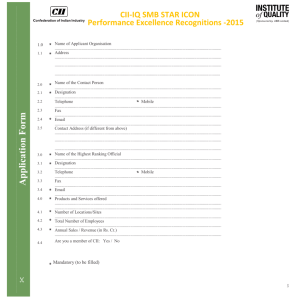

This article is an extract from Performance, Volume 5, Issue 2, May 2013. The full journal is available at www.ey.com/performance Case study Case study A view beyond the horizon: cross-industry innovation in the health care sector Why do firms within the health care sector frequently apply cross-industry innovation? This article highlights cross-industry innovation initiatives within this specialized market, and explores the organizational capabilities and internal structures that could foster cross-industry innovation in products, services and even new business models in this area. 10 Volume 5 │ Issue 2 This article is an extract from Performance, Volume 5, Issue 2, May 2013. The full journal is available at www.ey.com/performance Authors Karoline Bader MA PhD candidate at the Chair for Innovation Management Zeppelin Universität gGmbH, Germany Ellen Enkel Prof. Dr. Phil. Head of the Chair for Innovation Management Zeppelin Universität gGmbH, Germany Charlott Buchholz Bachelor student Corporate Management and Economics Zeppelin Universität gGmbH, Germany Lorenz Bohn Bachelor student Corporate Management and Economics Zeppelin Universität gGmbH, Germany 11 This article is an extract from Performance, Volume 5, Issue 2, May 2013. The full journal is available at www.ey.com/performance Case study CII is the process by which firms systematically incorporate external knowledge, concepts or technologies from more or less distant industries into their own innovation process. O ver the past decade, collaborations across industry boundaries have become increasingly popular in the corporate world. Cross-industry innovation (CII) is the process by which firms systematically incorporate external knowledge, concepts or technologies from more or less distant industries into their own innovation process. In so doing, firms can foster product, service and even business model innovations.1 Used primarily in the development of new products, CII is an attractive method for generating both radical and incremental innovations.2 The CII process can be defined as: 1. Abstracting a problem uncoupled from the company’s own industry 2. Finding solutions to this problem through analogies in foreign industries 3. Transferring these analogies in a way that they are applicable in the company’s own industry3 Prior research suggests that firms are able either to enhance a product’s novelty value (e.g., create more radical innovations) or increase effectiveness via 12 Volume 5 │ Issue 2 CII initiatives.4 In this context, analogical thinking helps firms to discover such innovations, and possibly increases financial performance after a successful transfer and implementation within the company’s own industry.5 CII also assists firms in cutting down uncertainty and risk in their innovation processes, because the solutions and technologies it introduces have already worked successfully in a different market.6 The strict laws and regulations of the health care sector can be challenging. Therefore, firms in this sector are often forced to achieve two simultaneous objectives: an increase in innovation novelty as well as an increase in efficiency. CII can be a logical way to achieve these goals, because differences in the mindsets of cross-industry partners help firms to look beyond their usual horizons. In addition, cross-industry solutions might enable firms to organize their innovation processes in a more effective way.7 In analyzing CII in the health care sector, we interviewed seven companies about their CII initiatives and market position, as well as organizational structures and processes for cross-industry thinking. We spoke to both large corporations and small and medium-sized enterprises, in order to guarantee an adequate data range.8 To augment validity and evaluate the results, This article is an extract from Performance, Volume 5, Issue 2, May 2013. The full journal is available at www.ey.com/performance A view beyond the horizon: cross-industry innovation in the health care sector CII assists firms in cutting down uncertainty and risk in their innovation processes, because the solutions and technologies it introduces have already worked successfully in a different market. the data collection was based on semistructured interviews that were triangulated with archival data, internal documents and management literature.9 The following two case studies are good examples of CII initiatives in the health care sector — and the actions taken by firms prior to their implementation. In this context, CII products, services and even business model imitations across industry boundaries are covered topics. With respect to the latter aspect, some firms in the health care sector have obviously started to imitate specific business model elements of distant industries and integrate them in their own business models. 3M and Aesculap offer particularly useful examples of CII processes, structures and formats, and demonstrate how to approach partners across industry boundaries. Table 1. Overview of case firms within the health care sector Company Number of employees Preferred cross-industry innovation formats Concrete cross-industry innovation examples 3M 84,000 ► Integration of lead users across industry boundaries (e.g., via workshops) ► Cross-business unit innovation Medical tapes, electronic stethoscopes, surgical masks MedCorp2 12,000 ► Scouting initiatives across industries (e.g., via fairs and conferences) ► Transfer of business model elements from foreign industries and integration within own, new business models Transfer of fleet management idea from automotive industry on surgical instruments for hospitals and on protective equipment for chemical plants Aesculap 10,000 ► Scouting initiatives across industries ► Transfer of business model elements from foreign industries and integration within own, new business models Procedure Kit: transfer of fleet management idea from automotive industry on specific instruments for surgeries MedCorp4 968 ► Scouting initiatives across industries and, particularly, transfer of foreign process solutions in the own area Process improvements, e.g., imitation of air cargo processes and services, and transfer on patient treatment (including safety measures) MedCorp5 640 ► Cross-business unit innovation Special lighting system with highest degree of adjustability and conscientious power consumption (transfer of solution from automotive industry) MedCorp6 MedCorp7 300 220 ► Pushing a single solution or technology in a variety of distant market domains ► Cross-business unit innovation Internal improvement of different production processes by transferring single functions across several business sectors ► Cross-business unit innovation Bone cement, Teflon-covered implants 1. C. Herstatt and K. Kalogerakis, “How to use analogies for breakthrough innovations,” International Journal of Innovation and Technology Management, vol. 2 no. 3, 2005, pp. 331–347 and E. Enkel and F. Mezger, “Imitation processes and their application for business model innovation: An explorative study,” International Journal of Innovation Management, vol. 17 no. 1, 2013 (forthcoming). 2. K. Kalogerakis, C. Lüthje and C. Herstatt, “Developing innovations based on analogies: Experience from design and engineering consultants,” Journal of Product Innovation Management, vol. 27 no. 3, 2010, pp. 418–436 and B. Nooteboom, W. Vanhaverbeke, G. Duysters, V. Gilsing and A. van den Oord, “Optimal cognitive distance and absorptive capacity,” Research Policy, vol. 36 no. 7, 2007, pp. 1016–1034. 3. O. Gassmann and M. Zeschky, “Opening up the solution space: The role of analogical thinking for breakthrough product innovation,” Creativity and Innovation Management, vol. 17 no. 2, 2008, pp. 97–106. 4. C. Herstatt and K. Kalogerakis, “How to use analogies for breakthrough innovations,” International Journal of Innovation and Technology Management, vol. 2 no. 3, 2005, pp. 331–347 and K. Kalogerakis, C. Lüthje and C. Herstatt, “Developing innovations based on analogies: Experience from design and engineering consultants,” Journal of Product Innovation Management, vol. 27 no. 3, 2010, pp. 418–436. 5. G. Gavetti, D. Levinthal and J. Rivkin, “Strategy making in novel and complex worlds: The power of analogy,” Strategic Management Journal, vol. 26 no. 8, 2005, pp. 691–712. 6. E. Enkel and O. Gassmann, “Creative imitation: Exploring the case of cross-industry innovation,” R&D Management, vol. 40 no. 3, 2010, pp. 256–70. 7. K. Kalogerakis, C. Lüthje and C. Herstatt, “Developing innovations based on analogies: Experience from design and engineering consultants,” Journal of Product Innovation Management, vol. 27 no. 3, 2010, pp. 418–436. 8. K. Eisenhardt and M. Graebner, “Theory building from cases: Opportunities and challenges,” Academy of Management Journal, vol. 50 no. 1, 2007, pp. 2–32. 9. R. Yin, Case study research: Design and methods (Thousand Oaks, CA: Sage Publications, 2003). 13 This article is an extract from Performance, Volume 5, Issue 2, May 2013. The full journal is available at www.ey.com/performance Case study Case study 3M A range of lead users, from theater makeup artists to veterinary scientists and oceanographers, contributed to the creation of an antimicrobial armor line. 14 3M (Minnesota Mining and Manufacturing) operates in various industries and is one of the world’s most innovative multitechnology companies. In 2011, 3M had 84,000 employees worldwide and achieved a turnover of US$29.6 billion. It sells industrial services, office supplies, a variety of products for the health care sector and much more. 3M’s ability to come up with both radical innovations, such as the Littmann Electronic Stethoscope or Post-it Notes, as well as incremental innovations, is highlighted by the firm’s successful product launches in a variety of markets. 3M’s emphasis on innovation means that it is important for the company that at least 35% of its products have not been on the market for more than five years. Since 3M generates a big portion of its turnover from radical innovations, CII has become a key initiative for the company. 3M also distinguishes between “inside-out” and “outside-in” CII processes. As part of its outside-in CII, 3M regularly integrates insights gained from lead users in distant fields into its innovation processes. For instance, the lead user methodology was applied to bring about a revolution in the field of surgical infection control. A range of lead users, from theater makeup artists to veterinary scientists and oceanographers, contributed to the creation of an antimicrobial armor line. Until this time, Volume 5 │ Issue 2 3M had only focused on surface infection. Based on insight gained from the crossindustry experts, 3M was able to develop a breakthrough product line that could armor catheters and tubes against unwanted microscopic visitors. Based on the success of a variety of projects using the lead user methodology at 3M, several different business divisions have now systematized this CII initiative. The inside-out CII process at 3M involves the transfer of specific solutions or technologies across industries that have already worked successfully in one of the firm’s actual markets. One example is the non-woven fabrics that have been applied in several 3M products. In general, non-woven fabrics are elastic, soft, flame retardant and liquid absorbent. Their resilience and semi-permeability make non-woven fabrics suitable for use in filtration systems, and their superior strength and dielectric performance make them perfect for use as electrical insulators in machines. As such, non-woven fabrics are widely used in the automotive and chemical industries. 3M’s objective is to distribute this technology through several markets if possible, as non-woven fabrics have a significant variety of potential uses. They can be used as a bacterial barrier, which makes them a perfect component for medical products such as surgical masks, and they can be This article is an extract from Performance, Volume 5, Issue 2, May 2013. The full journal is available at www.ey.com/performance A view beyond the horizon: cross-industry innovation in the health care sector used for medical tape, in place of plasters. Non-woven fabrics are also washable and water-repellant, which makes them ideal for clothing, such as coats and jackets, enabling 3M to also enter the fashion industry with this product. Although there are several examples of CII at 3M, it is sometimes still difficult to identify lucrative partnerships across industry boundaries. In order to know which cross-industry solutions and opportunities are already available within 3M, the company is structured in a way that is comparable to a big technology platform. 3M is organized so that technologies with potential cross-industry implications, for example, adhesive technology, are accessible to every individual business unit (e.g., for office supplies or medical tapes). In turn, each business unit is committed to sharing technology and innovation with the rest of the firm. 3M’s philosophy dictates that all technological solutions belong to everybody within the company. Hence, this organizational cross-linking encourages a high level of cross-business unit innovation within 3M. In addition, 3M is committed to stimulating employee creativity. The company’s “15 percent program” encourages all employees to allocate 15% of their paid working time to creative thinking and discussion of their ideas in teams (even across fields and business units). This program also has a positive impact on employees’ work satisfaction and individual performance, and has even reduced sick leave. In addition, 3M encourages its employees to switch jobs between industry sectors from time to time, to develop their skills in analogical thinking. Such initiatives also foster organizational cross-linking within 3M and facilitate innovation across business units, as employees get a better overview of technological solutions in use throughout the business. Because 3M can revert to such a broad knowledge base and use internal technological expertise from a variety of industries, integrating partners from outside the business is not always necessary. However, if technology screening across business units does not deliver a solution for a specific problem, then 3M addresses external partners and asks for help. Consequently, when employees at 3M need to solve a technological problem, they are encouraged to first screen the available solutions across internal business units before looking for external solutions. 3M is organized so that technologies with potential crossindustry implications, e.g., adhesive technology, are accessible to every business unit (e.g., office supplies or medical tapes). 15 This article is an extract from Performance, Volume 5, Issue 2, May 2013. The full journal is available at www.ey.com/performance Case study Case study Aesculap Aesculap AG is an affiliated company of B. Braun Melsungen AG, one of the world´s leading health care companies. Aesculap focuses on products and services for core processes in surgical medicine. In 2011, it had approximately 10,000 employees worldwide and, over the last few years, it has created an innovation-oriented culture and philosophy of which every employee within the company is aware. Today, the firm’s product range includes surgical instruments, implants, endoscopes, surgical motor systems, suture materials, container and storage systems, as well as vascular therapy products. Aesculap frequently involves external partners from different fields, such as biomaterials or computer hardware, in order to generate novel solutions and improve current products and services; for example, updating surgical instruments to reflect changing surgical techniques. Because the health care sector is a fairly stable market, enjoying few macroeconomic fluctuations, Aesculap is a very attractive collaboration partner for potential crossindustry partners. Aesculap also has several important and productive collaborations with a number of universities across a range of fields.10 Working with universities means that new ideas, concepts and cross-field technological solutions can already be integrated within the early innovation phase. 16 The company also leads the field in the development of innovative business models based on CII processes. It has created new business models by consciously imitating and transferring specific business model elements from other industries. In so doing, Aesculap integrates concepts and solutions that have already worked successfully in another industry. The Procedure Kit is one example that shows how to transfer a service, such as renting a car, into the health care sector. The Procedure Kit is a tool for highly complex surgeries that provides specialist instruments and implants in every single size. The kit also includes a full support service, including transportation to and from hospitals, the cleaning of the instruments after each surgery and other aspects of “fleet management.” This service means that hospitals can rent a Procedure Kit for a specific surgery that might only be conducted a few times a year, and hand it back afterward, rather than purchase and store the equipment. This can result in major cost savings for hospitals. Aesculap’s development of this business model involved insights gained from the car rental industry and, in particular, its fleet management procedures. For Aesculap, it is a profitable change from selling products to offering a wide service range, and, additionally, has allowed the company to extend its value chain. Volume 5 │ Issue 2 The Procedure Kit is one example that shows how to transfer a service, such as renting a car, into the health care sector. 10. Aesculap heavily focuses on university collaborations across fields, e.g., with Furtwangen University (medical engineering), University of Tübingen (material and life sciences), University of Stuttgart (biomaterials), University of Applied Sciences Esslingen (innovation management), RWTH Aachen (medical engineering), University of Heidelberg (life sciences, medical engineering), Ludwig-Maximilian-University Munich (biomechanics), University of Freiburg (engineering), University of Ulm (biomechanics), Berlin University of Technology (medical engineering) and University of Grenoble (medical informatics). This article is an extract from Performance, Volume 5, Issue 2, May 2013. The full journal is available at www.ey.com/performance A view beyond the horizon: cross-industry innovation in the health care sector We learned that several firms have identified the automotive and aviation industries as lead industries from which they can regularly transfer technologies, processes and concepts. Conclusion We found that firms within the health care sector require unique organizational capabilities and structures to actually create cross-industry products and services, or even conduct business model imitation across industries. Furthermore, a company’s top-level management needs to support such initiatives and should particularly foster analogical thinking across industry boundaries; for example, via job rotation in distant business units, regular cross-industry workshops and exchanges with external experts at conferences and fairs. Otherwise, CII is likely to work less successfully than initially planned. Based on our case studies in the health care sector, we learned that several firms have identified the automotive and aviation industries as lead industries from which they can regularly transfer technologies, processes and concepts. Two of our case study firms were even able to conduct business model imitation across the boundaries of seemingly very distinct industries — transferring the fleet management expertise from the rental car industry into surgical instruments and safety equipment. However, such radical initiatives are only feasible if a firm is willing to accept a certain risk level and if it is keen on imitating good solutions from other industries. Furthermore, scouting and screening initiatives need to be promoted outside of the firm’s own sector, because otherwise an increase in the products’ novelty value and the introduction of new trends are quite unlikely. In order to increase efficiency via CII, our case study firms predominantly mentioned cross-business unit innovation as a suitable solution. In this context, a certain degree of cross linking among the more or less distant business units is inevitable. Most of the firms that we examined are active in a variety of industries beyond health care, such as the fashion industry, office supplies, safety equipment and power tools, transportation, electronics and telecommunications. As a result, these firms work hard to organize themselves in such a way that distant business units can support each other with novel technological solutions. To sum up, firms in general should not undervalue the importance of CII, as it can provide new ways of thinking about and solving problems that can set firms apart from their direct competitors. CII can also help firms to produce more pioneering solutions within a specific market. Additionally, CII can be applied to achieve two separate goals: namely, an increase in novelty value as well as an increase in efficiency. 17