Modelling and control of an advanced camera gimbal

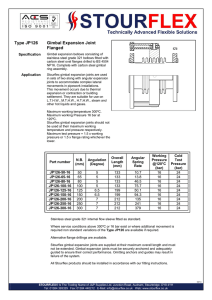

advertisement