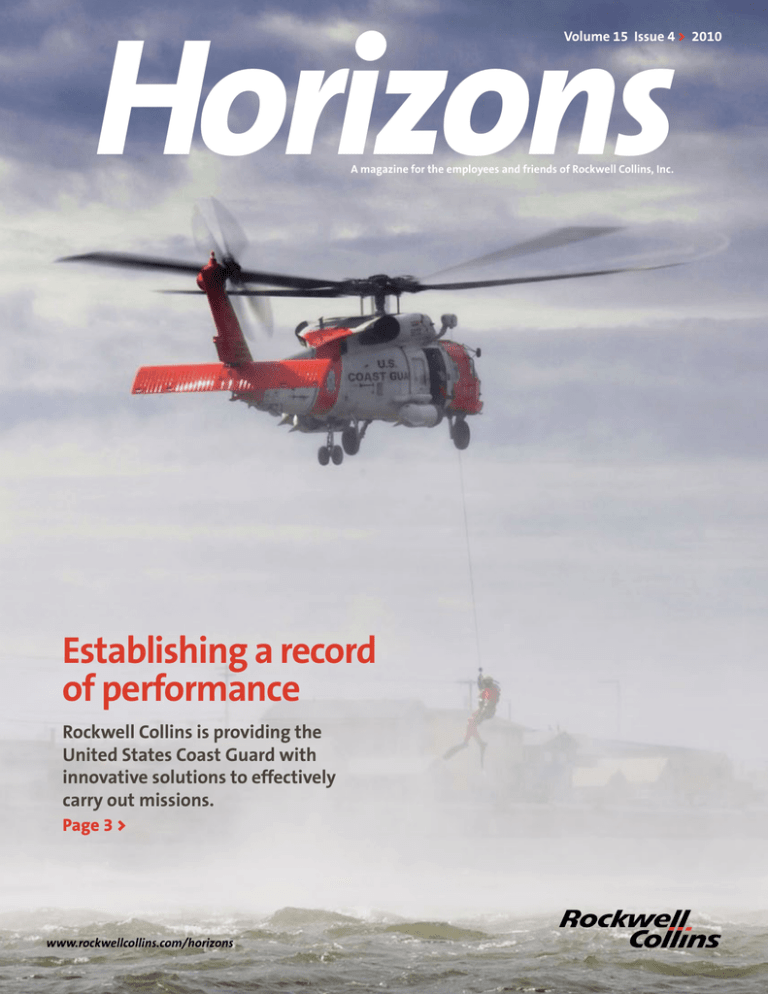

Horizons

Volume 15 Issue 4 > 2010

A magazine for the employees and friends of Rockwell Collins, Inc.

Establishing a record

of performance

Rockwell Collins is providing the

United States Coast Guard with

innovative solutions to effectively

carry out missions.

Page 3 >

www.rockwellcollins.com/horizons

Horizons

Volume 15 > Issue 4 > 2010

Providing exceptional customer value

T

he United States

subsystems integrator

Coast Guard’s

for cockpits and mission

motto is Semper

systems for the

Coast Guard.

Paratus, which means

“Always Ready.”

As a company, our

So when Coast Guard

ability to innovate and

personnel are on a search

adapt solutions to meet

and rescue mission,

the unique needs of

combating the illegal flow

customers is helping

of drugs into the U.S., or

us grow our market

supporting response and

share and become a

cleanup efforts during an environmental

complete life cycle systems provider. Yet,

disaster, they need equipment that is

as in the case with the Coast Guard, this

always ready.

level of trust and collaboration doesn’t

happen overnight with customers.

More than a decade ago, our company

Many times, it starts with a small group

recognized this when we established

of employees who go out of their way

a Performance Based Logistics (PBL)

to make sure the customer’s needs are

services contract with the Coast Guard

being met.

to help reduce long turnaround times

for equipment repairs. With this

As we expand our business globally and

contract, we focused on providing

develop relationships with customers in

exceptional customer value, and since

new market segments, it’s important for

then Rockwell Collins has exceeded the

our company to continue to find ways to

Coast Guard’s expectations with a

provide exceptional value. This level of

99 percent availability rate for parts

dedication and collaboration will help us

and repair.

realize continued success.

In this issue’s cover story, you’ll read

more about how this focus on customer

value not only helped us expand our PBL

Clay Jones

contract, but also led to our role as a

Chairman, President and CEO

Publisher: David Yeoman

Editorial director: Dan Sandersfeld

Horizons

Volume 15 > Issue 4 > 2010

The following articles may contain forward-looking

statements including statements about the company’s

business prospects. Actual results may differ materially

from those projected, as a result of certain risks and

uncertainties, including but not limited to those detailed

from time to time in our earnings press releases and

Securities and Exchange Commission filings.

2 > Are we there yet?

Our Airshow® moving map provides

the answer and so much more.

Editorial team:

Managing editor:

Robert Fleener +1.319.295.8791

Editor: Crystal Hardinger +1.319.295.3932

Staff writers:

Cindy Duran +1.319.263.1573

Karen Hildebrand +1.319.295.5762

Katie Shatzer +1.319.389.0448

Jill Wojciechowski +1.319.295.4998

COV E R STO RY

3 > Establishing a record of performance

Rockwell Collins is responding to the United States

Coast Guard’s need for innovative solutions.

Copy editors:

Ruth Anne Denker +1.319.295.0643

Karen Steggall +1.319.295.5327

7 > Lean at work

Rockwell Collins employees are realizing the

power of Lean ElectronicsSM through events.

Employee contributor in this issue:

Ernesto Duarte Magana, Mexicali, Mexico

How to contact us:

Email: empcomm@rockwellcollins.com

Mailing address: Horizons

Rockwell Collins M/S 124-302

400 Collins Road NE

Cedar Rapids, IA 52498-0001

Phone: +1.319.295.1000

Fax: +1.319.295.9374

Web address:

www.rockwellcollins.com/horizons

10 > Taking pilot controls to new heights

Our company’s first complete pilot control

system is debuting on the Boeing 787 Dreamliner.

14 > Extraordinary adventures

Matt Barton is making it possible for disabled youths

in East Sussex to participate in scouting activities.

How to contact the Ombudsman:

Phone: +1.866.224.8137 or +1.319.295.7714

Email: ombudsman@rockwellcollins.com

Horizons is published by Rockwell Collins

Enterprise Communications for our

employees, retirees, shareowners and

customers. We seek to inform and inspire

our readers by incorporating our company’s

Vision, business goals and other

enterprise-wide initiatives throughout our

publication. We also strive to spotlight issues

that affect our employees, our company

and our industry.

16 > Doing business globally

Employees are using the Country

Navigator tool to obtain hands-on advice.

Back Cover > Our hub in Southeast Asia

The service center in Singapore is a convenient

site for our Asia-Pacific customers.

All trademarks and registered trademarks

contained herein are the property of their

respective owners.

©2010 Rockwell Collins, Inc.

All rights reserved.

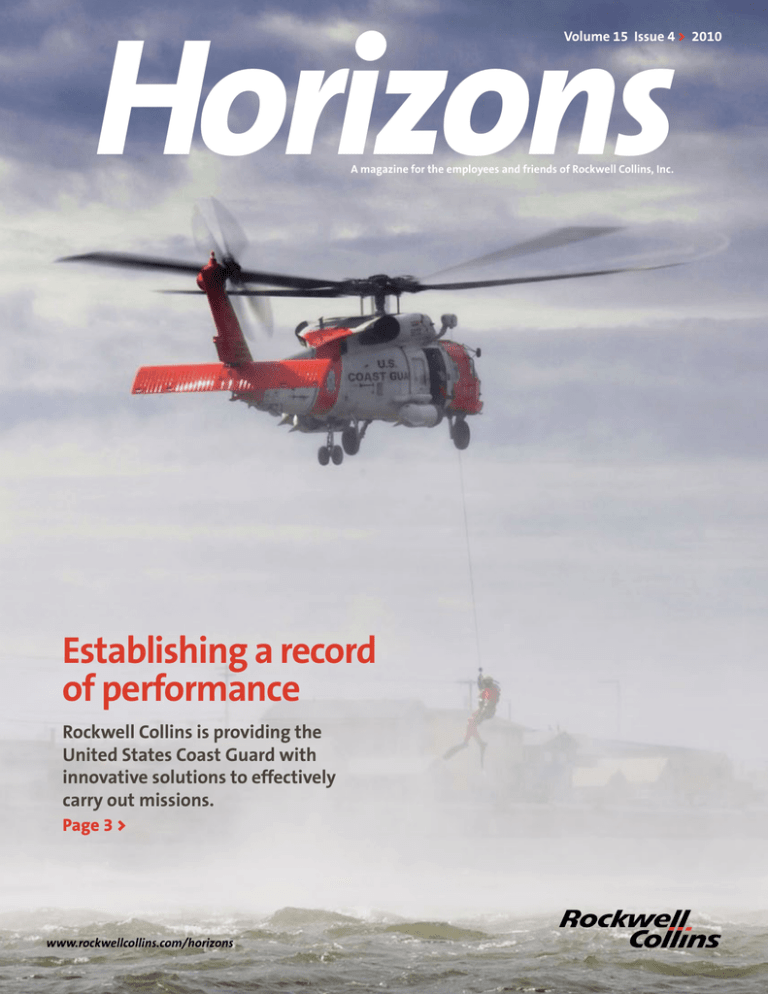

On the cover > A United States Coast Guard MH-60 Jayhawk helicopter crew hoists a

rescue swimmer after conducting a search and rescue demonstration in Alaska.

Photo courtesy of the U.S. Coast Guard.

Establishing a record

of performance

Are we

there yet?

Rockwell Collins is responding to the United States Coast Guard’s need for

innovative solutions to effectively carry out missions and reduce workload.

Our Airshow® moving map

provides the answer and

so much more.

By Katie Shatzer

W

hether traveling to the other

side of the country or the other

side of the world, the Rockwell

Collins Airshow® moving map provides

an easy answer to an age-old question:

Are we there yet?

Recognized as one of the most

popular moving map systems in the

industry, Airshow keeps passengers

informed, entertained and in touch with

information. Along with 3D moving

maps, the system displays world clocks,

flight instrument panels, information

tickers and content from media such as Bloomberg, CNN and The Wall Street Journal.

“It’s common to see passengers

watching Airshow throughout the

duration of the flight,” explained Lupita

Ho, a principal marketing manager for

Cabin Systems in Tustin, Calif. “It makes

the flight more enjoyable.”

Recent enhancements

Earlier this year, Rockwell Collins released

new software for Airshow 4000 for

> Latest generation of Airshow – A high-tech 3D route map based on data from NASA is one of the

features recently added to our Airshow product line. This enhancement allows passengers to decipher

their location more precisely.

business aircraft, while upgrades for

Airshow 4200 and 4200D for commercial

airlines are expected in 2011. In September, Airshow Interactive was

introduced, combining state-of-the-art

3D graphics with an interactive “infotainment” experience.

The new version of the software

contains a high-tech 3D route map based

on data from the National Aeronautics

and Space Administration and a virtual

head-up display (HUD) that presents

information as the pilot would see it

through a HUD. These features allow

passengers to decipher their location and

landmarks more precisely.

An up-to-date look and feel, along with

innovative time and flight status displays,

day and night views for 3D maps, and

details about points of interest, also were

Rockwell Collins images.

> Keeping passengers informed and entertained – As a leader in head-up displays for flight decks, Rockwell

Collins was able to integrate a virtual head-up display (pictured on the left) into the cabin as part of the

newest software enhancements to Airshow. The overall look and feel of the system also was updated.

2

HORIZONS > 2010

part of the software enhancements. In

addition, the software can be customized

for each aircraft.

“Airshow is all about eye-candy,” said

Jeff Davis, principal program manager for the moving map product line in

Tustin. “We’ve learned from customer

feedback that our products have to be

visually exciting.”

Industry leader

Rockwell Collins is a pioneer in providing

moving maps for aircraft. The Airshow

product line was first developed in the

1980s, and enhancements have been

added regularly to meet evolving market

needs.

The latest update to the software

began with the user in mind. Feedback

from current and potential customers,

aircraft manufacturers, a customer

advisory board and dealer networks was

important in the development of the new capabilities.

“We realize that we have competition,

so we are constantly striving to make

sure that we have the best designs and

features in the marketplace,” said Ho.

“This release marks another milestone

for our company, yet we need to remain

focused on innovation to sustain our

leadership position.” <h>

Photos courtesy of the U.S. Coast Guard

A

By Katie Shatzer

s their yacht’s mast dangled in defeat more than 1,250 miles

south of Kodiak, Alaska, this past spring, the crew of the

California — participants in the Clipper Round the World

yacht race — waited, hoping help would arrive soon.

Unforgiving Pacific waves 20 feet high

and 50 mph winds had ravaged the

yacht. But that was just part of the crew’s

worries — one member was injured and

the battery in the team’s hand-held radio

had dwindled.

Luckily, just 175 miles away, a United

States Coast Guard search and rescue

team knew the vessel’s exact location.

Inside a Coast Guard HC-130H aircraft, a

Rockwell Collins DF-430 direction finder

antenna had detected the Emergency

Position Indicating Radio Beacon (EPIRB)

that emanated from the California.

Widely used by the Coast Guard for

its unprecedented range and accuracy,

the DF-430 is one example of a Rockwell

Collins solution that helps the Coast

Guard maximize its resources and save lives.

“Older direction finders can only offer

a range of a few miles, while the DF-430

can pick up signals up to 200 miles away,”

explained Hervé Lalanne, a program

manager who has led the DF-430 product

line at Rockwell Collins for about eight

years. “That capability helps save lives.”

In the case of the California, once the

search and rescue team reached the

yacht, an orange canister with a VHF

radio was dropped from the HC-130H

aircraft to enable better communication.

The injured crew member was moved

to a nearby merchant vessel and race

organizers were notified of the distress

call. With the help of the Coast Guard

and the DF-430, the crew of the California

avoided tragedy and eventually was able

to make repairs in order to sail safely into

San Francisco.

“Using the new direction finder, we

were able to fly to the vessel’s precise

position, saving time and fuel,” said

Coast Guard Lt. Commander Mike

Woodrum. “A visual search of the waters

in the rough sea conditions would have

been extremely difficult, and there’s a

significant chance we wouldn’t have

been able to find the vessel without

these tools.”

VOLUME 15 > ISSUE 4

3

New level of trust

While search and rescue missions — like

the California — often receive the most

attention, the Coast Guard is unique in

that its core mission roles are to protect

the public, the environment and U.S.

security interests in maritime regions.

The Coast Guard is a key defender

of American ports, waterways and

coastal areas, and plays an important

role in combating the illegal flow of

drugs into the U.S. Additionally, during

environmental disasters — such as

the recent BP Deepwater Horizon oil

spill in the Gulf of Mexico — the Coast

Guard supports response and cleanup

efforts. This array of civil and military

responsibilities means that the Coast

Guard needs reliable and efficient

solutions to effectively carry out

missions while also reducing workload.

For more than three decades, Rockwell

Collins has been providing innovative

communication and navigation solutions

to support the Coast Guard. Yet, more

recently, our company has established

a new level of trust as a subsystems

integrator for cockpits and mission

systems and as a Performance Based

Logistics (PBL) service provider.

“Our strong relationship with the

Coast Guard over time has allowed

us to move into new roles,” said Jim

Perkins, a principal marketing manager in

Government Systems for Rockwell Collins.

“Along with providing individual products,

we’re working with the Coast Guard

to understand its missions and adapt

system solutions accordingly.”

An integrated solution

Within the next 10 years, the Coast Guard

plans to complete the conversion of 42

Photo by Ted Carlson, Mission Viejo, Calif.

> Adapted for the Coast Guard — The United States Coast Guard’s MH-60T includes the Rockwell Collins

Common Avionics Architecture System (CAAS) cockpit, which was first developed for the U.S. Army Special

Operations helicopters. While developing CAAS, Rockwell Collins applied standards from the commercial

industry to create an open system architecture. This non-proprietary architecture makes it easier to adapt

CAAS to meet the unique mission requirements of the Coast Guard.

Coast Guard HH-60J aircraft to MH-60T

aircraft in order to improve operational

capabilities and reliability. One of the

features of the MH-60T is the Rockwell

Collins Common Avionics Architecture

System (CAAS) cockpit, which offers

fully integrated flight and mission

management capabilities.

Initially developed for the U.S. Army’s

Special Operations Forces MH-47G

Chinook and the MH-60L/M Black Hawk

DF-430

Since 2007, nearly 100 rescues at sea have been attributed to the use of the

Rockwell Collins DF-430 direction finder antenna. Developed at our

facility in Toulouse, France, the DF-430 provides

360-degree coverage and detects signals

from unprecedented distances when

search and rescue teams are searching

for distressed vessels’ emergency beacons.

Along with the United States Coast Guard,

the DF-430 is used by search and rescue teams in more than 20 countries.

4

HORIZONS > 2010

aircraft, CAAS was designed with an open,

non-proprietary system architecture

utilizing existing commercial standards

to allow customers to easily upgrade the

avionics system with new hardware and

software over the many years they will

operate the helicopters.

Another benefit of the open system

architecture is that CAAS also can be

adapted to meet the unique mission

requirements of other branches of the

U.S. armed forces — like the Coast Guard.

“In the defense industry, proprietary

systems have been typical, but they make

it difficult for customers to update and

maintain the equipment,” said Robert

Koelling, a principal program manager

in Mobility and Rotary Wing Solutions in

Government Systems for Rockwell Collins.

“We’ve taken an innovative approach

with CAAS to give our customers a

reasonably priced solution with great

capability to reduce pilot workload and

simplify integration.”

Using CAAS for mission-specific tasks

Inside the MH-60T, one of the most

visible elements of the upgrade is the

new all-glass cockpit. Instead of round

dials, the cockpit now features five

multifunctional displays, which provide

flight-critical and mission-specific

information such as weather radar, flight

plans, imagery, maps, and engine and

powertrain data to the pilots.

When adapting CAAS for the MH60T, engineers not only had to take

into consideration requirements for

navigation and situational awareness,

but also mission-specific tasks.

For the Coast Guard, one of the

mission-specific requirements is an

image capture and transfer solution. On

the HH-60J aircraft, there wasn’t an easy

solution incorporated into the cockpit

systems to capture still images or video

from onboard sensors. “There is limited crew in the MH-60T,”

said Perkins. “Instead of focusing on

collecting images, the crew needs to be

able to focus on flying the aircraft safely

to complete the mission.” With the upgrade to the MH-60T,

Rockwell Collins engineers were able

to repurpose the “WPN” button in the

CAAS cockpit for the Coast Guard. In the

U.S. Army CAAS cockpit, “WPN” means

“Weapon,” but in the MH-60T CAAS

cockpit, “WPN” means “Want Picture Now.”

Today, by using the Forward Looking

Infrared (FLIR) Electro-Optical Sensor

System, the Coast Guard is able to

capture still images or video by simply

pushing the “WPN” button in the MH-60T; files remain on a hard drive until the aircraft lands. In the

future, the Coast Guard would like to

further upgrade the system to use the

“WPN” button to transmit images in near

real time.

Reducing workload

According to Perkins, part of the near

real-time image transfer solution might

be found in the ARC-220 radio, which

Rockwell Collins and the Coast Guard

are considering in order to implement

automatic position reporting, also

known as Blue Force Tracking (BFT).

“Right now, most position reporting

is done via voice,” explained Koelling.

“Implementing BFT would automate the

process, reducing workload for the pilots

and allowing them to focus on the task

at hand.”

Position reporting is conducted using

ARC-220 radios in conjunction with

the United States Customs and Border

Protection HF Cellular Over The Horizon

Enforcement Network (COTHEN).

Rockwell Collins helped develop

COTHEN more than 25 years ago for

the Customs department’s long-range

communication needs, and the Coast

Guard is increasingly making use of the network.

The network — which Rockwell Collins

services and supports — automatically

routes a transmission through fixed

sites across the U.S., making the network

as simple to use as a cell phone. The

ground radio network is compatible in

the air with ARC-220 radios in Coast

Guard helicopters.

“It’s one of a handful of ground

communication networks in the world

that is this automated,” said Lonnie

Pederson, a programs manager in

Surface Solutions in Government

Systems for Rockwell Collins. “The

Coast Guard does not have to invest in

additional HF ground infrastructure.

COTHEN provides them a highly

automated, robust and flexible longrange ground communications network

to use.”

Since most of the Coast Guard’s

ARC-220 radio

Rockwell Collins and the Coast Guard are considering a low-cost

solution for automatic position reporting, also known as

Blue Force Tracking (BFT), using existing solutions —

specifically our company’s ARC-220 radios and the

Customs and Border Protection HF Cellular Over The

Horizon Enforcement Network (COTHEN). Most of the

Coast Guard’s aircraft already fly with ARC-220 radios,

and Rockwell Collins helped develop COTHEN more than 25 years

ago for the Customs department’s long-range communication needs.

VOLUME 15 > ISSUE 4

5

Photo courtesy of the U.S. Coast Guard

> Providing exceptional customer value — When establishing the Performance Based Logistics (PBL)

services contract, Rockwell Collins focused

on theCollins

CoastLight

Guard’s

ollins Dark Yellow*

Rockwell

Blue most important requirement — mission

just six

part numbers

on a single platform. Today, our

PANTONE 131readiness. The first PBL contract started with

Spot color:

PANTONE

299

company’s

10-year contract includes theProcess

Coast color:

Guard’s

airborne

fleet, spanning 150 part

or: C:0 M:30 Y:100

K:10

C:80entire

M:15 Y:0

K:0

numbers

on five platforms. :229 G:168 B:17

(#D39100)

RGB color: R:0 G:164 B:224 (#00A0E2)

aircraft already fly with ARC-220 radios,

entire airborne fleet, spanning 150 part

Rockwell Collins Extra

Light Blue*

ollins Dark Green

implementing automatic position

numbers

on five platforms. Spotacolor: PANTONE

2915 current PBL arrangement wasn’t

PANTONE 371reporting using these radios offers

“The

Process color: C:60 M:5 Y:0 K:0

or: C:43 M:0 Y:100 K:56

low-cost

bornB:238

overnight,”

RGB color: R:77 G:190

(#63B5E8) said Kurt Kaufman, a

R:79 G:111 B:23

(#4A5F1D)solution. According to Perkins,

the implementation of BFT for the Coast

senior program manager for Rockwell

Guard also could contribute to the

Collins who has managed the PBL

development of a near real-time image

contract. “It was a matter of building

ollins Green transfer solution.

Rockwell Collins

Dark Gray

trust

through performance. The success

PANTONE 385

Spot color: PANTONE Warm Gray 10

“Enhanced

position reporting for

and

trust

Rockwell Collins has earned

or: C:3 M:0 Y:100

K:58

Process color: C:0 M:14 Y:28 K:55

known

Coast Guard assets could improve

R:129 G:124 B:0

(#6F6A12)

with

contract has established

RGB color: R:138

G:121the

B:102PBL

(#7B6E66)

the radio link options available for image

transfer,” said Perkins. “A good map

“The success and trust

of the locations of other assets and a

Rockwell Collins has earned

ollins Light Green

Rockwell Collins Gray

system able to recognize those assets

PANTONE 384

Spot color: PANTONE Warm Gray 8

could

with the PBL contract has

or: C:18 M:0 Y:100

K:31enable the Coast Guard’s desire

Process color: C:0 M:9 Y:16 K:43

:159 G:166 B:21

for(#8B9000)

a one-button capability that would

RGB color: R:161 G:149 B:138 (#92877F)

established our company as

transfer images in near real time.”

a complete life cycle systems

Performance Based Logistics services

provider

to the Coast

ollins Extra Light Green*

Rockwell Collins

Light Gray

A decade before the first MH-60T flew

PANTONE 583

Spot color: PANTONE Warm Gray 4

withK:17

a CAAS cockpit, our company’s

lor: C:23 M:0 Y:100

Process color:Guard.”

C:0 M:4 Y:9 K:24 — Kurt Kaufman

R:175 G:188 B:31

(#ABB400)

RGB color: R:201 G:193 B:184 (#BDB6B0)

services

organization began building

our reputation for providing exceptional

customer value. our company as a complete life cycle

In 1999, Rockwell Collins responded

systems provider to the Coast Guard.”

ollins Dark Blue

Rockwell Collins Extra Light Gray*

to the Coast Guard’s need for moreSpot

In the development of the PBL

PANTONE 2955

color: PANTONE Warm Gray 2

lor: C:100 M:45

Y:0 K:37

mission-ready

aircraft by replacingProcess

contract,

color: C:0

M:2 Y:5 K:9Rockwell Collins focused on

R:0 G:82 B:136 (#003B6F)

G:227

B:220Guard’s

(#D9D5D2)most important

firm-fixed-price service contracts RGB color: R:233

the

Coast

with a Performance Based Logistics requirement — mission readiness

(PBL) contract, which provides

— to present a service solution that

broader

coverage

and

logistics

emphasized

availability and reliability of

ollins Blue

Black*

management services.

equipment.

PANTONE 300

Spot color: Process Black

or: C:100 M:40

K:0 first PBL contract started with

Y:0

The

the prior firm-fixed-price repair

Process color:C:0“Under

M:0 Y:0 K:100

R:0 G:125 B:197 (#0068C6)

G:0 B:0 (#232020) a broken unit would come

just six part numbers on a single RGB color: R:0arrangement,

platform. Today, our company’s 10-year

in and we would complete an analysis,”

contract includes the Coast Guard’s

said Kaufman. “If it was not a standard

*This color may be used as a tint or percentage.

6

HORIZONS > 2010

repair, the Coast Guard would need

to provide repair authorization with

another purchase order, causing a large

lag time to get the broken unit released

for repair. Long turnaround times were

leading to mission-incapable aircraft. The

aircraft would not be ready for missions

because parts were unavailable.”

Today, under the PBL contract, when

Rockwell Collins receives a requisition

for a part from any of 25 locations,

a refurbished spare is automatically

shipped to the Coast Guard. In the

contract, the Coast Guard requires an

availability rate for parts and repair of

85 percent. So far, Rockwell Collins has

exceeded the Coast Guard’s expectations

with an availability rate of 99 percent.

Continuing to understand

customer needs

Whether developing the DF-430,

optimizing the CAAS cockpit,

adapting communication capabilities

or engineering PBL solutions, the

relationship between Rockwell Collins

and the Coast Guard is characterized

by our company’s ability to understand

customer needs and innovate

accordingly. As Rockwell Collins explores

new opportunities with the Coast

Guard and other military customers, a

resounding cry for mission readiness and

workload reduction shapes our strategy.

At the same time, as Government

Systems works to grow our maritime

business, our legacy of providing trusted

communication and navigation solutions

as well as adaptable mission systems

is opening doors. With the U.S. Navy,

Marine Corps and the Coast Guard

looking for commonality among their

solutions, it’s important for Rockwell

Collins to be able to demonstrate

our company’s abilities through past

performance.

“There are several opportunities in the

maritime market segment that align

with our core capabilities,” said Alan

Prowse, senior director of Field Sales

and Business Development Support

Operations for Government Systems.

“And as we form our strategies, we’re

certainly listening to our customers.” <h>

Lean at work

Rockwell Collins employees are realizing the

power of Lean Electronics through events.

SM

F

or many people, the quickest way to learn is by doing. This

also is true when it comes to learning Lean Electronics .

By participating in Lean events, Rockwell Collins employees

not only are able to learn more about tools and principles,

they’re also able to experience firsthand how Lean works.

“Employees start with identifying a problem within their own work

area and, by using simple tools, it helps them build their Lean knowledge,” said Todd Moser, manager of Enterprise Lean for Rockwell Collins. “As they start applying the tools, they gain actionable knowledge

and results.”

There are times, though, when more complex Lean events — such

as value stream mapping, rapid process improvements (RPI), projects

and bursts — are needed. Successful execution of these events and

their outcomes reinforce how Lean tools and principles can help our

company solve larger problems and make it easier to achieve our

goals. It also helps employees develop and understand common Lean

language, according to Moser.

“Having a common language and tool set enables and empowers all of our employees to drive continuous improvement in our daily

activities,” he explained. “Everyone can identify problems that lead to

waste and inefficiencies and then apply the most effective tools to implement improvements.”

The following pages highlight four examples of how Rockwell Collins employees learned more about Lean by participating in events. In each example, they were able to identify the customer need, determine a solution, and achieve results.

More important, though, is the fact that these employees will continue to carry their Lean experiences with them and can apply what they’ve learned as new challenges and opportunities arise.

SM

> Transferring knowledge – Through a series of Lean

events, Julie Ormsby, a manager of Technical Support in

Government Systems, learned more about Lean tools and

principles while also helping her team obtain more space

in the Government Systems Rotary Wing lab.

Photos by Paul Marlow, Cedar Rapids, Iowa

VOLUME 15 > ISSUE 4

7

Improving costs with red bins

What was the customer need?

• Improve product quality, cost effectiveness and responsiveness to external customers

Lean tools included: Plan Do Check Act, Visual controls,

Standard work, Error proofing

Lean solution:

In February 2010, the Displays Integrated Production Team (IPT)

and support staff implemented a “red bin” process, which involves

the use of a red rack where team members place all workmanship

defects found during assembly and test. This process provides a

forum that encourages team members to talk about problems and defects and to collaborate on resolutions. As defects are placed

on the rack, the team

members determine

root cause and define

resolutions using a consistent Plan Do Check Act

methodology. Through

twice-daily meetings,

all issues are reviewed.

When issues arise that

require inputs from other

organizations (such as design changes), the support and production teams collaborate with those organizations to determine the best solution to the problem. Results:

• Reduced Defective Parts per Million Opportunity (DPMO) by 45 percent

• Created an environment where the entire team (production personnel, support staff and leadership) is comfortable surfacing and discussing problems every day • Instilled ownership of identifying and solving problems among all team members

• Success by the Displays IPT has inspired other teams in both production and office environments to implement red bins

8

Filling requisitions through

updated recruiting practices

What was the customer need?

• More qualified candidates for job requisitions

Lean tools included: Value stream map,

standard work

Lean solution:

To ensure our recruiting efforts are relevant and effective, our Talent Acquisition team held a value stream

mapping event last year. They determined

significant gaps that were driving inefficiencies for both recruiters and hiring managers.

The standard hiring practice for most requisitions was to post a position, collect applications, coordinate interviews and extend

offers. While it seemed like a common-sense approach, the process

was not driving the desired results. Also, due to the lack of a strong

partnership between the recruiters and hiring managers and a high

volume of requisitions, most of the responsibility for reviewing and

screening candidates was being placed on the hiring managers.

In alignment with the value stream map, the team completed several RPIs, bursts and do-its to establish a new recruiting model.

This new model allows Talent Acquisition to become a more strategic partner to its internal customers.

Along with training employees on the new process, the Talent Acquisition team is monitoring standard work, ensuring it is sustained. The team also is assessing relevance based on the ever-changing hiring needs of our business.

Results:

• Better use of the candidate pool has led to more high-quality candidates for specific roles

• Upfront phone screens by recruiters have reduced the number of resumes hiring managers need to review from about 18 to five

• Recruiters have increased the number of candidate touch points on average from approximately one to five, resulting in better communication with candidates on the status of their applications

Gaining efficiencies with 5S

Establishing a customer-triggered pull system

What was the customer need?

• Obtain more space in the Government Systems Rotary Wing lab to accommodate rapid program growth

What was the customer need?

• Improve delivery timing for a single sales order of business and regional avionics

Lean tools included: 5S, Visual controls

Lean tools included: Value stream map,

Kanban, Visual controls

Lean solution:

With the growth of our business, the Rotary Wing program in Government Systems was faced with accommodating rapid program growth within their existing lab space. Through a 5S, the team eliminated significant clutter from the area, and also

recognized that the overall space was being used inefficiently. Through a series of bursts and do-its, the Government Systems

team identified and implemented quick-fix opportunities to

prepare for a larger renovation project. They also held burst events

with other departments to discuss changes, impacts, needs and

schedules, which helped gain buy-in and support. By organizing a three-phase process over 10 months, the team maintained a functioning lab for more than 30 programs while still accommodating customer needs.

Their project plan also took

into account the relationships

between programs and how to

better collocate teams so that the

space was used efficiently.

Results:

• Accommodated 12 new Rotary Wing programs with space available for future growth

• Moved all server stations to one

area, which freed up 48 linear feet of bench space for other hardware development

• Set up new work bays with a standard power package that is adaptable to any program, allowing reconfiguration without significant infrastructure changes

• Established a designated area for programs with frequent foreign national visitors to comply with export compliance guidelines and minimize visit disruptions

Lean references

Types of Lean events

Examples of tools that can be used in events

To learn more about Lean events and tools, employees can visit the Lean Electronics website, which is accessible via “L” in the Rockwell Collins Online Index.

Value steam mapping — Identifies opportunities for improvement; typically involves current state, ideal state and future state maps

Lean project — Used to implement more complex

improvements with greater long-term impact

Rapid process improvement (RPI) — 80 percent of

improvements are implemented during event; 20 percent of improvements are implemented within 30 days

Burst — Relatively simple tasks intended for quick impact

Do-it — A single task with immediate impact

5S — Sort, simplify, systematic clean, standardize and sustain

Error proofing – Comprehensive method to prevent

mistakes and defects

Plan Do Check Act — An improvement cycle based on

four stages – proposing a change in a process, implementing the change, measuring the results, and taking appropriate action

Kanban — Visual signal to produce information,

product or service

HORIZONS > 2010

Lean solution:

Cessna and Hawker Beechcraft build business aircraft in singlepiece flow. To align with this process, Rockwell Collins builds a

single sales order of avionics — which is typically 70 to 90 line

items per aircraft. All of the components are accumulated in containers

and shipped to the customer together.

These wheeled containers follow along

the final assembly stages of the aircraft

and are returned to Rockwell Collins for

future shipments. Since this process

is designed to be “just in time,” sales

order due dates and customer needs

have to be timed perfectly.

Problems arose when sales order due

dates weren’t lining up with customer

line rates. To solve this problem, Operations employees from our facility in Melbourne, Fla., used a go-and-see approach and walked the customers’ factory floors. In working with

our customers to map the value streams, build rates of various production lines were identified and the consumption rate of the avionics containers was defined.

The resulting solution is a sequential Kanban “pull” system on the containers, which synchronizes sales orders with build orders. This system allows customers to keep only a small quantity of containers on hand and dramatically reduces the inventory investment at the customers’ facilities.

Results:

• Reduced Rockwell Collins-managed inventory stored at customer sites by $6 million

• Reduced premium freight costs by $500,000 annually

• Increased productivity by 25 percent in the Rockwell Collins packing area

Standard work — Series of steps determined to be

the best way to perform a task

Value stream map — Identifies all actions and tasks – both value added and non-value added – required to bring an item (or an idea, information, product or service) from its inception through delivery

Visual controls – Method to facilitate the transfer of important information as quickly as possible

VOLUME 15 > ISSUE 4

9

Taking pilot controls to new heights

Our company’s first complete pilot control system is debuting on the Boeing 787 Dreamliner.

By Marielle Rodeheffer

Collins Dark Yellow*

or: PANTONE 131

color: C:0 M:30 Y:100 K:10

r: R:229 G:168 B:17 (#D39100)

Rockwell Collins Light Blue

Spot color: PANTONE 299

Process color: C:80 M:15 Y:0 K:0

RGB color: R:0 G:164 B:224 (#00A0E2)

l Collins Dark Green

or: PANTONE 371

color: C:43 M:0 Y:100 K:56

or: R:79 G:111 B:23 (#4A5F1D)

Rockwell Collins Extra Light Blue*

Spot color: PANTONE 2915

Process color: C:60 M:5 Y:0 K:0

RGB color: R:77 G:190 B:238 (#63B5E8)

l Collins Green

or: PANTONE 385

color: C:3 M:0 Y:100 K:58

or: R:129 G:124 B:0 (#6F6A12)

Collins Light Green

or: PANTONE 384

color: C:18 M:0 Y:100 K:31

r: R:159 G:166 B:21 (#8B9000)

Rockwell Collins Dark Gray

Spot color: PANTONE Warm Gray 10

Process color: C:0 M:14 Y:28 K:55

RGB color: R:138 G:121 B:102 (#7B6E66)

Rockwell Collins Gray

Spot color: PANTONE Warm Gray 8

Process color: C:0 M:9 Y:16 K:43

RGB color: R:161 G:149 B:138 (#92877F)

ll Collins Extra Light Green*

lor: PANTONE 583

color: C:23 M:0 Y:100 K:17

or: R:175 G:188 B:31 (#ABB400)

Rockwell Collins Light Gray

Spot color: PANTONE Warm Gray 4

Process color: C:0 M:4 Y:9 K:24

RGB color: R:201 G:193 B:184 (#BDB6B0)

ll Collins Dark Blue

lor: PANTONE 2955

color: C:100 M:45 Y:0 K:37

or: R:0 G:82 B:136 (#003B6F)

Rockwell Collins Extra Light Gray*

Spot color: PANTONE Warm Gray 2

Process color: C:0 M:2 Y:5 K:9

RGB color: R:233 G:227 B:220 (#D9D5D2)

ll Collins Blue

lor: PANTONE 300

color: C:100 M:40 Y:0 K:0

or: R:0 G:125 B:197 (#0068C6)

Black*

Spot color: Process Black

Process color: C:0 M:0 Y:0 K:100

RGB color: R:0 G:0 B:0 (#232020)

I

n the sky, as the new Boeing 787

Dreamliner completes rigorous testing to achieve certification, Boeing

test pilots are putting the Rockwell

Collins-designed pilot control system

through its paces, making note of any

adjustments that might be needed prior

to the aircraft’s entry into service.

On the ground, at our facility in Irvine,

Calif., Rockwell Collins employees are

fine-tuning the system as they receive

feedback from the Boeing team.

“When the pilot controls moved from a

lab environment to the actual flight deck,

we expected some changes,” explained

Tony Najjar, senior director of ElectroMechanical Systems (EMS) in Irvine for

Rockwell Collins. “Overall, feedback on our

pilot controls has been very positive, and

the adjustments we’ve made will make

the system even more efficient.”

The first system of its kind created for a

commercial jet, our pilot control technology has helped set a new standard for

the development of future pilot control

system packages.

“This program sets Rockwell Collins

up well to capitalize on two trends: the

adoption of fly-by-wire technology across

the commercial and business aviation

market segments and the outsourcing

of pilot control packages to system

integrators by original equipment

manufacturers,” explained Joel Otto,

senior director of Commercial Systems

Marketing for Rockwell Collins.

> Fine-tuning the system — Rockwell Collins

employees (left to right) Ferli Fernandes, Mai Tran

and Pedro Leon are examining one part of the pilot

control system for the Boeing 787 at our facility

in Irvine, Calif. When completed, the 787 pilot

controls are more than 100 pounds lighter

than the pilot controls on the Boeing 777.

Photo by Laurel Hungerford, Costa Mesa, Calif.

A real first

About seven years ago, Rockwell Collins

first approached Boeing with a proposal

for the 787’s throttle and control stand. At

that time, these capabilities were among

our company’s core competencies in the

area of pilot control technology.

Yet, in order to reduce costs and

streamline the design process and final

assembly, Boeing wanted the pilot controls to be built as one package, instead of

hundreds of parts that would have to be

assembled together later.

In the past, most of the design work

and manufacturing of the pilot control

systems was done in-house at Boeing.

But, according to Paul Barnes, principal

marketing manager in Irvine for Rockwell

Collins, Boeing’s request for one package

drove our company to think about what

more we could offer.

“Boeing’s approach provided Rockwell

Collins with the opportunity to think

about proposing more than the throttle

and control stand,” he said. “We jumped

at the opportunity to define the package

structure the way it is today. This was a

chance we had never had before – a real

first for us.”

In the end, Rockwell Collins offered a

package that was cost effective, and our

proposed controls – when completed –

would be more than 100 pounds lighter

than the Boeing 777 pilot controls. Overcoming design challenges

In 2004, Rockwell Collins was officially

awarded a contract that included not

only the throttle and control stand for the

787, but also the speedbrake, flap control

modules, and the pitch, roll and yaw primary pilot controls. Additionally, the contract included the sensors that interface

with the aircraft’s fly-by-wire systems,

where movements of the column, wheel

and pedals are converted to electronic signals and transmitted via electrical wires.

“This contract opened up a whole new

market segment for offering an entire

pilot control system,” said Barnes. “This was a huge opportunity for Rockwell Collins.”

Our role on the 787

Dreamliner program

Along with the pilot controls,

Rockwell Collins is providing

solutions and systems integration

for the following on the 787:

• Flight deck display system

• Crew alerting system

• Communication and

surveillance systems

• Core network

• Common data network

Yet, designing the 787 pilot controls

meant Rockwell Collins employees

needed to consider several important

requirements, some of which were new to

our company.

Not only did the control system have to

be lighter and cost effective, it also had to feel like the 777 control system in order to make the transition to the 787

easier for pilots.

According to Ferli Fernandes, principal

systems engineer in Irvine for Rockwell

Collins, suggesting the use of fly-by-wire

technology — which also was used on

the 777 — was one way our company was

*This color may be used as a tint or percentage.

10

HORIZONS > 2010

VOLUME 15 > ISSUE 4

11

able to meet some of those requirements.

“Ultimately, fly-by-wire controls weigh

less and take up less space,” said Fernandes, lead engineer on the 787 pilot controls. “But that left another challenge. The fly-by-wire controls had to be

designed to look and feel like those on a

mechanically controlled airplane.”

Creating the desired feel

With mechanical pilot control systems

— which typically consist of pulleys, bell

cranks and cables — the aerodynamic

forces on the control surfaces are felt

directly by the pilot in the form of force

or pressure, according to George Palmer,

senior captain at Rockwell Collins Flight

Operations. This tangible feedback

provides aerodynamic situational

awareness for the pilot, making the

“feel” of the pilot controls essential.

While fly-by-wire technology reduces

pilot workload, it also eliminates

mechanical gears that respond to the

pilot’s movements in a traditional pilot

control system. So the feel has to be

artificially added.

“When you feel a change in force or

pressure through the controls, you can

immediately deal with it if needed,” said

Palmer, who pilots our company’s corporate jets. “If feel wasn’t artificially provided in fly-by-wire systems, it would be

difficult to manually control the airplane.”

By combining computer software

with the hardware of the pilot controls,

Rockwell Collins employees were able

to create the desired feel. In fact, Boeing

pilots had the option of customizing the

force felt when flying the 787 during

the development of the pilot controls.

“By using the flight control system,

we can program in any force value,” said

Fernandes. “Ultimately, the experience of

flying the 787 Dreamliner is exactly what

pilots want it to be.”

A work of art and science

In addition to creating fly-by-wire controls

for the 787, the Rockwell Collins team

would be presented with other challenges throughout the project. For example, the team had to take the

aesthetic appeal of the pilot controls into consideration.

The rounded edges and flowing lines

of the 787 cabin would continue into

the flight deck, giving the entire interior

of the airplane a smooth, cohesive

appearance.

“In the past, we’ve only been concerned

with functionality,” said Barnes. “But now

we had to take into account how everything would appeal to the eye; this was

brand new territory for Rockwell Collins.”

By working hand in hand with Boeing

employees and holding regular crosscompany briefings, the Rockwell Collins

team was able to incorporate design feedback throughout the entire course of the pilot control creation process. “By the end of the process, the flight

deck of a 787 Dreamliner was truly a work of art and science,” said Barnes.

Photo by Laurel Hungerford, Costa Mesa, Calif.

> Creating one package – In order to reduce costs and streamline the design process and final

assembly, Boeing wanted the 787 pilot controls to be built as one package. Mai Tran, a senior

electro-mechanical assembler in Irvine, Calif., is installing connectors on the speedbreak module,

which is part of the Rockwell Collins pilot control system.

12

HORIZONS > 2010

Feedback from pilots was essential

While pilot input has always been part of the design process at Rockwell Collins

for pilot control packages, user evaluations were more critical for the 787 due to the size of the system.

Photo courtesy of Boeing

> Innovative design — The rounded edges and flowing lines of the Boeing 787 cabin continue into the flight deck, giving the entire interior of the airplane a

smooth, cohesive appearance. When designing the pilot control system, the Rockwell Collins team also had to consider the aesthetic appeal of the 787.

“With the pilot control packages we

worked on before, we could anticipate

what pilots would say,” said Fernandes.

“With the 787, we didn’t know what

to expect.”

Inside a lab in our Irvine facility, engineers constructed a platform — known

as the pilot control development rig — for

Boeing pilots to use for testing. Over the

course of a year, Rockwell Collins employees conducted three rounds of testing

with Boeing pilots.

“It was a single seat with a rough

construction of the pilot controls,” said

Barnes. “It simulated what the controls

would feel like, which can be very subjective based on the individual.”

Feedback from pilots ranged from how

the pilot controls felt during a turn, takeoff or landing, as well as how much

pressure was felt at a particular moment

and the amount of force needed to

manipulate certain pieces of equipment.

By incorporating pilot input during the

design process, our company was able to

meet more than 150 requirements set by

Boeing for the pilot control technology,

according to Fernandes.

“The real-time feedback was key,” he

said. “It’s difficult to artificially recreate

something so indefinable. Without the

live input from the pilots, it would have

been impossible.”

Irvine are continuing to consider ways

to perfect our pilot control technology.

In the future, the team hopes lessons

learned on the 787 system will continue

to position our company as a leader in

pilot control technology.

Building upon our success

Over the summer, the 787 successfully

landed outside of the United States for

the first time, traveling about eight hours

from Seattle, Wash., to Farnborough,

United Kingdom, where the airplane was

on display at the 2010 Farnborough International Airshow.

“The 787 Dreamliner is powerful, sleek

and awe-inspiring, and it has a pilot control system to match,” said Najjar. “Seeing

the airplane fly, knowing the pilots are

on board using controls we designed for

them, is truly exciting.”

As Rockwell Collins completes the

requirements for the 787, employees in

“By the end of the process,

the flight deck of a 787

Dreamliner was truly a

work of art and science.”

— Paul Barnes

“We were the first in the industry to develop a commercial pilot control system as one package,” said Najjar. “This success is an example of our company’s innovative capabilities.” <h>

VOLUME 15 > ISSUE 4

13

2 0 1 0 Volu nteer of th e Year

Award fi n alist

2 0 1 0 Rockwell Colli ns Volu nteer of th e Year Award Wi n n er

Extraordinary

adventures

Matt Barton is making it

possible for disabled youths

in East Sussex to participate

in scouting activities.

— including rock climbing, abseiling

(rappelling), skiing, shooting, fishing

and canoeing.

As part of a large team of volunteers,

Barton has found ways for 2nd Chailey

scouts to participate in activities that

normally would be impossible to do. For

example, he engineered a way for a boy

who uses a ventilator to safely ice skate

and ride a roller coaster.

“An assistant helped him breathe

as we went on the roller coaster and

around the skating rink,” said Barton.

“Logistically, it was quite difficult and

required a lot of planning, but he could

participate as part of this scout group.”

“Even though all of

the scouts have severe

disabilities, we do things

any scout group does.

We just adapt it so our

group can join in.”

— Matt Barton

Photo by Cate Lees, Kermer, West Sussex, United Kingdom

> A thrilling experience — Giles Martin (left), a member of the 2nd Chailey Scout Group, and Matt Barton, winner of the 2010 Rockwell Collins Volunteer of the

Year Award, nervously await the first drop on the Wipeout roller coaster at Pleasurewood Hills in the United Kingdom. Martin and Barton enjoy high-adrenaline

activities, so the roller coaster ride was one of the most memorable events of the day trip during the NORJAM scout jamboree in the United Kingdom.

By Katie Shatzer

E

ach summer, Matt Barton

departs with the 2nd Chailey

Scout Group on a camping

trip in the United Kingdom,

accompanied by more than 25 volunteers. Like thousands of other

scout groups worldwide, the East Sussex troop stays at a campsite for a week — learning, exploring and having a good time.

What’s unique about this scout group,

however, is the fact that many of the

14

HORIZONS > 2010

adult volunteers are medically trained

and the scouts use wheelchairs.

“Even though all of the scouts have

severe disabilities, we do things any

scout group does. We just adapt it so

our group can join in,” said Barton, an

engineering manager at our facility in

Burgess Hill, United Kingdom, and winner

of the 2010 Rockwell Collins Volunteer

of the Year Award. “The scouts — just

like most children — want to give new

activities a try. If they want to have a go

at something, we will do everything we

can to make it happen.”

Decades of commitment

Throughout his childhood, Barton was

actively involved in the Scout Association

in the United Kingdom. As a youth, he

also assisted with activities for the 2nd

Chailey Scout Group, since his father

was a leader. At age 18, Barton became

a leader as well. Since then, he has led

the group on a variety of adventures

This year, for their camping trip,

the group traveled to the Norfolk

Showground in Norwich, United

Kingdom, to join 5,000 other scouts at

the NORJAM scout jamboree. Barton

said this outing provided a great

opportunity for the scouts to camp with

another disabled group while becoming

more involved in the Scout Association

as a whole.

Typically, the yearly camping trip

requires two volunteers for each child in

addition to a support staff and a team

of nurses. Several members of Barton’s

family volunteer with the group,

including his father, his sister and his

wife, Chrissi, whom he met through

2nd Chailey Scout activities.

“It’s been a family thing for a long

time and really a team effort,” said

Barton. “All of the people involved play

their part to make it a good experience.”

Since some of the youths remain

part of the group for as long as nine

years, Barton said volunteers often form

strong relationships.

“A volunteer gets to know a scout and

stays with that person on an ongoing

basis,” explained Barton. “After a while,

they become good friends.”

A way of life

Geoff Blackham, a principal systems

engineer at our company, nominated

Barton — whom he’s known for more

than 10 years — for the Rockwell

Collins Volunteer of the Year Award.

“I’ve always been impressed by

Matt’s work ethic and attitude,” said

Blackham. “He’s someone who works

hard to get things done, and that

carries into his work with the scouts.”

While Barton acknowledged his

volunteer work can be physically and

mentally demanding, he said there will

always be a need for it. He hopes to

remain involved in scouting for years

to come, and hopes to see more scout

groups for disabled children formed

around the world.

“Scouting is a fantastic experience for

any child, whether they have disabilities

or not,” said Barton. “I got a lot out

of scouting as a child, and I enjoy still

being a part of it.” <h>

> Overcoming challenges — While attending

the NORJAM scout jamboree in the United

Kingdom, Giles Martin and Matt Barton also

descended a 30-foot tower with climbing ropes.

Even though Martin uses a wheelchair, he

was able to participate in the abseiling

(rappelling) activity just like any other scout

at the jamboree.

A labor of love

For seven years, Beronica Saveedra

Ramirez has been responsible for

the landscaping and maintenance

in a Mexicali park.

Beronica Saveedra Ramirez would like

future generations to be able to enjoy

Parque Villa Magica in Mexicali, Mexico,

the same way her children and neighbors

benefit from the park now.

This is one of the reasons Ramirez, a

production supervisor at our facility in

Mexicali, Mexico, spends hours each week

keeping her neighborhood park clean,

inviting and safe. For the past seven

years, she has assumed responsibility for

landscaping and maintenance of

the park.

After developers finished their work

in Ramirez’s neighborhood, they left the

upkeep of the park to the local residents

— numbering more than 3,500 people.

Every day, more than 100 people visit the

park, many of them children climbing on

playground equipment and teenagers

playing soccer.

“The park keeps kids occupied and

keeps them from playing in the street,”

said Ramirez. “Because the park is

beautiful, kids want to be there, and

parents can be comfortable knowing their

children are safe.”

VOLUME 15 > ISSUE 4

15

Doing

business

Rockwell Collins service anniversaries

Rockwell Collins offers congratulations to employees who have marked significant service award milestones in recent months.

45 years

August

Wanda L. Campbell

Thomas E. Kemp

Gary F. Lohrer

globally

September

Simone M. Bean

John M. Berthot

Kathleen J. Gorski

Margie M. Martinez

Martin F. Osier

Charles D. Webber

Employees are using the Country

Navigator tool to obtain hands-on

advice on how to work with people

around the world.

llins Dark Yellow*

By Cindy Duran

ANTONE 131

r: C:0 M:30 Y:100 K:10

229 G:168 B:17 (#D39100)

W

Rockwell Collins Light Blue

Spot color: PANTONE 299

Process color: C:80 M:15 Y:0 K:0

way

throughout

the world; and it

RGB color: R:0 G:164

B:224 (#00A0E2)

hat’s the best

helps

to develop business

employees gain more knowledge about

relationships with

geography and other countries.

people in China?

“Country Navigator is a key resource

Rockwell

Light Blue*employees worldwide better

llins Dark Green

How do you make

a Collins Extra

in helping

Spot color: PANTONE 2915

PANTONE 371

good

in thecolor: C:60understand

the global aspects of working

M:5 Y:0 K:0

or: C:43 M:0 Y:100

K:56impression while travelingProcess

United

Arab Emirates? How should

you R:77 G:190

together,”

Fitzgerald explained.

RGB color:

B:238 (#63B5E8)

:79 G:111 B:23

(#4A5F1D)

address customers in Germany? What

communication style should you use

Aligning with customers

when working with Americans?

In his role as manager of Manufacturing

llins Green

Rockwell Collins Engineering

Dark Gray

As

Rockwell

Collins

continues

to

in Melbourne, Fla., Joe ANTONE 385

Spot color: PANTONE Warm Gray 10

focus

thesecolor: C:0Hnat

III

interacts

with external customers

r: C:3 M:0 Y:100

K:58 on global market segments,Process

M:14 Y:28 K:55

129 G:124 B:0questions

(#6F6A12) are becoming more important

RGB color: R:138 during

G:121 B:102

(#7B6E66) audits of our processes.

industrial

to our company’s success. To help

Before meeting with Airbus employees

employees learn more about cultural

from France recently, Hnat and his

differences and global teaming, team used Country Navigator to better

lins Light Green

Rockwell Collins Gray

a

understand French culture. While

ANTONE 384Rockwell Collins recently launchedSpot

color: PANTONE Warm Gray 8

web-based

performance tool called

color: C:0

using

the

tool, he learned that debate

r: C:18 M:0 Y:100

K:31

Process

M:9 Y:16

K:43

159 G:166 B:21

(#8B9000)Navigator as part of Rockwell

RGB color: R:161isG:149

B:138 (#92877F)

Country

typically

encouraged in business

Collins University.

meetings in France.

So when he was

challenged by the Airbus

ollins Extra Light Green*

Rockwell Collins

Gray

“Country Navigator

is aLight

key

PANTONE 583

Spot color: PANTONE Warm Gray 4 team about a Rockwell

or: C:23 M:0 Y:100 K:17

Process color:

C:0 M:4 Y:9 K:24

resource in helping

employees

Collins policy and process,

R:175 G:188 B:31 (#ABB400)

RGB color: R:201 G:193 B:184 (#BDB6B0)

Hnat engaged in active

worldwide better understand

discussion rather than

the global aspects of working

becoming defensive.

And while he can’t credit

together.”

ollins Dark Blue

Rockwell Collins Extra Light Gray*

PANTONE 2955

Spot color: PANTONE Warm Gray 2 everything to the tool,

or: C:100 M:45 Y:0 K:37

— Joy Fitzgerald Process color: C:0 M:2 Y:5 K:9

Hnat acknowledges that

R:0 G:82 B:136 (#003B6F)

RGB color: R:233 G:227 B:220 (#D9D5D2)

Rockwell Collins received

According to Joy Fitzgerald, manager

its highest-ever audit score from Airbus

of Learning Design in Human Resources,

following the recent visit.

“I think Country Navigator helped us

ollins Blue Country Navigator offers three keyBlack*

PANTONE 300benefits: it allows employees to conduct

to be

more aligned,” he said. “I had been

Spot color: Process

Black

or: C:100 M:40 Y:0 K:0

Process color: C:0

M:0 Y:0 K:100

a

self-assessment

of

their

own

working

looking

for a tool like Country Navigator

R:0 G:125 B:197 (#0068C6)

RGB color: R:0 G:0 B:0 (#232020)

styles; it helps employees understand

for a long time. It had everything I needed

cultural differences among countries

to know about another culture.” October

Curtis A. Brown

Preparing for travel

Along with helping employees better

interact with people from other

countries, Country Navigator provides

“flight packs” that make it easier to

prepare for international business trips.

Essential information in the flight pack —

including facts about currency, language,

mindset and weather — can be printed,

emailed or saved.

Kurt Kaufman, a senior program

manager in International & Service

Solutions, recently used Country

Navigator to help him prepare for a

business trip to Brazil where he met with

customers from Embraer.

Since it was his first time visiting the

country and interacting with South

Americans, Kaufman consulted the tool

after participating in a Country Navigator

demo with his team.

“I found out that Brazil was in the top

10 countries least compatible with my

working style,” he said. “The additional

information gained by completing my

personal profile helped me be more

effective with dialogue and business

negotiations. I would highly recommend

to anyone doing business abroad to print

off a flight pack and take a moment to fill

out your profile to see how you relate to

individuals in the other country.” <h>

40 years

September

George Kvasna

Winfried Taeschner

October

Susan D. High

Carol A. Tope

35 years

August

Elizabeth A. Greene

Larry J. Neyens

Roger L. Patterson

Don A. Stulken

Cynthia A. Tippett

Perry J. Tormey

Gary P. Wenisch

Diane M. Wilder

September

Edgar Caples

Armin Jakob

Roland Mezieres

Terry L. Moffitt

Raymond C. Walaska Jr

Frank Weckbach

September

Lori K. Bohr

Aida Cantu

Gregory S. Churchill

Gwen L. Dawley

Charles E. Gorwood

Julie A. Hemesath

Susan K. Klostermann

Arno Loesch

Beverly A. Panos

Steve V. Pham

Ernesto F. Rodriguez

Rhonda L. Theismann

October

Mary K. Boykin

Shelia A. Brown

Dawn M. Carter

Rita A. Celejewski

Armin Goeckel

Gina S. Maxwell

Dominique Pampouly

Larry M. Schmaltz

Joe E. Spoden

Steven M. Stoa

30 years

August

Ruth E. Bensmiller

Michael D. Cole

Myrna A. Foltz

Steven G. Freilinger

James A. Giglio

Louis C. Hong

Julie J. Jordan

Mark W. Olson

Angelina H. Simkins

Gail M. Smith

October

Ronald C. Fairchild

Connie J. Hanson

Helmut Meyer

Ursula Schmidt

Robert P. Schminke

Sabine Schwarz

Gregory S. Smith

25 years

August

Ann R. Bell

Carl H. Bode

Christine C. Callahan

Daniel Cortez

Barbara J. Denny

Dorothy T. Dexter

Brigitte Escales-Cros

Brent A. Foss

David J. Hahn

Curt E. Hancock

Steven J. Henely

Rita F. Jillson

Lori J. Knockle

Mark L. McEachran

Randi A. Ruzicka

Stephen A. Thompson

Guadalupe Vazquez Rodriguez

Lisa S. Wagner

September

Susan M. Balik

John N. Barnett

Gilles H. Bioche

John J. Bychkowski

Roberta K. Cady

Richard A. Cleaver

Michael J. Devera

Karl A. Dietrich

Janice M. Duffy

Jeffrey D. Endres

Kevin S. Gordon

Grant P. Heathman

Patsy A. Housewright

Rebecca R. Kearns

Gary T. Kiefer

Michael Knapp

Vickie L. Knutson

Dawn M. Lechtenberg

Marcia A. Lembke

Amy J. McCourt

Linda R. Nieland

Kathy J. Pasker

Dean A. Paulson

Darwin N. Poock

Herbert Pux

Karen J. Quam

Rex A. Reeve

Gregory C. Renning

Jeffrey A. Schroeder

Mary B. Snitker

John V. Stith

Gary M. Thiedeman

Yen V. Vo

Michael A. Wagner

Kathy A. Wathier

Scott L. Wenthe

Darcy D. Whalen

Roger S. Young

Janet L. Zeidler

October

Susan C. Adrian

William J. Balsanek Jr

William H. Bell

John F. Biederman

Betty J. Bublitz

Lynn E. Clift

Katherine A. Cook

Mark E. Correll

Danny R. Daniels

Zelda G. De Hoedt

Martin J. Denlinger

Eveline Dittmann

Michael L. Eastman

James M. Emery

Richard W. Flesner

Jeffrey J. Grimley

Ladonna L. Hackman

John C. Hinde Jr

Kimberlie F. Maas

Werner Maehringer

Ann M. McDowell

Tammy A. McKenna

Michael H. Mickelson

Terry L. Milks

Todd J. Mitchell

Michael K. Patton

Kimberly A. Proctor

Blaine L. Rittmer

Daniel L. Schleder

Shauna Shopay

Mari L. Smith

Vanessa M. Soileau

Gary A. Swanstrom

Wolfgang Tempelhagen

Steven N. Ungs

Karen E. Wadlington

Lori L. Watts

Steven J. Zieser

Web extra: Rockwell Collins employees

celebrating 20 years of service or less are

recognized in Horizons online at

www.rockwellcollins.com/horizons.

Employees can access the web-based

Country Navigator tool via the School of

Professional Development page in the

Rockwell Collins University.

*This color may be used as a tint or percentage.

16

HORIZONS > 2010

VOLUME 15 > ISSUE 4

17

PRSTD STD

US Postage

PAID

Cedar Rapids, IA

Permit No. 90

Rockwell Collins, Inc.

400 Collins Road NE

Cedar Rapids, Iowa 52498-0001

Return Service Requested

Our hub in Southeast Asia

Rockwell Collins’ service center in

Singapore is a convenient site for

our Asia-Pacific customers.

By Marielle Rodeheffer

L

ocated within a six-hour flight of

about 70 percent of our customer

base in the Asia-Pacific region, the

Rockwell Collins Service Center

in Singapore is an ideal location for

maintenance, repair and overhaul work in

Southeast Asia. “Singapore is geographically central to

the Asia-Pacific region,” said T.C. Chan, vice

president and managing director of the

Asia-Pacific region for Rockwell Collins.

“Many international airlines link through

the country, and you can move in and out quickly, which is important to our customers.”

From the flagship airlines of Malaysia and

Thailand to All Nippon Airways in Japan,

customers recognize the Singapore facility

as our company’s Air Transport Center of

Excellence in the Asia-Pacific region. “We are well positioned in our

Commercial Systems market segments,”

said Chan. “Our Singapore facility is well connected.”

Solid reputation

In total, about 120 employees support our

customer service, sales, marketing and

other functions in the Singapore area. According to David Huat Leong Tan,

managing director of the service center in

Singapore, customers in the area trust our solutions. “Other companies want to service

customers as well,” said Tan. “But the

Rockwell Collins name is very trusted here,

and our brand recognition is good.”

Chan agrees, saying our recent letter

of intent with the Commercial Aircraft

Corporation of China (COMAC) to provide

integrated surveillance systems for the

C919 family of aircraft is a testament to

Rockwell Collins’ reputation throughout the

Asia-Pacific region.

“This C919 relationship helps build a

baseline for providing more work to our

service centers in the Asia-Pacific region like

Singapore and particularly to our service

center in Shanghai,” said Chan. “In the long

term, we hope to provide aftermarket and

spares support for the C919.”

The Singapore Service Center also is

preparing to lead the service and repair

work in the region for the Boeing 787 and

the Airbus A350.

Photos by Jonathan Koh, Singapore

Many customers that have ordered new aircraft — such as All Nippon

Airways, Air China, Air India and Korean

Air — already work with Rockwell Collins

employees in Singapore. “By installing the correct capabilities in

the region for future work, we show our

customers that we are reliable and will

support them throughout the life of our

equipment,” said Tan.

Well positioned

While the Singapore facility currently

services products for the Singapore and Thai

military, Chan hopes to provide more service

and support for the Government Systems

marketplace in the future. “The potential here is huge,” said Chan.

“We need to begin seeking out more

Government Systems opportunities.”

With growth in the Air Transport market

segment on the horizon and potential for

expansion in the Government Systems

marketplace, Tan believes the Singapore

Service Center is well positioned.

“I’m looking forward to the future,” said

Tan. “I think Singapore and the Asia-Pacific

region have a lot of great things in store for

Rockwell Collins.” <h>