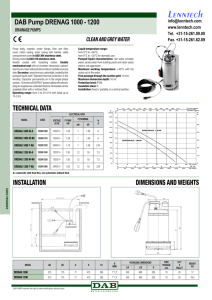

Electric Pumps Catalogue

advertisement