1 Introduction

advertisement

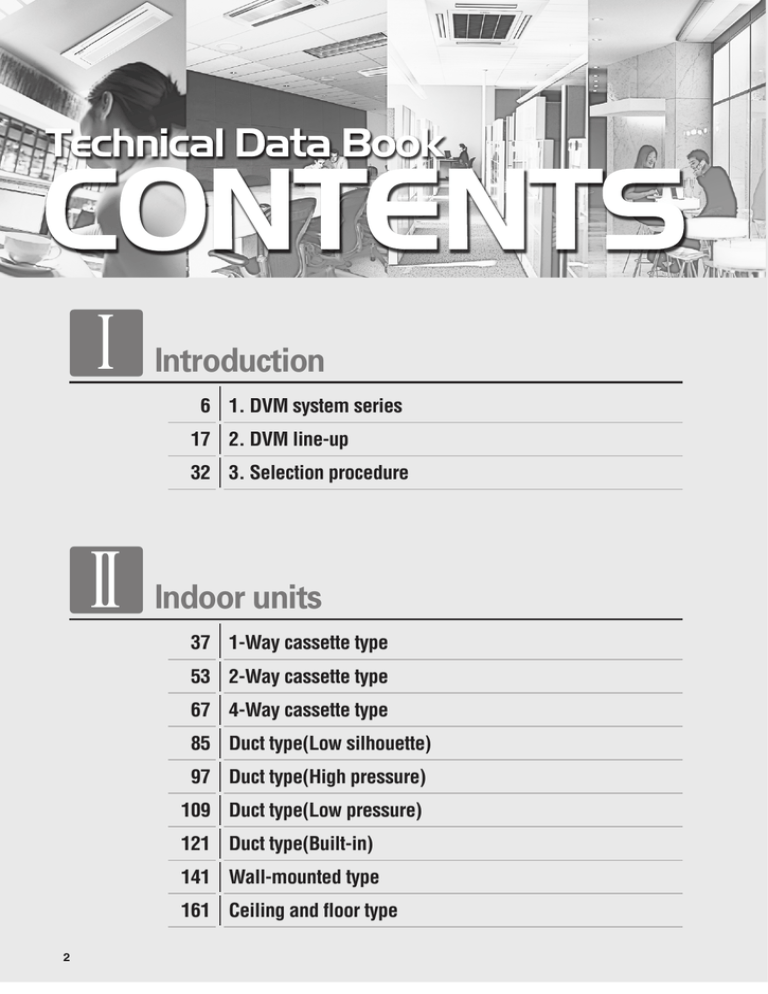

Ι

Introduction

6 1. DVM system series

17 2. DVM line-up

32 3. Selection procedure

ΙΙ

Indoor units

37 1-Way cassette type

53 2-Way cassette type

67 4-Way cassette type

85 Duct type(Low silhouette)

97 Duct type(High pressure)

109 Duct type(Low pressure)

121 Duct type(Built-in)

141 Wall-mounted type

161 Ceiling and floor type

2

Outdoor units

175 DVM series

Introduction

ΙΙΙ

241 DVM PLUS series

315 DVM HR MCU(Mode Change Unit)

Indoor units

ΙΛ

299 DVM HR series

Control systems

327 Individual control system

363 Other interface modules

391 Integrating power distribution system

Control systems

Installation

409 Indoor and outdoor unit

425 Installing the drain pipe and drain hose

431 Wiring

441 Installing the refrigerant pipe

Installation

Λ

Outdoor units

349 Centralized and other control system

473 Installing MCU(Mode Change Unit)

481 Setting the option switch and function of KEYs

493 Setting the addresses of the indoor unit

497 Test operation

511 Caution for refrigerant leak

CONTENTS • 3

Air Conditioner Technical Data Book

4

Introduction

Ι

Introduction

Introduction

1. DVM system series

1-1. What is DVM?······················································ 6

1-2. Features of DVM·················································· 8

1-3. Features of DVM PLUS····································· 13

1-4. Features of DVM Heat Recovery······················ 15

2. DVM line-up

2-1. Indoor unit ··························································· 17

2-2. Outdoor unit ······················································· 18

2-3. Indoor unit version ············································· 19

2-4. Outdoor unit version ·········································· 23

2-5. Accessories (options) ········································ 24

2-6. Line-up································································ 28

3. Selection procedure

3-1. Selection procedure standard of DVM system

based on cooling load········································ 32

3-2. DVM capacity correction ratio··························· 34

INTRODUCTION • 5

INTRODUCTION

1. DVM system series

1-1. What is DVM?

The DVM(Digital Variable Multi) air conditioning system is operated by a variable-capacity compressor

and is accommodated by multiple evaporators (indoor units). It is touted as the next-generation modular

system in the world of high-efficiency air conditioning. lt has undoubtedly changed the face of cooling

associated with high-storied buildings. It provides a broad range of different commercial applications for

settings such as offices, hotels and schools. With its easy installation and simple control system, the DVM

will more than meet the demands of the air conditioning market.

Indoor unit

1 -Way cassette

2 -Way cassette

4-Way cassette

Duct type (Low silhouette)

Duct type (High pressure)

Duct type (Low pressure)

Duct type (Built-in)

Wall-mounted type

Ceiling type

6

Introduction

Outdoor unit

DVM

6HP, 7HP

5HP, 6HP

10HP

DVM PLUS

14HP, 16HP, 18HP, 20HP

22HP, 24HP, 26HP, 28HP, 30HP

DVM HR(Heat Recovery)

10HP

INTRODUCTION • 7

INTRODUCTION

1. DVM system series

1-2. Features of DVM

1) The performance of the Digital Scroll compressor

• There will be running cost savings due to the high efficiency of the compressor.

• The wide capacity range will be able to control the room temperature and humidity very precisely for customer’s

comfort.

• The whole system is very reliable; the compressor is extremely reliable and the electronics is simple and the oil

return very well for system operation.

• No electromagnetic interference issue.

2) Pressure chamber of the Digital Scroll compressor

This cross section shows the top part of the Digital Scroll

compressor. It is designed for efficiency, reliability and durability.

The Digital Scroll can give a capacity range of 10% to 100%,

which is the widest in the industry. It has very excellent performance

and needs very simple electronics for operation.

PWM valve(Actuator)

Example : 20% Capacity

signal

2s

8s

100% Capacity

Example : 50% Capacity

signal

5s

0% Capacity

5s

Rotational

Scroll

Pump

3) Pulse width operation

• 10% ~ 100% wide capacity control

Floating Seal

• PWM operation of Loading Duty in

accordance with capacity demanded

Fixed Scroll

• Pressure / Autonomic dispersion control

Orbiting Scroll

Controller Signal

Orbiting Scroll

Note

8

◆ The Digital Scroll operates in 2 states: loaded state and unloaded state. There is an external solenoid valve in the

Digital Scroll. When a 220V signal is given to the solenoid valve, the top scroll moves up by about 1 mm.

The movement of the top scroll creates a gap between the 2 scroll elements and there is no axial sealing between the

scrolls. As a result, even though the motor is running, the compressor is unable to compress any refrigerant.

The capacity in the loaded state is 100% and during the unloaded state is 0%. Capacity from the compressor is a

time average of the loaded state and the unloaded state. For example, in a cycle time of 20 seconds, if the scrolls are

loaded for 10 seconds and unloaded for 10 seconds, the time-averaged capacity is 50%.

to control the cooling/heating system automatically

The PWM valve is designed specially as a solenoid valve to modulate the pressure forcing on the fixed scroll and

finally working on the compressor’s loading/unloading between the upper part of the fixed scroll and the suction pipe.

The PWM receives the On/Off signal and controls the loading/unloading status. When the PWM valve is turned off,

the fixed scroll is pushed down to the orbiting scroll (Loading). When the PWM valve is turned on, the fixed scroll is

separated from the orbiting scroll (Unloading). This process is repeatedly done to make the outdoor unit controlling

automatically depending on the number of operating indoor unit(s) and their weighting factors.

Running ratio of compressor(%)

2-compressor system(10.0Hp) Unit : kcal/h

100

90

80

70

60

50

40

30

20

10

0

0

5000

10000

15000

20000

25000

Total capacity of operating indoor unit(s)

5) EEV(Electronics Expansion Valve) : Optimized refrigerant control

EEV distributes the optimized refrigerant to each indoor

units with the least energy generated from the Digital

Scroll compressor loading/unloading function.

The indoor units senses not only the temperature

difference between inlet and outlet of evaporator but

also the superheat and room temperature profiles and

finally determines the refrigerant flow rates directly

linked with EEV steps.

❶

❷

1

0.5

0

-0.5

❸

-1

❹

❶ Falling room temperature

❷ Rising room temperature

❸ Open electronic expansion valve

❹ Closed electronic expansion valve

6) Unloaded power consumption is 10% of full load power in 6.0HP compressor

The graph shows that the unloaded power consumption is 10%

of full load power in case of 6 seconds loaded and

6 seconds unloaded.

In each cycle of modulation, the discharge pressure builds up

during the cycle is being loaded, then the discharge pressure

decreases during the cycle is being unloaded. Similarly, the

suction pressure decreases during the cycle is being loaded and

it increases during the cycle is being unloaded.

The transition time means the time to build up the pressure and

it is a fraction of a second. The average value is around 0.4

second. During transition time, the compressor capacity is much

less and this causes the average compressor capacity to be less

than the modulation percentage. Literally, a shorter transition

time gives better capacity from the compressor.

Loaded Power 5,300W

0

2

4

Unloaded Power 500W

6

8

10

12

14

16

18

20

Time(Sec)

INTRODUCTION • 9

Introduction

4) The

INTRODUCTION

1. DVM system series

7) Cost saving

The cooling/heating capacity is adjusted automatically with the variable compressor, which reduces power

consumption and running costs.

■ System cost comparison

Initial cost

(US$)

Running cost

(US$)

Division

Chiller

Unitary

DVM

Equipment

25,558

27,500

29,812

Piping

5,111

17/m2

17/m2

Duct-installation

17/m2

Grand

43,419

40,250

42,562

Power consumption

43kW x 1.0

52.5kW x 1.0

44.2kW x 0.8

(Variable compressor)

Monthly consumption

15,695kWh

19,162kWh

12,906kWh

Annual consumption

(6 months in a year)

94,170kWh

114,972kWh

77,436kWh

1 year rate

6,780

8,277

5,575

3 year rate

20,340

24,833

16,726

5 year rate

33,900

41,389

27,877

Comparison

121%

148%

100%

◆ Heat loads : 90,000 kcal/h in Korea

◆ Total area : 750m2

◆ Running : Every 3 months in summer and winter

8) Long pipes for easy installation and construction

• Fits best for constructing a big commercial building

and renovation

• The refrigerant pipe length between the outdoor and

indoor unit at can be extended up to 100 meters.

• The distance from the first refnet joint to the

indoor unit ≤ 30 meters.

10

15m Height between indoor units

• Equivalent piping length between outdoor and

indoor units ≤ 125(For 10.0Hp).

100m Max. piping length

• The value is calculated from the case where the

outdoor unit is installed above the indoor unit. If the

outdoor unit is located underneath the indoor unit,

the level difference would be the maximum of

40 meters.

50m Height between indoor and outdoor unit

• Height between indoor and outdoor unit can be

extended 50 meters.

Introduction

9) High elevation reliability

For high story building application, 100~150 meter-long pipes and

40~50 meter-high elevation reliability must be secured.

Compressor

50m

10m

0

10

12

14

16

Digital Scroll

Normal Scroll

Minimum oil level

18

20

22

24

26

28

30

35

40

Outdoor chamber

50min

Test of operation under low temperature and 50 meter-fall

• Condition under 20°C indoor and -5°C outdoor

• Condition under the minimum oil level of Compressor

• Refrigerant of an accumulator added

Measured data

Indoor chamber

(Capacity, Oil level, Liquid back, Starting, Outdoor air temp. etc.)

10) Easy oil return

• Easy oil return during low load operation

• No oil trap necessary

• Loaded cycle gas velocity sufficient to return oil

• No need to use oil separator or oil return cycle

For multi evaporator systems, oil return is a matter of concern.

Because at lower capacities, the gas velocities are lower and this

reduces the ability to return enough oil back to the compressor.

An inverter compressor has to go to a high speed periodically for

returning oil back adequately to the compressor.

The Digital Scroll system has no problem in returning oil even at low

capacities. Even at low capacities, the compressor runs at full loading

with the modulated intervals and while performing full capacity,

the compressor is pumping at full capacity, thus it shows the oil

return with high refrigerant velocity.

The second reason is that at low capacities, the compressor

continues to be unloaded for a longer period. In the unloaded state,

the compressor does not pump out any oil. Thus at lower capacities,

less oil leaves the compressor. No separate oil management system

is required for the Digital Scroll system.

INTRODUCTION • 11

INTRODUCTION

1. DVM system series

11) Space saving

The outdoor units connected with several indoor units do not require much space.

(1) Conventional System

High capacity of cooling tower

Air handling unit

+

Fan coil unit

Large apparatus room underground

(2) DVM System

Outdoor unit

Various shape of compact indoor unit

◆ Construct intelligent building with smart and compact structure

◆ Easy and low expense of installation

◆ Easy maintenance

12

Introduction

1-3. Features of DVM PLUS

1) Easy installation

• It is easy to install the pipes.

• The expense of installation is about 22% lower than that of same capacity. (DVM vs. DVM PLUS)

2) Various connection of indoor units (Free Joint Multi)

• Connect maximum 32 indoor units to 1 outdoor unit

• Apply various indoor units

3) Long piping and high height installation

• You can install pipes maximum 120m of piping and 50m of height.

4) Integrated unit

• Installation space : 5% saving for installation of same capacity (DVM vs. DVM PLUS)

• Light weight : 17% lighter weight of the product

DVM 30.0HP

Variable

3 lines of individual piping

DVM PLUS 30.0HP

Main outdoor unit

Sub outdoor unit

1 line of piping

INTRODUCTION • 13

INTRODUCTION

1. DVM system series

5) Running time balance system

• Running time balance system makes compressors of the outdoor

unit operating with balanced.

• This system helps PWM compressor operating for a long time.

1 2

3 4

1 2

3 4

1 2

3 4

6) Back up function

• If the one compressor becomes failure, the Back up function still

makes the rest compressor to operate with the balance.

1 compressor failure

Alarm

Keep operating by

Back up function

14

Introduction

1-4. Features of DVM Heat Recovery

1) High efficiency Mode Change Unit (MCU)

• Install up to 6 indoor units to a MCU

• High cooling and heating efficiency by controlling electric expansion valve in MCU

• Efficient installation according to algorithm of piping check

MCU without EEV: 4 Port / 6 Port

MCU with EEV: 4 Port

Electric expansion valve

2) Efficiency of pipe installation

• Connect maximum 4 MCU to 1 outdoor unit

• One simple system to cool and heat simultaneously

• Free installation by connecting MCU and refnet joint

2 system (DVM)

Cooling

operation

1 system (DVM HR)

Heating

operation

Heating and cooling operation

Cooling (OA room)

Heating (Office)

Cooling

Heating

Cooling (OA room)

Heating (Office)

Cooling

MCU(C/H) Converter

Heating

Cooling

Simultaneous cooling and heating

Heating

INTRODUCTION • 15

INTRODUCTION

1. DVM system series

3) Wide range of simultaneous cooling and heating

When cooling : -5°C~43°C

When heating : -15°C~21°C

When cooling main operation : -5°C~21°C

When heating main operation : -10°C~21°C

50

50

DVM Cooling operation condition

DVM Heating operation condition

40

Heating mode change

Fan mode (Indoor unit)

Outdoor Temperature (DB)

Outdoor Temperature (DB)

40

30

OD : 21°C

20

Cooling main

Operation condition

10

0

OD : -5°C

ID : 18°C

-10

ID : 30°C

Heating mode change

Fan mode (Indoor unit)

30

OD : 21°C

20

10

Heating main

Operation condition

0

OD : -10°C

-10

ID : 18°C

Cooling mode change

Fan mode (Indoor unit)

-20

Cooling mode change

Fan mode (Indoor unit)

-20

10

15

20

25

30

ID : 30°C

10

Indoor Temperature (DB)

Operation Condition (Cooling / Cooling Main)

15

20

25

30

Indoor Temperature (DB)

Operation Condition (Heating / Heating Main)

4) High energy efficiency due to heat recovery operation

6.0

Operating condition

– Outdoor temperature : DB 7°C / WB 6°C

– Indoor temperature : DB 24°C / WB 19°C

– Operation rate : Heating 60% / Cooling 40%

5.0

❊ If operation ratio is 60% for heating(cooling 40%)

the maximum COP is 5.05. It is twice higher than

general heat pump system.

COP (W/W)

4.0

If cooling and heating operations are selected

simultaneously, heat which is absorbed

on cooling operation can be converted to

heat-source of heating operation.

We can achieve high efficiency system

performance from this.

Main heating

operation

Main cooling

operation

3.0

2.0

1.0

0.0

0

Cooling

20

40

5) Algorithm for low noise level

The built in algorithm to reduce noise of indoor unit by converting cooling to heating.

It is quieter than any other HR(Heat Recovery) system.

16

60

Heating Capacity Ratio (%)

80

100

Heating

INTRODUCTION

2. DVM line-up

Introduction

2-1. Indoor unit

Model

AVM

K

H

020

E

A

0

①

②

③

④

⑤

⑥

⑦

① Semi-finished product

Variable capacity free

joint multi (DVM)

③ Mode

AVM

② Classification of product

1 Way

Cassette

type

⑤ Power supply

Cooling only (C/O)

C

220V, 60Hz

B

Heat pump (H/P)

H

208~230V, 60Hz

C

220~240V, 50Hz

E

④ Capacity (x 1/10 kW, 3 digits)

K

Watt

Btu/h

2 Way

G

4 Way

C

Low silhouette

50Hz

60Hz

7K

2000W

2000W

D

9K

2600W

3200W

High pressure

H

12K

3500W

4000W

Low pressure

L

18K

5200W

5200W

Built-in

B

20K

6000W

6000W

Slim

E

24K

7000W

7200W

Wall-mounted type

W

28K

8200W

8300W

Ceiling type

F

36K

10500W

10500W

44K

12800W

12800W

48K

14000W

14000W

Duct type

000

⑥ Refrigerant

R22/R407C

A

R410A

C

⑦ Version

INTRODUCTION • 17

INTRODUCTION

2. DVM line-up

2-2. Outdoor unit

Model

RVM

H

060

C

B

M

0

①

②

③

④

⑤

⑥

⑦

① Semi-finished product

④ Power supply

Variable capacity free

joint multi (DVM)

RVM

Module Multi (DVM PLUS)

RMA

Module Multi (DVM PLUS)

RMB

000

⑥ Combination of indoor unit

208~230V, 60Hz

C

Cassette

type

1 Way

K

2 Way

G

220V, 60Hz

B

220~240V, 50Hz

E

4 Way

C

208~230V, 60Hz, 3ø

F

Low silhouette

D

380~415V, 50Hz, 3ø

G

High pressure

H

Duct type

② Mode

380V, 60Hz, 3ø

H

Low pressure

L

460V, 60Hz, 3ø

J

Built-in

B

W

Ceiling type

F

Free

M

⑤ Refrigerant / Discharge direction

Cooling only (C/O)

C

Heat pump (H/P)

H

Heat Recovery (DVM HR)

R

③ Capacity (x 1/10 HP, 3 digits)

Refrigerant

Discharge

Classification

direction

Upward

A

Onward

B

Upward

C

Onward

D

Upward

E

Onward

F

R22

R407C

R410A

18

Wall-mounted type

⑦ Version

1) 1-Way cassette type (K)

Indoor unit model

Version

Heat pump

Cooling only

0

AVMKH020E(C)A0

AVMKC020E(C)A0

AVMKH026EA0

AVMKH032CA0 AVMKC026EA0

AVMKH035EA0

AVMKH040CA0 AVMKC035EA0

AVMKC032CA0

AVMKC040CA0

1

AVMKC020E(C)A1

AVMKH020E(C)A1

AVMKH026EA1

AVMKH032CA1 AVMKC026EA1

AVMKH035EA1

AVMKH040CA1 AVMKC035EA1

AVMKC032CA1

AVMKC040CA1

3

AVMKC020E(C)A3

AVMKH020E(C)A3

AVMKH026EA3

AVMKH032CA3 AVMKC026EA3

AVMKH035EA3

AVMKH040CA3 AVMKC035EA3

AVMKC032CA3

AVMKC040CA3

4

AVMKH020EA4

AVMKH026EA4

AVMKH035EA4

AVMKC020EA4

AVMKC026EA4

AVMKC035EA4

Reason of modification

–

– Integrated in electric expansion

valve

– Auto address setting for indoor unit

– Applicable non-polarity

communication

– DVM HR(Heat Recovery) indoor

2) 2-Way cassette type (G)

Indoor unit model

Version

Reason of modification

Heat pump

Cooling only

3

AVMGH052E(C)A3

AVMGH070EA3

AVMGH072CA3

AVMGC052E(C)A3

AVMGC070EA3

AVMGC072CA3

– Auto address setting for indoor unit

– Applicable non-polarity

communication

4

AVMGH052EA4

AVMGH070EA4

AVMGC052EA4

AVMGC070EA4

– DVM HR(Heat Recovery) indoor

3) 4-Way cassette type (C)

Indoor unit model

Version

Reason of modification

Heat pump

Cooling only

0

AVMCH052E(C)A0

AVMCH070EA0

AVMCH105E(C)A0

AVMCC052E(C)A0

AVMCH072CA0 AVMCC070EA0

AVMCC105E(C)A0

AVMCC072CA0

–

1

AVMCH052E(C)A1 AVMCH070EA1 AVMCC052E(C)A1

AVMCH105E(C)A1 AVMCH072CA1 AVMCC105E(C)A1

AVMCH140E(C)A1 AVMCH128E(C)A1 AVMCC140E(C)A1

AVMCC070EA1

AVMCC072CA1

AVMCC128E(C)A1

– New indoor design

– Modify the specification of drain hose

– Additional capacity of indoor unit

3

AVMCH052E(C)A3 AVMCH070EA3 AVMCC052E(C)A3

AVMCH105E(C)A3 AVMCH072CA3 AVMCC105E(C)A3

AVMCH140E(C)A3 AVMCH128E(C)A3 AVMCC140E(C)A3

AVMCC070EA3

AVMCC072CA3

AVMCC128E(C)A3

– Auto address setting for indoor unit

– Applicable non-polarity

communication

4

AVMCH052EA4

AVMCH105EA4

AVMCH140EA4

AVMCC070EA4

AVMCC128EA4

– DVM HR(Heat Recovery) indoor

AVMCH070EA4

AVMCH128EA4

AVMCC052EA4

AVMCC105EA4

AVMCC140EA4

INTRODUCTION • 19

Introduction

2-3. Indoor unit version

INTRODUCTION

2. DVM line-up

4) Duct type (Low silhouette : D)

Indoor unit model

Reason of modification

Version

Heat pump

Cooling only

0

AVMDH052E(C)A0

AVMDH070EA0

AVMDH072CA0

AVMDC052E(C)A0

AVMDC070EA0

AVMDC072CA0

–

3

AVMDH052E(C)A3

AVMDH070EA3

AVMDH072CA3

AVMDC052E(C)A3

AVMDC070EA3

AVMDC072CA3

– Auto address setting for indoor unit

– Applicable non-polarity

communication

4

AVMDH052EA4

AVMDH070EA4

AVMDC052EA4

AVMDC070EA4

– DVM HR(Heat Recovery) indoor

5) Duct type (High pressure : H)

Indoor unit model

Version

Heat pump

20

Reason of modification

Cooling only

0

AVMHH105E(C)A0

AVMHH128E(C)A0

AVMHC105E(C)A0

AVMHC128E(C)A0

–

3

AVMHH105E(C)A3

AVMHH128E(C)A3

AVMHH140E(C)A3

AVMHC105E(C)A3

AVMHC128E(C)A3

AVMHC140E(C)A3

– Auto address setting for indoor unit

– Applicable non-polarity

communication

4

AVMHH105EA4

AVMHH128EA4

AVMHC105EA4

AVMHC128EA4

– DVM HR(Heat Recovery) indoor

Indoor unit model

Reason of modification

Version

Heat pump

3

Cooling only

AVMLH105EA3

AVMLH128EA3

AVMLH140EA3

– Auto address setting for indoor unit

– Applicable non-polarity

communication

AVMLC105EA3

AVMLC128EA3

AVMLC140EA3

7) Duct type (Built in : B)

Indoor unit model

Version

Heat pump

Cooling only

Reason of modification

0

AVMBH020E(C)A0

AVMBH032CA0

AVMBH040CA0

AVMBH070EA0

AVMBH026EA0

AVMBH035EA0

AVMBH052E(C)A0

AVMBH072CA0

AVMBC020E(C)A0

AVMBC032CA0

AVMBC040CA0

AVMBC070EA0

AVMBC026EA0

AVMBC035EA0

AVMBC052E(C)A0

AVMBC072CA0

–

3

AVMBH020E(C)A3

AVMBH032CA3

AVMBH040CA3

AVMBH070EA3

AVMBH026EA3

AVMBH035EA3

AVMBH052E(C)A3

AVMBH072CA3

AVMBC020E(C)A3

AVMBC032CA3

AVMBC040CA3

AVMBC070EA3

AVMBC026EA3

AVMBC035EA3

AVMBC052E(C)A3

AVMBC072CA3

– Auto address setting for indoor unit

– Applicable non-polarity

communication

AVMBH020EA4

AVMBH070EA4

AVMBH026EA4

AVMBH035EA4

AVMBH052EA4

AVMBC020EA4

AVMBC070EA4

AVMBC026EA4

AVMBC035EA4

AVMBC052EA4

– DVM HR(Heat Recovery) indoor

4

INTRODUCTION • 21

Introduction

6) Duct type (Low pressure : L)

INTRODUCTION

2. DVM line-up

8) Wall mounted type (W)

Indoor unit model

Reason of modification

Version

Heat pump

Cooling only

0

AVMWH020E(C)A0

AVMWH032CA0

AVMWH040CA0

AVMWH070EA0

AVMWH026EA0

AVMWH035EA0

AVMWH052E(C)A0

AVMWH072CA0

AVMWC020E(C)A0

AVMWC032CA0

AVMWC040CA0

AVMWC070EA0

AVMWC026EA0

AVMWC035EA0

AVMWC052E(C)A0

AVMWC072CA0

1

AVMWH020E(C)A1

AVMWH032CA1

AVMWH040CA1

AVMWH070EA1

AVMWH026EA1

AVMWH035EA1

AVMWH052E(C)A1

AVMWH072CA1

AVMWC020E(C)A1

AVMWC032EA1

AVMWC040CA1

AVMWC070EA1

AVMWC026EA1

AVMWC035EA1

AVMWC052E(C)A1

AVMWC072CA1

– New grille design indoor unit

3

AVMWH020E(C)A3

AVMWH032CA3

AVMWH040CA3

AVMWH070EA3

AVMWH026EA3

AVMWH035EA3

AVMWH052E(C)A3

AVMWH072CA3

AVMWC020E(C)A3

AVMWC032CA3

AVMWC040CA3

AVMWC070EA3

AVMWC026EA3

AVMWC035EA3

AVMWC052E(C)A3

AVMWC072CA3

– Auto address setting for indoor unit

– Applicable non-polarity

communication

AVMWH020EA4

AVMWH070EA4

AVMWH026EA4

AVMWH035EA4

AVMWH052EA4

AVMWC020EA4

AVMWC070EA4

AVMWC026EA4

AVMWC035EA4

AVMWC052EA4

– DVM HR(Heat Recovery) indoor

4

–

9) Ceiling type (F)

Indoor unit model

Reason of modification

Version

Heat pump

22

Cooling only

0

AVMFH052EA0

AVMFH070EA0

AVMFC052EA0

AVMFC070EA0

–

3

AVMFH052EA3

AVMFH070EA3

AVMFC052EA3

AVMFC070EA3

– Auto address setting for indoor unit

– Applicable non-polarity communication

4

AVMFH052EA4

AVMFH070EA4

AVMFC052EA4

AVMFC070EA4

– DVM HR(Heat Recovery) indoor

Indoor unit model

Reason of modification

Version

Heat pump

3

RVMH060GDM3

RVMH100GCM3

5

RVMH100FAM5

Cooling only

-

RVMC070FAM5

– Auto address setting

– Applicable non-polarity

communication

– Special anti-corrosion

treatment outdoor unit

◆ Outdoor unit VS. Indoor unit combination ways

Version 0, 1, 3, 4 indoor unit combinations

are applicable

Case1 (O)

Version 0 outdoor unit

(DVM Series)

Version 3, 4 indoor unit combinations

are applicable

Case2 (O)

Case3 (X)

Version 3 outdoor unit

(DVM Series)

&

DVM Plus outdoor unit

Version 0, 1 indoor unit combinations

are not applicable

Version 4 indoor unit combinations

are applicable

Case4 (O)

Case5 (X)

DVM HR(Heat Recovery)

outdoor unit

Version 0, 1, 2, 3 indoor unit combinations

are not applicable

INTRODUCTION • 23

Introduction

2-4. Outdoor unit version

INTRODUCTION

2. DVM line-up

2-5. Accessories (options)

Classification

EEV Kit

(Distributor kit):

Set 2 or 3 EEV

Model

MXD-➀K➁➂➃

Standard for model name

MXD : Distributor kit

➀ : EEV Capacity (Double figures)

• 14(For 2.0kW~4.0kW Wall mounted type Indoor)

• 18(For 5.2kW~8.5kW Wall mounted type Indoor)

• 24(Ceiling type Indoor)

➁ : Number of ➀ Capa EEV

➂ : EEV Capacity (Double figures)

• 14(For 2.0kW~4.0kW Wall mounted type Indoor)

• 18(For 5.2kW~8.5kW Wall mounted type Indoor)

• 24(Ceiling type Indoor)

Example

• MXD-14K300A

(3EA of 14 Capa

EEV)

• MXD-14K218A

(2EA of 14 Capa

EEV, 1EA of 18

Capa EEV)

➃ : Version

MCU Kit

(Mode Change

Unit Kit):

4, 6 Indoor Unit

connection

MCU-➀➁➂➃➄➅

MCU : Mode Change Unit Kit

➀ : Indoor Unit Connection

• 4:4 Indoor unit can be connected

• 6:6 Indoor unit can be connected

➁ : Indoor Power Supply type

➂ : Refrigerant type

➃ : Language

➄ : EEV existence

• MCU-4ECEVO

- MCU for indoor 4

connection,

220~240V / 50Hz

- Power supply,

English, EEV

existence

• MCU-4ECEO

• V : EEV existence

• Blank : EEV nonexistence

➅ : Version

Discharge Duct

Refnet Joint

MDF-➀➁

MDF : Outdoor discharge duct

MXJ-Y➀➁➂

MXJ : Refnet joint

Y : One packing for gas and liquid

side

➀ : Hole size (ø, cm, Double figures)

➁ : Version

➀ : Inlet pipe diameter for gas side

(mm, Double figures)

➁ : Inlet pipe diameter for liquid side

(mm, Double figures)

➂ : Version

24

• MDF-45A

• MXJ-Y3112A

Refnet Header

Model

MXJ-H➀➁➂➃

Standard for model name

MXJ : Refnet header

H : One packing for gas and liquid

side

Example

• MXJ-H3112A

➀ : Inlet pipe diameter for gas side

(mm, Double figures)

➁ : Inlet pipe diameter for liquid

side (mm, Double figures)

➂ : Version

Drain Pump

MDP-➀➁➂

MDP : Drain pump for separate

sales

• MDP-075SA

➀ : Lift (mm, Three figures)

➁ : Inlet pipe diameter for liquid

side (mm, Double figures)

➂ : Version

Front Panel

M➀➁➂➃➄➅➆

➀ : G (Grille applicable, Front panel) • MGKH118IE0

- Overseas

➁ : Applicable indoor unit

- For 1W/C

• K : 1-Way cassette

• G : 2-Way cassette

• C : 4-Way cassette

- Heat Pump

- 8 Languages

➂ : Function Classification

• H : Cooling only & Heat pump

• N : Not used wireless remote control

➃ : Size (Mark the longer part

between the width and length,

cm, three figures)

➄ : Color (G : Gray, I : Ivory)

➅ : Language [E : English only

C : Chinese

A : Arabic

M : 8 Languages

U : 3 Languages

(°F & Inch)

S : Mexico]

➆ : Version

Wireless

Remote

Control

MR-➀➁➂➃

MR : Wireless Remote Control

➀ : Design of Wireless Remote

Control (A-compact)

➁ : Function Classification (C : For

• MR-AC10

(Wireless remote

control for

cooling only)

Cooling only, H : Heat pump)

➂, ➃ : Version

INTRODUCTION • 25

Introduction

Classification

INTRODUCTION

2. DVM line-up

Classification

Remote

Control

Receiver Kit

(For Duct)

Model

MRK-➀➁➂➃

Standard for model name

MRK : Remote Control Receiver Kit

Example

• MRK-A00

➀ : Receiver Kit design (A~present)

➁ : Function Classification

(C : For cooling only,

H : Heat Pump)

➂ : Version

Remote

Control

Receiver

wire

MRW-➀➁

Wired

Remote

Control

MWR-➀➁➂➃➄

MRW : Remote Control Receiver Kit

Wire

• MRW-10A

➀ : Length (m, Double figures)

➁ : Version

MWR : Wired Remote Control

• MWR-AH01

➀ : Remote Control Design

(A-Present)

➁ : Function Classification

(C : For cooling only,

H : Heat Pump)

➂, ➃ : Version

➄ : Language [None : 9 Languages

C : Chinese

U : 3 Languages

(°F & Inch)]

Transmitter

(Interface

Module)

MIM-➀➁➂➃

MIM : Interface Module

➀ : Applicable part

• A : Indoor unit

• B : Outdoor unit

• C : Others

➁, ➂ : Version

➃ : Language

(None : 9 Languages,

C : Chinese)

• MIM-B00 :

- Centralized

Controller interface

module(up to

10.0HP outdoor unit)

• MIM-B04 :

- Centralized

controller interface

module(up to

30.0HP outdoor unit)

• MIM-B01A :

- PLC interface

module

• MIM-B02 :

- Key-Tag interface

module

• MIM-B06 :

- Integrate power

distributor interface

module for PC

metering

• MIM-B07 :

- Longwork interface

module

• MIM-B08 :

- Peak power control

interface module

26

Model

MCM-➀➁➂➃➄

Controller

Standard for model name

MCM : Controller

➀ : Function

• A : Controller

• B : Measuring instrument

• C : Others

➁ : LCD Classification

➂, ➃ : Version

➄ : Language [None : 9 Languages

C : Chinese

U : 3 Languages

(°F & Inch)]

Water Coil

-

MWC-➀➁➂➃➄

MWC : Water Coil

➀, ➁, ➂ : Applicable Indoor unit

Capacity (x 10kW)

Example

• MCM-A200

(Centralized

Controller)

• MCM-A100

(Function

Controller)

• MCM-B100

(Integrating

power

distributor)

• MWC-083D0

(For 8300W of

Low silhouette)

➃ : Applicable products

(H : High static pressure Duct,

D : Small static pressure Duct,

B : Built-in Duct)

➄ : Version

INTRODUCTION • 27

Introduction

Classification

INTRODUCTION

2. DVM line-up

2-6. Line -up

1) Outdoor unit

(1) Cooling only

Design

Power supply

Model

Capacity (HP)

Refrigerant

208-230V~, 1ø

RVMC050CBM0

5.0

R22

380-415V~, 3ø

RVMC060GAM0

6.0

R22

380-415V~, 3ø

RVMC060GAM1

6.0

R22

60Hz

208-230V~, 3ø

RVMC070FAM0(5)

7.0

R22

50Hz

380-415V~, 3ø

RVMC100GAM0

10.0

R22

60Hz

208-230V~, 3ø

RVMC100FAM0

10.0

R22

60Hz

50Hz

◆ The system enables the connection of indoor units with a total capacity of between 50% to 130% of that

of the corresponding outdoor unit but where this capacity ratio exceeds 100% the actual capacity of each

indoor unit will fall a little short of its individual rated capacity when all the units are operated

simultaneously. (Except for the Middle East models)

28

Design

Power supply

Model

Capacity (HP)

Refrigerant

380-415V~, 3ø

RVMH060GBM0

6.0

R22

380-415V~, 3ø

RVMH060GDM0(3)

6.0

R407C

208-230V~, 1ø

RVMH050CBM0

5.0

R22

380-415V~, 3ø

RVMH100GAM0

10.0

R22

380-415V~, 3ø

RVMH100GCM0(3)

10.0

R407C

208-230V~, 3ø

RVMH100FAM0(5)

10.0

R22

380-415V~, 3ø

RMAH140GAM✼

14.0

R22

380-415V~, 3ø

RMAH160GAM✼

16.0

R22

380-415V~, 3ø

RMAH180GAM✼

18.0

R22

380-415V~, 3ø

RMAH200GAM✼

20.0

R22

380-415V~, 3ø

RMAH220GAM✼

22.0

R22

380-415V~, 3ø

RMAH240GAM✼

24.0

R22

380-415V~, 3ø

RMAH260GAM✼

26.0

R22

380-415V~, 3ø

RMAH280GAM✼

28.0

R22

380-415V~, 3ø

RMAH300GAM✼

30.0

R22

50Hz

60Hz

50Hz

60Hz

50Hz

50Hz

*Separate installation

of RMBH100GAM✼

◆ The system enables the connection of indoor units within 100%.

◆ The maximum number of connectable indoor unit should be computed on the basis of the minimum

capacity of indoor unit within 100%. (But, the minimum capacity of RMAH❊❊❊H1M❊ is 0.7HP)

(3) Heat recovery

Design

Power supply

50Hz

380-415V~, 3ø

Model

Capacity (HP)

Refrigerant

RVMR100GCM0

10.0

R407C

INTRODUCTION • 29

Introduction

(2) Heat pump

INTRODUCTION

2. DVM line-up

2) Indoor unit

Design

Power Cool/

2.0kW

2.6kW

3.2kW

3.5kW

4.0kW

5.2kW

6.0kW

supply Heat (7000Btu/h) (9000Btu/h) (11000Btu/h) (12000Btu/h) (13500Btu/h) (18000Btu/h) (20000Btu/h)

1-Way cassette type

Cooling only AVMKC020EA✼ AVMKC026EA✼

-

AVMKC035EA✼

-

-

-

Heat pump

-

AVMKH035EA✼

-

-

-

50Hz

AVMKH020EA✼ AVMKH026EA✼

Cooling only AVMKC020CA✼

-

AVMKC032CA✼

-

AVMKC040CA✼

-

-

Heat pump

AVMKH020CA✼

-

AVMKH032CA✼

-

AVMKH040CA✼

-

-

Cooling only

-

-

-

-

-

AVMGC052EA✼

-

Heat pump

-

-

-

-

-

AVMGM052EA✼

-

Cooling only

-

-

-

-

-

AVMGC052CA✼

-

Heat pump

-

-

-

-

-

AVMGH052CA✼

-

Cooling only

-

-

-

-

-

AVMCC052EA✼

-

Heat pump

-

-

-

-

-

AVMCH052EA✼

-

Cooling only

-

-

-

-

-

AVMCC052CA✼

-

Heat pump

-

-

-

-

-

AVMCH052CA✼

-

Cooling only

-

-

-

-

-

AVMDC052EA✼

-

Heat pump

-

-

-

-

-

AVMDH052EA✼

-

Cooling only

-

-

-

-

-

AVMDC052CA✼

-

Heat pump

-

-

-

-

-

AVMDH052CA✼

-

Cooling only

-

-

-

-

-

-

-

Heat pump

-

-

-

-

-

-

-

Cooling only

-

-

-

-

-

-

-

Heat pump

-

-

-

-

-

-

-

-

AVMBC035EA✼

-

AVMBC052EA✼

-

-

60Hz

2-Way cassette type

50Hz

60Hz

4-Way cassette type

50Hz

60Hz

Duct type (Low silhouette)

50Hz

60Hz

Duct type (High / Low pressure)

50Hz

60Hz

Duct type (Built-in)

50Hz

Cooling only AVMBC020EA✼ AVMBC026EA✼

-

AVMBH035EA✼

AVMBH052EA✼

-

Cooling only AVMBC020CA✼

-

AVMBC032CA✼

-

AVMBC040CA✼ AVMBC052CA✼

-

Heat pump

-

AVMBH032CA✼

-

AVMBH040CA✼ AVMBH052CA✼

-

-

AVMWC035EA✼

-

AVMWC052EA✼

-

-

Heat pump

60Hz

Wall-mounted type

50Hz

Ceiling type

AVMBH020CA✼

Cooling only AVMWC020EA✼ AVMWC026EA✼

-

AVMWH035EA✼

AVMWH052EA✼

-

Cooling only AVMWC020CA✼

-

AVMWC032CA✼

-

AVMWC040CA✼ AVMWC052CA✼

-

Heat pump

AVMWH020CA✼

-

AVMWH032CA✼

-

AVMWH040CA✼ AVMWH052CA✼

-

Cooling only

-

-

-

-

-

AVMFC052EA✼

-

Heat pump

60Hz

AVMBH020EA✼ AVMBH026EA✼

AVMWH020EA✼ AVMWH026EA✼

50Hz

Heat pump

-

-

-

-

-

AVMFH052EA✼

-

Cooling only

-

-

-

-

-

-

-

Heat pump

-

-

-

-

-

-

-

60Hz

◆ The design and capacity of indoor unit are subject to change with HQ notice.

30

Power Cool/

7.0kW

7.2kW

8.2kW

8.3kW

10.5kW

12.8kW

14.0kW

supply Heat (24000Btu/h) (24000Btu/h) (28000Btu/h) (28000Btu/h) (36000Btu/h) (44000Btu/h) (48000Btu/h)

1-Way cassette type

Cooling only

-

-

-

-

-

-

-

Heat pump

-

-

-

-

-

-

-

Cooling only

-

-

-

-

-

-

-

Heat pump

-

-

-

-

-

-

-

Cooling only AVMGC070EA✼

-

-

-

-

-

-

Heat pump

AVMGH070EA✼

-

-

-

-

-

-

Cooling only

-

AVMGC072EA✼

-

-

-

-

-

Heat pump

-

AVMGH072EA✼

-

-

-

-

-

Cooling only AVMCC070EA✼

-

-

-

AVMCC105EA✼

AVMCC128EA✼

AVMCC140EA✼

Heat pump

AVMCH070EA✼

-

-

-

AVMCH105EA✼

AVMCH128EA✼

AVMCH140EA✼

Cooling only

-

AVMCC072CA✼

-

-

AVMCC105CA✼

AVMCC128CA✼

AVMCC140CA✼

Heat pump

-

AVMCH072CA✼

-

-

AVMCH105CA✼

AVMCH128CA✼

AVMCH140CA✼

Cooling only AVMDC070EA✼

-

-

-

-

-

-

Heat pump

AVMDH070EA✼

-

-

-

-

-

-

Cooling only

-

AVMDC072CA✼

-

-

-

-

-

Heat pump

-

AVMDH072CA✼

-

-

-

-

-

Cooling only

-

-

-

-

AVMH(L)C105EA✼ AVMH(L)C128EA✼ AVMH(L)C140EA✼

Heat pump

-

-

-

-

AVMH(L)H105EA✼ AVMH(L)H128EA✼ AVMH(L)H140EA✼

Cooling only

-

-

-

-

AVMHC105CA✼

AVMHC128CA✼

-

Heat pump

-

-

-

-

AVMHH105CA✼

AVMHH128CA✼

-

-

-

-

-

-

-

50Hz

60Hz

2-Way cassette type

50Hz

60Hz

4-Way cassette type

50Hz

60Hz

Duct type (Low silhouette)

50Hz

60Hz

Duct type (High / Low pressure)

50Hz

60Hz

Duct type (Built-in)

50Hz

60Hz

Wall-mounted type

50Hz

60Hz

Ceiling type

Cooling only AVMBC070EA✼

Heat pump

AVMBH070EA✼

-

-

-

-

-

-

Cooling only

-

AVMBC072CA✼

-

-

-

-

-

Heat pump

-

AVMBH072CA✼

-

-

-

-

-

-

-

-

-

-

-

Cooling only AVMWC070EA✼

Heat pump

AVMWH070EA✼

-

-

-

-

-

-

Cooling only

-

AVMWC072CA✼

-

-

-

-

-

Heat pump

-

AVMWH072CA✼

-

-

-

-

-

Cooling only AVMFC070EA✼

-

-

-

-

-

-

50Hz

Heat pump

AVMFH070EA✼

-

-

-

-

-

-

Cooling only

-

-

-

-

-

-

-

Heat pump

-

-

-

-

-

-

-

60Hz

◆ The design and capacity of indoor unit are subject to change with HQ notice.

INTRODUCTION • 31

Introduction

Design

INTRODUCTION

3. Selection procedure

3-1. Selection procedure standard of DVM system based on cooling load

1) Indoor unit selection

Select the nearest load capacity indoor unit with given load after finding indoor and outdoor temperature

using indoor unit capacity table. (The indoor unit capacity should be larger than the given load)

◆ The described capacity may be different to each indoor unit according to combination.

So, the real capacity should be calculated with outdoor unit capacity table.

2) Outdoor unit selection

The allowable combination is described on the indoor unit combination from total capacity index table below.

For the standard of indoor unit and outdoor unit combination, select the nearest value that the total indoor unit

capacity index is less than a 100% outdoor unit combination capacity index.

■ Indoor unit combination total capacity index

Indoor unit combination rate

Outdoor unit

100%

90%

80%

70%

60%

50%

RVMH060GBM0

16.0

14.4

12.8

11.2

9.6

8.0

RVMH100GAM0

28.0

25.2

22.4

19.6

16.8

14.0

RVMH100FAM0

28.0(ISO)

25.2

22.4

19.6

16.8

14.0

◆ The system enables the connection of indoor units with a total capacity of between 50 to 100% of that of the

corresponding outdoor unit .

■ Indoor unit nominal capacity index

- 50Hz

- 60Hz

Unit size

020

026

035

052

060

070

082

105

128

140

Capacity index

2.0

2.6

3.5

5.2

6.0

7.0

8.2

10.5

12.8

14.0

Unit size

020

032

040

052

060

072

083

105

128

140

Capacity index

2.0

3.2

4.0

5.2

6.0

7.5

8.3

10.5

12.8

14.0

3) Actual performance data

(1) Select the exact table according to outdoor unit model and combination rate using outdoor

unit capacity table. According to given indoor and outdoor temperature, find outdoor unit

capacity and power input using the table.

Each indoor unit capacity (power input) is calculated as follow.

IUC=OUC x INX/TNX

IUC: Each indoor unit capacity (power input)

OUC: Outdoor unit capacity (power input)

INX: Each indoor unit capacity index

TNX: Total capacity index

(2) According to pipe length, change the indoor unit capacity. If the changed capacity is smaller

than load, change it to the larger capacity of indoor unit and repeat the selection progress.

32

Introduction

4) Selection example based on cooling load

(1) Given condition

1. Design condition (Cooling: Indoor WB 20°C, Outdoor DB 33°C)

2. Cooling load

Location

Room A

Room B

Room C

Room D

Room E

Room F

Load (kW)

2.4

2.6

3.2

3.4

4.8

7.2

3. Power supply unit: 3 Phase 380V 50Hz

4. Pipe length: 30m

(2) Indoor unit selection

Select the suitable capacity for condition of 'Indoor WB 20°C, Outdoor DB 33°C' using indoor unit capacity

table. The selected result is as follow.

Location

Room A

Room B

Room C

Room D

Room E

Room F

Load (kW)

2.4

2.6

3.2

3.4

4.8

7.2

Unit size

26

26

35

35

52

70

Capacity(kW)

2.8

2.8

3.77

3.77

5.6

7.54

(3) Outdoor unit selection

1. Assume the indoor unit and outdoor unit combination as follow.

Outdoor unit: RVMH100GAM0

Indoor unit: AVMKH026EA0 x 2, AVMKH035EA0 x 2, AVMCH052EA0 x 1, AVMCH070EA0 x 1

2. Indoor unit combination total capacity index

2.6x2 + 3.5x2 + 5.2x1 + 7.0x1 = 24.4, (24.4/28.0) x 100% = 87%

3. Result: Because it is within 50~130%, it is 'Right' selection (Within 100% for the Middle East).

(4) Real function data with indoor unit combination

1. For the 87% combination, calculate the cooling capacity of outdoor unit (RVMH100GAM0).

27.14kW ← 90% (Indoor temperature: WB 20°C, Outdoor temperature: DB 33°C)

24.12kW ← 80% (Indoor temperature: WB 20°C, Outdoor temperature: DB 33°C)

Therefore, 26.23 = 24.12 + {(27.14-24.12)/10}x7: Calculated in 87%

2. Outdoor unit (RVMH100GAM0) cooling capacity: 26.23kW ← 87%

(Indoor temperature: WB 20°C, Outdoor temperature: DB 33°C)

INTRODUCTION • 33

INTRODUCTION

3. Selection procedure

3-2. DVM capacity correction ratio

1) Change of cooling capacity

94.0%

50

2) Change of heating capacity

92.5%

91.0%

89.5%

88.0% 86.5%

40

20

Height difference 10

(m)

97.0%

100%

0

88.0% 86.5%

91.0%

94.0%

93.0%

92.0% 91.0%

99.0%

20

100%

94.0%

98.0%

30

98.5%

95.0%

97.0%

40

97.0%

30

96.0%

50

95.5%

100%

Height difference 10

(m)

0

98.0%

100%

92.0% 91.0%

94.0%

96.0%

-10

-10

-20

-20

-30

-30

-40

0

10

20

30

40

50

60

70

80

90

100

0

10

20

30

40

50

60

70

Piping length (m)

80

90

100

Piping length (m)

3) Each cooling capacity

Location

Room A

Room B

Room C

Room D

Room E

Room F

Load (kW)

2.4

2.6

3.2

3.4

4.8

7.1

Unit size

26

26

35

35

52

70

Capacity(kW)

2.71

2.71

3.65

3.65

5.42

7.30

◆ AVMKH026EA0: 26.23 x 26/244 x 0.97 = 2.71(kW)

◆ AVMKH035EA0: 26.23 x 35/244 x 0.97 = 3.65(kW)

◆ AVMCH052EA0: 26.23 x 52/244 x 0.97 = 5.42(kW)

◆ AVMCH070EA0: 26.23 x 70/244 x 0.97 = 7.30(kW)

34