EM-355(S) / EM-355B(S)B Processing Guideline

advertisement

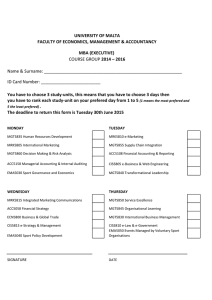

Elite Material Co., Ltd. Preliminary Technical Data http:\\www.emctw.com EM-355(S) / EM-355B(S)B Processing Guideline 1. Oxide Treatment EM-355(S) is compatible with most of oxide treatment used by PCB industry as below. Oxide Treatment Bake Suggestion Black Oxide chemically reduced with DMAB* 95-105oC (203-221oF) 35-45 Minutes 100-120oC (212-248oF)** 30-60 Minutes Oxide Replacement *DMAB: Dimethylamine Borane **For some critical condition, the additional baking after oxide replacement can improve the drying effectiveness and enhance the thermal reliability performance. The oven bake suggestions above are general suggestions from of a particular supplier of reduced oxide and oxide replacement chemistry. Higher baking temperature and longer baking time can degrade the coating’s acid resistance and/or reduce the peel strength between resin and copper surface after oxide treatment. It is recommended that the PWB fabricator test these suggestions to verify their performance in their particular applications. Each fabricator should consult its coating supplier for specific bake suggestions. 2. Prepreg Thickness Below table is unclad laminate thickness of EM-355(S). Pressed Prepreg thickness on various constructions could be calculated by equation A. Butter coat thickness should be maintained at least 5 μm for better adhesion. Type R/C(%) 106 106 1067 1067 1067 1078 1078 1080 1080 1080 1080 1086 1086 1086 2113 2113 3313 3313 3313 2116 2116 2116 2116 1501 1501 7628 / 7629 7628 / 7629 71±3.0 73±3.0 71±3.0 73±3.0 75±3.0 63±3.0 69±3.0 63±3.0 65±3.0 69±3.0 71±3.0 63±3.0 65±3.0 69±3.0 57±3.0 59±3.0 55±3.0 57±3.0 59±3.0 53±3.0 55±3.0 57±3.0 59±3.0 49±3.0 51±3.0 44±3.0 48±3.0 100% pressed thickness(mil) 2.1 2.3 2.5 2.8 3.0 3.0 3.8 3.0 3.3 3.8 4.1 3.4 3.6 4.1 4.1 4.4 4.0 4.3 4.5 4.9 5.2 5.5 5.9 7.0 7.4 7.9 8.6 H : prepreg thickness after filling inner layer pattern H0 : unclad laminate thickness R : residual copper ratio T : copper thickness Rev: 2015 Jun 1 Elite Material Co., Ltd. Preliminary Technical Data http:\\www.emctw.com 3. Press Cycle General press cycle for normal construction of multilayer PWB: >180°C (material temperature) x 60 min for board thickness<3.0mm. Curing For board thickness >3mm, please contact local customer service for further assistance. The material should reach a peak temperature of 195°C at least. Material Heat Rise 1.7 ~2.6°C/min (from 80°C to 155°C). Kiss pressure 5~7 kgf/cm2 (70~100 psi). Apply middle pressure and ramp up slowly to full pressure is preferable. Pressure Apply full pressure 25~32 kgf/cm2 (360 ~ 460 psi) when the material temperature reaches 100°C-120°C. Pressure could be reduced from full pressure to kiss pressure in multiple steps after 50~60 % curing stage is reached for stress relief. Cooling Rate < 2°C/min, is preferable starting from 190°C to 120°C. Please contact our customer service for setting suitable press cycle if necessary. Note The attached graph is for reference purpose only and may require further adjustment depending on the board size, thickness and complexity. 4. Prepreg storage (Shelf life) EM-355(S)B should be stored under 23℃, RH 55% for 3 month shelf life. Rev: 2015 Jun 2 Elite Material Co., Ltd. Preliminary Technical Data http:\\www.emctw.com 5. Drilling Parameter Drill Size Spindle In-feed Retract SFM Chip Load mm Krpm In/Min In/Min 0.25 120 60.1 500 309.21 0.50 750 Prefered 0.30 110 63.0 500 340.13 0.57 1000 Prefered 0.35 110 74.8 500 396.82 0.68 1000 Prefered 0.40 99 78.7 500 408.16 0.80 1000 Prefered 0.45 88 78.7 500 408.16 0.89 1000 Prefered 0.50 80 78.7 500 412.28 0.98 1000 Prefered 0.55 72 78.7 500 408.16 1.09 1200 Prefered 0.60 66 78.7 500 408.16 1.19 1200 Prefered 0.65 61 78.7 500 408.68 1.29 1200 Prefered 0.70 57 78.7 500 411.25 1.38 1200 Prefered 0.75 53 78.7 500 409.71 1.49 1500 Prefered 0.80 50 78.7 500 412.28 1.57 1500 Prefered surface feet/Min (mil /rev) Enter board Max Hit (LE Sheet) Notes: 1. UC type drill bit is recommended. 2. Total stack height depends on effective flute length of drill bit. Sufficient space for chip removing should be kept to ensure that chips could be removed entirely. 3. Peck drill is depending on following situations, at least 2 steps is highly recommended. 3.1 thick board with drill holes (high A/R) 3.2 >=2 stack height of thinner board such as 1.2mm or 1.6mm board thickness 3.3 with CAF requirement 3.4 wicking less than 50um criteria 4. The above is just for reference. Modification and adjustment should be done to ensure that hole wall roughness is less than 1.2 mil and nail head is less than 1.5x. 6. Post baking after deburr Bake the boards at 170℃ for 2hrs after drilling ( deburr ) is recommended to promote better hole wall reliability. Rev: 2015 Jun 3 Elite Material Co., Ltd. Preliminary Technical Data http:\\www.emctw.com 7. Smear Removal (1) Chemical Desmear: The typical sweller type glycol ether is prefer, cyclic amine solvent sweller such as n-methyl pyrolidone (NMP) is not recommended. (2) The typical desmear weight loss is as below figure shown. EM-355(S) Note: Please note that there are several factors would influence the hole wall cleanness such as drilling parameters, build up thickness, aspect ratio, it is necessary to adjust the proper parameter based on above factors. It is recommended to confirm the hole wall quality by SEM. Over desmear will cause crazing growth, reduce CAF resistance capability and induce delamination, please review cross-section carefully before any adjustment. (3) The following pictures show that the surface of hole wall is rough enough without any smear existing on the resin surface after desmear. Before desmear After desmear The above process recommendations are intended for general review purposes. Process adjustments may be required to achieve optimum results in your specific manufacturing environment. Rev: 2015 Jun 4