Infrastructure for your Architecture

Creating an electrical infrastructure that maximizes the reliability of your critical control circuits

Protect your Investment, Reduce your System Downtime

Allen-Bradley Bul. 4983 Surge Protective Devices help to protect your

electronic equipment to help extend the life of your investment.

Surge Protective Device Background

Information

Transient Definition: A high voltage transient is a high

energy, short term (1…10μs) deviation or change from

desired voltage levels. It is an unwanted bundle of high

electrical energy in the AC power line or communications

line. The transient can be noted as a single overvoltage

spike or a burst of spikes, sometimes followed by a ringing

waveform.

Causes of Transients:

Any electrical power sources that switches on/off

20% Outside Facility

• Lightning Strike

• Utility Grid Switching

80% Within Facility

•

•

•

•

Large Starters / Motors / Contactors

Variable Frequency Drives

Air Circuit Breakers

Welders

Effects of Noise and Transients (3 D’s): Process

errors, System Downtime, Component Failure

Disruption – Intermittent operation of the system/equipment. Examples include program and data errors, corruption of memory, and system crashes.

Degradation – Components exposed to repeat transients

and/or noise can experience shortened operating life. Over

time, these disturbances degrade equipment, which can

cause intermittent operation or corrupted data. The effects

of transients and noise are cumulative.

Destruction – Electronic equipment is sensitive to these

transients and may fail. An example of this would be

destruction due to damage on the printed circuit board

traces.

Advantages of using Surge Protective Devices:

•

•

•

•

•

Higher Surge Current Protection Rating

Longer Equipment Life Expectancy

Easy to Replace (when the device sacrifices its life)

Less expensive to install and replace

Remote and Visual Status Indication when protection has

reached end of life

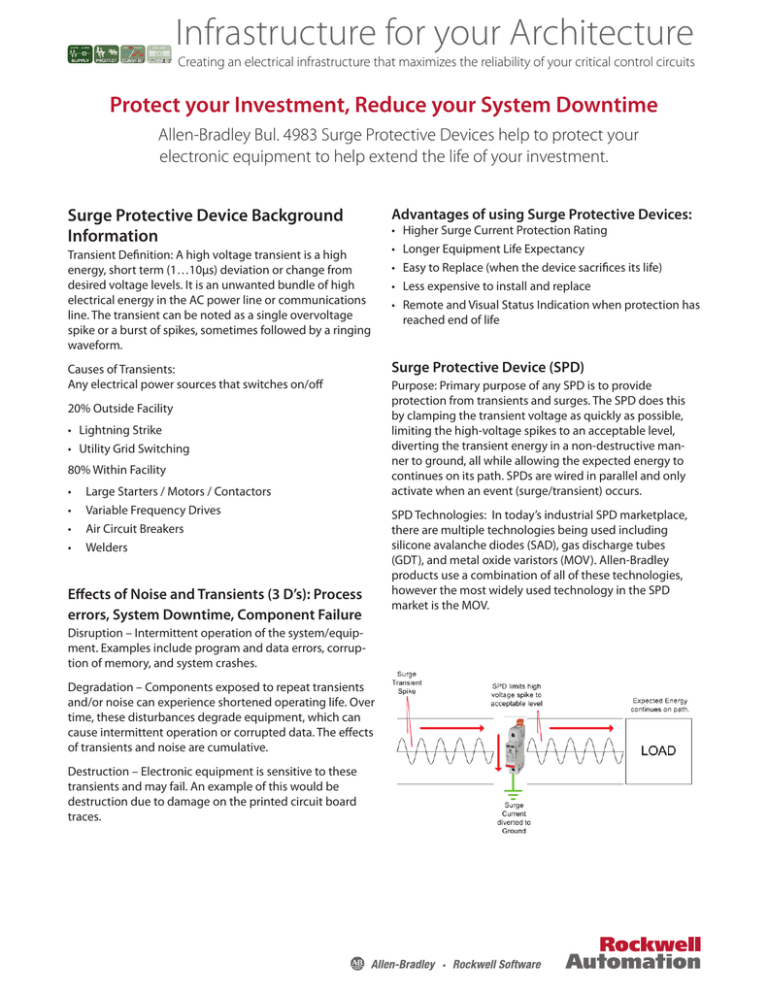

Surge Protective Device (SPD)

Purpose: Primary purpose of any SPD is to provide

protection from transients and surges. The SPD does this

by clamping the transient voltage as quickly as possible,

limiting the high-voltage spikes to an acceptable level,

diverting the transient energy in a non-destructive manner to ground, all while allowing the expected energy to

continues on its path. SPDs are wired in parallel and only

activate when an event (surge/transient) occurs.

SPD Technologies: In today’s industrial SPD marketplace,

there are multiple technologies being used including

silicone avalanche diodes (SAD), gas discharge tubes

(GDT), and metal oxide varistors (MOV). Allen-Bradley

products use a combination of all of these technologies,

however the most widely used technology in the SPD

market is the MOV.

MOVs

An MOV is an electronic component with a significant non-linear current/voltage characteristic. When used in a surge

protective device, the MOV is wired in parallel to the circuit and used to divert the excess transient energy to ground.

Essentially when the circuit voltage is below a certain “activation” voltage the device’s resistance is very high therefore

passing a low amount of current through it. However, when the circuit voltage is above the “activation” voltage the

device’s resistance is low and therefore passes a large amount of current through it.

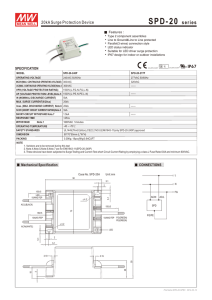

Specification Considerations when selecting Surge Protective Devices:

When selecting or comparing multiple SPDs, it is important to understand the ratings that are being presented as in

many cases these values can be complex and confusing. In this section, some of the key ratings will be described in order

to help develop a better understanding of the significance of these values and what they mean. These ratings are shown

in the 4983 Product Family Brochure in order to make the selection process easier for the customers as shown in the

example on Table 3.

Table 3: Example of the 4983 Product Family Brochure Selection Table

Maximum Continuous Operation Voltage (MCOV):

Maximum value of the voltage that can be applied before

“activating” or “turning on” the SPD. Once this value is

exceeded the MOV starts conducting thus shunting the

excess energy to ground and “clamping” the energy to an

acceptable level.

Voltage Protection Rating (VPR): UL 1449 maximum

rated surge voltage value that will be allowed to pass

through the circuit to the protected load device. This is

the maximum value that is measured after the SPD has

clamped/limited the surge voltage to the load. This is

commonly referred to as the “let-thru” voltage.

• 2

Impulse Surge Current Rating (Iimp): IEC rated peak onetime surge current value of a 10/350μs waveform that

can be safely diverted through the SPD. This 10/350μs

is an ANSI/IEEE C62.41 standard waveform that rises to

90% of the peak surge current value in 10μs and decays

to 50% of the peak surge current value in 350μs (see

Diagram 1). This is a very large energy waveform that can

be considered a “simulated” lightning strike.

Diagram 1: ANSI/IEEE C62.41 10/350μs Waveform Diagram

Maximum Discharge Current Rating (Imax): IEC rated

peak one-time surge current value of a 8/20μs waveform

that can be safely diverted through the SPD. This 8/20μs

waveform is an ANSI/IEEE C62.41 standard waveform that

rises to 90% of the peak surge current value in 8μs and

decays to 50% of the peak surge current value in 10μs

(see Diagram 2). This value is used as a selection value for

the desired protection level in most SPD offerings.

Diagram 2: ANSI/IEEE C62.41 8/20μs Waveform Diagram

Nominal Surge Current Rating (In): UL 1449 rated surge

current value of an 8/20μs waveform (see Diagram 2) that

can be safely diverted through the SPD at a minimum of

15 instances. UL declares the acceptable values for this

test with a maximum value of 20kA.

Diagram 3: Visual representation of the energy level difference between the two test waveforms

• 3

Allen-Bradley, Rockwell Software, and Rockwell Automation are trademarks of Rockwell Automation Inc.

Publication 4983-AT001A-EN-P – June 2011

Copyright ©2011 Rockwell Automation, Inc. All Rights Reserved. Printed in USA.