copper-nickel pipe fittings and flanges

advertisement

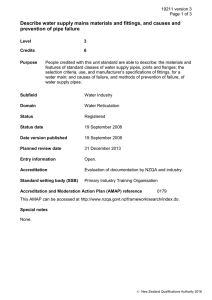

COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY SAMYANG METAL / 2 COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY Greetings Greetings Welcome! We SAMYANG Metal is the leading company NonFerrousMetal, which has continued a leading role in the marine industrial development of South Korea for the past 25 years by supplying quality nonferrous products at lowest reasonable prices. We are sure that you will be quite satisfied with our services and the excellent qualities of our goods. We Samyang metal is becoming a world’s premier non-ferrous fitting & flange manufacturer by striving continual management innovation and technology development. We Samyang metal is willing to take a role in domestic and international industrial development as well as in improving the quality of your life by improving the standard of living and protecting our natural environment. We Samyang metal appreciates your continued support and encouragement. May your visit at our web site be a pleasant one as well as a productive one. We are ready to serve you with all your nonferrous metal needs. Thank you Certificates Certificates ISO 9001 : 2000 DNV BV Lloyd INNO-BIZ Technology Laboratory Venture Business SAMYANG METAL / 3 COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY SAMYANG METAL / 4 COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY History History May 1981 Dec 1986 Apr 1994 Feb 1999 May 2002 Jul 2004 Dec 2004 Aug 2005 Established SAMYANG metal Co. at Janglim-Dong, Saha-Gu, Busan Moved to the new factory at Janglim-Dong, Saha-Gu, Busan Moved to the new factory at Hakjang-Dong, Sasang-Gu, Busan(2nd factory) Changed name to SAMYANG metal industrial Co., Ltd. Established new factory at Dadae-Dong, Saha-Gu, Busan(Main factory) Elected as president with Jin-Min, Seo Established new factory at Dadae-Dong, Saha-Gu, Busan(3rd factory) Established technology laboratory Award / Approval Award / Approval Apr 1987 Mar 1990 Mar 1992 Jan 1994 Feb 1995 Feb 1996 Jan 1997 Oct 1998 Jan 2004 Feb 2004 Nov 2005 Feb 2006 Mar 2006 Jul 2006 Approved by Hyundai heavy Ind. Co., Ltd. Approved by Nippon Kaiji Kyokai Approved by CSBC in Taiwan Approved by the Ministry of National Defense Approved by Daewoo, Samsung, Hanjin heavy Ind. Co., Ltd. Registered as a member of KFTA(Korea Foreign Trade Association) Won the prize from Korea Tacoma Shipyard as excellent supplier Won ISO 9002:1994 Won ISO 9001:2000 Approved by shipping classes(LR, DNV, ABS, BV, etc) Design item addition of ISO 9001:2000 Approved by ONGC in India Selected venture business from the SMBA(Small and Medium Business Administration) Selected INNO-BIZ from the SMBA(Small and Medium Business Administration) SAMYANG METAL / 5 COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY GENERAL INFORMATION THE MATERIAL THE FITTINGS & FLANGES FOR COPPER AND COPPER-NICKEL ALLOYS. FLANGES FOR COPPER-NICKEL PIPE FLANGES FOR COPPER PIPE BUTT WELDING FITTINGS FOR COPPER-NICKEL PIPE SOCKET WELDING FITTINGS FOR COPPER PIPE The Introduction of Cuni 90/10 and Cuni 70/30 Alloy ; The Attractive corrosion and biofouling - Resistance of copper-nickel naval service. In naval vessels, the 90-10 copper-nickel is preferred alloys in seawater and related environments have Led to their for surface ships; Whereas, the 70-30 alloy is used for submarines substantial use in marine service for many years. because its greater strength makes it more acceptable for the higher The two main, wrought copper-nickel Alloys chosen for seawater pressures encountered. These alloys are also used for power station service contain 10% or 30% Nickel, respectively. condensers and offshore seawater pipe work on oil/gas platforms: Development work began in the 1930s in response to A requirement Large quantities are selected for the desalination industry and they by the british navy for in improved condenser material. are additionally used for cladding and sheathing of marine structures Since the 1950s, the 90-10 Alloy has become accepted for and hulls. condenser service as well as for seawater pipe work in merchant and SAMYANG METAL / 6 COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY GENERAL INFORMATION THE MATERIAL Characteristics of Copper Nickel Alloy ; Good Resistance to stress corrosion & cavitaion erosion. Excelent resistance to sea water Good thermal stability (up to approx. 300 ) Good cold - workability Good Welding and solder properties. Chemical Composition and Comparision Table for Cu-Ni Alloys Comparison Table of Standard Specifications for Cu-Ni 90/10 Pipe DIN 17664 2.0872 DIN 86019 2.1972 BS 2871 CN 102 EEMUA 144-1987 UNS C 7060x MIL-T-16420K ASTM B 466 C 70600 JIS H 3300 C 7060T Cu+Ni+Fe Cu% Ni% Fe% Mn% C% Pb% rem. 9.0 - 11.0 1.0 - 2.0 0.5 - 1.0 max. 0.05 max. 0.03 rem. 9.0 - 11.0 1.5 - 1.8 0.5 - 1.0 max. 0.05 max. 0.01 rem. 10.0 - 11.0 1.0 - 2.0 0.5 - 1.0 max. 0.05 max. 0.01 rem. 10.0 - 11.0 1.5 - 2.0 0.5 - 1.0 max. 0.05 max. 0.01 rem. 9.0 - 11.0 1.0 - 1.8 max. 1.00 max. 0.05 max. 0.02 rem. 9.0 - 11.0 1.0 - 1.8 0.2 - 1.0 max. 0.05 S% P% Zn% max. 0.02 max. 0.02 max. 0.50 max. 0.005 max. 0.02 max. 0.05 max. 0.05 - max. 0.02 max. 0.02 max. 0.20 max. 0.02 max. 0.02 max. 0.50 max. 0.50 Other imp. max. 0.30 max. 0.20 max. 0.30 max. 0.30 - Cu+Ni+Fe+Mn : min 99.5% Comparison Table of Standard Specifications for Cu-Ni 70/30 Pipe DIN 17664 2.0882 Cu% Ni% Fe% Mn% C% Pb% S% P% Zn% Other imp. BS 2871 CN 107 MIL-T-16420K ASTM B 466 C 71500 rem. rem. rem. 30.0 - 32.0 0.4 - 1.0 0.5 - 1.5 30.0 - 32.0 0.4 - 1.0 0.5 - 1.5 29.0 - 33.0 0.4 - 1.0 max. 1.00 max. 0.05 max. 0.03 max. 0.06 max. 0.01 max. 0.05 max. 0.02 max. 0.02 max. 0.02 max. 0.50 max. 0.08 - max. 0.02 max. 0.02 max. 0.50 max. 0.30 - - SAMYANG METAL / 7 JIS H 3300 C 7150T rem. 29.0 - 33.0 0.4 - 1.0 0.2 - 1.0 max. 0.05 max. 0.50 Cu+Ni+Fe+Mn : min 99.5% COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY GENERAL INFORMATION THE FABRICATION TECHNIQUES FOR COPPER NICKEL ALLOY bending machine the tube must be filled. The most usual filler are dry silica sand free from all carbonaceous matter and sodium thiosulfate (hypo). The tube must be tightly packed. After bending it is important that the filler is completely removed and the tube thoroughly cleaned. Annealing Heating In the presence of contaminants such as sulphur, phosphorus, lead and other low-melting-point meals, copper alloys may become embrittled when heated. It is therefore important that the workpiece is clean and free from contaminants before heating. Sources of deleterious substances are marking and temperature-indicating paints and crayons, lubricating grease and fluids, fuels etc. Fuels must be low in sulphur; e. g. natural gas and liquid petroleum gas should contain less than 0.1% and town s gas 0.25% maximum of sulphur. Fuel oil should contain a Maximum of 0.5% sulphur. (all percentages are by weight.) For Cunifer 10 and Cunifer 30 the furnace atmosphere should be neutral or very slightly reducing. Electric heating is recommended. Hot working Hot working may be carried out in the following ranges : Cunifer 10 950 - 840 (1750 - 1550 ) Cunifer 30 1000 - 840 (1830 - 1550 ) See also the later section on got bending. The material may be charged into the furnace at maximum working temperature and allowed to soak until the workpiece is uniformly heated, approximately 60 minutes/100mm(4in) of section. The material should then be withdrawn immediately and worked within the specified range. Prolonged soaking should not be allowed. If during working, temperature of the metal falls below the specified minimum it must be reheated. Air cooling is satisfactory. Cold bending Metallurgical annealing is not necessary after hot working. For Cunifer 10 and Cunifer 30 a full anneal is achieved by heating to 750 - 840 (1380 - 1550 ) but a considerable degree of softening can be obtained b heating at 600 - 650 (1100 - 1200 ) Stress relief can be achieved by heating within the range 350 - 450 (660 - 840 ). Pickling After hot and/or cold bending, cleaning and stress relieving, all traces of scale should be removed by pickling or acid cleaning. A suitable pickling solution is 5 to 10% of sulphuric acid plus 25 50 g/l(4 8 oz/gal.) of sodium dichromate. After picking, the tube should be thoroughly rinsed in hot, fresh water. Joining Metallurgically, Cunifer 10 and Cunifer 30 are solid-solution alloys with no deleterious second phases and experience no phase transformation during heating and cooling. They are usually welded or brazed in the annealed condition. It is also essential that the surfaces adjacent to the joint must be clean and free from oxide. To remove oxide and other contaminants, an area approximately 25mm(1in) wide on each side of the joint should be prepared by scratch-brushing with a clean, stainless steel brush used only for copper alloy. This is followed by degreasing with a non-toxic non-flammable solvent. No pre-heat is required, but the material must be free from moisture. In cold or humid conditions, it should be warmed to about 25 (80 ). Interpass temperature should be controlled and should not exceed 10 (250 ). Modern welding techniques such as TIG and MIG may be used in addition to brazing for the joining. Pipes are normally supplied in the annealed condition. If possible, the tube should be bent using bending machines when the radius of curvature is equal to or greater than three times the diameter. Tubes up to 80mm(3in) diameter may be cold bent with radius of curvature equal to twice the diameter. For bend radii less than this it is advisable to use fittings. Where cold bending is done without the use of a tube SAMYANG METAL / 8 COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY GENERAL INFORMATION THE FABRICATION TECHNIQUES FOR COPPER NICKEL ALLOY JOINT PREPARATION Welding Consumables It is usual practice to weld Cunifer 10 with 70/30 copper-nickel bare filler metal. Flux-coated electrodes can be used for wall thicknesses of above 6mm. Welding consumables of almost matching composition to Cunifer 10 are, however, available. Under certain circumstances the use of a nominally 70/30 nickelcopper electrode or filler metal, particularly for dissimilar metal joints, is suggested. Cunifer 30 can be welded with 70/30 copper-nickel filler metal. Table 1 gives details of material specification. Thickness 1.5mm 3.0mm 3.0mm Welding Consumable Specifications Country 90/10 copper-nickel-iron 70/ 30 copper-nickel-iron Flux-coated electrode Germany British United States of America Filler wire Flux-coated electrode Filler wire DIN1733 DIN1733 DIN1733 DIN1733 S-CuNi10Fe S-CuNi10Fe S-CuNi30Fe S-CuNi30Fe Mat No. 2.0873 Mat No. 2.0873 Mat No. 2.0873 Mat No. 2.0873 BS2901:Part3 Type C16 90/10 Cu-Ni-Fe-Ti BS2901:Part3 Type C18 30/70 Cu-Ni-Fe-Ti AWS A 5.6 AWS A 5.7 Class ECuNi Class RCuNi Table 1 : Related specifications for flux-coated electrodes and bare filler wires for welding of Cunifer 10 and Cunifer 30. Welding Whichever process is used, tack welds should be kept to a minimum and as short as possible. Tack welds should be deposited in the opposite direction to the subsequent weld run and each tack must be thoroughly cleaned before welding commences. Manual metal arc welding is applicable to Cunifer 10 and Cunifer 30 with thicknesses greater than 6mm(0.2in) The majority of flux-coated electrodes are recommended for operation with direction current, electrode positive. Suggested joint preparations are shown in figure1. Figure 1 : Suggested joint preparations for the welding of Cunifer 10 and Cunifer 30. Manual metal arc welding is preferably carried out in the downhand position. Positional welding can be performed successfully by skilled operators. Positional welding is facilitated by making the root run by the TIG process. Direction of travel is then reversed and welding continued with a weave motion TIG is preferred for metal thicknesses up to and including 6mm(0.2in). TIG welding may also be used for the root runs in thicker material, the fill-up runs being deposited by the manual metal arc process. For Cunifer 10 and Cunifer 30, direct current is required. For all these materials shielding gas is 99.95% pure argon which is also used as the back purging gas for Cunifer 10 and Cunifer 30. Satisfactory filler wires are given in table 1 and suggested edge preparations are shown in figure1. Table 2 gives typical operating data for TIG welding. Metal thickness Diameter of tungsten electrode Diameter of filler wire Welding current mm in mm mm mm 1.5 0.06 1.6 1.5 or 2.0 60 - 80 2 0.08 1.6 2.0 80 - 100 4 0.16 2.4 or 3.2 2.0 to 4.0 170 - 190 6 0.24 3.2 3.2 to 5.0 240 - 280 8 0.32 3.2 3.2 to 5.0 240 - 280 10 0.40 3.2 3.2 to 5.0 240 - 280 Table 2 : Typical operating data for the TIG welding of Cunifer 10 and Cunifer 30 SAMYANG METAL / 9 COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY Butt Welding Fittings SAMYANG METAL / 10 COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY BUTT WELDING FITTINGS APPLIED SPECIFICATION Butt Welding Fittings meet the following national and international product standards Seamless Butt Welding Fittings Seamless butt weld fittings are produced from Seamless tube and pipe by either hot or cold extrusion, forming, forging, machining, or by a combination of two or more of these operation. Seamless butt weld fittings are available in standard size, as published in this catalogue, and in nonstandard sizes. Standard size fittings are genellaly available ex stock. Seam Welded Butt Welding Fittings Seam-Welded butt weld fittings are produced from hot or cold rolled, annealed and pickled sheet or plate, formed into half shells or segments and longitudinally seam-Welded. Seam-Welded Butt-Welding Fittings are available in standard sizes, as published in this catalogue, and in nonstandard sizes. Welding Welding is carried out by Code-qualified personnel (ASME Boiler and Pressure Vessel Code) whose qualifications are regularly checked and approved. Established welding methods include pulsed TIG and shielded-electrode techniques. End Preparation Unless otherwise agreed, Butt-Welding Fittings are supplied with plan ends. Cut square and deburred at a wall thickness of 2mm below. Alternatively, fittings with a wall thickness of 2.0mm and above can be supplied with beveled ends to ANSI B16.25 Material 90/10 Copper Nickel Alloy DIN 86013 2.1972, DIN 17664 2.0872 BS2871, 2872, 2875 CN102 EEMUA 144 ASTM B466, B467, C70600, MIL-T-16420K C70600 JIS H3300 C7060T 70/30 Copper Nickel Alloy DIN 17664 2.0882 BS2871, 2872, 2875 CN107 ASTM B466, B467, C71500, MIL-T-16420K C71500 JIS H3300 C7150T Dimension DIN 86011, 86087, 86088, 86089, 86090 BS1640 ANSI B16.9, B16.28 JMS 7354 Marking All Butt-Welding Fittings are marked with Alloy No, Heat No, Nominal Diameter, Degree and maker’s trade mark. Additional information, e, g standard and alloy number, maximum pressure rating in bar, can be added on request Inspection and Testing Throughout the manufacturing process from melting and alloying to the finished product, stringent quality control inspections and tests are carried out to ensure that product quality complies fully with customers requirements. All tests are performed in accordance with the requirements of the relevent specification. In addition, ultrasonic, radiographic, dye-penetrant, eddy current and other tests can be performed. For Seam-Welded Fittings it is standard practice to perform 100% radiographic inspection on all welds to ASME, SEC, VIII, UW51; DIN54109, Blatt2 or DIN54111, Teil 1. Certification All Butt-Welding Fittings are supplied with a certificate listing the test which have been performed in accordance with relevant specifications and/or customer requests. Supply Condition Unless otherwise agreed, seamless Butt-Welded Fittings are supplied. Heat-treatment scale is removed. Seam-Welded Butt-Welding Fittings are supplied in the asWelded condition. Packing The atmost care is taken to ensure that Butt-Welding Fittings are fully protected against damage during transit. SAMYANG METAL / 11 COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY BUTT WELDING FITTINGS Cu-Ni 90/10, Cu-Ni 70/30 Shipbuilding Fittings & Flanges SAMYANG METAL / 12 COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY BUTT WELDING FITTINGS TOLERANCES for Cu-Ni 90/10 Butt Welding Fittings To DIN86087-DIN86090 and others ANSI B16.9, B16.28, etc. Dimension to ANSI B16.9 Nominal pipe size inches All Fittings 1/2 to 2 1/2 3 to 3 1/2 4 5 to 8 10 to 18 20 to 24 26 to 30 32 to 48 +3/32 -1/16 +2.4 -1.6 +5/32 -1/8 +4.0 -3.2 +1/14 -3/16 +6.4 -4.8 +1/4 -3/16 +6.4 -4.8 +1/4 -3/16 +6.4 -4.8 Outside diameter at bevel inch mm Inside diameter at end inch mm Wall Thickness not less than 87 1/2% of nominal thickness Elbow & Tees Centre to end inch mm 1/16 1.6 Reducers Lap Joint Stub Ends Overall Length inch mm Caps Overall Length inch mm Lap Joint Stub Ends Outside dia of lap inch mm +0 -1/32 +0 -0.8 +0 -1/32 +0 -0.8 +0 -1/32 +0 -0.8 +0 -1/32 -0 -0.8 +0 -1/16 +0 -1.6 Thickness of lap inch mm +1/16 -0 +1.6 -0 +1/16 -0 +1.6 -0 +1/16 -0 +1.6 -0 +1/16 -0 +1.6 -0 Fillet radius of lap inch mm +0 -1/32 +0 -0.8 +0 -1/32 +0 -0.8 +0 -1/16 +0 -1.6 +0 -1/16 +0 -1.6 1/16 1.6 1/16 1.6 1/16 1.6 1/16 1.6 1/16 1.6 1/8 3.2 3/16 4.8 3/16 4.8 3/16 4.8 1/16 1.6 1/16 1.6 1/16 1.6 3/32 2.4 3/32 2.4 1/8 3.2 3/16 4.8 1/16 1.6 1/16 1.6 1/16 1.6 1/16 1.6 3/32 2.4 3/32 2.4 3/16 4.8 3/16 4.8 1/8 3.2 1/8 3.2 1/8 3.2 1/4 6.4 1/4 6.4 1/4 6.4 3/8 9.6 3/8 9.6 +0 -1/16 +0 -1.6 - - +1/16 -0 +1.6 -0 +1/16 -0 +1.6 -0 - - +0 -1/16 +0 -1.6 +0 -1/16 +0 -1.6 - +1/16 -1/32 +1.6 -0.8 1/32 0.8 Bevelling to ANSI B16.25 Nominal wall thickness end preparation less than “X” “X” to 7/8 inches inclusive Over 7/8 inches Cut squarely or slightly chamfered at manufacturer’s option Plain bevels as in sketch “a” Compound bevel as in sketch “b” “X” = 3/16 inch for carbon steel, ferritic alloy steel or wrought iron : 1/8 inch for austenitic and alloy steel SAMYANG METAL/13 COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY BUTT WELDING FITTINGS ELBOWS (LONG RADIUS) MATERIALS : Cu-Ni 90/10, Cu-Ni 70/30 DIMENSION : DIN 86090 Type & Construction : SEAMLESS (10 & Below) SEAM WELDED (12 & Over) Unit : mm Size N/D inch O/D (D) mm T R L 1/2 20.0 1.0 25.0 10.4 3/4 25.0 1.5 27.5 11.4 1 30.0 1.5 33.5 14.0 1 1/4 38.0 1.5 45.0 19.0 1 1/2 44.5 1.5 51.0 21.0 2 57.0 1.5 72.0 30.0 2 1/2 76.1 2.0 95.0 39.0 3 88.9 2.0 114.5 47.0 4 108.0 2.5 142.5 59.0 5 133.0 2.5 181.0 75.0 6 159.0 2.5 216.0 89.0 7 193.7 2.5 270.0 112.0 8 219.1 3.0 305.0 126.0 10 267.0 3.0 378.0 157.0 12 323.9 4.0 457.0 189.0 14 368.0 4.0 533.0 221.0 16 419.0 4.0 610.0 252.0 18 457.2 4.0 686.0 284.0 20 508.0 4.5 762.0 316.0 24 610.0 5.0 914.0 379.0 SAMYANG METAL / 14 COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY BUTT WELDING FITTINGS ELBOWS (SHORT RADIUS) MATERIALS : Cu-Ni 90/10, Cu-Ni 70/30 DIMENSION : According to JMS 7354 Radius Type & Construction : SEAMLESS (10 & Below) SEAM WELDED (12 & Over) Unit : mm Size N/D inch O/D (D) mm T R L 1 30.0 1.5 40 12 1 1/4 38.0 1.5 40 14 1 1/2 44.5 1.5 40 17 2 57.0 1.5 50 22 2 1/2 76.1 2.0 65 27 3 88.9 2.5 80 33 4 108.0 2.5 100 41 5 133.0 2.5 125 52 6 159.0 2.5 150 62 7 193.7 2.5 180 75 8 219.1 3.0 200 87 10 267.0 3.0 250 106 12 323.9 4.0 300 126 14 368.0 4.0 350 146 16 419.0 4.0 400 166 18 457.2 4.0 450 188 20 508.0 4.5 500 209 24 610.0 5.0 600 253 SAMYANG METAL / 15 COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY BUTT WELDING FITTINGS TEE (EQUAL PIECES) MATERIALS : Cu-Ni 90/10, Cu-Ni 70/30 DIMENSION : DIN 86088 (8 & Below) ANSI B16.9 (10 & Over) Type & Construction : SEAMLESS One Piece (8 & Below) SEAM & Branch Welded Piece (8 & Over) Unit : mm Size N/D inch O/D (D) mm T A C 1/2 20.0 1.0 25 25 3/4 25.0 1.5 29 29 1 30.0 1.5 38 38 1 1/4 38.0 1.5 48 48 1 1/2 44.5 1.5 57 57 2 57.0 1.5 64 64 2 1/2 76.1 2.0 76 76 3 88.9 2.0 86 86 4 108.0 2.5 105 105 5 133.0 2.5 124 124 6 159.0 2.5 143 143 8 219.1 3.0 178 178 10 267.0 3.0 216 216 12 323.9 4.0 254 254 14 368.0 4.0 279 279 16 419.0 4.0 305 305 18 457.2 4.0 343 343 20 508.0 4.5 381 381 24 610.0 5.0 432 432 SAMYANG METAL / 16 COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY BUTT WELDING FITTINGS TEE (REDUCING PIECES) MATERIALS : Cu-Ni 90/10, Cu-Ni 70/30 DIMENSION : DIN 86088 (8 & Below) ANSI B16.9 (10 & Over) Type & Construction : SEAMLESS One Piece (8 & Below) Unit : mm Size N/D (inch) T t A C 30.0 1.5 1.5 48 48 30.0 1.5 1.5 57 57 38.0 1.5 1.5 57 57 30.0 1.5 1.5 64 64 38.0 1.5 1.5 64 64 44.5 1.5 1.5 64 64 1.5 76 82 O/D (mm) D d D d 1 1/4 1 38.0 1 1/2 1 1/2 2 2 2 1 1 1/4 1 1 1/4 1 1/2 44.5 44.5 57.0 57.0 57.0 2 1/2 1 76.1 30.0 2.0 2 1/2 1 1/4 76.1 38.0 2.0 1.5 76 80 2 1/2 1 1/2 76.1 44.5 2.0 1.5 76 78 2 1/2 2 76.1 57.0 2.0 1.5 76 76 3 1 1/4 88.9 38.0 2.0 1.5 86 98 3 1 1/2 88.9 44.5 2.0 1.5 86 95 3 2 88.9 57.0 2.0 1.5 86 90 3 2 1/2 88.9 76.1 2.0 2.0 86 86 4 1 1/2 108.0 44.5 2.5 1.5 105 105 4 2 108.0 57.0 2.5 1.5 105 105 4 2 1/2 108.0 76.1 2.5 2.0 105 105 4 3 108.0 88.9 2.5 2.0 105 105 5 2 133.0 57.0 2.5 1.5 124 124 5 2 1/2 133.0 76.1 2.5 2.0 124 124 5 3 133.0 88.9 2.5 2.0 124 124 5 4 133.0 108.0 2.5 2.5 124 124 6 2 1/2 159.0 76.1 2.5 2.0 143 143 6 3 159.0 88.9 2.5 2.0 143 143 6 4 159.0 108.0 2.5 2.5 143 143 6 5 159.0 133.0 2.5 2.5 143 143 SAMYANG METAL / 17 COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY BUTT WELDING FITTINGS TEE (REDUCING PIECES) MATERIALS : Cu-Ni 90/10, Cu-Ni 70/30 DIMENSION : DIN 86088 ANSI B16.9 Type & Construction : SEAM & BRANCH Welded Piece (Run 8 & Over) Unit : mm Size N/D (inch) O/D (mm) T t A C 108.0 3.0 2.5 178 156 133.0 3.0 2.5 178 162 219.1 159.0 3.0 2.5 178 168 4 267.0 108.0 3.0 2.5 216 184 10 5 267.0 133.0 3.0 2.5 216 191 10 6 267.0 159.0 3.0 2.5 216 194 10 8 267.0 219.1 3.0 3.0 216 203 12 5 323.9 133.0 4.0 2.5 216 216 12 6 323.9 159.0 4.0 2.5 254 219 12 8 323.9 219.1 4.0 3.0 254 229 12 10 323.9 267.0 4.0 3.0 254 241 14 6 368.0 159.0 4.0 2.5 254 238 14 8 368.0 219.1 4.0 3.0 279 248 14 10 368.0 267.0 4.0 3.0 279 257 14 12 368.0 323.9 4.0 4.0 279 270 16 8 419.1 219.1 4.0 3.0 305 273 16 10 419.1 267.0 4.0 3.0 305 283 16 12 419.1 323.9 4.0 4.0 305 295 16 14 419.1 368.0 4.0 4.0 305 305 18 10 457.2 267.0 4.0 3.0 343 308 18 12 457.2 323.9 4.0 4.0 343 321 18 14 457.2 368.0 4.0 4.0 343 330 18 16 457.2 419.1 4.0 4.0 343 330 20 12 508.0 323.9 4.5 4.0 381 346 20 14 508.0 368.0 4.5 4.0 381 356 20 16 508.0 419.1 4.5 4.0 381 356 20 18 508.0 457.2 4.5 4.0 381 368 24 14 610.0 368.0 5.0 4.0 432 406 24 16 610.0 419.1 5.0 4.0 432 406 24 18 610.0 457.2 5.0 4.0 432 419 24 20 610.0 508.0 5.0 4.5 432 432 D d D d 8 4 219.1 8 5 219.1 8 6 10 SAMYANG METAL / 18 COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY BUTT WELDING FITTINGS END CAPS MATERIALS : Cu-Ni 90/10, Cu-Ni 70/30 DIMENSION : DIN86011 Type & Construction : SEAMLESS One Piece Unit : mm Size N/D inch O/D (D) mm T H 1 30.0 1.5 19.0 1 1/4 38.0 1.5 20.5 1 1/2 44.5 1.5 22.0 2 57.0 1.5 28.0 2 1/2 76.1 2.0 32.0 3 88.9 2.0 36.0 4 108.0 2.5 40.0 5 133.0 2.5 44.0 6 159.0 2.5 49.0 8 219.1 3.0 61.0 10 267.0 3.0 70.0 12 323.9 4.0 81.0 14 368.0 4.0 89.0 16 419.0 4.0 99.0 18 457.2 4.0 107.0 20 508.0 4.5 116.0 610.0 5.0 136.0 24 SAMYANG METAL / 19 COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY BUTT WELDING FITTINGS REDUCER (CONCENTRIC, ECCENTRIC) MATERIAL : Cu-Ni 90/10, Cu-Ni 70/30 DIMENSION : DIN86089 Type & Construction : SEAMLESS One Piece Unit : mm Size N/D (inch) O/D (mm) T t D d D d 10B 10B L 1 3/4 30.0 25.0 1.5 1.5 35 1 1/4 3/4 38.0 25.0 1.5 1.5 50 1 1/4 1 38.0 30.0 1.5 1.5 50 1 1/2 3/4 44.5 25.0 1.5 1.5 80 1 1/2 1 44.5 30.0 1.5 1.5 80 1 1/2 1 1/4 44.5 38.0 1.5 1.5 80 2 3/4 57.0 25.0 1.5 1.5 80 2 1 57.0 30.0 1.5 1.5 80 2 1 1/4 57.0 38.0 1.5 1.5 80 2 1 1/2 57.0 44.5 1.5 1.5 80 2 1/2 1 76.1 30.0 2.0 1.5 90 2 1/2 1 1/4 76.1 38.0 2.0 1.5 90 2 1/2 1 1/2 76.1 44.5 2.0 1.5 90 2 1/2 2 76.1 57.0 2.0 1.5 90 3 1 1/4 88.9 38.0 2.0 1.5 90 3 1 1/2 88.9 44.5 2.0 1.5 90 3 2 88.9 57.0 2.0 1.5 90 3 2 1/2 88.9 76.1 2.0 1.5 90 4 1 1/4 108.0 38.0 2.5 1.5 100 4 1 1/2 108.0 44.5 2.5 1.5 100 4 2 108.0 57.0 2.5 1.5 100 4 2 1/2 108.0 76.1 2.5 2.0 100 4 3 108.0 88.9 2.5 2.0 100 5 2 133.0 57.0 2.5 1.5 140 5 2 1/2 133.0 76.1 2.5 2.0 140 5 3 133.0 88.9 2.5 2.0 140 5 4 133.0 108.0 2.5 2.5 140 6 2 1/2 159.0 76.1 2.5 2.0 150 6 3 159.0 88.9 2.5 2.0 150 6 4 159.0 108.0 2.5 2.5 150 6 5 159.0 133.0 2.5 2.5 150 8 4 219.1 108.0 3.0 2.5 155 8 5 219.1 133.0 3.0 2.5 155 8 6 219.1 159.0 3.0 2.5 155 10 5 267.0 133.0 3.0 2.5 210 10 6 267.0 159.0 3.0 2.5 210 10 8 267.0 219.1 3.0 3.0 210 SAMYANG METAL / 20 COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY BUTT WELDING FITTINGS REDUCER (CONCENTRIC, ECCENTRIC) MATERIAL : Cu-Ni 90/10, Cu-Ni 70/30 DIMENSION : DIN86089 Type & Construction : SEAM Welded Piece Unit : mm Size N/D (inch) D T t d 10B 10B O/D (mm) L d D 12 6 323.9 159 4.0 2.5 210 12 8 323.9 219.1 4.0 3.0 210 12 10 323.9 267 4.0 3.0 210 14 8 368 219.1 4.0 3.0 330 14 10 368 267 4.0 3.0 330 14 12 368 323.9 4.0 4.0 330 16 10 419.1 267 4.0 3.0 356 16 12 419.1 323.9 4.0 4.0 356 16 14 419.1 368 4.0 4.0 356 18 8 457.2 219.1 4.0 3.0 381 18 10 457.2 267 4.0 3.0 381 18 12 457.2 323.9 4.0 4.0 381 18 14 457.2 368 4.0 4.0 381 18 16 457.2 419.1 4.0 4.0 381 20 10 508 267 4.5 3.0 508 20 12 508 323.9 4.5 4.0 508 20 14 508 368 4.5 4.0 508 20 16 508 419.1 4.5 4.0 508 20 18 508 457.2 4.5 4.0 508 24 14 610 368 5.0 4.0 508 24 16 610 419.1 5.0 4.0 508 24 18 610 457.2 5.0 4.0 508 24 20 610 508 5.0 4.5 508 SAMYANG METAL / 21 COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY BUTT WELDING FITTINGS REDUCER (CONCENTRIC, ECCENTRIC) MATERIAL : Cu-Ni 90/10, Cu-Ni 70/30 DIMENSION : JMS 7354 Type & Construction : SEAMLESS One Piece Unit : mm Size N/D (inch) O/D (mm) T t D d D d 10B 10B L 1 3/4 30.0 25.0 1.5 1.5 100 1 1/4 3/4 38.0 25.0 1.5 1.5 100 1 1/4 1 38.0 30.0 1.5 1.5 100 1 1/2 3/4 44.5 25.0 1.5 1.5 100 1 1/2 1 44.5 30.0 1.5 1.5 100 1 1/2 1 1/4 44.5 38.0 1.5 1.5 100 2 3/4 57.0 25.0 1.5 1.5 100 2 1 57.0 30.0 1.5 1.5 100 2 1 1/4 57.0 38.0 1.5 1.5 100 2 1 1/2 57.0 44.5 1.5 1.5 100 2 1/2 1 76.1 30.0 2.0 1.5 100 2 1/2 1 1/4 76.1 38.0 2.0 1.5 100 2 1/2 1 1/2 76.1 44.5 2.0 1.5 100 2 1/2 2 76.1 57.0 2.0 1.5 100 3 1 1/4 88.9 38.0 2.0 1.5 100 3 1 1/2 88.9 44.5 2.0 1.5 100 3 2 88.9 57.0 2.0 1.5 100 3 2 1/2 88.9 76.1 2.0 1.5 100 4 1 1/4 108.0 38.0 2.5 1.5 100 4 1 1/2 108.0 44.5 2.5 1.5 100 4 2 108.0 57.0 2.5 1.5 100 4 2 1/2 108.0 76.1 2.5 2.0 100 4 3 108.0 88.9 2.5 2.0 100 5 2 133.0 57.0 2.5 1.5 100 5 2 1/2 133.0 76.1 2.5 2.0 100 5 3 133.0 88.9 2.5 2.0 100 5 4 133.0 108.0 2.5 2.5 100 6 2 1/2 159.0 76.1 2.5 2.0 100 6 3 159.0 88.9 2.5 2.0 100 6 4 159.0 108.0 2.5 2.5 100 6 5 159.0 133.0 2.5 2.5 100 8 4 219.1 108.0 3.0 2.5 200 8 5 219.1 133.0 3.0 2.5 150 8 6 219.1 159.0 3.0 2.5 150 10 5 267.0 133.0 3.0 2.5 200 10 6 267.0 159.0 3.0 2.5 200 10 8 267.0 219.1 3.0 3.0 150 SAMYANG METAL / 22 COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY BUTT WELDING FITTINGS REDUCER (CONCENTRIC, ECCENTRIC) MATERIAL : Cu-Ni 90/10, Cu-Ni 70/30 DIMENSION : JMS 7354 Type & Construction : SEAM Welded Piece Unit : mm Size N/D (inch) T t d 10B 10B O/D (mm) L D d D 12 6 323.9 159 4.0 2.5 200 12 8 323.9 219.1 4.0 3.0 150 12 10 323.9 267 4.0 3.0 100 14 8 368 219.1 4.0 3.0 200 14 10 368 267 4.0 3.0 150 14 12 368 323.9 4.0 4.0 100 16 10 419.1 267 4.0 3.0 200 16 12 419.1 323.9 4.0 4.0 150 16 14 419.1 368 4.0 4.0 100 18 8 457.2 219.1 4.0 3.0 200 18 10 457.2 267 4.0 3.0 200 18 12 457.2 323.9 4.0 4.0 200 18 14 457.2 368 4.0 4.0 150 18 16 457.2 419.1 4.0 4.0 100 20 10 508 267 4.5 3.0 200 20 12 508 323.9 4.5 4.0 200 20 14 508 368 4.5 4.0 200 20 16 508 419.1 4.5 4.0 150 20 18 508 457.2 4.5 4.0 100 24 14 610 368 5.0 4.0 200 24 16 610 419.1 5.0 4.0 200 24 18 610 457.2 5.0 4.0 150 24 20 610 508 5.0 4.5 100 SAMYANG METAL / 23 COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY BUTT WELDING FITTINGS BRANCHES (SADDLE) MATERIAL : Cu-Ni 90/10, Cu-Ni 70/30 DIMENSION : DIN86087 Type & Construction : SEAMLESS (8” & below) Seam Welded Unit : mm Outside Diameter of Branch Pipe N/D (inch) O/D (mm) Wall Thickness T Height H Length L 74 1 1/2 44.5 1.5 35 2 57 1.5 40 97 2 1/2 76.1 2.0 50 126 3 88.9 2.5 55 149 4 108 2.5 75 188 5 133 2.5 85 233 6 159 2.5 95 279 8 219.1 3.0 125 379 10 267 3.0 155 447 12 323.9 4.0 185 560 14 368 4.0 200 613 16 419 4.0 225 680 18 457.2 4.0 250 800 20 508 4.5 275 880 24 610 5.0 300 1020 SAMYANG METAL / 24 COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY BUTT WELDING FITTINGS BRANCHES (WELDOLETS) MATERIAL : Cu-Ni 90/10, Cu-Ni 70/30 Type & Construction : Forgings or Machined Bar Unit : mm Outlet Size N/D (inch) O/D (D) (mm) T H B C 1/2 20 1.0 19.1 34.9 23.8 3/4 25 1.5 22.2 44.5 30.2 1 30 1.5 27.0 54.0 36.5 1 1/4 38 1.5 31.8 65.1 44.5 1 1/2 44.5 1.5 33.3 73.0 50.8 2 57 1.5 38.1 88.9 65.1 2 1/2 76.1 2.0 41.3 103.2 76.2 3 88.9 2.5 44.5 122.2 93.7 4 108 2.5 50.8 152.4 120.7 5 133 2.5 57.2 179.4 141.3 6 159 2.5 60.3 215.9 169.9 8 219 3.0 69.9 263.5 220.7 10 267 3.0 77.8 322.3 274.7 12 323.9 4.0 85.7 377.8 325.4 14 368 4.0 88.9 409.6 357.2 16 419 4.0 93.7 463.6 408.0 18 457.2 4.0 96.8 520.7 458.8 20 508 4.5 101.6 571.5 508.0 24 610 5.0 115.9 689.0 614.4 SAMYANG METAL / 25 COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY Flanges SAMYANG METAL / 26 COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY FLANGE APPLIED SPECIFICATION Flanges, Composite and Solid Flange, meet the following national and international standards and their standards are detailed in the relevant product tables. Material BS 2872 CN102, CN107 ASTM B151 C70600, C71500, JIS C7060, C7150 DIN CuNi10Fe1Mn, CuNi30Mn1Fe Dimension BS4501 ASTM B16.5 DIN 86037 JIS B2240 Composite Flange Composite weld-neck and composite slip-on flanges are made up from components, an inner Flange (Welding collar) in Cu-Ni 90/10 or Cu-Ni 70/30 and an outer flange in carbon steel. Composite blind flanges are made up from a carbon steel blind flange with a welded-on and machined disc in Cu-Ni 90/10 or Cu-Ni 70/30. Product Range Composite and solid flanges are available in standard sizes machining those of the relevant pipes and butt welding fittings. Non-standard size flanges are produced to certain minimum quantity limitations available on application. Solid Flanges Solid flanges in Cu-Ni 90/10 or Cu-Ni 70/30 are produced from bar or plate by hot forging and machining. Sliver Alloy Rings Solid sliver brazing flanges in corporate integral silver brazing alloy rings and under normal circumstances there is generally no need to socket feed with additional brazing alloy. The silver brazing alloy to AWS A5.8 - BAG1~BAG7, JIS E3261 BAG1~BAG7 OR BS1845 AG1~AG7. Marking Each flanges is marked with Trade mark, Material and size. Additional information, such as standard and alloy number and pressure rating, can be added on request. Inspection And Testing A Series of stringent quality-control inspections and test is performed throughout the entire manufacturing process, from melting and alloying to the finished product to ensure product quality which complies with the customer s requirements. Final inspection generally includes visual and dimensional control, as well as chemical and mechanical tests, to ensure chemical, physical and dimensional accuracy. Certification All flanges are supplied with a certificate individually stating the tests which have been performed in accordance with the relevant specification and/or customer s requirements. Packing The atmost care is taken to ensure that flanges are fully protected against damage during transit to their destination. SAMYANG METAL / 27 COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY FLANGE TOLERANCE MATERIAL : Cu-Ni 90/10, Cu-Ni 70/30 DIMENSION : ANSI B16.5 24 OR LESS OUTSIDE DIAMETER ALL TYPE 24 OVER THREADED SOCKET, SLIP-ON & LAP JOINT APPLIED SIZE 10 OR LESS 12 & OVER INSIDE DIAMETER 10 OR LESS WELDING NECK 12 - 18 24 OR LESS WELDING NECK 24 OVER SOCKET, SLIP-ON & LAP JOINT 1/16 mm: 1.6 Inch: 1/8 mm: 3.2 on boring gauge Inch:+1/32 - 0 mm:+0.8 - 0 Inch: 1/16 - 0 mm:+1.6 - 0 Inch: 1/32 mm: 0.8 Inch: 1/16 mm: 1.6 20 & OVER OUTSIDE DIAMETER OF HUB Inch: 12 OR LESS Inch:+1/8 -1/16 mm:+3.2 -1.6 Inch: 1/16 mm: 1.6 Inch: 1/8 mm: 3.2 Inch:+1/16 -1/32 mm:+1.6 -0.8 14 & OVER SAMYANG METAL / 28 Inch:+1/8 -1/16 mm:+3.2 -1.6 COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY FLANGE TOLERANCE MATERIAL : Cu-Ni 90/10, Cu-Ni 70/30 DIMENSION : ANSI B16.5 Inch:+3/32 -1/32 5” OR LESS DIAMETER OF HUB AT POINT OF WELDING mm:+2.4 -0.8 WELDING NECK Inch:+5/32 -1/32 6” AND OVER mm:+4.0 -0.8 Inch: 1/32 1/16’RAISED FACE DIAMETER OF CONTACT FACE mm: 0.8 1/4” RAISED FACE. TONGUE&GROOVE MALE,FEMALE Inch: 1/64 mm: 0.4 Inch: 1/16 BOLT CIRCLE mm: 1.6 BOLT HOLE SPACING 2 1/2 OR LESS ECCENTRICITY OF BOLT CERCLE WITH RESPECT TO FACING DRILLING ALL TYPE 3 OVER Inch: 1/32 mm: 0.8 Inch:MAX 1/32 mm:MAX 0.8 Inch: 1/16 mm:MAX 1.6 ECCENTRICITY OF BOLT CIRCLE WITH RESPECT TO BORE Inch:MAX 1/32 ECCENTRICITY OF FACING WITH RESPECT TO BORE Inch:MAX 1/32 18” OR LESS THICKNESS 20” & OVER 10” OR LESS LENGTH THRU HUB 12” & OVER SAMYANG METAL / 29 mm:MAX 0.8 mm:MAX0.8 Inch:+1/8 -0 mm: 3.2 -0 Inch:+3/16 -0 mm:+4.8 -0 Inch: 1/16 mm: 1.6 Inch: 1/8 mm: 3.2 COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY FLANGE COMPOSITE WELDING NECK MATERIAL : INNER Cu-Ni 90/10, Cu-Ni 70/30 OUTER CARBON STEEL GALVANIZED DIMENSION : INNER BASED ON DIN86037 OUTER BASED ON ANSI B16.5 ANSI 150LB Unit : mm PIPE (A) O/D 50 57 D2 99 D4 59 T 45 T1 6 S 2.0 D 152 C 120.6 D3 62 t 19.1 N 4 H 19 65 76.1 120 78 45 6 2.5 178 139.7 81 22.4 4 19 88.9 130 91 50 7 2.5 191 152.4 94 23.9 4 19 108 158 110 50 7 2.5 229 190.5 113 23.9 8 19 7 2.5 254 215.9 138 23.9 8 22 80 100 INTERNAL FLANGE BOLT N/D EXTERNAL FLANGE 125 133 188 135.5 50 150 159 212 162 50 9 2.5 279 241.3 164 25.4 8 22 200 219 268 222 50 9 3.0 343 298.4 225 28.4 8 22 250 267 320 270 50 9 3.0 406 361.9 273 30.2 12 25 300 323.9 370 327 50 11 4.0 483 431.8 330 31.8 12 25 350 368 430 371 50 11 4.0 533 476.2 374 35.1 12 28 400 419 482 422 50 12 4.0 597 539.7 426 36.6 16 28 450 457.2 530 460 50 12 4.0 635 577.8 465 39.6 16 32 500 508 585 511 50 12 4.5 699 635.0 517 42.9 20 32 600 610 685 613 60 14 5.0 813 749.3 618 47.8 20 35 Unit : mm ANSI 300LB INTERNAL FLANGE BOLT N/D PIPE EXTERNAL FLANGE (A) O/D D2 D4 T T1 S D C D3 t N H 50 57 99 59 45 6 2.0 165 127.0 62 22.4 8 19 65 76.1 120 78 45 6 2.5 190.5 149.3 81 25.4 8 22 80 88.9 130 91 50 7 2.5 209.5 168.3 94 28.4 8 22 100 108 158 110 50 7 2.5 254 200.0 113 31.8 8 22 125 133 188 135.5 50 7 2.5 279 235.0 138 35.1 8 22 150 159 212 162 50 9 2.5 318 269.9 164 36.6 12 22 200 219 268 222 50 9 3.0 381 330.2 225 41.1 12 25 250 267 320 270 50 9 3.0 445 387.3 273 47.8 16 28 300 323.9 370 327 50 11 4.0 521 450.8 330 50.8 16 32 350 368 430 371 50 11 4.0 584 514.3 374 53.8 20 32 400 419 482 422 50 12 4.0 648 571.5 426 57.2 20 35 450 457.2 530 460 50 12 4.0 711 628.5 465 60.5 24 35 500 508 585 511 50 12 4.5 775 685.9 517 63.5 24 35 600 610 685 613 60 14 5.0 914 812.8 618 69.9 24 41 SAMYANG METAL / 30 COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY FLANGE COMPOSITE WELDING NECK MATERIAL : INNER Cu-Ni 90/10, Cu-Ni 70/30 OUTER CARBON STEEL GALVANIZED DIMENSION : INNER DIN86037 OUTER DIN86037 PN10 PN16 Unit : mm DIN 10BAR INTERNAL FLANGE BOLT N/D PIPE EXTERNAL FLANGE (A) O/D D2 D4 T T1 S D C D3 t N H 20 25 58 27 40 5 1.5 105 75 28 14 4 14 25 30 68 32 40 5 1.5 115 85 33 14 4 14 32 44.5 78 40 40 5 1.5 140 100 42 18 4 18 40 57 88 46.5 45 6 1.5 150 110 50 18 4 18 50 76.1 102 59 45 6 1.5 165 125 62 18 4 18 65 88.9 122 78 45 6 2.0 185 145 81 18 4 18 80 108 138 91 50 7 2.5 200 160 94 18 8 18 100 133 158 110 50 7 2.5 220 180 113 18 8 18 125 159 188 135.5 50 7 2.5 250 210 138 18 8 18 150 219.1 212 161.5 50 9 2.5 285 240 164 22 8 22 200 267 268 222 50 9 3.0 340 295 255 22 8 22 250 323.9 320 270 50 9 3.0 395 350 273 22 12 22 300 368 370 327 50 11 4.0 445 400 331 22 12 22 350 419.1 430 371 60 11 4.0 505 460 375 22 16 22 400 457.2 482 422 50 12 4.0 565 515 426 26 16 26 450 419 530 460 50 12 4.0 615 565 465 26 20 26 500 457.2 585 511 50 12 4.5 670 620 517 26 20 26 600 610 685 613 60 14 5.0 780 725 618 30 20 30 Unit : mm DIN 16BAR INTERNAL FLANGE BOLT N/D PIPE EXTERNAL FLANGE (A) O/D D2 D4 T T1 S D C D3 t N H 20 25 58 27 40 5 1.5 105 75 28 14 4 14 25 30 68 32 40 5 1.5 115 85 34 14 4 14 32 38 78 40 40 5 1.5 140 100 42 18 4 18 40 44.5 88 46.5 45 6 1.5 150 110 49 18 4 18 50 57 102 59 45 6 1.5 165 125 62 18 4 18 65 76.1 122 78 45 6 2.0 185 145 81 18 4 18 80 88.9 138 91 50 7 2.5 200 160 94 18 8 18 100 108 158 110 50 7 2.5 220 180 113 18 8 18 125 133 188 135.5 50 7 2.5 250 210 138 18 8 18 150 159 212 161.5 50 9 2.5 285 240 164 22 8 22 200 219.1 268 222 50 9 3.0 340 295 225 22 12 22 250 267 320 270 50 9 3.0 405 355 273 24 12 26 300 323.9 370 327 50 11 4.0 460 410 331 28 12 26 350 368 430 371 60 11 4.0 520 470 375 32 16 26 400 419.1 482 422 50 12 4.0 580 525 426 36 16 30 SAMYANG METAL / 31 COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY FLANGE COMPOSITE WELDING NECK MATERIAL : INNER Cu-Ni 90/10, Cu-Ni 70/30 OUTER CARBON STEEL GALVANIZED DIMENSION : INNER BASED ON DIN86037 OUTER BASED ON JIS B2210 Unit : mm JIS 5K INTERNAL FLANGE BOLT N/D PIPE EXTERNAL FLANGE (A) O/D D2 D4 S T T1 D C D3 t N H 50 57 88 59 1.5 45 6 130 105 62 14 4 15 65 76.1 113 78 2.0 45 6 155 130 81 14 4 15 80 88.9 124 91 2.5 50 7 180 145 94 14 4 19 100 108 144 110 2.5 50 7 200 165 113 16 8 19 125 133 179 136 2.5 50 7 235 200 138 16 8 19 150 159 209 162 2.5 50 9 265 230 164 18 8 19 200 219 255 222 3.0 50 9 320 280 225 20 8 23 250 267 320 270 3.0 50 9 385 345 273 22 12 23 300 323.9 365 327 4.0 50 11 430 390 330 22 12 23 350 368 408 371 4.0 50 11 480 435 374 24 12 25 400 419 468 422 4.0 50 12 540 495 426 24 16 25 450 457.2 528 460 4.0 50 12 605 555 465 24 16 25 500 508 578 511 4.5 50 12 655 605 517 24 20 25 600 610 685 613 5.0 60 14 770 715 618 26 20 27 Unit : mm JIS 10K INTERNAL FLANGE BOLT N/D PIPE EXTERNAL FLANGE (A) O/D D2 D4 S T T1 D C D3 t N H 50 57 88 59 1.5 45 6 155 120 62 16 4 19 65 76.1 113 78 2.0 45 6 175 140 81 18 4 19 80 88.9 124 91 2.5 50 7 185 150 94 18 8 19 100 108 144 110 2.5 50 7 210 175 113 18 8 19 125 133 179 136 2.5 50 7 250 210 138 20 8 23 150 159 209 162 2.5 50 9 280 240 164 22 8 23 200 219 255 222 3.0 50 9 330 290 225 22 12 23 250 267 320 270 3.0 50 9 400 355 273 24 12 25 300 323.9 365 327 4.0 50 11 445 400 330 24 16 25 350 368 408 371 4.0 50 11 490 445 374 26 16 25 400 419 468 422 4.0 50 12 560 490 426 28 16 27 450 457.2 528 460 4.0 50 12 620 560 465 30 20 27 500 508 578 511 4.5 50 12 675 620 517 30 20 27 600 610 685 613 5.0 60 14 795 730 618 32 24 33 SAMYANG METAL / 32 COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY FLANGE COMPOSITE SLIP-ON & SILVER BRAZING MATERIAL : INNER Cu-Ni 90/10, Cu-Ni 70/30 OUTER CARBON STEEL GALVANIZED DIMENSION : INNER BASED ON BS4504 OUTER BASED ON ANSI B16.5 Unit : mm ANSI 150LB PIPE INTERNAL FLANGE BOLT EXTERNAL FLANGE N/D (inch) O/D (mm) d D2 D4 T T1 D C D1 D3 t t1 H N 1/2 16 16.1 40 21 16 5 89 60.3 42 23 11.1 3 15.9 4 3/4 25 25.1 53 31 16 5 98 69.8 55 33 12.7 3 15.9 4 1 30 30.1 60 36 18 5 108 79.4 62 38 14.3 3 15.9 4 1 1/4 38 38.1 70 45 18 5 117 88.9 72 47 15.9 3 15.9 4 1 1/2 44.5 44.6 80 51 19 5 127 98.4 82 53 17.5 3 15.9 4 2 57 57.2 99 67 19 6 152 120.6 101 69 19.0 4 19 4 2 1/2 76.1 76.3 120 87 19 6 178 139.7 122 89 22.3 4 19 4 3 88.9 89.2 130 100 21 7 190 152.4 133 103 24.0 5 19 4 4 108 108.4 158 120 23 7 229 190.5 161 123 24.0 5 19 4 Unit : mm ANSI 150LB PIPE INTERNAL FLANGE BOLT EXTERNAL FLANGE N/D (inch) O/D (mm) d d1 D2 D4 T T1 Y M W W1 D C D1 D3 t t1 H N 1/2 16 16.10 14.7 41 29 15 5 9.5 3 3.5 3 89 60.3 42 30 11.1 3 15.9 4 3/4 25 25.10 23.5 48 34 16 5 9.5 3 3.5 3 98 69.8 49 35 12.7 3 15.9 4 1 30 30.10 28.4 58 39 16 5 12.5 3 3.5 5 108 79.4 59 40 14.3 3 15.9 4 1 1/4 38 38.10 36.2 69 48 18 5 14 3 3.5 6 117 88.9 70 49 15.9 3 15.9 4 1 1/2 44.5 44.60 42.5 74 55 18 5 15.5 3 3.5 6 127 98.4 76 56 17.5 4 15.9 4 2 57 57.15 54.8 84 68 20 6 15.5 3 5.5 6 152 120.6 86 70 19.0 5 19 4 2 1/2 76.1 76.25 72 109 87 20 6 15.5 4 5.5 6 178 139.7 111 89 22.3 6 19 4 SAMYANG METAL / 33 COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY FLANGE COMPOSITE SILVER BRAZING MATERIAL : INNER Cu-Ni 90/10, Cu-Ni 70/30 OUTER CARBON STEEL GALVANIZED DIMENSION : INNER BASED ON BS4504 OUTER BASED ON JIS2240 5K NOM Dia Unit : mm Outer Applicable Pipes Flange Inner OD Thk D D1 D3 t t1 Bolt Hole C N H 10 16.0 1.0 75 39 26 9 2.0 55 4 12 15 20.0 1.0 80 44 30 9 2.0 60 4 20 25.0 1.5 85 49 35 10 2.5 65 25 30.0 1.5 95 59 40 10 2.5 32 38.0 1.5 115 71 49 12 40 44.5 1.5 120 76 56 50 57.0 1.5 130 86 70 BOLT SCREW Flange Stopper Groove d1 m W W1 4 14.0 3 3.5 4 15 5 18.0 3 3.5 4 34 16 5 22.0 3 3.5 4 58 39 16 5 27.0 3 3.5 4 38.1 70 48 18 5 35.0 3 3.5 5 M12 44.6 74 55 18 5 41.5 3 3.5 5 M12 57.1 84 63 20 6 54.0 3 5.5 5 d D2 D4 T T1 M10 16.1 38 25 14 12 M10 20.1 43 29 4 12 M10 25.1 48 75 4 12 M10 30.1 3.5 90 4 15 M12 12 3.5 95 4 15 14 4.5 105 4 15 10K NOM Dia Unit : mm Outer Applicable Pipes Inner Flange Bolt Hole d D2 D4 T T1 M12 16.1 38 25 14 15 M12 20.1 43 29 15 M12 25.1 48 34 4 19 M16 30.1 58 100 4 19 M16 38.1 3.5 105 4 19 M16 4.5 120 4 19 M16 D D1 D3 t t1 C N H 90 39 26 12 3.0 65 4 15 1.0 95 44 30 12 3.0 70 4 1.5 100 49 35 14 3.5 75 4 30.0 1.5 125 59 40 14 3.5 90 32 38.0 1.5 135 71 49 16 3.5 40 44.5 1.5 140 76 56 16 50 57.0 1.5 155 86 70 16 10 OD 16.0 Thk 1.0 15 20.0 20 25.0 25 BOLT SCREW Flange SAMYANG METAL / 34 Stopper Groove 4 d1 14.0 m 3 W 3.5 W1 4 15 5 18.0 3 3.5 4 16 5 22.0 3 3.5 4 39 16 5 27.0 3 3.5 4 70 48 18 5 35.0 3 3.5 5 44.6 74 55 18 5 41.5 3 3.5 5 57.1 84 63 20 6 54.0 3 5.5 5 COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY FLANGE COMPOSITE SLIP-ON MATERIAL : INNER Cu-Ni 90/10, Cu-Ni 70/30 OUTER CARBON STEEL GALVANIZED DIMENSION : INNER BASED ON BS4504 OUTER BASED ON DIN 2567(10B) DIN 2543(16B DIN 10 BAR Unit : mm N/D PIPE INTERNAL FLANGE EXTERNAL FLANGE (A) O/D d D2 D4 T T1 D C D1 D3 t t1 N H 50 57 57.5 84 67 20 7 165 125 86 69 14 6 4 18 65 76.1 76.6 109 86 20 7 185 145 111 88 14 6 4 18 80 88.9 89.4 120 101 20 8 200 160 122 103 16 6 4 18 100 108 109.0 140 121 22 10 220 180 142 123 18 8 8 18 125 133 134.0 175 146 22 10 250 210 177 148 18 8 8 18 150 159 160.0 205 173 24 10 285 240 207 175 20 8 8 23 200 219 220.1 251 234 24 10 340 295 253 236 20 8 8 23 250 267 268.2 313 282 28 12 395 350 315 284 24 10 12 23 300 323.9 325.1 361 342 32 12 445 400 364 345 26 10 12 23 350 368 369.2 405 386 34 12 505 460 408 389 28 10 16 23 463 442 30 10 16 27 BOLT 400 419 420.2 460 439 36 12 565 515 500 508 509.3 568 531 40 14 670 620 571 534 34 12 20 27 600 610 611.5 678 635 42 15 780 725 681 638 38 13 20 30 DIN 16 BAR Unit : mm N/D PIPE INTERNAL FLANGE (A) O/D d 50 57 65 76.1 80 EXTERNAL FLANGE D2 D4 T T1 D C 57.5 84 67 20 7 165 76.6 109 86 20 7 185 88.9 89.4 120 101 20 8 100 108 109.0 140 121 22 125 133 134.0 175 146 150 159 160.0 205 200 219 220.1 250 267 300 BOLT D1 D3 t t1 N H 125 86 69 14 6 4 18 145 111 88 14 6 4 18 200 160 122 103 16 6 8 18 10 220 180 142 123 18 8 8 18 22 10 250 210 177 148 18 8 8 18 173 24 10 285 240 207 175 20 8 8 23 251 234 24 10 340 295 253 236 20 8 12 23 268.2 313 282 28 12 405 355 315 284 24 10 12 27 323.9 325.1 361 342 32 12 460 410 364 345 26 10 12 27 350 368 369.2 405 386 34 12 520 470 408 389 28 10 16 27 400 419 420.2 460 439 36 12 580 525 463 442 30 10 16 30 500 508 509.3 568 531 40 14 715 650 571 534 34 12 20 33 600 610 611.5 678 635 42 15 840 770 681 638 38 13 20 36 SAMYANG METAL / 35 COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY FLANGE COMPOSITE SLIP-ON MATERIAL : INNER Cu-Ni 90/10, Cu-Ni 70/30 OUTER CARBON STEEL GALVANIZED DIMENSION: INNER BASED ON BS4501 OUTER BASED ON JIS B2210 Unit : mm JIS 5K N/D PIPE INTERNAL FLANGE EXTERNAL FLANGE BOLT (A) O/D d D2 D4 T T1 D C D1 D3 t t1 N H 40 44.5 45.0 74 55 18 6 120 95 76 57 12 5 4 15 50 57 57.5 84 67 20 7 130 105 86 69 14 6 4 15 65 76.1 76.6 109 86 20 7 155 130 111 88 14 6 4 15 80 88.9 89.4 120 101 20 8 180 145 122 103 16 6 4 19 100 108 109.0 140 121 22 10 200 165 142 123 18 8 8 19 125 133 134.0 175 146 22 10 235 200 177 148 18 8 8 19 150 159 160.0 205 173 24 10 265 230 207 175 20 8 8 19 200 219 220.1 251 234 24 10 320 280 253 236 20 8 8 23 250 267 268.2 313 282 28 12 385 345 315 284 24 10 12 23 300 323.9 325.1 361 342 32 12 430 390 364 345 26 10 12 23 350 368 369.2 405 386 34 12 480 435 408 389 28 10 12 25 400 419 420.2 460 439 36 12 540 495 463 442 30 10 16 25 450 457.2 458.4 518 477 38 14 605 555 521 480 32 12 16 25 500 508 509.3 568 531 40 14 655 605 571 534 34 12 20 25 600 610 611.5 678 635 42 15 770 715 681 638 38 13 20 27 Unit : mm JIS 10K N/D PIPE INTERNAL FLANGE EXTERNAL FLANGE BOLT (A) O/D d D2 D4 T T1 D C D1 D3 t t1 N H 40 44.5 45.0 74 55 18 6 140 105 76 57 12 5 4 19 50 57 57.5 84 67 20 7 155 120 86 69 14 6 4 19 65 76.1 76.6 109 86 20 7 175 140 111 88 14 6 4 19 80 88.9 89.4 120 101 20 8 185 150 122 103 16 6 4 19 100 108 109.0 140 121 22 10 210 175 142 123 18 8 8 19 125 133 134.0 175 146 22 10 250 210 177 148 18 8 8 23 150 159 160.0 205 173 24 10 280 240 207 175 20 8 8 23 200 219 220.1 251 234 24 10 330 290 253 236 20 8 8 23 250 267 268.2 313 282 28 12 400 355 315 284 24 10 12 25 300 323.9 325.1 361 342 32 12 445 400 364 345 26 10 12 25 350 368 369.2 405 386 34 12 490 445 408 389 28 10 16 25 400 419 420.2 460 439 36 12 560 510 463 442 30 10 16 27 450 457.2 458.4 518 477 38 14 620 565 521 480 32 12 16 27 500 508 509.3 568 531 40 14 675 620 571 534 34 12 20 27 600 610 611.5 678 635 42 15 795 730 681 638 38 13 24 33 SAMYANG METAL / 36 COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY FLANGE COMPOSITE BLIND MATERIAL : A105 & Cu-Ni 90/10 PLATE OVERLAY DIMENSION : ANSI B16.5 ANSI 150LB Unit : mm Outernal Flange Bolt N/D (Inch) D C d T N H 15A (1/2) 88.9 60.3 35.0 11.1 4 15.9 20A (3/4) 98.4 69.8 42.9 12.7 4 15.9 25A (1) 107.9 79.4 50.8 14.3 4 15.9 32A (1 1/4) 117.5 88.9 63.5 15.9 4 15.9 40A (1 1/2) 127.0 98.4 73.1 17.5 4 15.9 50A (2) 152.4 120.6 92.0 19.1 4 19.0 65A (2 1/2) 177.8 139.7 105.0 22.2 4 19.0 80A (3) 190.5 152.4 127.0 23.8 4 19.0 100A (4) 228.6 190.5 157.2 23.8 8 19.0 125A (5) 254.0 215.9 186.0 23.8 8 22.2 150A (6) 279.4 241.3 215.9 25.4 8 22.2 200A (8) 342.9 298.4 269.7 28.6 8 22.2 250A (10) 406.4 361.9 323.9 30.2 12 25.4 300A (12) 482.6 431.8 381.0 31.8 12 25.4 533.4 476.2 425.1 34.9 12 28.6 596.9 539.7 482.6 36.5 16 28.6 635.0 577.8 533.4 39.7 16 31.7 698.5 635.0 584.2 42.9 20 31.7 812.8 749.3 692.1 47.6 20 34.9 350A (14) 400A (16) 450A (18) 500A (20) 600A (24) ANSI 300LB Unit : mm Outernal Flange Bolt N/D (Inch) D C d T N H 15A (1/2) 95.2 66.7 35.0 14.2 4 15.9 20A (3/4) 117.5 82.5 42.9 15.7 4 19.0 25A (1) 123.8 88.9 50.8 17.5 4 19.0 32A (1 1/4) 133.3 98.4 63.5 19.0 4 19.0 40A (1 1/2) 155.6 114.3 73.0 20.5 4 22.2 50A (2) 165.1 127.0 92.1 22.3 8 19.0 65A (2 1/2) 190.5 149.2 104.8 25.4 8 22.2 80A (3) 209.5 168.3 127.0 28.4 8 22.2 100A (4) 254.0 200.0 157.2 31.7 8 22.2 125A (5) 279.4 234.9 185.7 35.0 8 22.2 150A (6) 317.5 269.9 215.9 36.5 12 22.2 200A (8) 381.0 330.2 269.9 41.1 12 25.4 250A (10) 444.5 387.3 323.8 47.7 16 28.6 300A (12) 520.7 450.8 381.0 50.8 16 31.7 350A (14) 584.2 514.3 425.1 54.0 20 31.7 400A (16) 647.4 571.5 482.6 57.2 20 34.9 450A (18) 711.2 628.6 533.4 60.3 24 34.9 500A (20) 774.7 685.8 584.2 63.5 24 34.9 600A (24) 914.4 812.8 692.1 69.8 24 41.3 SAMYANG METAL / 37 COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY FLANGE COMPOSITE BLIND MATERIAL : CARBON Steel & Cu-Ni 90/10 PLATE OVERLAY DIMENSION : JIS B2210 5K Unit : mm N/D Outernal Flange Bolt Handle Q TY D C d T N H 15 80 60 44 9 4 12 20 85 65 49 10 4 12 25 95 75 59 10 4 12 32 115 90 70 12 4 15 40 120 95 75 12 4 15 50 130 105 75 14 4 15 65 155 130 110 14 4 15 80 180 145 121 14 4 19 100 200 165 141 16 8 19 125 235 200 176 16 8 19 150 265 230 206 18 8 19 1 200 320 280 252 20 8 23 2 210 250 385 345 317 22 12 23 2 250 300 430 390 360 22 12 23 2 300 350 480 435 403 24 12 25 2 300 400 540 495 463 24 16 25 2 300 450 605 555 523 24 16 25 2(1) 300 500 655 605 573 24 20 25 2(1) 300 600 770 715 680 26 20 27 2(1) 300 A 10K Unit : mm N/D Outernal Flange Bolt Handle Q TY D C d T N H 15 95 70 51 12 4 15 20 100 75 56 14 4 15 25 125 90 67 14 4 19 32 135 100 76 16 4 19 40 140 105 81 16 4 19 50 155 120 96 16 4 19 65 175 140 116 18 4 19 80 185 150 126 18 8 19 100 210 175 151 18 8 19 125 250 210 182 20 8 23 150 280 240 212 22 8 23 1 200 330 290 262 22 12 23 2 210 250 400 355 324 24 12 25 2 250 300 445 400 368 24 16 25 2 300 350 490 445 413 26 16 25 2 300 400 560 510 475 28 16 27 2 300 450 620 565 530 30 20 27 2(1) 300 500 675 620 585 30 20 27 2(1) 300 600 795 730 690 32 24 33 2(1) 300 A : THE GAP DISTANCE BETWEEN HAND GRIP. SAMYANG METAL / 38 A COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY FLANGE SOLID SOCKET WELDING & SILVER BRAZING BRAZING ALLOY : AWS A5.8 BAG-1A MATERIAL : Cu-Ni 90/10, Cu-Ni 70/30 DIMENSION : ANSI B16.5 ANSI 150# Unit : mm Outside Diameter DIMENSION N/D (inch) O/D (mm) D d0 D1 D2 D3 T t PCD 1/2 16 16.1 14 88.9 30.2 34.9 15.9 11.1 60.3 3/4 25 25.1 22 98.4 38.1 42.9 15.9 12.7 69.8 1 30 30.1 27 107.9 49.2 50.8 17.5 14.3 79.4 1 1/4 38 38.1 35 117.5 58.7 63.5 20.6 15.9 1 1/2 44.5 44.6 41.5 127 65.1 73.0 22.6 2 57 57.1 54 152.4 77.8 92.1 2 1/2 76.1 76.2 72 177.8 90.5 3 88.9 89.0 84 190.5 4 108 108.1 103 228.6 N M W WI 15.9 4 3 3.2 5 15.9 4 3 3.2 5 15.9 4 3 3.2 5 88.9 15.9 4 3 3.2 6 17.5 98.4 15.9 4 3 3.2 6 25.5 19.1 120.6 19.1 4 3 5.3 7 104.8 28.6 22.2 139.7 19.1 4 4 5.3 7 107.9 127 30.2 23.8 152.4 19.1 4 4 5.3 7 134.9 157.2 33.3 23.8 192.5 19.1 8 4 5.3 7 H ANSI 300# Unit : mm Outside Diameter DIMENSION N/D (inch) O/D (mm) D d0 1/2 16 16.1 3/4 25 25.1 1 30 1 1/4 D1 D2 D3 T t PCD H 14 95.2 38.1 34.9 22.2 14.3 66.7 15.9 22 117.5 47.6 42.9 25.4 15.9 82.5 19.1 30.1 27 123.8 54.0 50.8 27.0 17.5 88.9 38 38.1 35 133.3 63.5 63.5 27.0 19.0 1 1/2 44.5 44.6 41.5 155.6 69.8 73.0 30.2 2 57 57.1 54 165.1 84.1 92.1 2 1/2 76.1 76.2 72 190.5 100.0 3 88.9 89.0 84 209.5 4 108 108.1 103 254.0 M W WI 4 3 3.2 5 4 3 3.2 6 19.1 4 3 3.2 6 98.4 19.1 4 3 3.2 7 20.6 114.3 22.2 4 3 3.2 7 33.3 22.2 127.0 19.1 8 3 5.3 7 104.8 38.1 25.4 149.2 22.2 8 4 5.3 7 117.5 127 42.9 28.6 168.3 22.2 8 4 5.3 7 146.0 157.2 47.6 31.8 200.0 22.2 8 4 5.3 7 SAMYANG METAL / 39 N COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY FLANGE SOLID SOCKET WELDING & SILVER BRAZING BRAZING ALLOY : AWS A5.8 BAG-1A MATERIAL : Cu-Ni 90/10, Cu-Ni 70/30 DIMENSION : JMS 7801, 7802 JIS 5K Unit : mm DImension N/D (A) O. D 10 16 15 20 20 Thk . BOLT D d T t A B C N H d1 M W W1 1.0 75 16.1 15 9 26 30 55 4 12 14 3 3.2 5 M10 1.0 80 20.1 15 9 30 34 60 4 12 18 3 3.2 5 M10 25 1.5 85 25.1 16 10 37 41 65 4 12 22 3 3.2 5 M10 25 30 1.5 95 30.1 16 10 42 46 75 4 12 27 3 3.2 5 M10 32 38 1.5 115 38.1 18 12 50 54 90 4 15 35 3 3.2 6 M12 40 44.5 1.5 120 44.6 18 12 57 61 95 4 15 41.5 3 3.2 6 M12 50 57 1.5 130 57.1 20 14 69 73 105 4 15 54 3 5.3 7 M12 65 76 2.0 155 76.1 20 14 89 93 130 4 15 72 4 5.3 7 M12 80 89 2.5 180 89.1 22 14 104 108 145 4 19 84 4 5.3 7 M16 100 108 2.5 200 108.1 24 16 124 129 165 8 19 103 4 5.3 7 M16 JIS 10K Unit : mm DImension N/D (A) O. D 10 16 15 20 20 BOLT Thk . D d T t A B C N H d1 M W W1 1.0 90 16.1 16 12 26 30 65 4 15 14 3 3.2 5 M12 1.0 95 20.1 16 12 30 34 70 4 15 18 3 3.2 5 M12 25 1.5 100 25.1 18 14 37 41 75 4 15 22 3 3.2 6 M12 25 30 1.5 125 30.1 18 14 42 46 90 4 19 27 3 3.2 6 M16 32 38 1.5 135 38.1 20 16 50 54 100 4 19 35 3 3.2 7 M16 40 44.5 1.5 140 44.6 20 16 57 61 105 4 19 41.5 3 3.2 7 M16 50 57 1.5 155 57.1 20 16 69 73 120 4 19 54 3 5.3 7 M16 65 76 2.0 175 76.1 24 18 90 94 140 4 19 72 4 5.3 7 M16 80 89 2.5 185 89.1 24 18 105 110 150 8 19 84 4 5.3 7 M16 100 108 2.5 210 108.1 26 18 126 131 175 8 19 103 4 5.3 8 M16 SAMYANG METAL / 40 COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY FLANGE SOLID SLIP-ON MATERIAL : Cu-Ni 90/10, Cu-Ni 70/30 DIMENSION : BASED ON ANSI B16.5 ANSI 150# Unit : mm Outside Diameter N/D (inch) Dimension O/D (mm) D D1 D2 D3 T t PCD H N 2 57 57.4 152.4 77.8 92.1 25.4 19.1 120.6 19.1 4 2 1/2 76.1 76.5 177.8 90.5 104.8 28.6 22.2 139.7 19.1 4 3 88.9 89.4 190.5 107.9 127.0 30.2 23.8 152.4 19.1 4 4 108 108.5 228.6 134.9 157.2 33.3 23.8 190.5 19.1 8 5 133 133.8 254.0 163.5 185.7 36.5 23.8 215.9 22.4 8 6 159 159.8 279.4 192.1 215.9 39.7 25.4 241.3 22.4 8 8 219.1 220.3 342.9 246.1 269.9 44.4 28.6 298.4 22.4 8 10 267 268.4 406.4 304.8 323.8 49.2 30.2 361.9 25.4 12 12 323.9 325.4 482.6 365.1 381.0 55.6 31.8 431.8 25.4 12 14 368 369.5 533.4 400.0 425.1 57.1 34.9 476.2 28.5 12 16 419.1 420.5 596.9 457.2 482.6 63.5 36.5 539.7 28.5 16 18 457.2 458.7 635.0 504.8 533.4 68.3 39.7 577.8 31.8 16 20 508 509.5 698.5 558.8 584.2 73.0 42.9 635.0 31.8 20 24 610 611.5 812.8 663.6 692.1 82.5 47.6 749.3 35.1 20 ANSI 300# Unit : mm Outside Diameter N/D (inch) Dimension O/D (mm) D D1 D2 D3 T t PCD H N 2 57 57.4 165.1 84.1 92.1 33.3 22.2 127.0 19.1 8 2 1/2 76.1 76.5 190.5 100.0 104.8 38.1 25.4 149.2 22.4 8 3 88.9 89.4 209.5 117.5 127.0 42.9 28.6 168.3 22.4 8 4 108 108.5 254.0 146.0 157.2 47.6 31.8 200.0 22.4 8 5 133 133.8 279.4 177.8 185.7 50.8 34.9 234.9 22.4 8 6 159 159.8 317.5 206.4 215.9 52.4 36.5 269.9 22.4 12 8 219.1 220.3 381.0 260.3 269.9 61.9 41.3 330.2 25.4 12 10 267 268.4 444.5 320.7 323.8 66.7 47.6 387.3 28.5 16 12 323.9 325.4 520.7 374.6 381.0 73.0 50.8 450.8 31.8 16 14 368 369.5 584.2 425.4 425.1 76.2 54.0 514.3 31.8 20 16 419.1 420.5 647.7 482.6 482.6 82.5 57.2 571.5 35.1 22 18 457.2 458.7 711.2 533.4 533.4 88.9 60.3 628.5 35.1 24 20 508 509.5 774.7 587.4 584.2 95.2 63.5 685.8 35.1 24 24 610 611.5 914.4 701.7 692.1 106.4 69.8 812.8 41.2 24 SAMYANG METAL / 41 COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY FLANGE SOLID SLIP-ON MATERIAL : Cu-Ni 90/10, Cu-Ni 70/30 DIMENSION : JIS B2240 JIS 5K Unit : mm Outside Diameter Dimension N/D (inch) O/D (mm) D D1 50 57.0 57.4 65 76.1 76.5 80 88.9 100 D3 t C H N 130 85 14 105 15 4 155 110 14 130 15 4 89.4 180 121 14 145 19 4 108.0 108.5 200 141 16 165 19 8 125 133.0 133.8 235 176 16 200 19 8 150 159.0 159.8 265 206 18 230 19 8 200 219.1 220.3 320 252 20 280 23 8 250 267.0 268.4 385 317 22 345 23 12 300 323.9 325.4 430 360 22 390 23 12 350 368.0 369.5 480 403 24 435 25 12 400 419.1 420.5 540 463 24 495 25 16 450 457.2 458.7 605 523 24 555 25 16 500 508.0 509.5 655 573 24 605 25 20 600 610.0 611.5 770 680 26 715 27 20 Unit : mm JIS 10K Outside Diameter Dimension O/D (mm) D D1 50 57 57.4 65 76.1 76.5 80 88.9 100 N/D (inch) D3 t C H N 155 96 16 120 19 4 175 116 18 140 19 4 89.4 185 126 18 150 19 8 108 108.5 210 151 18 175 19 8 125 133 133.8 250 182 20 210 23 8 150 159 159.8 280 212 22 240 23 8 200 219.1 220.3 330 262 22 290 23 12 250 267 268.4 400 324 24 355 25 12 300 323.9 325.4 445 368 24 400 25 16 350 368 369.5 490 413 26 445 25 16 400 419.1 420.5 560 475 28 510 27 16 450 457.2 458.7 620 530 30 565 27 20 500 508 509.5 675 585 30 620 27 20 600 610 611.5 795 690 32 730 33 24 SAMYANG METAL / 42 COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY FLANGE SOLID WELDING NECK MATERIAL : Cu-Ni 90/10, Cu-Ni 70/30 DIMENSION : ANSI B16.5 Unit : mm ANSI 150# Outside Diameter Dimension N/D inch O/D (D) mm D1 D2 t T 1 1/2 44.5 127 65 18 2 57 152 78 19 2 1/2 76.1 178 90 3 88.9 190 4 108 5 PCD H 62 98.4 15.9 4 64 120.6 19.1 4 22 70 139.7 19.1 4 108 24 70 152.4 19.1 4 229 135 24 76 190.5 19.1 8 133 254 164 24 89 215.9 22.4 8 6 159 279 192 25 89 241.3 22.4 8 8 219.1 343 246 28 102 298.4 22.4 8 10 267 406 305 30 102 362.0 25.4 12 12 323.9 483 365 32 114 431.8 25.4 12 14 368 533 400 35 127 476.2 28.5 12 16 419.1 597 457 37 127 539.8 28.5 16 18 457.2 635 505 40 140 577.8 31.8 16 20 508 698 559 43 144 635.0 31.8 20 24. 610 813 664 48 152 749.3 35.1 20 N Unit : mm ANSI 300# Outside Diameter Dimension N/D inch O/D (D) mm D1 D2 t T PCD H 1 1/2 44.5 156 70 21 68 114.3 22.4 4 2 57 165 84 22 70 127 19.1 8 2 1/2 76.1 190 100 25 76 149.4 22.4 8 3 88.9 210 117 28 79 168.2 22.4 8 4 108 254 146 32 86 200 22.4 8 5 133 279 178 35 98 203.2 22.4 8 6 159 318 206 37 98 269.9 22.4 12 N 8 219.1 381 260 41 111 330.2 25.4 12 10 267 444 321 48 117 387.4 19.1 16 12 323.9 521 375 51 130 450.8 31.8 16 14 368 584 425 54 143 514.4 31.8 20 16 419.1 648 483 57 148 571.5 35.1 20 18 457.2 711 533 60 159 628.6 35.1 24 20 508 775 587 64 162 685.8 35.1 24 24. 610 914 702 70 168 812.8 41.2 24 SAMYANG METAL / 43 COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY FLANGE SOLID BLIND MATERIAL : Cu-Ni 90/10, Cu-Ni 70/30 DIMENSION : ANSI B16.5 ANSI 150# Unit : mm Outside Diameter Dimension N/D (inch) O/D (mm) D1 D2 t PCD 1/2 20.0 88.9 34.9 11.1 60.3 15.9 4 3/4 25.0 98.4 42.9 12.7 69.8 15.9 4 1 30.0 108.0 50.8 14.3 79.4 15.9 4 1 1/4 38.0 117.5 63.5 15.9 88.9 15.9 4 1 1/2 44.5 127.0 73.0 17.5 98.4 15.9 4 2 57.0 152.4 92.1 19.1 120.6 19.0 4 2 1/2 76.1 177.8 104.8 22.3 139.7 19.0 4 3 88.9 190.5 127.0 23.8 152.4 19.0 4 4 108.0 228.6 157.2 23.8 190.5 19.0 8 5 133.0 254.0 185.7 23.8 215.9 22.2 8 6 159.0 279.4 215.9 25.4 241.3 22.2 8 8 219.1 342.9 269.9 28.6 298.4 22.2 8 10 267.0 406.4 323.8 30.2 361.9 25.4 12 12 323.9 482.6 381.0 31.8 431.8 25.4 12 14 368.0 533.4 425.1 34.9 476.2 28.6 12 16 419.1 596.9 482.6 36.5 539.7 28.6 16 18 457.2 635.0 533.4 39.7 577.8 31.7 16 20 508.0 698.5 584.2 42.9 635.0 31.7 20 24 610.0 812.8 692.1 47.6 749.3 34.9 20 H ANSI 300# N Unit : mm Outside Diameter N/D (inch) O/D (mm) 1/2 3/4 Dimension N D1 D2 t PCD H 20.0 95.2 34.9 14.3 66.7 15.9 4 25.0 117.5 42.9 15.9 82.5 19.0 4 1 30.0 123.8 50.8 17.5 88.9 19.0 4 1 1/4 38.0 133.3 63.5 19.0 98.4 19.0 4 1 1/2 44.5 155.6 73.0 20.6 114.3 22.2 4 2 57.0 165.1 92.1 22.2 127.0 19.0 8 2 1/2 76.1 190.5 104.8 25.4 149.2 22.2 8 3 88.9 209.5 127.0 28.6 168.3 22.2 8 4 108.0 254.0 157.2 31.8 200.0 22.2 8 5 133.0 279.4 185.7 34.9 234.9 22.2 8 6 159.0 317.5 215.9 36.5 269.9 22.2 12 8 219.1 381.0 269.9 41.3 330.2 25.1 12 10 267.0 444.5 323.8 47.6 387.3 28.6 16 12 323.9 520.7 381.0 50.8 450.8 31.7 16 14 368.0 584.2 425.1 54.0 514.3 31.7 20 16 419.1 647.7 482.6 57.2 571.5 34.9 16 18 457.2 711.2 533.4 60.3 628.6 34.9 20 20 508.0 774.7 584.2 63.5 685.8 34.9 20 24 610.0 914.4 692.1 69.8 812.8 41.3 24 SAMYANG METAL / 44 COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY FLANGE SOLID BLIND MATERIAL : Cu-Ni 90/10, Cu-Ni 70/30 DIMENSION : JIS B 2240 JIS 5K Unit : mm Outside Diameter Dimension N/D (inch) O/D (mm) D1 D2 t PCD H N 10 16 75 39 9 55 12 4 15 20 80 44 9 60 12 4 20 25 85 49 10 65 12 4 25 30 95 59 10 75 12 4 32 38 115 70 12 90 15 4 40 44.5 120 75 12 95 15 4 50 57 130 85 14 105 15 4 65 76.1 155 110 14 130 15 4 80 88.9 180 121 14 145 19 4 100 108 200 141 16 165 19 8 125 133 235 176 16 200 19 8 150 159 265 206 18 230 19 8 200 219.1 320 252 20 280 23 8 250 267 385 317 22 345 23 12 300 323.9 430 360 22 390 23 12 350 368 480 403 24 435 25 12 400 419.1 540 463 24 495 25 16 450 457.2 605 523 24 555 25 16 500 508 655 573 24 605 25 20 600 610 770 680 26 715 27 20 JIS 10K Unit : mm Outside Diameter Dimension N/D (inch) O/D (mm) D1 D2 t PCD H N 10 16 90 46 12 65 15 4 15 20 95 51 12 70 15 4 20 25 100 56 14 75 15 4 25 30 125 67 14 90 19 4 32 38 135 76 16 100 19 4 40 44.5 140 81 16 105 19 4 50 57 155 96 16 120 19 4 65 76.1 175 116 18 140 19 4 80 88.9 185 126 18 150 19 8 100 108 210 151 18 175 19 8 125 133 250 182 20 210 23 8 150 159 280 212 22 240 23 8 200 219.1 330 262 22 290 23 12 250 267 400 324 24 355 25 12 300 323.9 445 368 24 400 25 16 350 368 490 413 26 445 25 16 400 419.1 560 475 28 510 27 16 450 457.2 620 530 30 565 27 20 500 508 675 585 30 620 27 20 600 610 795 690 32 730 33 24 SAMYANG METAL / 45 COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY CAPILLARY FITTINGS (Silver Brazing Fittings) Capillary Fitting Designation of Sizes and fittings. A fitting in which the joint is made the flow of solder by capillary action among the annular spare between the outside of the tube and the inside of the socket of the fitting. The size by which fittings are designated shall be nominal outside diameter of the tube with which the fittings are to be used. The outside diameters in the relevant product tables. Union Joint Material Silver brazing and threaded fittings are produced by hot-forging and casting, and supplied with machined surfaces. Silver-Brazing Alloy Rings - AWS A5.8 BAG1~BAG14 - JIS E3261 BAG1~BAG7 - BS 1845 AG1~AG7 Aluminum Brass - ASTM B111 B543 C687 - BS 2872 CZ110 - JIS H3300 C6870, C6871, C6872 Union type fittings have round-nose to cone seat joint and to ensure freedom leaks, care must be taken to avoid damage to the. jointing faces. with joints of this type it is essential to use a suitable jointing compound or tape to ensure completely satisfactory result. Flux Flux is recommended and specially suitable for use with silver brazing fittings. Satisfactory joints can, however, be made with other suitable silver brazing fluxes. Socket Weld Fittings Cu-Ni Alloy (Cu-Ni 90/10, 70/30) - ASTM B111 B543 C706 ,C715 - BS 2872 CN102, CN107 - JIS H3300 C7060, C7150 All silver-brazing fittings can be also supplied as socket-weld fittings without integral silver brazing alloys. These fittings have no silver ring groove. Bronze casting - ASTM B61, B62 - BS 1400 LG4 - JIS H5111 BC1~BC7 Thread Threaded fittings are suplied with threads according to NPT, API, BSP, JIS and DIN. When other standards are requested, the total length of the fitting may vary slightly. SAMYANG METAL / 46 COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY COUPLING STRAIGHT & REDUCING COUPLING (Capillaryend Capillaryend ) MATERIAL : Aluminum Brass Cu-Ni alloy Bronze Casting ENDS : Capillary ends with integral silver brazing alloy rings. Unit : mm Building-in Dimension for Straight and Reducing Coupling Nominal Size A d d1 6 10.0 - 8 12.0 - 12 16.0 16 Actual Tube O.D E l L L1 16 8.0 10 22 - 18 10.0 10 22 - - 22 14.0 10 22 - 20.0 - 27 18.0 10 22 - 16 12 20.0 16.0 27 18.0 10 - 27 D 20 25.0 - 32 22.0 10 22 - 20 12 25.0 16.0 32 22.0 10 - 35 20 16 25.0 20.0 32 22.0 10 - 27 25 30.0 - 37 27.0 11 24 - 25 12 30.0 16.0 37 27.0 11 - 35 25 16 30.0 20.0 37 27.0 11 - 34 25 20 30.0 25.0 37 27.0 11 - 30 32 38.0 - 45 35.0 15 32 - 32 16 38.0 20.0 45 35.0 15 - 45 32 20 38.0 25.0 45 35.0 15 - 41 32 25 38.0 30.0 45 35.0 15 - 36 40 44.5 - 52 41.5 15 32 - 40 16 44.5 20.0 52 41.5 15 - 50 40 20 44.5 25.0 52 41.5 15 - 49 40 25 44.5 30.0 52 41.5 15 - 44 40 32 44.5 38.0 52 41.5 15 - 42 50 57.0 - 65 54.0 15 33 - 50 20 57.0 25.0 65 54.0 15 - 52 50 25 57.0 30.0 65 54.0 15 - 50 50 32 57.0 38.0 65 54.0 15 - 49 50 40 57.0 44.5 65 54.0 15 - 44 SAMYANG METAL / 47 COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY ELBOW & CAP 45 & 90 ELBOW (Capillary end Capillary end) MATERIAL : Aluminum Brass Cu-Ni alloy Bronze Casting END : Capillary ends with integral silver brazing alloy rings. Unit : mm Building-in Dimension for 45 and 90 Elbow Nominal Size A Actual Tube O.D d D E l B L 12 16 22 14.0 10 15 21.0 16 20 27 18.0 10 18 23.5 20 25 32 22.0 10 23 26.0 25 30 37 27.0 11 28 29.5 32 38 45 35.0 15 38 36.5 40 44.5 52 41.5 15 42 41.0 50 57 65 54.0 15 51 47.5 END CAP (Capillary end) MATERIAL : Aluminum Brass Cu-Ni alloy Bronze Casting DIMENSION : Capillary ends with integral silver brazing alloy rings. Unit : mm Building-in Dimension for END CAP Nominal Size A Actual Tube O.D d D E l L 12 16.0 22 14.0 10 21.0 16 20.0 27 18.0 10 23.5 20 25.0 32 22.0 10 26.0 25 30.0 37 27.0 11 29.5 32 38.0 45 35.0 15 30.0 40 44.5 52 41.5 15 41.3 50 57.0 65 54.0 15 47.5 SAMYANG METAL / 48 COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY TEE EQUAL & REDUCING TEE (Capillary end Capillary end) MATERIAL : Aluminum Brass Cu-Ni alloy Bronze Casting END : Capillary ends with integral silver brazing alloy rings. Unit : mm Building-in Dimension for Equal and Reducing Tee Nominal Size A Actual Tube O.D d D D1 E E1 l l1 L L1 - d1 12 16.0 - 22 - 14.0 - 10 - 21.0 16 20.0 - 27 - 18.0 - 10 - 23.5 - 16 12 20 16 27 22 18.0 14.0 10 10 - 23.5 20 25.0 - 32 - 22.0 - 10 - 26.0 - 20 12 25.0 16.0 32 22 22.0 14.0 10 10 26.0 26.0 20 16 25.0 20.0 32 27 22.0 18.0 10 10 26.0 26.0 25 30.0 - 37 - 27.0 - 11 - 29.5 - 25 12 30.0 16.0 37 22 27.0 14.0 11 10 29.5 28.5 25 16 30.0 20.0 37 27 27.0 18.0 11 10 29.5 28.5 25 20 30.0 25.0 37 32 27.0 22.0 11 10 29.5 28.5 32 38.0 - 45 - 35.0 - 15 - 37.5 - 32 16 38.0 20.0 45 27 35.0 18.0 15 10 32.5 35.0 32 20 38.0 25.0 45 32 35.0 22.0 15 10 32.5 35.0 32 25 38.0 30.0 45 37 35.0 27.0 15 11 33.5 35.0 40 44.5 - 52 - 41.5 - 15 - 41.5 - 40 16 44.5 20.0 52 27 41.5 18.0 15 10 36.0 41.0 40 20 44.5 25.0 52 32 41.5 22.0 15 10 36.0 41.0 40 25 44.5 30.0 52 37 41.5 27.0 15 11 36.0 41.0 40 32 44.5 38.0 52 45 41.5 35.0 15 15 41.0 41.0 50 57.0 - 65 - 54.0 - 15 - 47.5 - 50 20 57.0 25.0 65 32 54.0 22.0 15 10 42.5 47.5 50 25 57.0 30.0 65 37 54.0 27.0 15 11 43.5 47.5 50 32 57.0 38.0 65 45 54.0 35.0 15 15 47.5 47.5 50 40 57.0 44.5 65 52 54.0 41.5 15 15 47.5 47.5 SAMYANG METAL / 49 COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY CONNECTOR MALE & FEMALE CONNECTOR MATERIAL : Cu-Ni alloy Al-Brass Bronze Casting END : Capillary ends with integral silver brazing alloy rings. THREAD : According to NPT, API BSP, DIN or other Unit : mm Building-in Dimension for Male and Female Connector Nominal Size A Actual Tube O.D d E E1 D D1 l L L1 NPT T H H1 12 16.0 10 14 22 27 10 30 32 1/2 22 27 20 25.0 14 22 32 32 10 33 32 3/4 32 32 25 30.0 20 27 37 40 11 40 37 1 41 41 32 38.0 27 35 45 48 15 45 41 1 1/4 46 46 40 44.5 35 41.5 52 55 15 48 43 1 1/2 55 55 50 57.0 45 54 65 70 15 51 43 2 65 70 MALE UNION CONNECTOR MATERIAL : Cu-Ni alloy Al-Brass Bronze Casting END : Capillary ends with integral silver brazing alloy rings. THREAD : According to NPT, API BSP, DIN or other Unit : mm Building-in Dimension for Male Union Connector Nominal Size A Actual Tube O.D d E D L L1 L2 H H1 NPT T 12 20 16 25 14.0 22 74 10 19.0 36 32 3/4 16 20 20 25 18.0 27 79 10 19.0 41 36 3/4 20 25 25 30 22.0 32 82 10 21.0 46 41 1 25 32 30 38 27.0 37 89 11 23.0 50 50 1 1/4 32 40 38 44.5 35.0 45 97 15 25.0 60 55 1 1/2 40 20 44.5 25 41.5 52 100 15 25.5 70 60 3/4 50 50 57 57 57.0 65 109 15 27.5 85 70 2 SAMYANG METAL / 50 COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY OUTLET & BUSH FORGED OUTLET Self-reinforced branch connector thread, socket weld and Capillary type MATERIAL : Cu-Ni Alloy Al-Brass Bronze Casting Weld preparation : 40 2 1/2 END : Socket weld, Thread and Capillary end THREAD : According to NPT, API BSP, DIN and other Unit : mm Building-in Dimension for Socket weld Thread and Brazed outlet Head Size Branch Size Actual Tube O.D d Inlet l L NPT T 25 to 610 1/2 16 28 9.7 24 1/2 30 to 610 3/4 25 33 12.7 25.4 3/4 1 30 35 12.7 28.6 1 1 1/4 38 49 12.7 30.2 1 1/4 1 1/2 44.5 53 12.7 33 1 1/2 2 57 67 15.8 47.6 2 44.5 to 610 57to 610 76.1 to 610 108 to 610 BUSH MATERIAL : Cu-Ni Alloy Al-Brass Bronze Casting THREAD : According to NPT, API BSP, DIN or other Unit : mm Building-in Dimension for Sprinkler Bush Nominal Size (A) Actual Tube O.D d L 12 16.0 10 16 20.0 10 20 25.0 10 25 30.0 12 32 38.0 15 40 44.5 15 50 57.0 15 SAMYANG METAL / 51 NPT T On Applicable COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY SAMYANG METAL / 52 COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY GENERAL INFORMATION THE PIPE STANDARD The Applicable Standard Specifications for Cu-Ni 90/10 Pipes & Cu-Ni 70/30 Pipes Country GERMANY UNITED KINGDOM U.S.AMERICA FRANCE JAPAN SEAMLESS DIN 86019 DIN 1755 DIN 85004(Navy) BS 2871 PT2 EEMUA 144 NES 779 PT3(Navy) ASTM B466 MIL-T-16420K Type GRADE 1 GAM MM11(Navy) S.T.F.22.54./C.004(Navy) H3300 SEAM WELDED DIN 86018 BS 2875 ASTM B467 ASTM B608 MIL-T-16420K Type GRADE 1 or GRADE 2 GAM MM11(Navy) S.T.F.22.54./C.005(Navy) H3320 Kind SAMYANG METAL / 53 COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY GENERAL INFORMATION THE PIPE JAPANESE STANDARD-PIPES DIMENSION Cu-Ni 90/10 Cu-Ni 70/30 SEAMLESS and SEAM Pipe According to Metric Size, Navy(mm, inch) NDS Size Inch (NDS) Size Metric Size 5K Nominal Diameter MM M.M (NDS) Size 10K Outside Diameter Wall Thickness Outside Diameter Wall Thickness Outside Diameter Wall Thickness Outside Diameter Wall Thickness mm mm mm mm mm mm mm mm 16 20 25 30 38 44.5 57 76.1 1.0 1.0 1.5 1.5 1.5 1.5 1.5 2.0 15.14 21.49 28.25 34.60 40.95 54.05 66.75 1.21 1.21 1.42 1.42 1.42 1.62 1.62 6.35 12.71 15.14 21.49 28.25 34.60 40.95 54.05 66.75 0.89 0.89 1.65 1.65 1.65 1.65 1.83 2.11 2.41 15 20 25 30 38 45 55 70 1.5 88.9 108 2.5 2.5 79.86 106.27 1.82 2.33 79.86 106.27 2.41 2.77 85 95 110 3.0 3.0 133 159 2.5 2.5 131.67 157.68 2.33 2.64 131.67 157.68 3.18 3.40 130 160 219.1 - 3.0 - 208.48 - 2.64 - 208.48 - 3.76 - 180 210 230 267 323.9 3.0 4.0 260.50 312.11 3.25 3.68 260.50 312.11 4.75 6.35 260 310 368 419.1 4.0 4.0 - - - - - - 457.2 4.0 - - - - - - 508 4.5 - - - - - - 610 711 5.0 6.0 - - - - - - inch SEAMLESS 6A 10A 15A 20A 25A 32A 40A 50A 65A 80A 1 1 90A 100A 125A 4 150A 175A 200A 225A 250A 1 2 2 3 3 5 6 7 8 - 300A 350A 10 12 14 400A 16 1.5 1.5 1.5 2.0 2.0 2.0 2.0 3.0 3.0 4.0 4.0 4.0 4.0 4.5 5.5 - SEAMLESS or SEAM WELDED 450A 500A 18 20 SEAM WELDED 600A 700A 24 28 SAMYANG METAL / 54 COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY GENERAL INFORMATION THE PIPE US NAVY STANDARDS DIMENSION Cu-Ni 90/10 Cu-Ni 70/30 SEAMLESS and SEAM Pipe according to MIL-T-16420K Outside Diameter of Pipe D Nominal inch Actual inch Class 200 Class 700 Minimum Wall Thickness Minimum Wall Thickness Actual mm Actual inch Actual mm Actual inch Actual mm 0.250 0.500 6.35 12.70 0.035 0.035 0.89 0.89 0.065 1.65 0.540 0.675 0.840 1.050 1.315 1.660 1.900 13.72 17.15 21.34 26.67 33.40 42.16 48.27 0.065 0.065 0.065 0.065 0.065 0.072 0.072 1.65 1.65 1.65 1.65 1.65 1.83 1.83 0.065 0.072 0.072 0.083 0.095 0.095 0.109 1.65 1.83 1.83 2.11 2.41 2.41 2.77 2.375 2.875 3.500 4.000 4.500 5.000 5.563 6.625 7.625 60.32 73.03 88.90 101.60 114.30 127.00 141.30 168.30 193.70 0.083 0.083 0.095 0.095 0.109 0.120 0.125 0.134 0.134 2.11 2.11 2.41 2.41 2.77 3.05 3.18 3.40 3.40 0.120 0.134 0.165 0.180 0.203 0.203 0.220 0.259 0.284 3.05 3.40 4.19 4.57 5.15 5.15 5.59 6.58 7.21 8.625 9.625 10.750 219.10 244.48 273.05 0.148 0.187 0.187 3.76 4.75 4.75 0.340 0.340 0.380 8.64 8.64 9.65 12.750 323.90 0.250 6.35 0.454 SEAMLESS TYPE 1 1 1 2 2 3 3 4 5 6 8 10 12 Class 50 SEAMLESS TYPE 11.53 Class 700 or SEAM WELDED TYPE 14 14.000 15.000 355.60 381.00 0.165 - 4.19 - 0.473 0.503 12.01 12.77 16 18 16.000 18.000 406.40 457.20 0.165 0.180 4.19 4.57 0.534 - 13.56 - 20 20.000 508.20 0.180 4.57 - - SEAM WELDED TYPE 22 22.000 558.80 0.180 4.57 - - 30 22.750 30.000 577.85 762.20 0.180 0.250 4.57 6.35 - - 40 40.000 1016.00 0.312 7.92 - - SAMYANG METAL / 55 COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY GENERAL INFORMATION THE PIPE US STANDARDS DIMENSION Cu-Ni 90/10 Cu-Ni 70/30 SEAMLESS and SEAM Pipe according to ANSI/ASTM B36.19M Outside Diameter of Pipe D Nominal inch Schedule 5S Schedule 10S Minimum Wall Thickness Minimum Wall Thickness Actual inch Actual mm Actual inch Actual mm Actual inch Actual mm 0.405 0.540 10.29 13.72 - - 0.049 0.065 1.24 1.65 0.675 0.840 17.15 21.34 0.065 1.65 0.065 0.083 1.65 2.11 1.050 1.315 1.660 1.900 2.375 26.67 33.40 42.16 48.27 60.32 0.065 0.065 0.065 0.065 0.065 1.65 1.65 1.65 1.65 1.65 0.083 0.109 0.109 0.109 0.109 2.11 2.77 2.77 2.77 2.77 2.875 3.500 4.000 4.500 5.536 6.625 8.625 10.750 12.750 73.03 88.90 101.60 114.30 141.30 168.30 219.10 273.05 323.90 0.083 0.083 0.083 0.083 0.109 0.109 0.109 0.134 0.156 2.11 2.11 2.11 2.11 2.77 2.77 2.77 3.40 3.96 0.120 0.120 0.120 0.120 0.134 0.134 0.148 0.165 0.180 3.05 3.05 3.05 3.05 3.40 3.40 3.76 4.19 4.57 SEAMLESS 1 1 1 2 2 3 3 4 5 6 8 10 12 Outside Diameter of Pipe D Nominal inch Class 200 Schedule 40S Class 700 Schedule 80S Minimum Wall Thickness Minimum Wall Thickness Actual inch Actual mm Actual inch Actual mm Actual inch Actual mm 0.405 10.29 0.068 1.73 0.095 2.41 0.540 0.675 0.840 1.050 13.72 17.15 21.34 26.67 0.088 0.091 0.109 0.113 2.24 2.31 2.77 2.87 0.119 0.126 0.147 0.154 3.02 3.20 3.73 3.91 SEAMLESS 1 1.315 33.40 0.133 3.38 0.179 4.55 1 1 2 1.660 1.900 2.375 42.16 48.27 60.32 0.140 0.145 0.154 3.56 3.68 3.91 0.191 0.200 0.218 4.85 5.08 5.54 2 3 2.875 3.500 73.03 88.90 0.203 0.216 5.16 5.49 0.276 0.300 7.01 7.62 3 4 5 4.000 4.500 5.563 101.60 114.30 141.30 0.226 0.237 0.258 5.74 6.02 6.55 0.318 0.337 0.375 8.08 8.56 9.53 6 8 6.625 8.625 168.30 219.10 0.282 0.322 7.11 8.18 0.432 0.500 10.97 12.70 10 12 10.750 12.750 273.06 323.90 0.365 0.375 9.27 9.53 0.500 0.500 12.70 12.70 SAMYANG METAL / 56 COPPER-NICKEL PIPE FITTINGS AND FLANGES FOR SHIPBUILDING AND OFFSHORE INDUSTRY GENERAL INFORMATION THE PIPE EUROPEAN STANDARDS DIMENSION Cu-Ni 90/10 Cu-Ni 70/30 SEAMLESS and SEAM Pipes according to DIN 1755 T3, DIN86018, DIN86019 BS2871 PT2 & EEMUA 144. Outside Diameter of Pipe D Nominal 10 bar 14 bar 16 bar 20 bar Minimum Wall Thickness Minimum Wall Thickness Minimum Wall Thickness Minimum Wall Thickness ND Actual mm Actual mm Actual mm Actual mm Actual mm 10 15 20 25 32 40 50 10 12 16 20 25 30 38 44.5 57 1.0 1.0 1.0 1.0 1.5 1.5 1.5 1.5 1.5 1.0 1.0 1.0 1.0 1.5 1.5 1.5 1.5 1.5 1.0 1.0 2.0 2.0 2.0 2.5 2.5 2.5 2.5 1.0 1.0 2.0 2.0 2.0 2.5 2.5 2.5 2.5 65 80 76.1 88.9 2.0 2.0 2.0 2.5 2.5 2.5 2.5 2.5 100 125 150 108 133 159 2.5 2.5 2.5 2.5 3.0 3.0 3.0 3.0 3.0 3.0 3.0 3.5 175 200 193.7 219.1 2.5 3.0 3.5 3.5 3.0 4.0 3.5 4.5 12 14 250 300 350 267 323.9 368 3.0 4.0 4.0 4.0 5.0 5.5 4.5 5.5 6.5 5.5 7.0 8.0 16 400 419.1 4.0 6.0 7.0 9.0 457.2 508 4.0 4.5 6.0 6.5 8.0 8.0 8.5 9.5 11.0 600 610 5.0 9.0 10.5 13.0 700 800 900 711 813 914 6.0 6.0 8.0 10.0 11.0 12.0 13.5 15.5 15.0 17.0 19.0 inch SEAMLESS 1 1 1 2 2 3 4 5 6 7 8 10 SEAMLESS or SEAM WELDED 18 20 450 500 SEAM WELDED 24 28 32 36 SAMYANG METAL / 57 HEAD OFFICE & FACTORY #1500-13, Dadae-dong, Saha-gu, Busan, korea TEL : +82-51-266-6655 FAX : +82-51-266-0022 HOMEPAGE : http://www.cuniship.com E-MAIL : cunis@cuniship.com 2nd OFFICE & FACTORY #276-20, Hakjang-dong, Sasang-gu, Busan, korea TEL : +82-51-316-7752 FAX : +82-51-316-7750 HOMEPAGE : http://www.cuniship.com E-MAIL : cunis@cuniship.com 3rd OFFICE & FACTORY #1507-10, Dadae-dong, Saha-gu, Busan, korea TEL : +82-51-266-3229 FAX : +82-51-266-0022 HOMEPAGE : http://www.cuniship.com E-MAIL : cunis@cuniship.com