XP6 Copper Alloy - PMX Industries, Inc.

advertisement

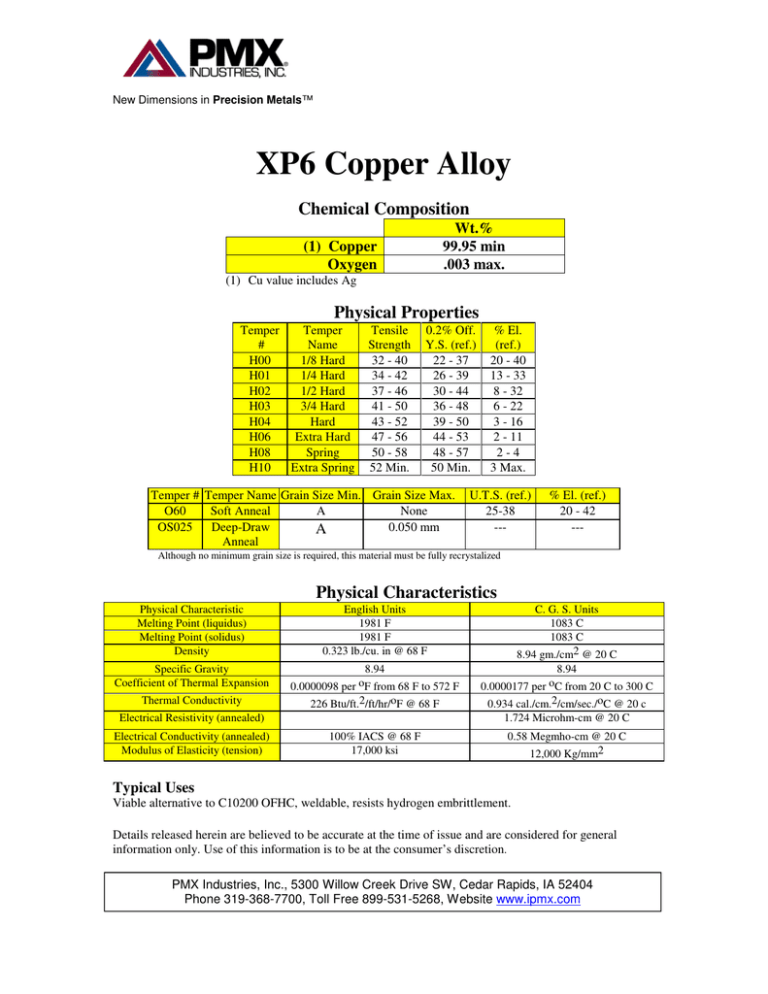

New Dimensions in Precision Metals™ XP6 Copper Alloy Chemical Composition Wt.% 99.95 min .003 max. (1) Copper Oxygen (1) Cu value includes Ag Physical Properties Temper Temper # Name H00 1/8 Hard H01 1/4 Hard H02 1/2 Hard H03 3/4 Hard H04 Hard H06 Extra Hard H08 Spring H10 Extra Spring Tensile Strength 32 - 40 34 - 42 37 - 46 41 - 50 43 - 52 47 - 56 50 - 58 52 Min. 0.2% Off. Y.S. (ref.) 22 - 37 26 - 39 30 - 44 36 - 48 39 - 50 44 - 53 48 - 57 50 Min. Temper # Temper Name Grain Size Min. Grain Size Max. O60 Soft Anneal None A OS025 Deep-Draw 0.050 mm A Anneal % El. (ref.) 20 - 40 13 - 33 8 - 32 6 - 22 3 - 16 2 - 11 2-4 3 Max. U.T.S. (ref.) 25-38 --- % El. (ref.) 20 - 42 --- Although no minimum grain size is required, this material must be fully recrystalized Physical Characteristics Physical Characteristic Melting Point (liquidus) Melting Point (solidus) Density Specific Gravity Coefficient of Thermal Expansion Thermal Conductivity English Units 1981 F 1981 F 0.323 lb./cu. in @ 68 F 8.94 8.94 0.0000098 per oF from 68 F to 572 F 226 Btu/ft.2/ft/hr/oF @ 68 F 0.0000177 per oC from 20 C to 300 C 0.934 cal./cm.2/cm/sec./oC @ 20 c Electrical Resistivity (annealed) Electrical Conductivity (annealed) Modulus of Elasticity (tension) C. G. S. Units 1083 C 1083 C 8.94 gm./cm2 @ 20 C 1.724 Microhm-cm @ 20 C 100% IACS @ 68 F 17,000 ksi 0.58 Megmho-cm @ 20 C 12,000 Kg/mm2 Typical Uses Viable alternative to C10200 OFHC, weldable, resists hydrogen embrittlement. Details released herein are believed to be accurate at the time of issue and are considered for general information only. Use of this information is to be at the consumer’s discretion. PMX Industries, Inc., 5300 Willow Creek Drive SW, Cedar Rapids, IA 52404 Phone 319-368-7700, Toll Free 899-531-5268, Website www.ipmx.com