PRODUCT BULLETIN SSB 001-5400-1100

ELECTRIC SHAFT

DIGITAL SYSTEM

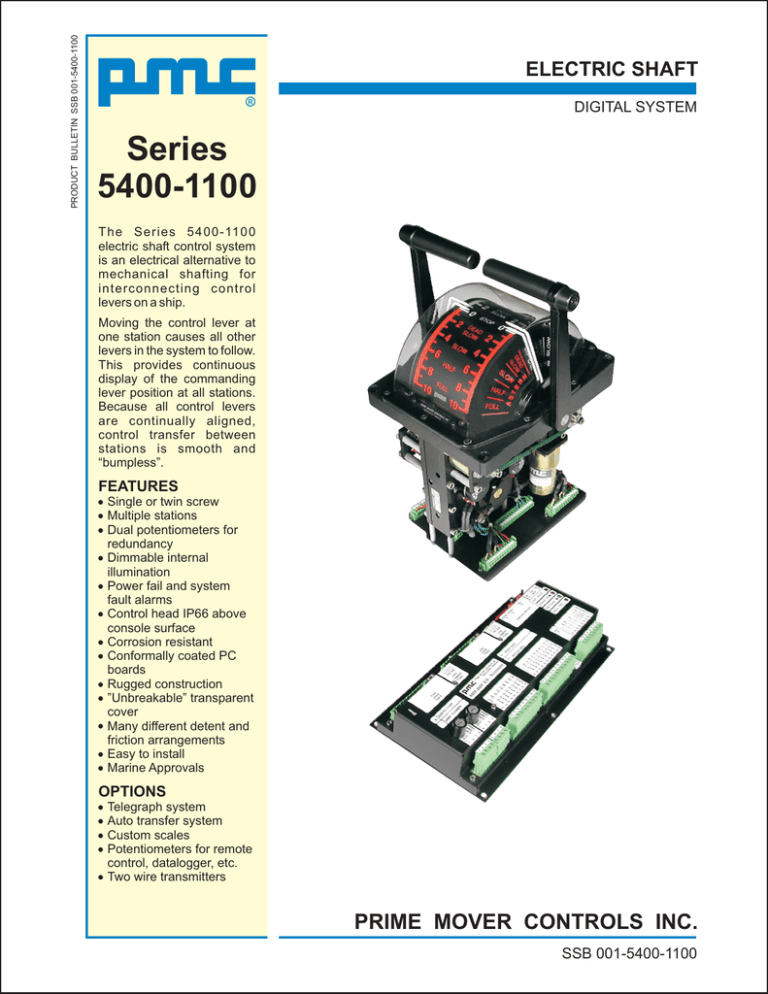

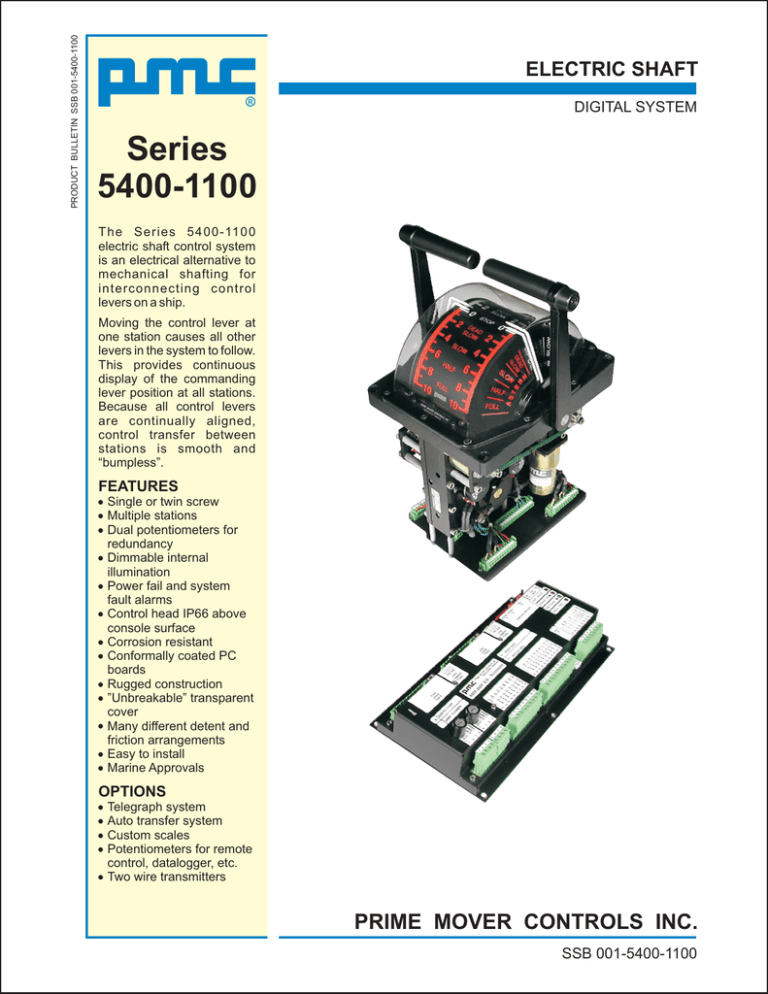

Series

5400-1100

The Series 5400-1100

electric shaft control system

is an electrical alternative to

mechanical shafting for

interconnecting control

levers on a ship.

Moving the control lever at

one station causes all other

levers in the system to follow.

This provides continuous

display of the commanding

lever position at all stations.

Because all control levers

are continually aligned,

control transfer between

stations is smooth and

“bumpless”.

FEATURES

! Single or twin screw

! Multiple stations

! Dual potentiometers for

redundancy

! Dimmable internal

illumination

! Power fail and system

fault alarms

! Control head IP66 above

console surface

! Corrosion resistant

! Conformally coated PC

boards

! Rugged construction

! ”Unbreakable” transparent

cover

! Many different detent and

friction arrangements

! Easy to install

! Marine Approvals

OPTIONS

!

!

!

!

Telegraph system

Auto transfer system

Custom scales

Potentiometers for remote

control, datalogger, etc.

! Two wire transmitters

PRIME MOVER CONTROLS INC.

SSB 001-5400-1100

ELECTRIC SHAFT

Electric Shaft System

Series 8503-2000 Digital Servo Controller are used

in conjunction with Type 5401-1100 or 5040-1100

control heads to form an electric shaft system.

The electric shaft control system is an electrical

a l t e r n a t i v e to m e c h a n i c a l s h a f t i n g f o r

interconnecting control levers on a ship.

Moving the control lever at one station causes all

other levers in the system to follow. This provides

continuous display of the commanding lever

position at all stations. Because all control levers

are continually aligned, control transfer between

stations is smooth and “bumpless”.

The system uses dual 24VDC inputs from ship’s

power supplies and serial communication with error

detection to ensure trouble free operation.

Diagnostics

Troubleshooting guidance is provided by a

Watchdog LED and a Fault Code LED. Under

normal operating conditions the Watchdog LED

will flash.

The Fault Code LED flashes two digit codes which

correspond to particular fault conditions.

A fault relay opens on a general system fault. A

critical fault relay opens when a fault is detected in

the system that would cause an electric shaft lever to

TYPICAL SCALES

Command Orders

To place a new command: Ensure that the station

you are operating is in command. Move the

Command Lever to the desired command position.

This will transmit the new command position to all

the stations. All other stations (unless disabled) will

align their Command Levers to the new command

position.

Command Jog

Jog buttons can be added, allowing the operator to

make fine adjustments to the Command Lever

position.

Control Transfer

Generally, command is transferred by pressing a

Control Transfer button. Optional auto transfer is

available, where moving the Command Lever at the

desired control station will also transfer command.

The control transfer logic can be performed by the

Digital Servo Controller or via external logic (PLC,

relays, control transfer boards).

Command Position

Optional command signal transmitters can be

installed at the factory. These transmitters work

independently of the electric shaft circuitry in the

Digital Servo Controller. Each transmitter has it's

own power supply with a self resetting internal fuse.

Even with a complete failure of other circuitry on

the Digital Servo Controller the transmitter will

continue to function properly.

PRIME MOVER CONTROLS

ELECTRIC SHAFT

7

8

8

9

9

1

3

4

5

6

7

DIPS

1-8

8

C

SW

T1

DE

TEST

MODE

WATCHDOG

P/N

RX

TX

KF

KA

I0

I1

I2

I3

I4

I5

I6

I7

I8

I9

UNIT

ID

20 21 22 23 24 25 26 27 28 29 30

20 21 22 23 24 25 26 27 28 29 30

TX \ RX ACTIVE

FAULT CODE

S/N

DATA

11 12 13 14 15 16 17 18 19

11 12 13 14 15 16 17 18 19

SW

T2

TEST / SETUP

SERVICE PIN

31 32 33 34 35 36 37 38

C

DE

H

I J

I J

WHEELHOUSE #1

2

KB

KB

DE

CONFIGURATION SWITCHES

KB

KB

KB

-

7

6

6

O0

O1

O2

O3

O4

O5

O6

O7

FUSE

24VDC

4

4

C

ROTARY ROTARY

A

B

STBD

COMMAND

SIGNAL

KB

3

VOUT

PORT

COMMAND

SIGNAL

3

2

2

STBD

COMMAND

SIGNAL

-

1

1

31 32 33 34 35 36 37 38

+

FUSE

24VDC

+

RX

TX

KF

TX \ RX ACTIVE

KA

KB

I0

I1

I2

I3

I4

I5

I6

I7

I8

I9

O0

O1

O2

O3

O4

O5

O6

O7

VOUT

KB

KB

I J

PORT

COMMAND

SIGNAL

H

I J

KB

DE

PRIME MOVER CONTROLS INC.

VANCOUVER, CANADA

8503-2000 E/S - TELEGRAPH

LEVER TELEGRAPH

31 32 33 34 35 36 37 38

C

STBD

LEVER

CABLE

31 32 33 34 35 36 37 38

H

H

I J

STBD

COMMAND

SIGNAL

H

UNIT

ID

20 21 22 23 24 25 26 27 28 29 30

20 21 22 23 24 25 26 27 28 29 30

11 12 13 14 15 16 17 18 19

ZERO SPAN

PORT

COMMAND

SIGNAL

ELECTRIC SHAFT

FAULT CODE

DATA

11 12 13 14 15 16 17 18 19

9

9

ZERO SPAN

PORT

LEVER

CABLE

WATCHDOG

S/N

DE

I J

+

C

SW

T2

H

+

DE

TEST

MODE

SERVICE PIN

I J

C

SW

T1

TEST / SETUP

H

8

F G

8

7

P/N

8503-2000 E/S - TELEGRAPH

8

6

F G

7

5

F G

-

7

6

6

4

DIPS

1-8

F G

FUSE

24VDC

4

4

3

CONFIGURATION SWITCHES

F G

3

2

F G

3

2

2

1

DE

F G

-

1

C

ROTARY ROTARY

A

B

STBD

COMMAND

SIGNAL

I J

DE

F G

FUSE

24VDC

STBD

LEVER

CABLE

PRIME MOVER CONTROLS INC.

VANCOUVER, CANADA

ELECTRIC SHAFT

LEVER TELEGRAPH

1

ZERO SPAN

PORT

COMMAND

SIGNAL

H

C

ZERO SPAN

PORT

LEVER

CABLE

WHEELHOUSE #2

TYPICAL

THREE STATION

ELECTRIC SHAFT

7

9

8

C

DE

KB

7

SW

T1

TEST

MODE

WATCHDOG

11 12 13 14 15 16 17 18 19

20 21 22 23 24 25 26 27 28 29 30

20 21 22 23 24 25 26 27 28 29 30

RX

TX

KF

TX \ RX ACTIVE

KA

UNIT

ID

KB

S/N

DATA

11 12 13 14 15 16 17 18 19

SW

T2

TEST / SETUP

FAULT CODE

31 32 33 34 35 36 37 38

C

DE

I J

COMMUNICATION

TERMINATOR

6

SERVICE PIN

I0

I1

I2

I3

I4

I5

I6

I7

I8

I9

O0

O1

O2

O3

O4

O5

O6

O7

VOUT

PORT

COMMAND

SIGNAL

STBD

COMMAND

SIGNAL

8

5

P/N

KB

+

+

6

4

DIPS

1-8

31 32 33 34 35 36 37 38

H

4

9

KB

KB

I J

3

8

H

-

7

6

I J

2

FUSE

24VDC

4

3

CONFIGURATION SWITCHES

F G

1

3

2

2

H

-

1

1

DE

ROTARY ROTARY

A

B

STBD

COMMAND

SIGNAL

F G

8503-2000 E/S - TELEGRAPH

LEVER TELEGRAPH

FUSE

C

F G

PRIME MOVER CONTROLS INC.

VANCOUVER, CANADA

ELECTRIC SHAFT

24VDC

STBD

LEVER

CABLE

I J

DE

F G

DIGITAL SERVO

CONTROLLER

ZERO SPAN

PORT

COMMAND

SIGNAL

H

C

ZERO SPAN

PORT

LEVER

CABLE

8545-11001

1

2

2

1

1

2

2

TERMINATOR

PRIME MOVER CONTROLS INC.

VANCOUVER CANADA

TO ALARM SYSTEM

PRIMARY 24VDC

CONTROL

TRANSFER

SECONDARY 24VDC

ENGINE CONTROL ROOM

PRIME MOVER CONTROLS

RELATED PRODUCT BULLETINS

PROPULSION TELEGRAPH/CONTROL HEAD

TYPE PCH

Series

5400-1100

5401-1100

Series 5040-1100

Electric Shaft Remote Control Head

PRODUCT BULLETIN SB 5040-1100

PRODUCT BULLETIN SB 5400-1100

Series 5400-1100/5401-1100

Propulsion Telegraph/Control Head

ELECTRIC SHAFT REMOTE CONTROL HEAD

Series

5040-1100

Dependable Precise

Control

The Series 5400-1100

Propulsion Control Head is a

versatile remote control

device.

The Series 5040-1100 MCHES control head provides

remote control for a wide

range of applications.

The Series 5401-1100

Propulsion Telegraph is a

traditional lever telegraph.

Illumination

Optional illumination is

available with a variety of

scales.

FEATURES

! Single or twin screw

! Dimmable internal

illumination

! IP66 above console

! Corrosion resistant

! Rugged construction

! ”Unbreakable” transparent

cover

! Many different detent and

friction arrangements

! Easy to install

! Removable terminal

blocks

! Marine approvals

Watertight

Completely watertight

design with corrosion

resistant materials allows

installation in outside

stations.

Versatile

Modular construction allows

many potentiometer, scale,

switch, handle and

servomotor options.

Servo Positioning

Motor Driven control lever

servo positioning system

provides accurate

responsive follow up.

OPTIONS

! Electric shaft system

! Telegraph system

! Auto transfer system

! Multiple potentiometers for

remote control,

datalogger, etc.

! Multiple two wire

transmitters

# 4-20mA

# 20-4mA

# 20-4-20mA

# custom

! Multiple switches

! Pneumatic control

! Custom scales

! Dual lever coupling

mechanism

Control Transfer

Transfer between stations is

activated automatically by

moving the lever at any

station or manually with a

pushbtton.

Bumpless Transfer

Control transfer between

stations is always smooth

because all levers are

continuously aligned with the

controlling station.

Options

Many options and support

products are available which

allow numerous system

configurations.

PRIME MOVER CONTROLS INC.

PRIME MOVER CONTROLS INC.

SB 5400-1100

SB 5040-1100

Series 8503-2000

Digital Servo Controller

Type 5401-1100

Propulsion Order Telegraph System

DIGITAL SERVO CONTROLLER

Series

8503-2000

ELECTRIC SHAFT/PROPULSION TELEGRAPH

Electric Shaft

The electric shaft control

system is an electrical

alternative to mechanical

shafting for interconnecting

remote control levers on a

ship. Moving the control

lever at one station causes

all other levers in the system

to follow.

This provides

continuous display at all

stations of the position of the

lever at the controlling

station. Because all control

levers are continually

aligned, control transfer

between stations is smooth

and "bumpless".

PROPULSION ORDER TELEGRAPH

DIGITAL SYSTEM

Series

5401-1100

The Series 5401-1100

propulsion telegraph system

provides a means of bidirectional communication

between the bridge and the

engine room.

This

communication is in the form

of orders placed and

acknowledged by moving

the command lever.

FEATURES

!

Single or twin screw

! Multiple stations

! Bi-directional

communication of orders

and replies

! Dimmable internal

illumination

! Contacts for external

signal bells

! Wrong direction alarms

! Power fail and system

fault alarms

! Control head IP66 above

console surface

! Corrosion resistant

! Conformal coated PC

boards

! Rugged construction

! ”Unbreakable” transparent

cover

! Many different detent and

friction arrangements

! Easy to install

! Marine approvals

Telegraph

The propulsion telegraph

provides a means of l

communication between the

bridge and engine room.

This communication is in the

form of orders placed and

acknowledged by moving

the command / reply lever to

align with the acknowledge /

command pointer.

FEATURES

! Single or twin screw

! Up to nine bridge units and

six engine room units

! Telegraph compatible with

Type 8202 push button

telegraphs

! Optional independent

command position outputs

(4-20mA or 2k-12kHz)

! Optional gateway for

connecting to data logger,

printer or PLC

! Reliable communication

and transceiver technology

for the marine environment

! Dual 24VDC inputs use

ship's power supplies

! Self diagnostics with status

indication

! Relay output for unit fault

! Marine approvals

PRODUCT BULLETIN SSB 001-5401-1100

SB 5040-1100

PRODUCT BULLETIN SB 8503-2000

SB 5400-1100

OPTIONS

! Electric shaft system

! Custom scales

! Potentiometers for remote

control, data logger, etc.

! Two wire transmitters

! Switches

! Repeaters

PRIME MOVER CONTROLS INC.

PRIME MOVER CONTROLS INC.

SB 8503-2000

SSB 001-5401-1100

SB 8503-2000

SSB 001-5401-1100

PRIME MOVER CONTROLS INC.

PROD_REF\5400_PCH\C_BULLTN\SSB-001-5400R00.CDR

3600 GILMORE WAY, BURNABY B.C. CANADA V5G 4R8

TEL (604) 433-4644 FAX (604) 433-5570 www.pmc-controls.com

ALL RIGHTS RESERVED