KleanEdgeCove Series

advertisement

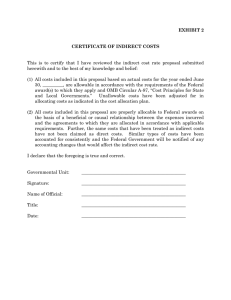

For more information, or to download Cutsheets and IES files, visit www.forumlighting.com/product-lines/kec/ To talk to a sales representative directly, call 412-781-5970 or email a team member below: Steve Seligman, VP Spec Sales sseligman@forumlighting.com Inside Sales / Quotations sales@forumlighting.com FORUM KLEAN EDGE COVE BY FORUM PRODUCT GUIDE EXPLORE THE SYSTEM POWERFEED LOCATIONS PRE-DRILLED AT FACTORY WALL ENGAGING PROFILE CORNERS MACHINED AND FULLY WELDED AT FACTORY – SEE NEXT PAGE FOR OPTIONS * System also available in Fluourescent lamping — see next page. TAPERED ALIGNMENT PIN ALIGNMENT TAB WITH SET SCREW A fully integrated cove lighting system which creates a straight, clean cove every time, in every space. Klean Edge Cove is a 2” x 8” housing, with a 4 ¾” aperture. Three unique profiles provide maximum aesthetic impact. Staggered lamps and shielding options provide seamless light quality, without scalloping for even distribution. Klean Edge Cove accommodates both regular and highoutput T5 lamps, and the latest in LED technology. LENS ALIGNMENT TAB SLOT REFLECTOR AND ELECTRONICS ASSEMBLIES – LED CONFIGURATION SHOWN* ALIGNMENT PIN HOLE DRYWALL MUD GROOVES 12” ADDITIONAL EXTRUSION PROVIDED FOR PRECISE FIELD CUT CREATE & CUSTOMIZE KEC is designed with unique features that make installation easy, secure, and accurate. Each custom order comes preconfigured to accommodate your specific layout. Staggered Geartray Fluorescent KEC utilizes modular geartray assemblies in various lengths to achieve standard 6” lamp stagger for any length run. Each geartray drops into the extruded housing and is secured by self-tapping hardware. Telescoping Assembly Fluorescent and LED runs are configured with a telescoping geartray assembly to reach light to the end of any length installation run as well as into the corners of patterns, providing approximately 12” of adjustability for Fluorescent and 6” of adjustability for LED. INFINITE CONFIGURATION POSSIBILITIES With three front profiles, two standard corner and end options, and custom corner angles available, your imagination is the limit for what KEC can acheive. The KEC system provides everything you need for complete customization. SABRE FRONT 90° * INSIDE CORNER * Custom angles available FLAT FRONT 90° * OUTSIDE CORNER ROUND FRONT BEGINNING OF RUN END CAP END OF RUN END CAP SURFACE/ DIRECT DIRECT surface/ direct direct GET THE LOOK SUSPENDED DIRECT/ INDIRECT INDIRECT DIRECT/ INDIRECT suspended direct/indirect ASYMM. RECESSED/ DIRECT asymm. recessed/ direct direct/ indirect indirect RECESSED/ DIRECT recessed/ direct SURFACE/ DIRECT LED DIRECT LED surface/ direct INDIRECT SUSPENDED DIRECT/ INDIRECT suspended direct/indirect LED LE D direct DIRECT/ INDIRECT direct/ indirect ASYMM. RECESSED/ DIRECT asymm. recessed/ direct indirect Klean Edge Cove gives a continuous and seamless look along the entire length of the installation. ST AGGERED 1 LED T8 MM. SSED/ CT ST INWALL/ HORIZ. LAMPING AT A GLANCE: AGGERED 2 LED T5 HO INWALL/ LED VERT. 2 LED INTEGRATED T5 COVE HO T5 LEDT8 INWALL/ HORIZ. in-wall/ horizontal inve INWALL/ HORIZ. in-wall/ horizontal Rock Screw Comfort Angle Groove Mounting Location 5.5” Overhang Built into the environment KEC housing sections are secured to structure on the back face with #6 sheetrock screws. Pilot holes are drilled at the factory. The housing is also secured on the underside by a 3/4” #6 screw approximately 5” out from the back face. Hardware is to be provided by others. This area is then taped and mudded, giving a seamless transition from ceiling to fixture. 73/4” 21/3” Mud Comfort Angle Groove Mounting Location SABRE EDGE 51/2”Overhang 3/4” #6 Sheet Rock Screw Mud Groove Additional Profile options 73/4” 8 7/8” 2 1/2” 2 3/4” 2 5/16” FLAT EDGE 2 5/16” ROUND EDGE HOUSING 6063 T5 extruded aluminum profile approximately 2” x 8”. Integrated features allow for seamless alignment over longer runs, easy installation and removal of geartrays and lens, and seamless integration into sheetrock construction. SHIELDING Satin frosted, white opal, and clear acrylic lenses are snap-in. An open configuration without shielding is the default configuration for fluorescent. Optimized clear acrylic lens is the default configuration for LED. GEARTRAY / REFLECTOR Integrated geartray and reflector made from 20 GA cold rolled steel in a pre-paint white finish. Fully wired units remain completely accessible from above. Continuous light quality with telescoping assembles provides adjustability within ant length of installation. DRIVER Electronic, high power factor, low THD, driver used. 120V, 277V, and Universal Voltage available standard. Please consult factory for special driver requirements.