Technical

Bulletin

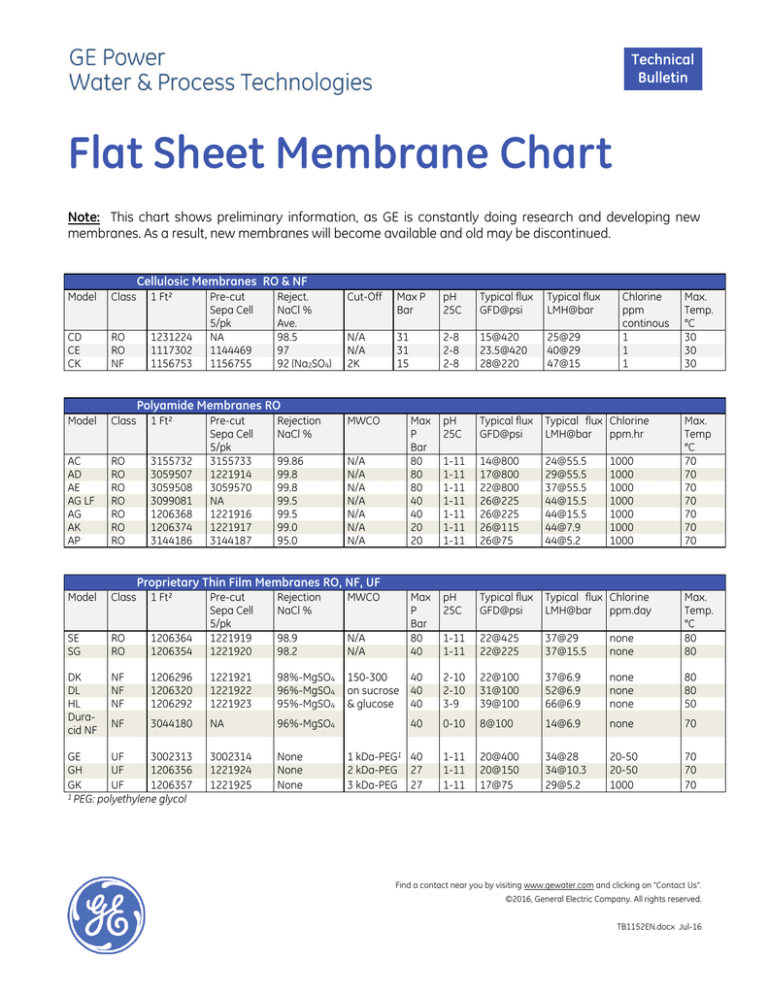

Flat Sheet Membrane Chart

Note: This chart shows preliminary information, as GE is constantly doing research and developing new

membranes. As a result, new membranes will become available and old may be discontinued.

Cellulosic Membranes RO & NF

Model

Class

1 Ft²

CD

CE

CK

RO

RO

NF

1231224

1117302

1156753

Model

Class

1 Ft²

AC

AD

AE

AG LF

AG

AK

AP

RO

RO

RO

RO

RO

RO

RO

3155732

3059507

3059508

3099081

1206368

1206374

3144186

Model

Class

1 Ft²

SE

SG

RO

RO

DK

DL

HL

Duracid NF

Pre-cut

Sepa Cell

5/pk

NA

1144469

1156755

Reject.

NaCl %

Ave.

98.5

97

92 (Na2SO4)

Cut-Off

Max P

Bar

pH

25C

Typical flux

GFD@psi

Typical flux

LMH@bar

Chlorine

ppm

continous

1

1

1

Max.

Temp.

°C

30

30

30

N/A

N/A

2K

31

31

15

2-8

2-8

2-8

15@420

23.5@420

28@220

25@29

40@29

47@15

Max

P

Bar

80

80

80

40

40

20

20

pH

25C

Typical flux

GFD@psi

Typical flux Chlorine

LMH@bar

ppm.hr

1-11

1-11

1-11

1-11

1-11

1-11

1-11

14@800

17@800

22@800

26@225

26@225

26@115

26@75

24@55.5

29@55.5

37@55.5

44@15.5

44@15.5

44@7.9

44@5.2

pH

25C

Typical flux

GFD@psi

Typical flux Chlorine

LMH@bar

ppm.day

1-11

1-11

22@425

22@225

37@29

37@15.5

none

none

Max.

Temp.

°C

80

80

Polyamide Membranes RO

Pre-cut

Sepa Cell

5/pk

3155733

1221914

3059570

NA

1221916

1221917

3144187

Rejection

NaCl %

MWCO

99.86

99.8

99.8

99.5

99.5

99.0

95.0

N/A

N/A

N/A

N/A

N/A

N/A

N/A

1000

1000

1000

1000

1000

1000

1000

Max.

Temp

°C

70

70

70

70

70

70

70

Proprietary Thin Film Membranes RO, NF, UF

Rejection

NaCl %

MWCO

1206364

1206354

Pre-cut

Sepa Cell

5/pk

1221919

1221920

98.9

98.2

N/A

N/A

Max

P

Bar

80

40

NF

NF

NF

1206296

1206320

1206292

1221921

1221922

1221923

98%-MgSO4

96%-MgSO4

95%-MgSO4

150-300

on sucrose

& glucose

40

40

40

2-10

2-10

3-9

22@100

31@100

39@100

37@6.9

52@6.9

66@6.9

none

none

none

80

80

50

NF

3044180

NA

96%-MgSO4

40

0-10

8@100

14@6.9

none

70

3002314

1221924

1221925

None

None

None

1 kDa-PEG1 40

2 kDa-PEG 27

3 kDa-PEG 27

1-11

1-11

1-11

20@400

20@150

17@75

34@28

34@10.3

29@5.2

20-50

20-50

1000

70

70

70

GE

UF

3002313

GH

UF

1206356

GK

UF

1206357

1 PEG: polyethylene glycol

Find a contact near you by visiting www.gewater.com and clicking on “Contact Us”.

©2016, General Electric Company. All rights reserved.

TB1152EN.docx Jul-16

Polyethersulfone / Polysulfone Membranes UF

Class

1 Ft²

Pre-cut

Rejection

MWCO

Sepa Cell

NaCl %

dextran

5/pk

PW

UF

1206353 1221929

None

20 K2

PT

UF

1221934 1221932

None

5K

PU

UF

3033509 3033508

None

10 K

2 MWCO rating based on protein

Model

JX

PVDF Membranes UF & MF

Class

1 Ft²

Pre-cut

Sepa Cell

5/pk

MF

1206351 1221931

Model

Type

Model

MW

Ultrafillic Membranes UF

1 Ft²

Pre-cut

Sepa Cell

5/pk

Ultra1221961 1221962

fillic

Rejection

NaCl %

MWCO

None

0.3 µm

Rejection

NaCl %

MWCO

None

50 K

proteins

Max

P

Bar

10

10

10

pH

25C

Typical flux Typical

GFD@psi

flux

LMH@bar

85@30

144@2.1

90@50

153@3.5

85@30

144@2.1

Chlorine

ppm.day

Max

P

Bar

5

pH

25C

Chlorine

ppm.day

1-11

Typical flux Typical

GFD@psi

flux

LMH@bar

130@30

220@2.1

Max

P

Bar

7

pH

25C

Typical flux Typical flux Chlorine

GFD@psi

LMH@bar ppm

2-9

176@20

1-11

1-11

1-11

299@1.4

5000

5000

5000

5000

25

Max.

Temp.

°C

70

70

70

Max.

Temp.

°C

70

Max.

Temp.

°C

80

Within most membrane designations, several different membrane elements are available, that are differentiated by numbers after the membrane designation mentioned here.

These membranes are available in the following configurations:

1. pre-cut flat sheets for Sepa test cells

2. flat sheets of 1 ft² each (924 cm²) in 12”x12” size

3. spiral wound modules

Contact GE to know the construction size available for each polymer type.

Flat sheet membranes are not available in large quantities except under special arrangements.

Page 2

Technical Bulletin

Compatibility with Chemicals

Type-…

CA

PA

PS/PES

PVDF

PAN

Aliphatic Solvent

excellent

excellent

excellent

excellent

excellent

Alcohols

fair

good

excellent

good

excellent

Ester Ketone

poor

poor

poor

poor

excellent

Aromatic

poor

poor

poor

excellent

excellent

Weak Bases

poor

good

excellent

excellent

good

Weak Acids

fair

excellent

excellent

excellent

excellent

Strong Bases

poor

poor

fair

fair

fair

Strong Acids

poor

good

excellent

excellent

good

Oxidants

fair

poor

good

good

good

Aprotic Solv.

poor

poor

poor

poor

poor

The above is made in lieu of all other warranties expressed or implied. Manufacturers and sellers only obligation shall be to issue credit against the purchase or replacement of such quantity of the membrane elements

proved to be defective in material or workmanship. Neither manufacturer nor seller shall be liable for any

injury, loss or damage, direct or indirect, special or consequential, arising out of the use of misuse or inability

to use such product. The information contained herein is based on technical data and tests which we believe

to be reliable and is intended for use by persons having technical skill at their discretion and risk. Since the

conditions of use outside GE’s control, we can assume no liability whatsoever for results obtained or damages incurred through the application of the data presented. This information is not intended as a license to

operate under, or a manufacturer.

Technical Bulletin

Page 3