Renewable Energy 35 (2010) 845–851

Contents lists available at ScienceDirect

Renewable Energy

journal homepage: www.elsevier.com/locate/renene

Research and development of maximum power transfer tracking system

for solar cell unit by matching impedance

Tun-Ping Teng a, *, Hwa-Ming Nieh a, Jiann-Jyh Chen b, Yu-Cheng Lu c

a

Department of Industrial Education, National Taiwan Normal University, 162, He-ping East Road, Section 1, Taipei 10610, Taiwan, ROC

Department of Electrical Engineering, Nei-Hu Vocational High School, Taipei, 11493, Taiwan, ROC

c

Department of Electrical Engineering, National Taipei University of Technology, Taipei 10608, Taiwan, ROC

b

a r t i c l e i n f o

a b s t r a c t

Article history:

Received 2 January 2009

Accepted 5 September 2009

Available online 13 October 2009

Employing the theorem that matching impedance produces maximum power transfer, the current study

develops a low-cost and highly efficient ‘‘maximum power point tracker for a solar cell unit,’’ for the

purpose of allowing a solar cell to achieve optimal power transfer under different solar intensities and

temperatures. Circuit control takes a single-chip microprocessor as the core and the booster circuit

design undergoes the solar cell charging operation even though the solar cell output voltage is lower

than the rated storage battery voltage. Experiments conducted in this study prove that the tracker this

study develops effectively enhances the utilization efficiency of a solar cell. When a solar cell is at an

output voltage above 30% of the rated voltage, it can charge a storage battery. When it reaches above 80%

of the rated voltage, its power conversion efficiency can reach above 85%. The charge and discharge

management mechanism of the device also avoids excessive charge and discharge of the storage battery,

and extends storage battery longevity.

Ó 2009 Elsevier Ltd. All rights reserved.

Keywords:

Solar cell

Maximum power transfer

Matching impedance

Booster circuits

1. Introduction

By adjusting the solar cell unit axial direction, the solar tracking

system helps the solar cell unit possess the best receiving effect

[1–8]. After the received energy is transformed as electric energy, it

is delivered to the storage battery for charging or loading. If electric

energy is required to perform parallel connection with an electricity system or supply general home appliances, an inverter is

needed to transform the direct current (DC) to an alternative

current (AC). To date, there are many highly efficient designs [9].

Nevertheless, the power transfer value of solar cell changes with

solar intensity. The solar tracker acquires maximum solar power

only when it is under the same light intensity, but it is unknown

whether transformed electricity can be most efficiently utilized. As

to the control of charge and discharge load, although the conventional relay-operated structure is simple, it cannot perform accurate load adjustment [10]. To achieve load control, many researches

have adopted a microcontroller-based method to control solar

transfer to achieve continuous control [11–14]. Circuit detection is

typically employed to detect ever-changing electric signals, and

further match with different arithmetic methods to control the

* Corresponding author. Tel.: þ886 2 77343358; fax: þ886 2 23929449.

E-mail address: tube.t5763@msa.hinet.net (T.-P. Teng).

0960-1481/$ – see front matter Ó 2009 Elsevier Ltd. All rights reserved.

doi:10.1016/j.renene.2009.09.001

charge and discharge mode, to acquire highest utilization efficiency

of a solar cell.

The current study is based on the concept of maximum power

transfer. Equal system impedance and load impedance achieve

maximum power transfer, acquiring the highest utilization efficiency of a solar cell. The controller proposed by this study uses

a microprocessor (microcontroller unit, or MCU) as the control core.

Detecting power transfer change of solar cell units, achieves power

impedance. Matching impedance is performed by pulse width

modulation (PWM), achieving maximum power transfer without

needing to use a complicated control circuit and arithmetic

procedures. This method does not need to focus on the characteristic curve of the solar cell unit to undergo design. Instead, directly

referring to the actual situation acquires maximum power transfer

under this situation. Changing different solar cell unit by this

method only requires performing simple software modification

according to different specifications. Concerning using booster

circuits to solve the problem of excessive low output voltage of

a solar cell, even though it is under very low voltage output

condition, charging can still be carried out for a storage battery,

extending chargeable time and raising charging efficiency. Finally,

through the charge and discharge management mechanism of

a storage battery, charging voltage is controlled to be within the

rated 120%, and discharge voltage to be within the rated 80%. Such

a design effectively extends storage battery longevity. Apart from

846

T.-P. Teng et al. / Renewable Energy 35 (2010) 845–851

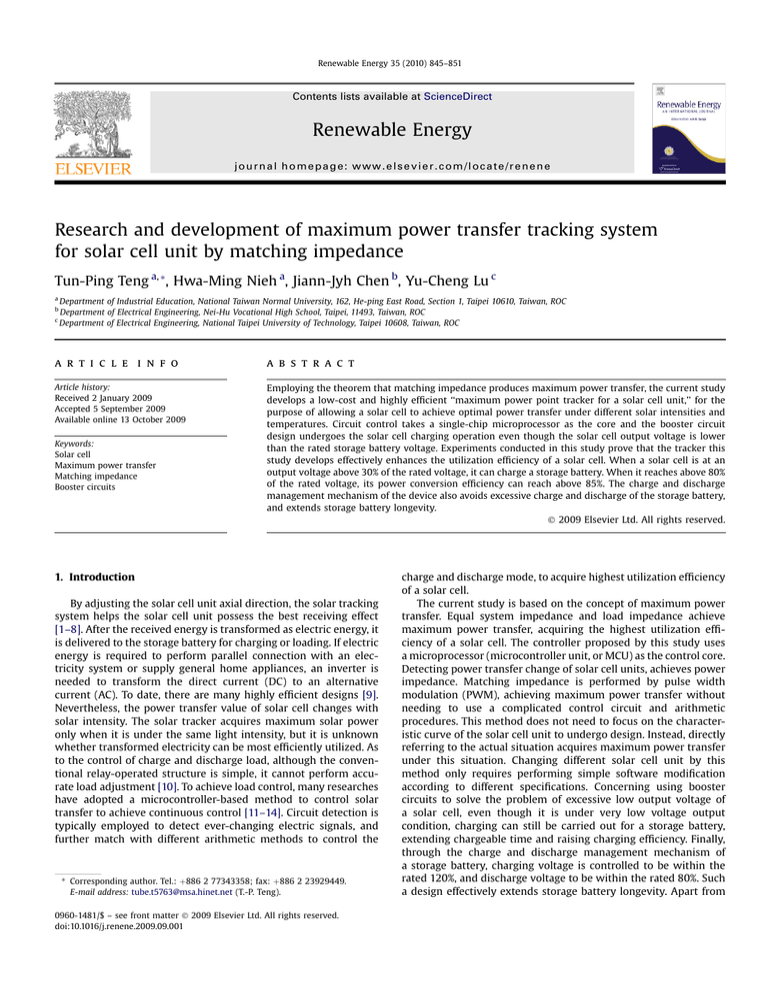

Fig. 1. Schematic demonstration of maximum power transfer for solar cell unit.

enhancing charging performance, the design also achieves environmental protection and decreases waste.

2. Related theories

The solar cell is a type of power, and its power transfer changes

with solar intensity. Any changes of solar cell power transfer, also

change its voltage and internal impedance. Circuit analysis is

sometimes interested in determining the maximum power delivered to a load. By employing Thevenin’s theorem, this work

determines the maximum power a circuit can supply and the

manner for adjusting the load in order to affect maximum power

transfer.

Suppose that the given circuit is shown in Fig. 1. The power

delivered to the load is expressed as:

PL ¼ IL2 RL ¼

VTH

RTH þ RL

2

RL

(1)

We want to determine the RL value that maximizes this quantity.

Hence, we differentiate the expression with respect to RL and

equate the derivative to zero.

2 2V 2 R ðR

ðRTH þ RL Þ2 VTH

dPL

TH L TH þ RL Þ

¼

¼ 0

dRL

ðRTH þ RL Þ4

(2)

which yields

RL ¼ RTH

(3)

In other words, maximum power transfer takes place when the

load resistance RL ¼ RTH. Although this is a very important result,

this study derives it using a simple network indicated in Fig. 1.

When RL is adjusted to equal RTH, the maximum power transfer for

solar cell units can be acquired.

According to the above concept of maximum power transfer, the

simplest way to achieve maximum power transfer is to use a group

of variable resistors to achieve matching impedance (RL ¼ RTH). This

method achieves maximum power transfer of a solar cell under

different solar intensities. Actual application of this theory would

be restricted. The power transfer of a solar cell, no matter whether

it is connected to a storage battery or a service load, still has load

impedance. For example, for a storage battery load, the internal

impedance (RB) of the storage battery would change as affected by

the charging situation. The maximum adjustment range of variable

resistance would be limited in the range of RB w RVR þ RB. If internal

impedance of the solar cell is outside of this range, the theoretical

value of maximum power transfer will not exist. But the adjustable

best situation under this condition can still be achieved. Manual

adjustment of variable resistance cannot achieve automation with

the constantly changing output impedance of the solar cell and

storage battery. When solar cell output voltage is lower than

storage battery voltage, the charge also cannot be achieved. To solve

these problems, pulse width modulation (PWM) can be used to

control the pulse width and change the impedance value by the

side of the load. PWM only requires adjusting the pulse width

moderately, and then the equivalent impedance by the side of the

load can change to match with the internal impedance of the solar

cell unit. This process achieves maximum power transfer of the

above limitation condition. Using booster circuits, even though

solar cell output voltage is lower than storage battery voltage,

charging can still be undergone.

3. Description of system and control circuits

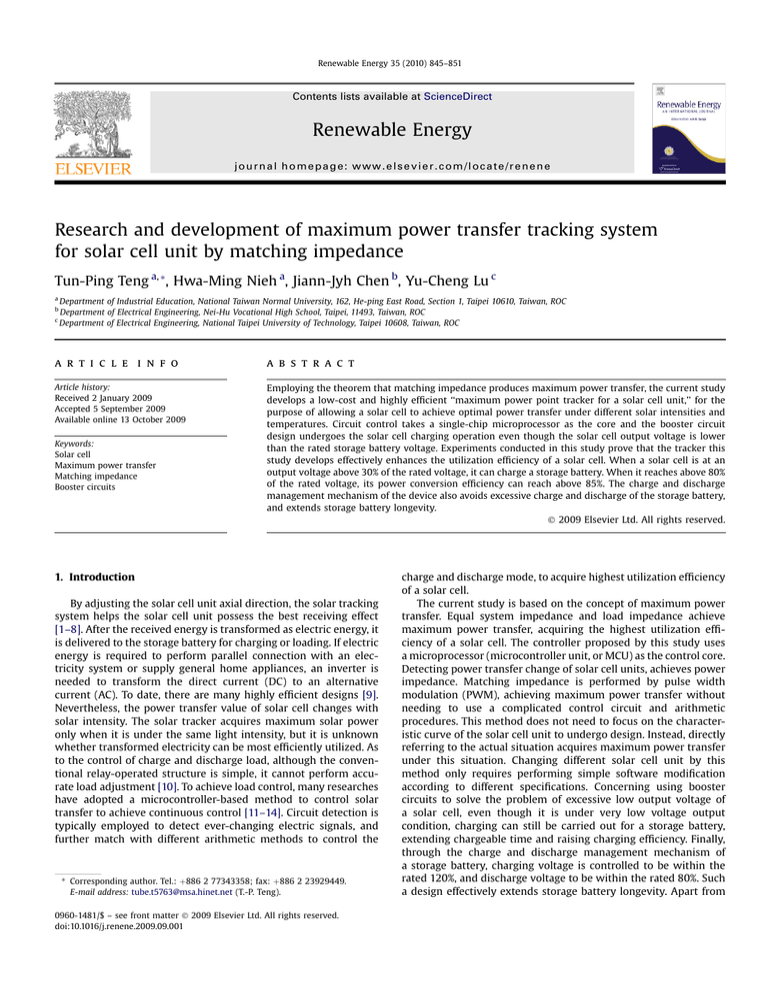

Fig. 2 shows the circuit block diagram of the experiment in

which the microprocessor (MCU) is the core, and circuits attain the

voltage and current of the solar cell unit. The experiment calculates

solar cell unit power and controls booster circuits using MCU,

charging batteries even though the sunlight is very weak. This

study conducts moderate battery voltage surveillance, and controls

battery charge and discharge. Fig. 3 shows the complete control

circuits, indicating their main operation as follows:

3.1. Signal sampling circuits for voltage and current

In Fig. 3(a), block A shows the signal sampling circuits used in

this study. The voltage sampling adopts voltage division between R1

and R2, taking the applicable range of the matched AD converter.

The current sampling employs the voltage drop caused after the

current goes through R10. The voltage drop is converted to current

value by Ohm’s law, and further amplified by the reversing

amplifier built-in MCU. For calculating electric power, the CPU

calculates the measured voltage and current values after they have

performed AD conversion, eventually acquiring the solar cell power

transfer. PWM transfer adjustment uses power comparison. The

current detected power rate is compared with that of the previous

sampling time. By comparing the results, the PWM transfer is

adjusted before storage battery charging, achieving matching

impedance, and keeping power transfer at maximum value.

3.2. Driving and booster circuits

Fig. 2. Block diagram of control circuits.

In Fig. 3(a), block B shows the driving and booster circuits used

in this study. The driving circuit conducts current amplification

using a pair of bipolar junction transistors (BJTs). When n-channel

metal-oxide-semiconductor (NMOS), which serves as a switch,

increases its duties, the output voltage of storage battery drops, and

rises contrarily. Using the driving current increases output ability

and improves transient effect of the electric capacitor. Connecting

the NMOS gate with resistance (R15) reduces interruption by

confused signals and maintains a stable output. Booster circuits are

T.-P. Teng et al. / Renewable Energy 35 (2010) 845–851

847

Fig. 3. Schematic diagram of the full control circuits. (a) Main circuits, (b) microprocessor circuits, (c) power supply.

used to solve the problem of failed charging for the excessively low

solar cell output. Suppose that the solar cell output voltage is 8 V

and the specific storage battery voltage is 12 V. In this case, solar

cell units cannot undergo storage battery charging. If charging is

needed, the charging voltage has to be higher than that of storage

voltage. Therefore, the current study suggests using booster circuits

to achieve this goal, thus enabling the charging operation despite

weaker solar intensity. Under charging mode, NMOS is at the cutoff period, and diode D1 is forward bias, making the storage battery

and electric capacitor C4 to start charging. During this time, voltage

applied to the two ends of the storage battery is the sum of the solar

cell’s output voltage and inductor L1’s voltage, achieving voltage

rise. Through the charge and discharge time of the electric capacitor, the voltage size at the two ends of the inductor can be changed

immediately, changing total output voltage value. In Fig. 3(a), block

C shows the discharge control circuits. The circuits prescribe that

120% of rated storage battery voltage is at a fully charged status, and

the charging device does not need further charging. The level lower

than 80% of rated voltage is at ceased output status, and the battery

does not supply power anymore.

848

T.-P. Teng et al. / Renewable Energy 35 (2010) 845–851

theorem. This research uses PWM to adjust the pulse cycle to adjust

system impedance and acquire maximum power transfer under this

actual condition. The built-in operational amplifier (OPA) forms

a signal amplifying circuit with an external feedback component and

further amplifies the measured signal to match signal sampling

circuits.

3.4. Power supply

Fig. 3(c) shows the power supply circuits used for circuit control.

The power supply circuits stabilize the voltage by a three-terminal

voltage stabilizing component (HT-7550). Such power supply at

stable voltage has positive output voltage. To improve transient

response, both input and output ends are in parallel connection

with the electric capacitor to reach a status with more stabilized

power supply. The output end is attached with an LED for understanding the working condition of power circuits.

3.5. Software flowchart

Fig. 4. Flowchart of control program.

3.3. Microprocessor

Fig. 3(b) presents the single-chip controller circuits used in this

study. The single chip used (EM78P419N) belongs to the high-speed

small-sized central processing unit (CPU), which contains input,

output, control arithmetic logic unit and memory unit. The working

frequency can reach 20 MHz and uses 5 V DC power with interrupting

function. The circuit adopts a 16 MHz oscillator and each command

needs two oscillation cycles. Every command takes around 0.125

microsecond’s time to execute. Functions of this single chip include

analog-to-digital converter (ADC), pulse width modulation (PWM) and

reversing amplifier, effectively shrinking circuit space. ADC is

employed to convert current and voltage data by converting analog

signals to digital signals, readable by a microcomputer to make analysis

and calculation. Using the calculated power, this work judges whether

the next step needs charge, discharge or a stand-by procedure and

performs matching impedance based on the maximum power transfer

Fig. 4 presents the flowchart of the MCU control software. The

circuit operation directly uses the solar cell as a daytime or nighttime sensor. When there is sufficient light, charging (Voc > 3 V) is

carried out; and at night (Voc < 1 V), it is purely in output mode,

and SW2 manually determines whether power supply is needed.

When carrying out charging in the daytime, this study must

determine whether the battery is fully charged. If it is fully charged

and stays at stand-by, battery charging is not performed. Charging

time is carried out by comparing power transfers. When current

power (Pn) is greater than the previous transferred power (Pn1), it

enters voltage comparison. Current output voltage (Vn) that is also

higher than the previous voltage (Vn1) implies that current voltage

output should steadily increase, raising output voltage continuously. When current power is smaller than previous power transfer,

it enters another comparison mode. These comparisons are used to

perform matching impedance. At nighttime, the mode allows the

storage battery to perform discharge. During this time, the

discharge circuit is turned on, allowing the storage battery to

transfer electricity. Currently, the storage battery output voltage is

under surveillance. If it is lower than 80% of rated voltage, power

supply will cease. If it detects that daytime is coming, it will enter

daytime mode to carry out charging.

4. Experimental design and procedures

The solar cell unit used in this study is under AM1.5, and its rated

output voltage and output current are 10 V and 3 A respectively,

with storage battery specifications being 12 V/7 Ah. To confirm

maximum power performance of the controller, the current

Fig. 5. Experiment of maximum power transfer.

T.-P. Teng et al. / Renewable Energy 35 (2010) 845–851

Fig. 6. Diagram of maximum power transfer performance experiment simulated by DC

power supply.

849

Fig. 8. Diagram of maximum power transfer performance experiment by solar cell

units with variable resistance.

investigation employs an actual experiment to compare the difference between the maximum power value simulated by variable

resistance and the maximum power value tracked by the controller.

As Fig. 5 indicates, to consider both the stability and authenticity

of the experiment, this study uses power supply and the solar cell

unit respectively to prove maximum power transfer performance of

the tracking solar cell unit of this controller. First, power supply is

used to simulate transfer of the solar cell unit. Through the limitation

of maximum output current, the experiment simulates maximum

transfer of a solar cell unit under different light intensities. The

experimental procedures are: use the SWb to switch the current to

connection with variable resistance. Set the DC power supply at

different short-circuit currents (ISC) and open-circuit voltages (VOC).

Adjust the variable resistance RL until it reaches maximum power

transfer (PO,Res). Record the maximum power value of every current

output condition. After that, use the SWb to switch the current to

connection with the controller. Observe the power transfer (PO,Con)

of this time, and use the variable resistance difference during

adjustment. When using the controller to conduct the experiment

under each of the different conditions, the storage battery should be

connected by the controller with 20 W halogen light for discharging

until the controller stops discharging automatically. Doing this

keeps each experiment at the same standard value.

To understand maximum power tracking performance of the

solar cell unit, this study replaces power supply by solar cell units to

carry out the same experiment. Using a simulated light source

(mercury-arc lamp) of different intensities, the experiment adjusts

solar cell light absorption and compares maximum power tracking

between the controller and variable resistance under different

conditions, confirming controller performance when tracking

maximum power transfer.

Fig. 7. Diagram of maximum power ratio simulated by DC power supply.

Fig. 9. Comparison of maximum power transfer performance by solar cell.

5. Uncertainty analysis

This experiment determines experimental result uncertainty by

measurement errors of the parameters, such as voltage, current and

lighting power. The maximum power transfer performance

850

T.-P. Teng et al. / Renewable Energy 35 (2010) 845–851

Fig. 10. Comparison of output voltage of solar cell at maximum power transfer point.

experiment, simulated by DC power supply, measured power from

readings of the digital voltage meter (V) and digital current

meter (A).

sffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffi

2 2

DV

DA

þ

¼

P

V

A

dP

(4)

The precision of the digital voltage meter was 10 mV. The

precision of the digital current meter was 10 mA. Experiment

uncertainty was therefore less than 1.5%.

The maximum power transfer performance experiment by solar

cell units measured power from readings of the digital voltage

meter (V) and digital current meter (A); solar power was determined by solar power meter (SP) readings.

sffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffi

2 2 DV

DA

DSP 2

þ

þ

¼

P

V

A

SP

dP

(8)

The precision of the digital voltage meter was 10 mV. The

precision of the digital current meter was 10 mA. The precision of

the solar power meter was 5%. Experiment uncertainty was

therefore less than 7%.

6. Result and discussion

Fig. 6 shows using DC power supply to simulate maximum power

transfer of variable resistance and the controller under different

open-circuit voltages and short-circuit currents. To avoid the

unstable phenomenon when the preset value of minimum charging

voltage is around 3 V, the minimum experimental voltage is preset

at 4 V. The figure shows that when voltage is above 8 V, the

controller tracks above 72% of the theoretical value simulated by

variable resistance. However, when it is at low voltage, controller

performance reduces drastically; when open-circuit voltage is 4 V

and short-circuit voltage is 3 A, controller performance reduces to

around 6%; and rated voltage around 10 V, achieves the best efficiency. Fig. 7 shows the maximum power ratio tracked by the

controller and variable resistance under different open-circuit

voltages and short-circuit currents. Although the maximum power

transfer efficiency at low voltage is very low, charging operation can

still be carried out. When voltage of the charging circuit traditionally

switched by relay is lower than storage battery voltage, charging

cannot be carried out. However, the controller proposed by this

study does not have this drawback. Low power transfer occurring at

the voltage far lower than the rated voltage is mainly caused by

booster circuits, to keep the voltage connected to the end of the

storage battery higher than the storage battery voltage, for charging

operation. Booster component C4 and L1 charge–discharge delay are

the main reasons for reducing power transfer performance.

Fig. 8 presents the diagram of experimental results after using the

solar cell unit to conduct a maximum power transfer experiment under

different light intensities and resistance variations. The figure shows

that different light intensities acquire the maximum power transition

point by adjusting variable resistance. The solar cell unit is then

switched to the controller to carry out the same experiment. This

research compares maximum power tracked by the controller and

variable resistance under different light intensities, as Fig. 9 shows.

Except under lower light intensity (30 W/m2), with maximum power

efficiency tracked below 80%, all others are higher than 80%. The rather

poor effect at low light intensity rate is caused by lower output voltage of

the solar cell. Fig. 10 shows that controller voltage during maximum

power tracking is lower than the voltage when maximum power is

adjusted by variable resistance. When controller voltage is lower than

storage battery voltage, charging can still be carried out. Power transfer

is lower than the simulated value of variable resistance not only because

of the delay phenomenon caused by booster circuits, but also because of

extreme limitation adjustment for equivalent controller impedance.

Impedance of the entire control system is composed of variable

controller impedance (RVR) and internal storage battery impedance (RB).

The control system can therefore be adjusted to the impedance range,

RB w RVR þ RB. In the case of RTH > RVR þ RB or RTH < RB, the controller

cannot track the theoretical value of maximum power. Although such

a limitation makes tracking unavailable for the theoretical value of

maximum power transfer, the maximum value under limited conditions can be reached. Hence, the control circuit proposed by this study

effectively enhances utilizing solar generation efficiency.

7. Conclusion

The tracker designed by this study has excellent tracking performance of the maximum power transfer point and uses the solar cell to

serve as a light sensor to judge the operation mode, without needing

to install a light sensor. When the rated solar cell voltage is 10 V, this

work makes a comparison with the theoretical value, with its output

efficiency reaching above 90%. Charging can also be performed under

low power transfer, effectively enhancing utilization efficiency of the

solar cell. If enhancing output power or replacing solar cells of

different specifications is necessary, we are only required to amplify

power component specifications and replace sampling circuit resistance value. The manufacturing cost of this tracker is also lower than

US$10, so it has extremely high promotion value.

Acknowledgement

The authors would like to thank the National Science Council of

the Republic of China, Taiwan for their financial support for this

research under Contract No. NSC-97-2514-S-588-001-GJ and NSC98-2514-S-003-009-NE.

References

[1] Baltas P, Tortoreli M, Russel P. Evaluation of power output for fixed and step

tracking photovoltaic arrays. Solar Energy 1986;37(2):147–63.

[2] Sala G, Anton I, Arborio JC, Luque A, Camblor E, Mera E. The 480 kWP

EUCLIDESTM – thermie power plant: installation, setup and first results. In:

Proceeding of the 16th European photovoltaic solar energy conference and

exhibition. Glasgow, Scotland: WIP - Stephens & Associates; May 2000.

T.-P. Teng et al. / Renewable Energy 35 (2010) 845–851

[3] Poulek V, Libra MA. Very simple solar tracker for space and terrestrial applications. Solar Energy Materials and Solar Cells 2000;60:99–103.

[4] Abdallah S, Salem N. Two axes sun tracking system with PLC control. Energy

Conversion and Management 2004;45(11–12):1931–9.

[5] Clifford MJ, Eastwood D. Design of a novel passive solar tracker. Solar Energy

2004;77(3):269–80.

[6] Roth P, Georgiev A, Boudinov H. Cheap two axis sun following device. Energy

Conversion and Management 2005;46(7–8):1179–92.

[7] Rubio FR, Ortega MG, Gordillo F, López-Martı́nez M. Application of new control

strategy for sun tracking. Energy Conversion and Management 2007;48:2174–84.

[8] Huang BJ, Sun FS. System analysis of 1-axis three-position tracking solar

PV. Journal of the Chinese Society of Mechanical Engineers 2007;28(3):

307–13.

851

[9] Lee SH, Song SG, Park SJ, Moon CJ, Lee MH. Grid-connected photovoltaic

system using current-source inverter. Solar Energy 2008;82:411–9.

[10] Preiser K, Kuhmann J, Biennann E, Herberg T. Quality of charge controllers in solar

home systems: results of a detailed test. In: ISES conference. Harare: FhG-ISE; 1995.

[11] Remote Area Power Supply (RAPS) design manual. IRDC/DMEA Publication;

1992.

[12] Masheleni H, Carelse XF. Microcontroller-based charge controller for standalone photovoltaic system. Solar Energy 1997;61(4):225–30.

[13] Krauter S, Ochs F. Integrated solar home system. Renewable Energy 2004;29:

153–64.

[14] Chu CC, Chen CL. A variable step maximum power point tracking for photovoltaic power system. Journal of the Chinese Society of Mechanical Engineers

2008;29(3):225–31.