Fabrication Technology for Efficient High Power Silicon

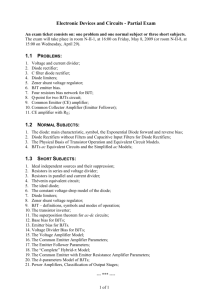

advertisement