Support Mullions for use in Oversize Openings

advertisement

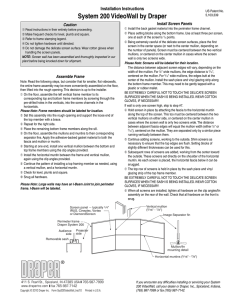

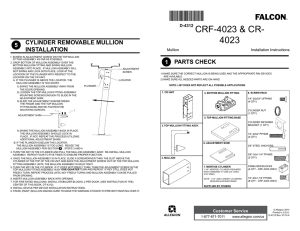

Document number 462105 FABRICATION AND FIELD INSTALLATION INSTRUCTIONS ® Support Mullions for use in Oversize Openings These installation instructions apply to the fabrication and construction of generic support mullions. Support mullions are necessary whenever static fire dampers are installed into a vertical opening that is larger than the largest UL rated size for that damper. The mullions allow construction of a fire barrier that is larger than the maximum available size. The opening must not exceed 120 in. (3048mm) high, but can be any width provided a vertical support mullion is used a maximum of every 120 inches (3048mm). To properly use support mullions they must be fabricated and installed according to the following instructions. Application Wall Opening Generic steel mullions can be used to separate vertically mounted galvanized steel fire dampers in wall openings larger than the UL permitted multiple damper assembly size. Mullions can either be used vertically, horizontally or both to split up a vertical wall opening requiring use of a damper having a 11/2 hour fire resistance rating. Maximum mullion span is 120 in. (3048mm) plus expansion allowance when used either horizontally or vertically. Steel mullions are intended for use in a concrete block or solid concrete wall. Hollow concrete blocks are to be filled with concrete (minimum 3500 psi) to permit proper mullion anchoring. Wall thickness is to be 7 in. (178mm) minimum, 12 in. (305mm) maximum. Sleeves are to be around each damper assembly. Mullions are not intended to be in the airstream, (i.e. exposed to flow) or to be a part of the ductwork. Wall Mullion Cap B-B (Typical) Mullion Assembly A-A (Typical) Retaining Angles (Typical) G Sleeve (Typical) G Horz. to Vert. Mullion Cap C-C (Typical) G E E G F F D D SPECIAL NOTE: Support mullions may only be used with static-rated fire damper assemblies; they cannot be used to install combination fire-smoke dampers in wall openings that exceed the maximum UL-approved size for the fire-smoke damper model being installed. Support mullion assemblies consist of three basic parts: the wall mullion cap, the horizontal to vertical mullion cap and the mullion sections. Determine the quantity of each piece required to complete the installation. Formed Section View (2 req’d) 33/8 7/8 3/4 Table 1 2 Dimensional Information shown in inches (mm). Opening Width/Height D H 12 (305) 111/2 (292) 31/4 (83) 24 (610) 231/2 (597) 3 3/8 (86) 36 (914) 33 3/8 (847) 31/2 (89) 48 (1219) 471/4 (1200) 3 5/8 (92) 60 (1524) 59 1/8 (1501) 33/4 (95) 72 (1829) 71 (1803) 3 7/8 (98) 84 (2134) 82 7/8 (2105) 4 (102) 96 (2438) 943/4 (2406) 4 1/8 (105) 108 (2743) 1063/4 (2711) 4 1/4 (108) 1183/4 (3016) 4 3/8 (111) 120 (3048) C-4 2 C= Wall Thickness Assembled View 31/2 D 3/16 in. blind rivet (stl) or 3/4 in. long intermittent welds 12 in. on center, 6 in. maximum from both ends, both sides of assembly. E = Wall Thickness in. (13mm) F = Wall Thickness + 1/4 in. (6mm) 3/16 in. typical rivet location 1/2 Detail A-A Mullion Assembly All dimensions shown are in inches. Fabrication of Wall Mullion Caps 2 Wall mullion caps must be constructed from 12 ga. steel with a minimum yield strength of 42,000 psi. 1. Fabricate the formed section as shown to right. 113/16 2 H H 2. Shear the cap end plate to required dimensions. Formed Section End View 3. Weld the cap end plates to the formed section with 1/8 in. (3mm) fillet welds completely around the top edges of the formed section. 4. Drill and countersink 8 holes ( 4 on each side) for 1/4-20 flat head machine screws. Mullions must be constructed from 16 ga. (1.5mm) steel with a minimum yield strength of 42,000 psi. 2. Connect the two mullion sections together. Use 3/16 in (4.7mm) steel blind rivets of 3/4 in. (19mm) long intermittent welds 12 in. (305mm) on center and a 6 in. (152mm) maximum from both ends. Important: Both sides of the mullion piece should be fastened using the method described above. H E/8 Important: The “D” dimension shown has been calculated to include the necessary clearances required for thermal expansion in the mullions. The values can be found using the wall opening dimensions and tables on this page. 1.Form two identical pieces of mullion section as shown. Wall Mullion Cap Assembled View Weld ­Fabrication of Mullion Sections 31/4 Cap End Plate (2 req’d) E/4 E E/4 E/4 31/4 Detail B-B Wall Mullion Cap E/8 All dimensions shown are in inches. Fabrication of Horizontal to Vertical Mullion Caps Horizontal to vertical mullion caps must be constructed from 12 ga. (2.7mm) steel with a minimum yield strength of 42,000 psi. Important: The H, E and F dimensions shown have been calculated to provide the correct performance. The values can be found by using the wall opening dimensions and Table 1. 1. Form the horizontal mullion channel as shown. 2. D rill 12, 3/ 16 in. (4.7mm) dia. holes into the horizontal mullion channel using the dimensions shown. 3. Form the center channel as shown. NOTE: If the center channel is to be made from two pieces, weld them together with an 1/8 in. (3mm) fillet weld. 4. Shear the end plates to the dimensions required. 5. Weld the end plates to the center channel with 1/8 in. (3mm) fillet welds completely around the top edges of the center section. 3/4 dia. (12 holes) 11/2 6 Side View 11/2 3/4 F ntal Mullion Channel 3/4 3/16 in. dia. (12 holes) H End View Weld Center Channel 31/4 3/4 1 1" min. Assembled View 11/2 3/4 Top View 11/2 Side View One or two piece End Plate 1/2 Total expansion clearance between sleeve and wall/ Weld mullion of 1/8 in. (3mm) per foot of wall opening or mullion span should be allowed. Maximum clearance is 11/4 inches (31mm). Center Channel H 6 11/2 One or two piece End View 1 1 11/2 Side View F 1/2 End Plate Top View Static Fire Damper Installation Galvanized steel static fire dampers must be UL classified for 11/2 hour fire resistance. They must be installed in One or two piece galvanized steel sleeves and be retained by minimum Weld retaining in. (38mm Channel x 38mm), 16 ga. (1.5mm) End Plate 1 1/2 in. x 1 1/2Center angles on each side of the wall. Retaining angles must overlap mullions or wall by 1in. (25mm) minimum. Fasten Side View H to sleeve using 1/4 in. (6mm) dia. bolts, 3/16 in. (4.7mm) steel rivets, welding, or #10 sheet metal screws. All must be attached 6 in. (152mm) on 13centers, 2 in. (51mm) 1 /16 E 31/4 maximum from corners. Do not fasten retaining angles to End View the wall or mullions. Mullions must be free to float. Horizontal Mullion Channel 3/16 in. Note: Mullion caps must be inserted into the ends of the mullions before they are anchored to the vertical mullions or wall. 113/16 End View E Weld Side View 1 M Use 3/16 dia. steel blind rivets at installation 31/4 1 1/2 in. x 1 1/2 in. min. 16 ga. galvanized retaining angle 113/16 End View E 3/4 Assembled View End View Wall Sleeve Retaining Angles Detail D-D Weld Detail E-E 1" min. Use 3/16 dia. steel blind rivets at installation Assembled View Mullion Wall 13/8 3/16 d Mullion 1 1/2 in. x 1 1/2 in. min. 16 ga. galvanized retaining angle Use 3/16 dia. steel blind rivets at installation Sleeve Sleeve Retaining Angles 1" min. D-D Detail Detail E-E Mullion Mullion Cap Wall Mullion Installation Before the static fire dampers are installed into the wall the mullions must first be anchored into the wall. The fire Mullion dampers may then be installed into the mullion assembly. 3 1/4" Min. Wall Thickness 7"min. & 12" max. 1 /8 3/16 attach theSleeve mullions to the wall follow these Retaining Angles 1/4-20 Sleeve x in. 1. Anchor wall mullion caps to wall using 3/8 in. (9.5mm) diameter by 1 long flat Detail head steel bolts andMullion D-D Mullion Cap in. (25mm) long concrete expansion anchorsDetail (Hilti). IfE-E steel lintels are present, use two 1 in. (25mm) long welds on each side of mullion caps. Mullion G Det Detail F-F 5/16 Note: End caps must be inserted into the ends of the mullions before they are anchored to the wall. Retaining Angles Detail F-F 13/8 3/16 1 1/2 in. x 1 1/2 in. Toga.correctly min. 16 galvanized steps:1" min. retaining angle W 7 G G 1/4" G End Cap Min. Wall Thickness 7"min. & 12" max. Mullion 2. Anchor horizontal mullion caps to vertical mullion Sleeve caps with 3/16 in. (4.7mm) diameter steel blind rivets in 12 Detail F-F places. G Detail G-G E Detail E-E Copyright © 2013 Greenheck Fan Corporation D E 462105 G Support Mullion Rev. 5 Jan 2013 F G F D