Circuit Note

CN-0150

Devices Connected/Referenced

Circuits from the Lab™ reference circuits are engineered and

tested for quick and easy system integration to help solve today’s

analog, mixed-signal, and RF design challenges. For more

information and/or support, visit www.analog.com/CN0150.

AD8318

1 MHz to 8 GHz, 70 dB, Logarithmic

Detector/Controller

AD7887

2.7 V to 5.25 V, Micropower, 2-Channel,

125 kSPS, 12-Bit ADC in 8-Lead MSOP

ADR421

Precision, Low Noise, 2.5 V Reference

Software-Calibrated, 1 MHz to 8 GHz, 60 dB RF Power

Measurement System Using a Logarithmic Detector

A simple two-point system calibration is performed in the

digital domain.

EVALUATION AND DESIGN SUPPORT

Circuit Evaluation Boards

CN-0150 Circuit Evaluation Board (EVAL-CN0150A-SDPZ)

System Demonstration Platform (EVAL-SDP-CB1Z)

Design and Integration Files

Schematics, Layout Files, Bill of Materials

The AD8318 maintains accurate log conformance for signals of

1 MHz to 6 GHz and provides useful operation to 8 GHz.

The device provides a typical output voltage temperature

stability of ±0.5 dB.

CIRCUIT FUNCTION AND BENEFITS

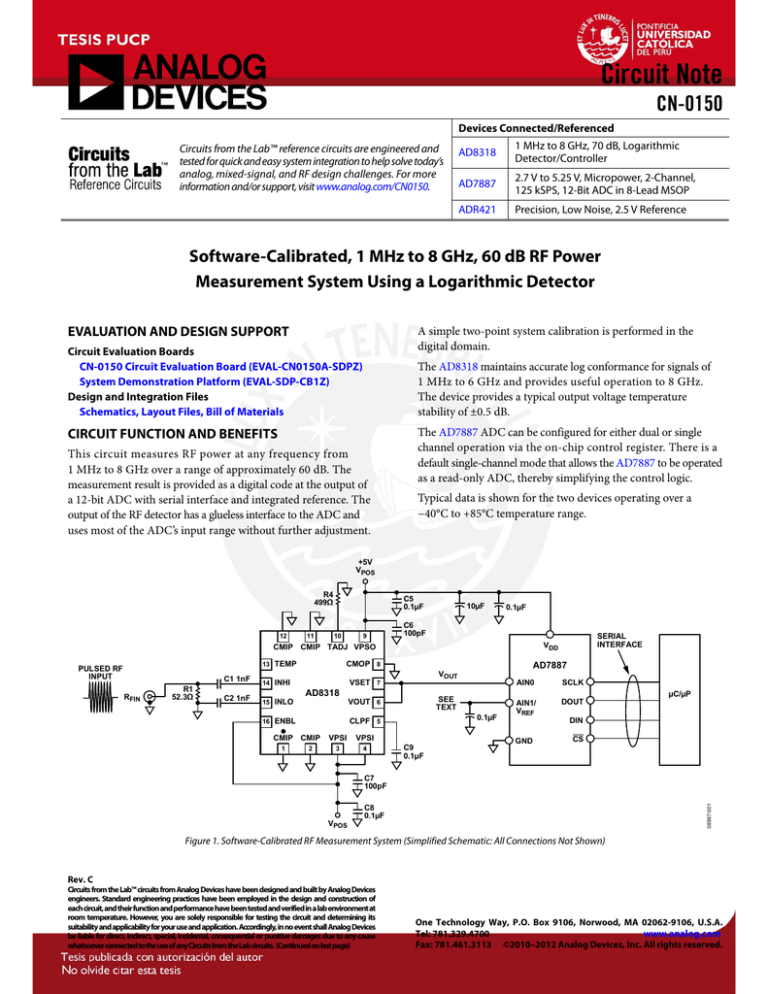

This circuit measures RF power at any frequency from

1 MHz to 8 GHz over a range of approximately 60 dB. The

measurement result is provided as a digital code at the output of

a 12-bit ADC with serial interface and integrated reference. The

output of the RF detector has a glueless interface to the ADC and

uses most of the ADC’s input range without further adjustment.

The AD7887 ADC can be configured for either dual or single

channel operation via the on-chip control register. There is a

default single-channel mode that allows the AD7887 to be operated

as a read-only ADC, thereby simplifying the control logic.

Typical data is shown for the two devices operating over a

−40°C to +85°C temperature range.

+5V

VPOS

R4

499Ω

12

11

C5

0.1µF

10

9

10µF

0.1µF

C6

100pF

13 TEMP

PULSED RF

INPUT

C1 1nF

RFIN

R1

52.3Ω

C2 1nF

CMOP 8

14 INHI

15 INLO

16 ENBL

1

SEE

TEXT

VOUT 6

0.1µF

CLPF 5

CMIP CMIP

2

VPSI

VPSI

3

4

AD7887

VOUT

VSET 7

AD8318

SERIAL

INTERFACE

VDD

CMIP CMIP TADJ VPSO

C9

0.1µF

AIN0

SCLK

AIN1/

VREF

DOUT

GND

µC/µP

DIN

CS

C7

100pF

C8

0.1µF

08967-001

VPOS

Figure 1. Software-Calibrated RF Measurement System (Simplified Schematic: All Connections Not Shown)

Rev. C

Circuits from the Lab™ circuits from Analog Devices have been designed and built by Analog Devices

engineers. Standard engineering practices have been employed in the design and construction of

each circuit, and their function and performance have been tested and verified in a lab environment at

room temperature. However, you are solely responsible for testing the circuit and determining its

suitability and applicability for your use and application. Accordingly, in no event shall Analog Devices

be liable for direct, indirect, special, incidental, consequential or punitive damages due to any cause

whatsoever connected to the use of any Circuits from the Lab circuits. (Continued on last page)

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700

www.analog.com

Fax: 781.461.3113 ©2010–2012 Analog Devices, Inc. All rights reserved.

CN-0150

Circuit Note

CIRCUIT DESCRIPTION

The RF signal being measured is applied to the AD8318. The

device is configured in its so-called measurement mode, with

the VSET and VOUT pins connected together. In this mode,

the output voltage vs. the input signal level is linear-in-dB

(nominally −24 mV/dB) and has a typical output voltage range

of 0.5 V to 2.1 V.

The AD8318 output is connected directly to the AD7887, 12-bit

ADC. The ADC uses its internal reference and is configured for

a 0 V to 2.5 V input, resulting in an LSB size of 610 μV. With the RF

detector providing a nominal −24 mV/dB, the digital resolution

is 39.3 LSBs/dB. With this much resolution, there is little value

in trying to scale the 0.5 V to 2.1 V signal from the RF detector

to exactly fit the 0 V to 2.5 V range of the ADC.

The transfer function of the detector can be approximated by

the equation

Using the two known input power levels, PIN_1 and PIN_2,

and the corresponding observed ADC codes, CODE_1 and

CODE_2, SLOPE_ADC, and INTERCEPT can be calculated

using the following equations:

SLOPE_ADC = (CODE_2 − CODE_1)/(PIN_2 − PIN_1)

INTERCEPT = PIN_2 − (CODE_2/SLOPE_ADC)

Once SLOPE_ADC and INTERCEPT are calculated and stored (in

nonvolatile RAM) during factory calibration, they can be used

to calculate an unknown input power level, PIN, when the

equipment is in operation in the field using the equation

PIN = (CODE_OUT/SLOPE_ADC) + INTERCEPT

Figure 3 through Figure 8 show how the system transfer function

deviates from this straight line equation, particularly at the

endpoints of the transfer function. This deviation is expressed

in dB using the equation

Error (dB) = Measured Input Power − True Input Power =

(CODE_OUT/SLOPE_ADC) + INTERCEPT – PIN_TRUE

VOUT = SLOPE × (PIN − INTERCEPT)

where SLOPE is in mV/dB (−24 mV/dB nominal); INTERCEPT is

the x-axis intercept with a unit of dBm (20 dBm nominal);

and PIN is the input power expressed in dBm. A typical plot

of detector output voltage vs. input power is shown in Figure 2.

1.5

1.5

0.5

1.2

0

–0.5

0.9

0.6

0.3

RANGE OF

CALCULATION

OF SLOPE AND

INTERCEPT

0

–65 –60 –55 –50 –45 –40 –35 –30 –25 –20 –15 –10 –5

PIN (dBm)

–1.0

–1.5

0

5

10 15

INTERCEPT

Figure 2. Typical Output Voltage vs. Input Signal Level for the AD8318

The plots shown in Figure 3 through Figure 8 show the typical

system performance that can be obtained using the AD8318 and

AD7887BR in an RF power measurement system. The graphs

depict the RF input power in dBm vs. the ADC output code and

output error in dB (scaled on the axes on the right side of the

plots). They were generated from data taken with various input

power levels, frequencies, and temperatures and with both internal

and external ADC voltage references. The charts show improved

system performance and lower temperature drift with the use of

a low drift external ADC voltage reference. (See the Common

Variations section for more details about the use of an external

reference.

A complete design support package for this circuit note can be

found at www.analog.com/CN0150-DesignSupport.

At the output of the ADC, the equation can be written as

CODE_OUT = SLOPE_ADC × (PIN − INTERCEPT)

4

4.0k

Because the slope and intercept of the system vary from device

to device, a system level calibration is required. A calibration is

performed by applying two known signal levels close to the

endpoints of the AD8318 linear input range and measuring the

corresponding output codes from the ADC. The calibration

points chosen should be well within the linear operating

range of the device (−10 dBm and −50 dBm in this case).

3.5k

3.0k

CODE_2

ADC CODE

where SLOPE_ADC is in codes/dB and PIN and INTERCEPT

are in dBm. Figure 3 shows a typical detector power sweep in

terms of input power and observed ADC codes.

+25°C CODE

–40°C CODE

+85°C CODE

+25°C ERROR

–40°C ERROR

+85°C ERROR

3

2

2.5k

1

2.0k

0

1.5k

–1

1.0k

–2

0.5k

–3

CODE_1

0

–70

OUTPUT ERROR (dBm)

1.0

–4

–60 –50

–40

–30

–20 –10

0

10

INPUT POWER (dBm)

PIN_2

PIN_1

Figure 3. Input = 900 MHz, ADC Using an Internal 2.5 V Reference

Rev. C | Page 2 of 5

08967-003

1.8

08967-002

VOUT (V)

2.1

2.0

VOUT 25°C

ERROR 25°C

ERROR (dB)

2.4

where:

CODE_OUT is the ADC output code.

SLOPE_ADC is the stored ADC slope in codes/dB.

INTERCEPT is the stored intercept.

PIN_TRUE is the exact (and unknown) input level.

Circuit Note

CN-0150

2

3.0k

2.0k

0

1.5k

–1

1.0k

–2

0.5k

–3

0

–70

–60

–50

–40

–30

–20

–10

0

10

–4

INPUT POWER (dBm)

–1

1.0k

–2

0.5k

–3

–20

–10

0

10

–4

ADC CODE

1.5k

–30

INPUT POWER (dBm)

ADC CODE

3.0k

2

0

1.5k

–1

1.0k

–2

0.5k

–3

–40

–30

–20

–10

0

10

–30

–20

–10

0

10

–4

4

+25°C CODE

–40°C CODE

+85°C CODE

+25°C ERROR

–40°C ERROR

+85°C ERROR

3

2

2.5k

1

2.0k

0

1.5k

–1

1.0k

–2

0.5k

–3

–60

–50

–40

–30

–20

–10

0

10

–4

INPUT POWER (dBm)

The AD7887 is a 2-channel, 12-bit ADC with an SPI interface.

The second input channel of this device can be connected to the

AD8318 TEMP pin. This provides a convenient measure of the

ambient temperature around the AD8318. Like the AD8318

power measurement output, the TEMP voltage output should

also be calibrated.

2.0k

–50

–40

COMMON VARIATIONS

1

–60

–50

3

2.5k

0

–70

–60

4

–4

INPUT POWER (dBm)

Figure 6. Input = 1.9 GHz, ADC Using an External 2.5 V Reference

OUTPUT ERROR (dBm)

3.5k

–3

Figure 8. Input = 2.2 GHz, ADC Using an External 2.5 V Reference

08967-006

+25°C CODE

–40°C CODE

+85°C CODE

+25°C ERROR

–40°C ERROR

+85°C ERROR

0.5k

0

–70

Figure 5. Input = 1.9 GHz, ADC Using an Internal 2.5 V Reference

4.0k

–2

3.0k

0

–40

1.0k

2

2.0k

–50

–1

3.5k

1

–60

1.5k

3

2.5k

0

–70

0

Figure 7. Input = 2.2 GHz, ADC Using an Internal 2.5 V Reference

OUTPUT ERROR (dBm)

ADC CODE

3.0k

2.0k

4.0k

08967-005

3.5k

1

INPUT POWER (dBm)

4

+25°C CODE

–40°C CODE

+85°C CODE

+25°C ERROR

–40°C ERROR

+85°C ERROR

2.5k

0

–70

Figure 4. Input = 900 MHz, ADC Using an External 2.5 V Reference

4.0k

2

OUTPUT ERROR (dBm)

1

3

08967-008

2.5k

+25°C CODE

–40°C CODE

+85°C CODE

+25°C ERROR

–40°C ERROR

+85°C ERROR

OUTPUT ERROR (dBm)

3.5k

ADC CODE

ADC CODE

3.0k

3

OUTPUT ERROR (dBm)

3.5k

4

4.0k

08967-004

+25°C CODE

–40°C CODE

+85°C CODE

+25°C ERROR

–40°C ERROR

+85°C ERROR

08967-007

4

4.0k

If the end application requires only a single channel, the 12-bit

AD7495 can be used. In multichannel applications that require

multiple ADCs and DAC channels, the AD7294 can be used.

In addition to providing four 12-bit DAC outputs, this subsystem

chip includes four uncommitted ADC channels, two high-side

current sense inputs, and three temperature sensors. Current

and temperature measurements are digitally converted and

available to read over the I2C-compatible interface.

The temperature stability of the circuit can be improved using an

external ADC reference. The AD7887 internal 2.5 V reference has

a 50 ppm/°C drift, which is approximately 15 mV over a 125°C

range. Because the detector has a slope of −24 mV/dB, the ADC

reference drift contributes approximately ±0.3 dB to the temperature

drift error budget. The AD8318 temperature drift is approximately

±0.5 dB over a similar temperature range. (This varies with

frequency. See the AD8318 data sheet for more details.)

Rev. C | Page 3 of 5

CN-0150

Circuit Note

If an external voltage reference is to be used, the ADR421 2.5 V

reference is recommended. Its 1 ppm/°C temperature drift results

in a reference voltage variation of only 312 μV from −40°C to

+85°C. This has a negligible effect on the overall temperature

stability of the system.

6 V wall wart can be connected to the barrel connector on the

board and used in place of the 6 V power supply. Connect the USB

cable supplied with the SDP board to the USB port on the PC.

Note: Do not connect the USB cable to the mini USB connector

on the SDP board at this time.

If a less dynamic range is required, the AD8317 (55 dB) or AD8319

(45 dB) log detector can be used. If a true rms responding power

measurement is required, the AD8363 (50 dB) or ADL5902

(65 dB) can be used.

Test

CIRCUIT EVALUATION AND TEST

Apply power to the 6 V supply (or wall wart) connected to

EVAL-CN0150A-SDPZ circuit board. Launch the evaluation

software and connect the USB cable from the PC to the USB

mini connector on the SDP board.

This circuit uses the EVAL-CN0150A-SDPZ circuit board and

the EVAL-SDP-CB1Z System Demonstration Platform (SDP)

evaluation board. The two boards have 120-pin mating connectors,

allowing for the quick setup and evaluation of the circuit’s

performance. The EVAL-CN0150A-SDPZ board contains the

circuit to be evaluated, as described in this note, and the SDP

evaluation board is used with the CN0150A evaluation software to

capture the data from the EVAL-CN0150A-SDPZ circuit board.

Once USB communications are established, the SDP board can

now be used to send, receive, and capture serial data from the

EVAL-CN0150A-SDPZ board.

Equipment Needed

Temperature testing was performed using a Test Equity Model 107

environmental chamber. The EVAL-CN0150A-SDPZ evaluation

board was placed in the chamber via a slot in the test chamber

door, with the SDP evaluation board extending outside.

• PC with a USB port and Windows® XP or Windows Vista®

(32-bit), or Windows 7 (32-bit)

• EVAL-CN0150A-SDPZ Circuit Evaluation Board

The data in this circuit note were generated using a Rohde &

Schwarz SMT-03 RF signal source and an Agilent E3631A power

supply. The signal source was set to the frequencies indicated in

the graphs, and the input power was stepped and data recorded

in 1 dB increments.

Information and details regarding how to use the evaluation

software for data capture can be found in the CN0150A

evaluation software readme file.

• EVAL-SDP-CB1Z SDP Evaluation Board

• CN0150A Evaluation Software

• Power supply: 6 V or 6 V wall wart

Information regarding the SDP board can be found in the SDP

User Guide.

• Environmental chamber

• RF signal source

LEARN MORE

• Coaxial RF cable with SMA connectors

CN0150 Design Support Package:

http://www.analog.com/CN0150-DesignSupport

Getting Started

SDP User Guide

Load the evaluation software by placing the CN0150A evaluation

software CD in the CD drive of the PC. Using My Computer,

locate the drive that contains the evaluation software CD and

open the readme file. Follow the instructions contained in the

readme file for installing and using the evaluation software.

MT-031 Tutorial, Grounding Data Converters and Solving the

Mystery of “AGND” and “DGND,” Analog Devices.

MT-077 Tutorial, Log Amp Basics, Analog Devices.

MT-078 Tutorial, High Speed Log Amps, Analog Devices.

Functional Block Diagram

MT-101 Tutorial, Decoupling Techniques, Analog Devices.

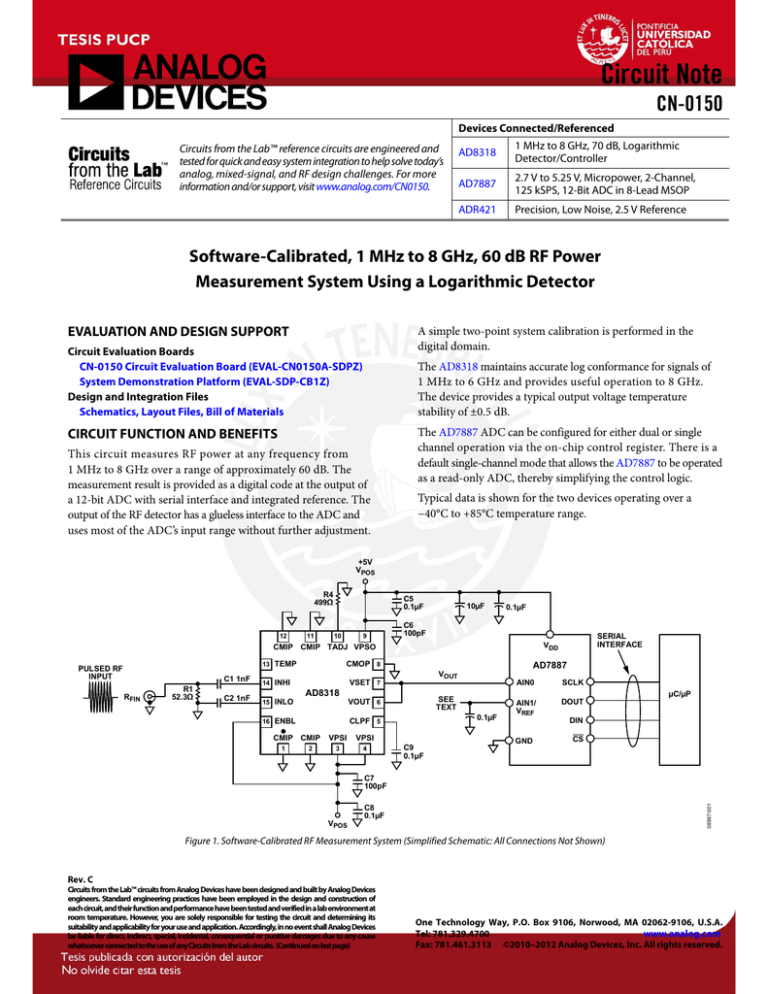

See Figure 1 of this circuit note for the circuit block diagram

and the EVAL-CN150A-SDPZ-SCH-Rev0.pdf file for the

circuit schematics. This file is contained in the CN0150

Design Support Package.

Whitlow, Dana. Design and Operation of Automatic Gain

Control Loops for Receivers in Modern Communications

Systems. Chapter 8. Analog Devices Wireless Seminar. 2006.

Setup

Connect the 120-pin connector on the EVAL-CN0150A-SDPZ

circuit board to the CON A connector on the EVAL-SDP-CB1Z

evaluation (SDP) board. Use nylon hardware to firmly secure

the two boards, using the holes provided at the ends of the 120-pin

connectors. Using an appropriate RF cable, connect the RF signal

source to the EVAL-CN0150A-SDPZ board via the SMA RF

input connector. With power to the supply off, connect a 6 V power

supply to the +6V and GND pins on the board. If available, a

Data Sheets and Evaluation Boards

CN-0150 Circuit Evaluation Board (EVAL-CN0150A-SDPZ)

System Demonstration Platform (EVAL-SDP-CB1Z)

AD7887 Data Sheet

AD7887 Evaluation Board

AD8318 Data Sheet

AD8318 Evaluation Board

ADR421 Data Sheet

Rev. C | Page 4 of 5

Circuit Note

CN-0150

REVISION HISTORY

2/12—Rev. B to Rev. C

Changed 70 dB to 60 dB in Circuit Note Title ..............................1

3/11—Rev. A to Rev. B

Added Evaluation and Design Support Section............................1

Added Circuit Evaluation and Test Section...................................4

8/10— Rev. 0 to Rev. A

Changes to the Circuit Function and Benefits Section ................1

Changes to the Circuit Description Section ..................................2

Changes to the Common Variations Section ................................4

4/10—Revision 0: Initial Version

I2C refers to a communications protocol originally developed by Philips Semiconductors (now NXP Semiconductors).

(Continued from first page) Circuits from the Lab circuits are intended only for use with Analog Devices products and are the intellectual property of Analog Devices or its licensors. While you

may use the Circuits from the Lab circuits in the design of your product, no other license is granted by implication or otherwise under any patents or other intellectual property by

application or use of the Circuits from the Lab circuits. Information furnished by Analog Devices is believed to be accurate and reliable. However, Circuits from the Lab circuits are supplied

"as is" and without warranties of any kind, express, implied, or statutory including, but not limited to, any implied warranty of merchantability, noninfringement or fitness for a particular

purpose and no responsibility is assumed by Analog Devices for their use, nor for any infringements of patents or other rights of third parties that may result from their use. Analog Devices

reserves the right to change any Circuits from the Lab circuits at any time without notice but is under no obligation to do so.

©2010–2012 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

CN08967-0-2/12(C)

Rev. C | Page 5 of 5

Circuit Note

CN-0178

Circuits from the Lab™ reference circuits are engineered and

tested for quick and easy system integration to help solve today’s

analog, mixed-signal, and RF design challenges. For more

information and/or support, visit www.analog.com/CN0178.

Devices Connected/Referenced

ADL5902

50 MHz to 9 GHz, 65 dB TruPwr™ Detector

AD7466

Micropower, 12-Bit, 200 kSPS SAR ADC

Software-Calibrated, 50 MHz to 9 GHz, RF Power Measurement System

EVALUATION AND DESIGN SUPPORT

The measurement result is provided as serial data at the output

of a 12-bit ADC (AD7466). A simple 4-point system calibration

at ambient temperature is performed in the digital domain.

Circuit Evaluation Boards

CN-0178 Circuit Evaluation Board (EVAL-CN0178-SDPZ)

System Demonstration Platform (EVAL-SDP-CB1Z)

Design and Integration Files

Schematics, Layout Files, Bill of Materials

The interface between the RF detector and the ADC is

straightforward, consisting of two signal scaling resistors and

no active components. In addition, the ADL5902 internal 2.3 V

reference voltage provides the supply and reference voltage for

the micropower ADC. The AD7466 has no pipeline delay and

is operated as a read-only SAR ADC.

CIRCUIT FUNCTION AND BENEFITS

This circuit uses the ADL5902 TruPwr™ detector to measure the

rms signal strength of RF signals with varying crest factors

(peak-to-average ratio) over a dynamic range of approximately

65 dB and operates at frequencies from 50 MHz up to 9 GHz.

+5V

+5V

C3

0.1µF

C7

0.1µF

C4

100pF

C5

100pF

VPOS

VPOS

3

10

TEMPERATURE

SENSOR

ADL5902

RFIN

R3

60.4Ω

C10

100pF

The overall circuit achieves temperature stability of

approximately ±0.5 dB.

C9A

0.1µF

8

TEMP

C10A

10µF

VDD

1

INHI

INLO

14

X2

C12

100pF

NC

IDET

VIN

R10

3

1.21kΩ

15

LINEAR-IN-dB VGA

(NEGATIVE SLOPE)

7

X2

VSET

G=5

6

R11

2kΩ

VOUT

BIAS AND POWERDOWN CONTROL

5

11

1

R9

1430Ω

12

9

VTGT

R10

3.74kΩ

CS

DGND

C9

0.1µF

AD7466

2

4

COMM

DATA

CS

GND

COMM

R11

2kΩ

09331-001

R12

301Ω

VREF

CLK

SDATA

5

6

CLPF

26pF

SCLK

4

CONTROL

LOGIC

VREF

2.3V

NC 13

TADJ

12-BIT

SUCCESSIVE

APPROXIMATION

ADC

ITGT

2

NC 16

T/H

Figure 1. Software-Calibrated RF Power Measurement System

Rev.A

Circuits from the Lab™ circuits from Analog Devices have been designed and built by Analog Devices

engineers. Standard engineering practices have been employed in the design and construction of

each circuit, and their function and performance have been tested and verified in a lab environment at

room temperature. However, you are solely responsible for testing the circuit and determining its

suitability and applicability for your use and application. Accordingly, in no event shall Analog Devices

be liable for direct, indirect, special, incidental, consequential or punitive damages due to any cause

whatsoever connected to the use of any Circuits from the Lab circuits. (Continued on last page)

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700

www.analog.com

Fax: 781.461.3113 ©2010–2011 Analog Devices, Inc. All rights reserved.

CN-0178

Circuit Note

Data is shown for the two devices operating over a −40°C to

+85°C temperature range.

The transfer function of the detector can be approximated by

the equation

VOUT = SLOPE_DETECTOR × (PIN − INTERCEPT)

CIRCUIT DESCRIPTION

CODE = SLOPE × (PIN − INTERCEPT)

where SLOPE is the combined slope of the detector, the scaling

resistors, and the ADC, and has the unit of counts/dB; PIN and

INTERCEPT still have the unit of dBm.

Figure 3 shows a typical detector power sweep in terms of input

power and observed ADC output codes for a 700 MHz input

signal.

4096

6

+85°C CODE

–40°C CODE

+25°C CODE

+25°C ERROR 4-POINT CAL @ 0dBm,

–20dBm, –45dBm, AND, –58dBm

+85°C ERROR 4-POINT CAL

–40°C ERROR 4-POINT CAL

3755

3413

3072

5

4

3

2731

2

2389

1

2048

0

1707

–1

1365

–2

1024

–3

683

–4

341

–5

A typical plot of detector output voltage vs. input power is

shown in Figure 2 (without output scaling).

0

–70

–6

–60

–50

–40

–30

PIN (dBm)

–20

–10

0

10

ERROR (dB)

The ADC full-scale voltage is equal to 2.3 V. The maximum

detector output voltage (when operating in its linear input

range) is approximately 3.5 V (see ADL5902 data sheet figures

6, 7, 8, 12, 13, and 14) and must, therefore, be scaled down by a

factor of 0.657 before driving the AD7466. This scaling is

implemented using a simple resistor divider R10 and R11

(1.21 kΩ and 2.0 kΩ). These values provide an actual scaling

factor of 0.623, which ensures that the ADL5902 RF detector

does not overdrive the ADC by building in some room for

resistor tolerance.

At the output of the ADC, VOUT is replaced by the ADC’s

output code, and the equation can be rewritten as

09331-003

The power supply voltage and reference voltage for the AD7466

12-bit ADC are provided by the ADL5902 internal 2.3 V

reference. Because the AD7466 consumes so little current

(16 µA when sampling at 10 kSPS), the ADL5902’s reference

voltage output can supply the ADC, as well as the temperature

compensating and rms accuracy-scaling network consisting of

R9, R10, R11, and R12.

where SLOPE_DETECTOR is in mV/dB; INTERCEPT is the

x-axis intercept with a unit of dBm; PIN is the input power

in dBm.

ADC CODE

The RF signal being measured is applied to the input of the

ADL5902, a linear-in-dB rms-responding rms detector. The

external 60.4 Ω resistor, R3, combined with the relatively high

input impedance of the ADL5902 ensures a broadband 50 Ω

match to the RF input. The ADL5902 is configured in its

so-called “measurement mode,” with the VSET and VOUT

pins connected together. In this mode the output voltage is

proportional to the logarithm of the rms value of the input. In

other words, the reading is presented directly in decibels and is

scaled to 1.06 V per decade, or 53 mV/dB.

Figure 3. ADC Output Code and Error vs. RF Input Power @ 700 MHz

4.0

3.5

Overall SLOPE and INTERCEPT will vary from system to

system. This variation is caused by part to part variations in the

transfer function of the RF detector, the scaling resistors, and

the ADC. As a result, a system level calibration is required to

determine the complete system SLOPE and INTERCEPT. In this

application, a 4-point calibration is used to correct for some

nonlinearity in the RF detector’s transfer function, particularly

at the low end. This 4-point calibration scheme yields three

SLOPE and three INTERCEPT calibration coefficients, which

should be stored in nonvolatile RAM (NVM) after calibration.

3.0

VOUT (V)

2.5

2.0

1.5

1.0

0

–70

–60

–50

INTERCEPT

–40

–30

PIN (dBm)

–20

–10

0

10

09331-002

0.5

Figure 2. ADL5902 RMS Detector, Output Voltage vs. Input Power @ 900 MHz

Rev. A| Page 2 of 5

Circuit Note

CN-0178

Figure 4 and Figure 5 show the performance of the circuit at

1 GHz and 2.2 GHz, respectively.

4096

6

+85°C CODE

–40°C CODE

+25°C CODE

+25°C ERROR 4-POINT CAL @ 0dBm,

–20dBm, –45dBm, AND, –58dBm

+85°C ERROR 4-POINT CAL

–40°C ERROR 4-POINT CAL

The SLOPE and INTERCEPT calibration coefficients are

calculated using the equations

ADC CODE

3072

INTERCEPT1= CODE_1/(SLOPE_ADC × PIN_1)

This calculation is then repeated using CODE_2/CODE_3

and CODE_3/CODE_4 to calculate SLOPE2/INTERCEPT2

and SLOPE3/INTERCEPT3, respectively. The six calibration

coefficients should then be stored in NVM along with CODE_1,

CODE_2, CODE_3, and CODE_4.

2

2389

1

2048

0

1707

–1

1365

–2

1024

–3

683

–4

341

–5

0

–70

–6

–60

–20

–10

0

10

6

+85°C CODE

–40°C CODE

+25°C CODE

+25°C ERROR 4-POINT CAL @ 0dBm,

–20dBm, –45dBm, AND, –58dBm

+85°C ERROR 4-POINT CAL

–40°C ERROR 4-POINT CAL

ADC CODE

3072

Figure 3 also includes plots of error vs. temperature. In this case

the measured ADC codes at +85°C and −40°C are compared to

the straight line equations at ambient. This is consistent with a

real world system where system calibration is generally only

practical at ambient temperature.

–30

4096

PIN = (CODE/SLOPE) + INTERCEPT

= (CODE/SLOPE) + INTERCEPT – PIN_TRUE

–40

Figure 4. ADC Output Code and Error vs. RF Input Power @ 1 GHz

3413

Error (dB) = Calculated RF Power − True Input Power

–50

PIN (dBm)

3755

Figure 3 also shows the transfer function variation of the circuit

vs. the above straight line equations. This error function is

caused by bending at the edges of the transfer function, small

ripple in the linear operating range, and drift over temperature.

The error is expressed in dB using the equation

3

2731

When the circuit is in operation in the field, these calibration

coefficients are used to calculate an unknown input power level,

PIN, using the equation

In order to retrieve the appropriate SLOPE and INTERCEPT

calibration coefficients during circuit operation, the observed

CODE from the ADC must be compared to CODE_1, CODE_2,

CODE_3, and CODE_4. For example if the CODE from the

ADC is between CODE_1 and CODE_2, then the SLOPE1 and

INTERCEPT1 should be used. This step can also be used to

provide an underrange or overrange warning. For example, if

the CODE from the ADC is greater than CODE_1 or less than

CODE_4, it indicates that the measured power is outside of the

calibration range

4

5

4

3

2731

2

2389

1

2048

0

1707

–1

1365

–2

1024

–3

683

–4

341

–5

0

–70

–6

–60

–50

–40

–30

–20

–10

0

10

PIN (dBm)

ERROR (dB)

SLOPE1 = ( CODE _1 – CODE_2)/(PIN_1 − PIN_2)

5

ERROR (dB)

3413

09331-004

3755

09331-005

The calibration is performed by applying four known signal

levels to the ADL5902 and measuring the corresponding output

codes from the ADC. The calibration points chosen should be

within the linear operating range of the device. In this example,

calibration points at 0 dBm, −20 dBm, −45 dBm, and −58 dBm

were used.

Figure 5. ADC Output Code and Error vs. RF Input Power @ 2.2 GHz

The performance of this or any high speed circuit is highly

dependent on proper PCB layout. This includes, but is not

limited to, power supply bypassing, controlled impedance lines

(where required), component placement, signal routing, and

power and ground planes. (See MT-031 Tutorial, MT-101 Tutorial,

and article, A Practical Guide to High-Speed Printed-CircuitBoard Layout, for more detailed information regarding PCB

layout.)

A complete design support package for this circuit note can be

found at www.analog.com/CN0178-DesignSupport.

Rev. A| Page 3 of 5

CN-0178

Circuit Note

COMMON VARIATIONS

Functional Block Diagram

For applications that require less RF detection range, the

AD8363 rms detector can be used. The AD8363 has a detection

range of 50 dB and operates at frequencies up to 6 GHz. For

non-rms detection applications, the AD8317/AD8318/AD8319

or ADL5513 can be used. These devices offer varying detection

ranges and have varying input frequency ranges up to 10 GHz

(see CN-0150 for more details).

See Figure 1 of this circuit note for the circuit block diagram,

and the file “EVAL-CN0178-SDPZ-SCH-Rev0.pdf ” for the

circuit schematics. This file is contained in the CN0178 Design

Support Package.

The AD7466 is a single channel, 12-bit ADC with SPI interface.

If the end application requires a multichannel ADC, the dual

12-bit AD7887 can be used. In multichannel applications that

require multiple ADC and DAC channels, the AD7294 can be

used. In addition to providing four 12-bit DAC outputs, this

subsystem chip includes four uncommitted ADC channels,

two high-side current sense inputs, and three temperature

sensors. Current and temperature measurements are digitally

converted and available to read over the I2C-compatible

interface.

CIRCUIT EVALUATION AND TEST

This circuit uses the EVAL-CN0178-SDPZ circuit board and

the EVAL-SDP-CB1Z System Demonstration Platform (SDP)

evaluation board. The two boards have 120-pin mating

connectors, allowing for the quick setup and evaluation of the

circuit’s performance. The EVAL-CN0178-SDPZ board contains

the circuit to be evaluated, as described in this note, and the

SDP evaluation board is used with the CN0178 evaluation

software to capture the data from the EVAL-CN0178-SDPZ

circuit board.

Equipment Needed

• PC with a USB port and Windows® XP or Windows Vista®

(32-bit), or Windows® 7 (32-bit)

• EVAL-CN0178-SDPZ Circuit Evaluation Board

Setup

Connect the 120-pin connector on the EVAL-CN0178-SDPZ

circuit board to the connector marked “CON A” on the

EVAL-SDP-CB1Z evaluation (SDP) board. Nylon hardware

should be used to firmly secure the two boards, using the holes

provided at the ends of the 120-pin connectors. Using an

appropriate RF cable, connect the RF signal source to the

EVAL-CN0178-SDPZ board via the SMA RF input connector.

With power to the supply off, connect a +6 V power supply to

the pins marked “+6 V” and “GND” on the board. If available, a

+6 V "wall wart" can be connected to the barrel connector on

the board and used in place of the +6 V power supply. Connect

the USB cable supplied with the SDP board to the USB port on

the PC. Note: Do not connect the USB cable to the mini USB

connector on the SDP board at this time.

Test

Apply power to the +6 V supply (or “wall wart”) connected to

EVAL-CN0178-SDPZ circuit board. Launch the Evaluation

software, and connect the USB cable from the PC to the USB

mini-connector on the SDP board.

Once USB communications are established, the SDP board can

now be used to send, receive, and capture serial data from the

EVAL-CN0178-SDPZ board.

The data in this circuit note were generated using a Rohde &

Schwarz SMT-03 RF signal source, and an Agilent E3631A

power supply. The signal source was set to the frequencies

indicated in the graphs, and the input power was stepped and

data recorded in 1 dB increments.

Temperature testing was performed using a Test Equity Model

107 environmental chamber. The CN0178-SDPZ evaluation

board was placed in the chamber via a slot in the test chamber

door, with the SDP evaluation board extending outside.

• EVAL-SDP-CB1Z SDP Evaluation Board

• CN0178 Evaluation Software

• Power supply: +6 V, or +6 V “wall wart”

Information and details regarding how to use the evaluation

software for data capture can be found in the CN0178

Evaluation Software ReadMe file.

• Environmental chamber

• RF signal source

• Coaxial RF cable with SMA connectors

Information regarding the SDP board can be found in the

SDP User Guide.

Getting Started

Load the evaluation software by placing the CN0178 Evaluation

Software disc in the CD drive of the PC. Using "My Computer,"

locate the drive that contains the evaluation software disc and

open the Readme file. Follow the instructions contained in the

Readme file for installing and using the evaluation software.

Rev. A| Page 4 of 5

Circuit Note

CN-0178

LEARN MORE

Data Sheets and Evaluation Boards

CN0178 Design Support Package:

http://www.analog.com/CN0178-DesignSupport

CN-0178 Circuit Evaluation Board (EVAL-CN0178-SDPZ)

System Demonstration Platform (EVAL-SDP-CB1Z)

SDP User Guide

ADL5902 Data Sheet

Ardizzoni, John. A Practical Guide to High-Speed PrintedCircuit-Board Layout, Analog Dialogue 39-09, September

2005.

ADL5902 Evaluation Board

AD7466 Data Sheet

CN-0150 Circuit Note, Software-Calibrated, 1 MHz to 8 GHz,

70 dB RF Power Measurement System Using the AD8318

Logarithmic Detector , Analog Devices.

AD7466 Evaluation Board

MT-031 Tutorial, Grounding Data Converters and Solving the

Mystery of “AGND” and “DGND”, Analog Devices.

3/11—Rev. 0 to Rev. A

REVISION HISTORY

MT-073 Tutorial, High Speed Variable Gain Amplifiers (VGAs),

Analog Devices.

MT-077 Tutorial, Log Amp Basics, Analog Devices.

Added Evaluation and Design Support Section ............................ 1

Added Circuit Evaluation and Test Section ................................... 4

10/10—Rev. 0: Initial Version

MT-078 Tutorial, High Speed Log Amps, Analog Devices.

MT-081 Tutorial, RMS-to-DC Converters, Analog Devices.

MT-101 Tutorial, Decoupling Techniques, Analog Devices.

Whitlow, Dana. Design and Operation of Automatic Gain

Control Loops for Receivers in Modern Communications

Systems. Chapter 8. Analog Devices Wireless Seminar. 2006.

I2C refers to a communications protocol originally developed by Philips Semiconductors (now NXP Semiconductors).

(Continued from first page) Circuits from the Lab circuits are intended only for use with Analog Devices products and are the intellectual property of Analog Devices or its licensors. While you

may use the Circuits from the Lab circuits in the design of your product, no other license is granted by implication or otherwise under any patents or other intellectual property by

application or use of the Circuits from the Lab circuits. Information furnished by Analog Devices is believed to be accurate and reliable. However, "Circuits from the Lab" are supplied "as is"

and without warranties of any kind, express, implied, or statutory including, but not limited to, any implied warranty of merchantability, noninfringement or fitness for a particular

purpose and no responsibility is assumed by Analog Devices for their use, nor for any infringements of patents or other rights of third parties that may result from their use. Analog Devices

reserves the right to change any Circuits from the Lab circuits at any time without notice but is under no obligation to do so.

©2010–2011 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

CN09331-0-3/11(A)

Rev. A| Page 5 of 5

1

2

3

4

5

6

7

8

9

+5V_RF

C7

100pF

+5V_RF

C6

100pF

A

+5V_RF

C5

C3

0.1uF

10uF

+3.3V

C4

0.1uF

A

C8 0.1uF

C9

0.1uF

8

CMIP

CMIP

CMIP

CMIP

1

2

11

12

PAD

TADJ

17

10

C10

GND GND 1

VIN VOUT

GND TRIM

6

5

NIC

NIC

3

7

TP

TP

8

1

3

TP5

3

Q3

BSN20

2

DOUT

Q5

BSN20

2

DIN

3

2

SCLK

3

2

SPI_SEL_A_1

2

SPI_MOSI_1

SPI_MISO_1

Q6

BSN20

3

TP3

GND GND

2

Q4

BSN20

3

TP4

AD7887

0.1uF

+5V_RF U3

2

4

3

2

CS

1

CLPF

5

1

7

6

8

CS

DOUT

AIN0

AIN1/VREF DIN

SCLK

GND

R16

4.7K

1

7

VDD

R13

4.7K

Q1

BSN20

1

VSET

5

4

VOUT

Q2

BSN20

1

6

TEMP

U1

AD8318

GND

VOUT

R20

3.3K

R15

4.7K

1

INLO

C2

13

1000pF

TP9

2

R14

4.7K

1

R17

3.3K

R19

3.3K

1

15

B

GND

TP2

R1

52.3

GND

GND

TP1

CMOP

INHI

VPSO

ENBL

C1

1000pF

14

GND

GND

9

16

GND

U2

VPSI

VPSI

J3

142-0701-801

Coax, Board Edge

3

4

GND

R18

3.3K

3

3

Q7

BSN20

2

SPI_CLK_1

B

Q8

BSN20

ADR421

R2

499

GND

GND

J4

FX8-120S-SV(21)

F

+5V_SDP

+5V_SDP

6

SCL_0

SDA_0

4

24LC32A

Y

GND

R21

20.0

GND

SCL_0

SDA_0

SPI_CLK

SPI_MISO

SPI_MOSI

SPI_SEL_A

GND

SPI_MISO_1

VIN

7

8

IN

IN

6

SD

SPI_SEL_A_1

F1

1210L035YR

350mA - Hold

700mA - Trip

6V

PGND

J2

1

3

2

U4

BNX016-01

1

+6V

PJ-002A

2.1mm X 2.5mm OD

OUT

OUT

OUT

D1

6.8V

1.2V@1A

SMBJ5342B-TP

C11

4.7uF

3

PGND

FB

5

ADP3336

R10

64.9K

7

8

OUT

OUT

OUT

IN

IN

C14

6

1.0uF

TP8

TP6

GND

PGND

+5V_RF

1

2

3

+5V_RF

C15

R11

210K

SD

FB

1.0uF

E

D3

SML-LX15GC

2.2V@20mA

5

ADP3336

R12

64.9K

GND

TP21 TP20 TP19 TP7

1.0uF

TP15

GND

FID1 FID2 FID3

D

C17

U8

VIN

4

5

6

+5V_SDP

GND

D2

TP16

400mV@2A

SBR2U30P1-7

2

+5V_SDP

1

2

3

R9

210K

4

1

2

R8

78.7K

TP14

C16

1.0uF

R24

20.0

J1

ADP3336

U6

SPI_MOSI_1

R23

20.0

1.0uF

5

GND

SPI_CLK_1

R22

20.0

FB

C

C13

74HC1G125

GND

TP10

TP11

TP12

TP13

+3.3V

R7

140K

GND

2

1

TP17

TP18

GND GND GND GND GND

GND

A

OE

1

2

3

SD

GND

GND

OUT

OUT

OUT

IN

IN

4

A0 VCC

WP

A1

SCL

A2

VSS SDA

1.0uF

5

U9

8

7

6

5

VCC

U5

1

2

3

4

R5

100K

7

8

C12

R6

OPEN

R4

100K

VIN

+5V_SDP

+3.3V

GND

E

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

4

D

BMODE1

RESET_IN

UART_TX

UART_RX

GND

GND

NC

NC

NC

EEPROM_A0

NC

NC

NC

NC

NC

NC

GND

GND

NC

NC

NC

NC

TMR_D

TMR_C

TIMERS

TMR_B

TMR_A

GPIO7

GPIO6

GND

GND

GENERAL

GPIO5

GPIO4

INPUT/OUTPUT

GPIO3

GPIO2

GPIO1

GPIO0

SCL_0

SCL_1

I2C

SDA_0

SDA_1

GND

GND

SPI_CLK

SPI_SEL1/SPI_SS

SPI_MISO

SPI_SEL_C

SPI

SPI_MOSI

SPI_SEL_B

SPI_SEL_A

GND

GND

SPORT_INT

SPORT_TSCLK

SPORT_DT3

SPORT_DT0

SPORT_DT2

SPORT

SPORT_TFS

SPORT_DT1

SPORT_RFS

SPORT_DR1

SPORT_DR0

SPORT_DR2

SPORT_RSCLK

SPORT_DR3

GND

GND

PAR_CLK

PAR_FS1

PAR_FS2

PAR_FS3

PAR_A0

PAR_A1

PAR_A2

PAR_A3

GND

GND

PAR_INT

PAR_CS

PAR_WR

PAR_RD

PAR_D0

PAR_D1

PAR_D2

PAR_D3

PAR_D4

PAR_D5

GND

GND

PARALLEL

PAR_D6

PAR_D7

PAR_D8

PAR_D9

PORT

PAR_D10

PAR_D11

PAR_D12

PAR_D13

GND

PAR_D14

PAR_D15

GND

PAR_D16

PAR_D17

PAR_D18

PAR_D19

PAR_D20

PAR_D21

PAR_D22

PAR_D23

GND

GND

VIO(+3.3V)

USB_VBUS

GND

GND

GND

GND

NC

NC

NC

VIN

3

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

C

+3.3V

TP22

U7

+3.3V

R3

165

GND

F

1

2

3

+2.3V

VCC2 VCC1

1

5

Y

3

2

3

C14 10uF

.020kGND

R11

C18 .1uF

VCC1 VCC2

6

3

A

5

+3.3V_EEPROM

Y

C22 10uF

.020k GND

1

OE

2

A

R10

F

+5V_SDP

GND

1uF

U10

8

7

6

5

IC_ADG3231

GND C19

10uF

U5

6

VCC2 VCC1

1

5

3

Y

A

GND

6

SD

1

2

3

OUT

OUT

OUT

C27

1uF

4

GND

GND

R22

GND

.020k

GND

R9

GND

C

C28

5

FB

1uF

4

2

24LC32A

C24 10uF

IN

IN

+3.3V

TP6

GND

7

8

R21

GND

A0 VCC

A1

WP

A2

SCL

VSS SDA

R23

1uF

C23 .1uF

GND

NC

Open

R5

R6

100.0k

R4

1

2

3

4

C30

5

FB

B

+3.3V

GND

C20 .1uF

U6

TP19

4

TP17

TP18

GND

TP14

IN

IN

6

SD

SPI_SEL_A

GND

1uF

PGND

3

U8

4

5

6

C2

GND

IN

IN

6

SD

OUT

OUT

OUT

FB

E

1

2

3

5

C3

1uF

GND

GND

GND

D3

SML-LX15GC

2.2V@20mA

1uF

+3.3V_EEPROM

+5V_ANALOG

TP4

GND

7

8

R2

GND GND

6.8V

1.2V@1A

SMBJ53428B-TP

400mV@2A TP3

SBR2U30P1-7

2

165

C1

D1

4.7uF

PGND

U7

BNX016-01

1

R3

PJ-002A

2.1mm X 2.5mm OD

R13

4

1 VIN_JACK

3

2

210k

TP24 TP25

J2

R1

GND GND GND GND

6V

700mA - Trip

350mA - Hold

1210LO35YR

F1

TP2

PGND

GND

1

2

ID1 ID2 ID3

C16

5

FB

1uF

J1

TP20 TP21 TP22 TP23

D

1

2

3

OUT

OUT

OUT

C15

TP1

+5V_SDP

TP5

7

8

210k

TP16

64.9k

SPI_CLK

SPI_MISO

U9

R12

TP15

64.9k

SCL_0

SDA_0

4

E

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

C29

Y

R24

1

2

4

D

SD

GND

GND C17

10uF

GND

+2.3V

100.0k

C

6

1

2

3

OUT

OUT

OUT

4

GND

J4

RESET_IN

BMODE1

UART_RX

UART_TX

GND

GND

NC

NC

EEPROM_A0

NC

NC

NC

NC

NC

NC

NC

GND

GND

NC

NC

NC

NC

TMR_C

TMR_D

TIMERS

TMR_A

TMR_B

GPIO6

GPIO7

GND

GND

GENERAL

GPIO4

GPIO5

INPUT/OUTPUT

GPIO2

GPIO3

GPIO0

GPIO1

SCL_1

SCL_0

I2C

SDA_1

SDA_0

GND

GND

SPI_SEL1/SPI_SS

SPI_CLK

SPI_SEL_C

SPI_MISO

SPI

SPI_SEL_B

SPI_MOSI

GND

SPI_SEL_A

SPORT_INT

GND

SPORT_DT3

SPORT_TSCLK

SPORT_DT2

SPORT_DT0

SPORT

SPORT_DT1

SPORT_TFS

SPORT_DR1

SPORT_RFS

SPORT_DR2

SPORT_DR0

SPORT_DR3

SPORT_RSCLK

GND

GND

PAR_FS1

PAR_CLK

PAR_FS3

PAR_FS2

PAR_A1

PAR_A0

PAR_A3

PAR_A2

GND

GND

PAR_CS

PAR_INT

PAR_RD

PAR_WR

PAR_D1

PAR_D0

PAR_D3

PAR_D2

PAR_D5

PAR_D4

GND

GND

PARALLEL

PAR_D7

PAR_D6

PAR_D9

PAR_D8

PORT

PAR_D11

PAR_D10

PAR_D13

PAR_D12

PAR_D14

GND

GND

PAR_D15

PAR_D17

PAR_D16

PAR_D19

PAR_D18

PAR_D21

PAR_D20

PAR_D23

PAR_D22

GND

GND

USB_VBUS

VIO(+3.3V)

GND

GND

GND

GND

NC

NC

VIN

NC

IN

IN

GND

GND

D2

GND

IC_ADG3231

+2.3V

TP7

7

8

5

GND

U4

+3.3V_EEPROM

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

U11

+3.3V

C21 .1uF

97.6k

+3.3V

102.5k

+2.3V

GND VCC

GND

A

140k

4

5

R16

U3

6

78.7k

NC

NC

GND

R8

1.43k

A

3

GND

9

4

2

VIN

CS

SDATA

SCLK

GND C12

10uF

GND

NC

8

VDD

6

2k

7

IC_ADG3231

TP13

TP12

1TP11

NC

GND

GND

8

C13 .1uF

U1

IC_ADL5902_LFCSP_VQ

GND

7

+3.3V

C11 .1uF

IC_AD7466_TSSOP8

TP9

1.21k

R14

6

U2

GND

TP8

R17

1

VSET

C26

10uF

GND

3.74k

11

VOUT

C25

.1uF

7

R18

2k

10

VPOS2

NC

NC

NC

.1uF

VTGT

12

2

13

16

100pF

8

TADJ/PWDN

COMM

COMM

COMM

C6

TEMP

301

CLPF

C5

GND

R15

INLO

5

6

GND

GND

VREF

15

5

TP10

C8

3

INHI

VPOS1

14

4

9

17

B

60.4

R7

C4

J3

100pF

GND

100pF

C9

A

.1uF

C10

C7

.1uF

GND

4

+5V_ANALOG

100pF

+5V_ANALOG

F

GUIA DE USO DEL ANALIZADOR DE CAMPOS ELECTROMAGNÉTICOS SRM-3006

DEL NARDA SAFETY TEST SOLUTIONS

A continuación se describirán los pasos realizados a la hora de analizar los puntos

medidos por el equipo SRM-3006.

1. El equipo viene con el software SRM-3006_Tools, el cual te permite realizar

operaciones básicas como la de configurar el equipo según la medición a realizar,

descargar y visualizar los datos almacenados en el equipo, entre otras opciones

básicas. Como se necesita trabajar con los datos almacenados, se necesita

descargar el software SRM-3006_TS, el cual te permite una evaluación de los

datos, para el caso de la presente tesis, te permite realizar la integración del todo

el rango medido.

2. Una vez descargo el software e importado todos los puntos medidos almacenados

en el equipo (en formato .CSV), se procederá a trabajar con las mediciones.

Para ello se debe crear una database en formato .srmdb, realizando los siguientes

pasos: File>New>Database como se observa en la figura 1.

Figura 1: Creación de una database en el software SRM-3006_TS

3. Luego de haber creado la database, se procederá a almacenar toda la data

importada del analizador dentro del archivo .srmdb creado. Para ello en la pestaña

Database debajo del pestaña Import/Export se encuentra la opción Data. Luego de

darle clic, se abrirá el cuadro de la figura 2. Allí se selecciona Folder, ya que en mi

caso importe una gran cantidad de datos y los almacené una carpeta (folder),

luego seleccionas la ubicación del folder y finalmente te aparecerá la figura 3, con

todos los datos que se encontraron en tu folder. Seleccionas lo que se requieren,

en mi caso todo, y le das a la opción Save.

Figura 2: Cuadro de importación de datos

Figura 3: Cuadra de selección de datos a analizar

4. Luego se empezaran a importar toda la data seleccionada (figura 4) y se podrá

visualizar cada punto medido en la parte inferior izquierda, en el cuadra Database.

Finalmente se selecciona el dato y en la esquina derecha inferior se encuentra

habilitada el cuadro de Evaluation, en donde se encuentra la opción Integration. Se

puede realizar la integración de manera manual en la misma grafica o bien

seleccionando una frecuencia de integración mínima o máxima (figura 5).

Figura 4: Importación de los datos en la archivo database creado

Figura 5: Evaluación de uno de los datos importados

Elaborado por Giancarlo Villena Prado

RESULTADOS DE LAS PRUEBAS DEL SISTEMA

Como se mencionó en el documento de tesis, los resultados fueron analizados a través de

la herramienta API de Google Maps. A continuación se escribirán los URL’s donde se

puede analizar con mayor detalle cada punto analizado según la prueba realizada:

1. Pruebas realizadas a nivel del suelo:

Prueba con la antena de retorno de 850 MHz

https://www.google.com/fusiontables/DataSource?docid=1vIPyIPD416j_5FfYPz_-rczxCwhib-JDq4x2bUX#map:id=3

Prueba con la antena de retorno de 1900 MHz

https://www.google.com/fusiontables/DataSource?docid=1xHSgUc9fNnzYJ

-eid7jwPIHdhL7ScaOS0_4vcYsO&pli=1#map:id=3

2. Pruebas realizadas en el drone alrededor de la antena de telefonía celular:

Prueba con la antena de retorno de 850 MHz

https://www.google.com/fusiontables/DataSource?docid=1bcI5O7JUrGrXqTD2Pyfwg5di53QpBS6n-0CMVR6#map:id=3

Prueba con la antena de retorno de 1900 MHz

https://www.google.com/fusiontables/DataSource?docid=1tgQ1_rEmwQhw

8svLCCdyuGjq7zc1UV2Z2-RNrD57&pli=1#map:id=3