2C Motor Starters Hazardous and Non

advertisement

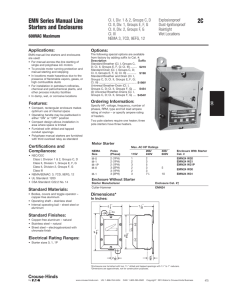

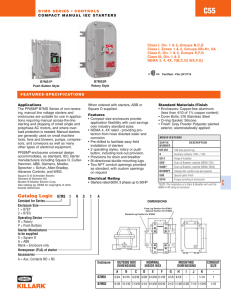

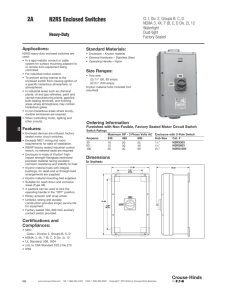

2: 5: SYS19: BASE2 PDFINFO 50: 95: 98: JOB: CRMAIN06-0341-2 Name: 2C-341 100: DATE: JAN 19 2006 Time: 5:18:12 PM Operator: RB COLOR: CMYK TCP: 15001 Typedriver Name: TS name csm no.: 100 Motor Starters Hazardous and Non-Hazardous 2C Description Page No. Application/Selection 342 Magnetic Line Starters & Enclosures Single speed, non-reversing EBMS Series EPC Series EBMS Series with Advantage* Starter 343-346 349-351 347, 348 Manual Line Starters & Enclosures EMN Series 353 Manual Motor Starting Switches & Enclosures EFD Series MC Series EDS Series GHG 635 Series 354 360, 361 355-357 358, 359 Special Feature Kits For EPC Series 352 *Advantage is a trademark of Cutler-Hammer Inc. US: 1-866-764-5454 STIBOINFO((CRH:66008com:2C:341)) CH0 0 0 0 2 C CAN: 1-800-265-0502 Copyright© 2006 Cooper Crouse-Hinds 341 Zoom: 100 2: 5: SYS19: BASE2 PDFINFO 50: 95: 98: 100: JOB: CRMAIN06-0342-2 Name: 2C-342 DATE: JAN 19 2006 Time: 5:18:13 PM Operator: RB COLOR: CMYK TCP: 15001 Typedriver Name: TS name csm no.: 100 Motor Starters 2C Application and Selection Quick Selector Chart Application: Selection: Options: Line starters are housed in enclosures suitable for specific environments, and are used for: ɀ across-the-line starting of motors ɀ motor running protection ɀ undervoltage protection ɀ remote or manual starting and stopping Considerations for selection of proper enclosure: ɀ The environment of the enclosure location in accordance with NEC/CEC and NEMA/ EEMAC requirements ɀ The characteristics of the starter to be enclosed ɀ See ‘‘Quick-Selector’’ below for guidance Many options are available on: ɀ material and finishes where special atmospheric conditions prevail ɀ special features for specific applications. See individual listings for available options, many of which are available in kit form for field addition to existing units. Quick Selector Chart Enclosures for Starters NEMA/EEMAC Size Starters Single Speed Non-reversing Enclosures NEC/CEC – Hazardous Area Compliance NEMA/ EEMAC Enclosure Type MC None 3,4,12 Manual EPC Cl. I, Div. 1 & 2, Groups C,D Cl. II, Div. 1, Groups E,F,G Cl. II, Div. 2, Groups F,G Cl. III 3,4,7CD, 9EFG,12 Magnetic 0-2 Poly-AC Allen-Bradley Cutler-Hammer G.E. Square D Threaded EBMS Cl. I, Div. 1 & 2, Groups B,C,D Cl. II, Div. 1, Groups E,F,G Cl. II, Div. 2, Groups F,G Cl. III 3,4,7BCD, 9EFG,12 Magnetic 0-5 Poly-AC Allen-Bradley G.E. Square D Cutler-Hammer Bolted/ Ground Joint/ Gasketed EMN Cl. I, Div. 1 & 2, Groups C,D Cl. II, Div. 1, Groups E,F,G Cl. II, Div. 2, Groups F,G Cl. III 3, 7CD, 9EFG,12 Manual 0-1P Single and Poly-AC Allen-Bradley Cutler-Hammer G.E. Square D Bolted/ Ground Joint EDS, Cl. I, Div. 1 & 2, Groups B*,C,D EDSC‡ Cl. II, Div. 1, Groups E,F,G Cl. II, Div. 2, Groups F,G Cl. III 3,7CD, 9EFG,12 Manual DC and Single AC Allen-Bradley G.E. Cutler-Hammer Bolted/ Ground Joint EFD 3,7BCD, 9EFG,12 Manual DC and Single and Poly-AC G.E. Square D Bolted/ Ground Joint Cl. I, Div. 1 & 2, Groups B,C,D Cl. II, Div. 1, Groups E,F,G Cl. II, Div. 2, Groups F,G Cl. III Starter Type Motor Phase and Type Manufacturers Equipment Enclosed – Starter Cover Type Single-AC Cutler-Hammer Gasketed ‡ Factory sealed units listed on pages 440 and 441. * Check listings for Group B suitability. 342 STIBOINFO((CRH:66008com:2C:342)) CH0 0 2 C- 0 US: 1-866-764-5454 CAN: 1-800-265-0502 Copyright© 2006 Cooper Crouse-Hinds Zoom: 100 2: 5: SYS19: BASE2 PDFINFO 50: 95: 98: JOB: CRMAIN06-0343-1 Name: 2C-343 100: DATE: JAN 19 2006 Time: 5:18:14 PM Operator: RB EBMS Magnetic Line Starters and Enclosures Application: Spectrum EBM TM hinged cover motor control enclosures are used: ɀ For general motor control – indoors or outdoors – in damp, wet, dirty, dusty hazardous locations, without the need for a protective shelter. ɀ In areas where frequent washdowns are necessary or where heavy rain or water spray is prevalent. ɀ For across-the-line starting, stopping, speed changing and reversing of polyphase AC induction motors. ɀ To provide motor overload and undervoltage protection. ɀ On switchracks or other assemblies where it’s desired that motor control be centrally located. Features: ɀ Rugged, corrosion resistant, cast copperfree aluminum construction (less than 0.4 of 1%). ɀ Motor starter operating handle located through the right side wall of the body permits visual confirmation of correct component assembly and operation. ɀ Total compliance to the wiring end room requirements of the National Electrical Code® and Canadian Electrical Code. ɀ Semi-clamshell enclosure design, with an external flanged ground joint between body and cover makes interior components more accessible. ɀ Minimum enclosure-to-enclosure spacing with little interference between the opened cover and an adjacent enclosure. ɀ Copper-free aluminum hinges allow the cover to swing well out of the way. ɀ Stainless steel, quick release, captive, hex head cover bolts. Stainless steel springs provide clear indication cover bolts are fully retracted from body. ɀ Versatile, internal operating mechanisms allow for field adjustment to accommodate popular manufacturers’ starters. ɀ Simple, straightforward installation of starter on pre-drilled mounting plate within enclosure. Mounting plate also field removable. COLOR: CMYK Cl. I, Div. 1 & 2, Groups B,C,D Cl. II, Div. 1, Groups E,F,G Cl. II, Div. 2, Groups F,G Cl. III NEMA 3,3R,4‡,7BCD,9EFG,12 ɀ Neoprene cover gasket permanently attached to the cover seals out moisture. ɀ Bodies have top and bottom drilled and tapped entrances for power conduits plus one at the bottom for control conduit. Removable reducers are supplied as standard, to accommodate smaller size conduits. All conduit entrances are plugged. ɀ Tap-on mounting feet. ɀ Optional EMPS control devices may be added to enclosure cover. ɀ Steel bracket for lifting larger enclosures during installation supplied as standard. TCP: 15001 Typedriver Name: TS name csm no.: 100 Explosionproof Dust-Ignitionproof Raintight Wet Locations Watertight 2C Standard Materials: ɀ Body and cover – copper-free aluminum ɀ Operating handle – copper-free aluminum ɀ Operating shaft and bushing – stainless steel ɀ Interior parts – sheet steel, electrogalvanized ɀ Cover bolts, washers and retractile springs – stainless steel Electrical Rating Range: ɀ Motor starters – NEMA/EEMAC sizes 0-5 Certifications & Compliances: ɀ NEC/CEC: Class I, Division 1 & 2, Groups B,C,D Class II, Division 1, Groups E,F,G Class II, Division 2, Groups F,G Class III ɀ UL Standards: UL1203 – Hazardous (classified) Locations ɀ NEMA: 3,3R,4‡,7BCD,9EFG,12 ɀ CSA Standard: C22.2 No. 30 National Electrical Code is a Registered Trademark of the National Fire Protection Association. ‡ Enclosure not suitable for NEMA 4 with cover mounted operators. Breather and drain entries must be plugged for NEMA 4 rating. Spectrum EBM motor control enclosures accommodate popular makes of starters. US: 1-866-764-5454 STIBOINFO((CRH:66008com:2C:343)) CH0 0 2 C- 3 CAN: 1-800-265-0502 Copyright© 2006 Cooper Crouse-Hinds 343 Zoom: 100 2: 5: SYS19: BASE2 PDFINFO 50: 95: 98: JOB: CRMAIN06-0344-3 Name: 2C-344 100: DATE: JAN 19 2006 Time: 5:18:15 PM Operator: RB EBMS Magnetic Line Starters and Enclosures 2C Options COLOR: CMYK TCP: 15001 Cl. I, Div. 1 & 2, Groups B,C,D Cl. II, Div. 1, Groups E,F,G Cl. II, Div. 2, Groups F,G Cl. III NEMA 3,3R,4‡,7BCD,9EFG,12 Explosionproof Dust-Ignitionproof Raintight Wet Locations Watertight Catalog Number System Example The following options are available from the factory by adding suffix to catalog number. Suffixes are added alphanumerically. EBMS1FB-(A)-W6413-(B) (A) Options in this position are additions to the enclosures and should be listed alphanumerically. (B) Options in this position are modifications to the motor starter and should be listed alphanumerically. Description ɀ Less Overload Relays (lighting contactor) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Suffix to be added to Cat. No. CL Position in Cat. No. A ɀ Less overload relays (motor contactor) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . CM A ɀ Control Circuit Transformer, 100VA for NEMA/EEMAC sizes 0-2, 600/480/240-120, 50/60 Hertz, with provision for fusing both primary leads and one secondary lead (fuses not included) . . . . . . . . . . . . . . . . . . . . FTPS100 A FTPS200 A FTPS300 J1 1 A A ɀ Control Circuit Transformer, 200VA for NEMA/EEMAC size 3, 600/480/240-120, 50/60 Hertz, with provision for fusing both primary leads and one secondary lead (fuses not included) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ɀ Control Circuit Transformer, 300VA for NEMA/EEMAC size 4, 5 600/480/240-120, 50/60 Hertz, with provision for fusing both primary leads and one secondary lead (fuses not included) . . . . . . . . . . . . . . . . . . . . ɀ Pilot Light, 120VAC, Red Jewel, w/blank indicating plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ɀ Pilot Light, 120VAC, Green Jewel, w/blank indicating plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . J3 1 A ɀ Less Heaters in Starter Overload Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ɀ Start-Stop Pushbuttons (requires 2 spaces) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0 PB23 1 ‡ B A ɀ On-Off Selector Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . RR2 1‡ A ɀ Hand-Off-Auto Selector Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ɀ Space Heater, 120 Volt, 25 Watts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . RR3 1 ‡ R11 A A ɀ Space Heater, 240 Volt, 25 Watts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . R22 A ɀ Space Heater, 480 Volt, 25 Watts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ɀ Automatic Reset Overload Relay. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . R44 S1 A A ɀ Std. Drain, Class I, B,C&D; Class II, EF&G; Class III . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S756‡ A ɀ Std. Breather & Drain, Class I, B,C&D; Class II, EF&G; Class III . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ɀ Side Conduit Entrances (check factory for application) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S756V‡ S366 A A ɀ Back Conduit Entrances (check factory for application) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S367 A ɀ External Epoxy Finish . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ɀ Internal and External Epoxy Finish . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ɀ Additional control contacts, N.O. or N.C. – for single speed, non-reversing starters only (number limited by design of starter. Details on specific makes and sizes on request.) Aux. Contacts on starter 1 N.O. & 1 N.C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Aux. Contacts on starter 2 N.O. & 2 N.C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Aux. Contacts on starter 3 N.O. & 3 N.C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 Point Term. Block – 30 Amp, 300V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ɀ General Purpose Control Relay, 4 Pole N.O., contacts rated 10A @ 600V, coil 120VAC, 50-60 Hz . . . . . . . . . S752 S753 A A S781 S782 S783 S786 S787* B B B A A 1 When specifying non-standard markings on any one of the following options with Spectrum EBM TM Motor Controls (J1, J3, PB23, RR2, RR3) it is necessary to order DSL Legend Plates for identification and marking of the device(s) being used. See page 329 for DSL Legend Plate listings. * Use this option with NEMA/EEMAC Size 0 or 1 starters necessitates a larger enclosure. Use ‘‘B’’ size enclosure. Example: W/O Starter Enclosure Cat. No. EBMSFA Enclosure for S787 EBMSFB ‡ Enclosure not suitable for NEMA 4 with cover mounted operators. Breather and drain entries must be plugged for NEMA 4 rating. 344 STIBOINFO((CRH:66008com:2C:344)) CH0 0 2 C- 4 Typedriver Name: TS name csm no.: 100 US: 1-866-764-5454 CAN: 1-800-265-0502 Copyright© 2006 Cooper Crouse-Hinds Zoom: 100 2: 5: SYS19: BASE2 PDFINFO 50: 95: 98: JOB: CRMAIN06-0345-2 Name: 2C-345 100: DATE: JAN 19 2006 Time: 5:18:15 PM Operator: JB EBMS Magnetic Line Starters and Enclosures Single-Speed Non-Reversing 3-Pole 60 hertz, 600 VAC Maximum COLOR: CMYK Cl. I, Div. 1 & 2, Groups B,C,D Cl. II, Div. 1, Groups E,F,G Cl. II, Div. 2, Groups F,G Cl. III NEMA 3,3R,4 ‡,7BCD,9EFG,12 TCP: 15001 Typedriver Name: TS name csm no.: 100 Explosionproof Dust-Ignitionproof Raintight Wet Locations Watertight 2C Ordering Information: ɀ To order an enclosure complete with motor starter, insert the manufacturer’s symbol in the designated position (see ‡) of the catalog number. Symbols are shown in the footnotes. ɀ Also specify HP, voltage, frequency, RPM, type and full load ampere rating of motor – or specify ampere rating of heaters. ɍɍ Motor starters are furnished with three heaters when heater ratings are fully specified. ɀ Enclosures without starters may be ordered. Select from the listings below. For catalog numbers of manufacturers motor starters that can be accommodated see Section 6C of this catalog. EBMS Series Enclosures for Magnetic Line Starters Single Speed Non-Reversing Motor Starter Max. HP Polyphase Volts NEMA Size Enclosure Without Starter Cat. No. With Starter Cat. No. ɍɍ 2 120 0 EBMSFA EBMS0FA-*613 3 3 120 240 1 0 EBMSFA EBMSFA EBMS1FA-*613 EBMS0FA-*623 5 5 480 600 0 0 EBMSFA EBMSFA EBMS0FA-*643 EBMS0FA-*663 71⁄2 71⁄2 120 240 2 1 EBMSFB EBMSFA EBMS2FB-*613 EBMS1FA-*623 10 10 480 600 1 1 EBMSFA EBMSFA EBMS1FA-*643 EBMS1FA-*663 15 15 120 240 3 2 EBMSFH EBMSFB EBMS3FH-*613 EBMS2FB-*623 25 25 480 600 2 2 EBMSFB EBMSFB EBMS2FB-*643 EBMS2FB-*663 30 240 3 EBMSFH EBMS3FH-*623 50 50 50 480 600 240 3 3 4 EBMSFH EBMSFH EBMSFH EBMS3FH-*643 EBMS3FH-*663 EBMS4FH-*623 100 100 100 480 600 240 4 4 5 EBMSFH EBMSFH EBMSFL EBMS4FH-*643 EBMS4FH-*663 EBMS5FL-*623 200 200 480 600 5 5 EBMSFL EBMSFL EBMS5FL-*643 EBMS5FL-*663 EBMS Series starter enclosures are available with magnetic line starters. NEMA sizes 0-5. ‡ Enclosure not suitable for NEMA 4 with cover mounted operators. Breather and drain entries must be plugged for NEMA 4 rating. * Motor starters: Manufacturer Allen Bradley Square D General Electric Cutler-Hammer US: 1-866-764-5454 STIBOINFO((CRH:66008com:2C:345)) CH0 0 2 C- 5 CAN: 1-800-265-0502 Copyright© 2006 Cooper Crouse-Hinds Symbol AB D G W 345 Zoom: 100 2: 5: SYS19: BASE2 PDFINFO 50: 95: 98: 100: JOB: CRMAIN06-0346-1 Name: 2C-346 DATE: JAN 19 2006 Time: 5:19:22 PM Operator: RB TCP: 15001 Typedriver Name: TS name csm no.: 100 Cl. I, Div. 1 & 2, Groups B,C,D Cl. II, Div. 1, Groups E,F,G Cl. II, Div. 2, Groups F,G Cl. III NEMA 3,3R,4‡,7BCD,9EFG,12 EBMS Magnetic Line Starters and Enclosures 2C COLOR: CMYK Dimensions Explosionproof Dust-Ignitionproof Raintight Wet Locations Watertight Single-Speed Non-Reversing Sizes 0, 1, 2, 3, 4 and 5 Starters Dimensions are approximate, not for construction purposes. Enclosure Only Cat. No. Enclosure Size Symbol A B C D E F G **J Conduit Entry Trade Size D&Tɍ w/RE K L M N O 1.5⍯ 3.25 3.13 10.25 — — 2⍯ 1.5⍯ 3.25 3.13 10.25 — — 3⍯ 3⍯ 2.5⍯ 2.5⍯ 3.25 3.25 3.13 3.94 10.25 11.66 — — — — 3.25 4.00 3.00 3.50 10.78 13.03 — 41.50 — 18.00 Size 0,1 FVNR Starter§ EBMSFA A 18.25 17.25 19.00 6.00 12.63 14.38 12.13 2⍯ Size 2 FVNR Starter EBMSFB B 25.75 24.75 26.50 6.00 12.63 14.38 12.13 Size 3,4 FVNR EBMSFD*** Starter EBMSFH D H 28.25 27.25 29.00 37.50 36.50 38.25 6.00 12.63 14.06 12.13 6.00 14.25 16.00 13.54 Size 5 FVNR EBMSFK*** K 43.12 41.50 42.25 12.00 17.25 19.88 11.00 (2) 3⍯ (2) 2.5⍯ Starter EBMSFL L 53.25 51.50 52.88 12.00 17.50 20.18 15.00 (2) 4⍯ (2) 3.5⍯ § Use EBMSFB enclosure when S787 option is ordered with size 0 or 1 starter. * 1⍯ Drilled & Tapped conduit entry for control conductors supplied with PLG plug (top & bottom) ** Conduit entrance for power conductors (top and bottom). (All conduit entrances supplied with RE reducer and PLG plug.) *** For Cutler-Hammer W200 Advantage starters. ® ɍ Drilled & Tapped. ‡ Enclosure not suitable for NEMA 4 with cover mounted operators. Breather and drain entries must be plugged for NEMA 4 rating. 346 STIBOINFO((CRH:66008com:2C:346)) CH0 0 2 C- 6 US: 1-866-764-5454 CAN: 1-800-265-0502 Copyright© 2006 Cooper Crouse-Hinds Zoom: 100 2: 5: SYS19: BASE2 PDFINFO 50: 95: 98: 100: JOB: CRMAIN06-0347-3 Name: 2C-347 DATE: JAN 19 2006 Time: 5:19:23 PM Operator: RB COLOR: CMYK Cl. I, Div. 1 & 2, Groups B,C,D Cl. II, Div. 1, Groups E,F,G Cl. II, Div. 2, Groups F,G Cl. III NEMA 3,3R,4‡,7BCD,9EFG,12 Spectrum TM EBM Enclosures Supplied with Cutler-Hammer Advantage TM Starters TCP: 15001 Typedriver Name: TS name csm no.: 100 Explosionproof Dust-Ignitionproof Raintight Wet Locations Watertight 2C Application: Spectrum EBM-E series of hinged cover motor control enclosures are used: ɀ for general motor control – indoors and outdoors – in damp, wet, dirty, dusty hazardous locations without the need for a protective shelter. ɀ in areas where frequent washdowns are necessary or where heavy rain or water spray is prevalent. ɀ for across-the-line starting and stopping of polyphase ac induction motors. ɀ to provide motor overload and undervoltage protection. ɀ on switchracks or other assemblies where it’s desired that motor control be centrally located. Features: ɀ Total compliance to the wiring end room requirements of the National Electrical Code® 1993. ɀ Solid state electronic Cutler-Hammer Advantage TM starter. ɀ Smaller enclosures required than for conventional starter applications. ɀ Elimination of heater elements, contact chatter, and welding due to low voltage supply. ɀ Precise overcurrent protection and constant coil power. ɀ Same performance and labor-saving benefits from the versatile Spectrum EBM Enclosure product line. ɀ Universal mounting plates and hardware for all major manufacturers’ components. ɀ Mercury switch electronic overload reset. ɀ Optional EMPS control devices may be added to enclosure cover. Spectrum EBM-E Series Combination Line Starter with Advantage Starter shown. Circuit breakers not provided in EBMS series. Options: (Starter only) See page 344 for options for the EBM enclosures supplied with Cutler-Hammer Advantage starters. The following suffixes cannot be ordered with this style equipment: 0, S1. Standard Materials: ɀ Body and cover – copper-free aluminum ɀ Operating handle – copper-free aluminum ɀ Operating shafts and bushings – stainless steel ɀ Interior parts – sheet steel, electrogalvanized ɀ Cover bolts, washers, and rectractile springs – stainless steel Electrical Rating Ranges: ɀ Motor starters – NEMA sizes 1-5 Certifications and Compliances: ɀ NEC/CEC: Class I, Division 1 & 2, Groups B,C,D Class II, Division 1, Groups E,F,G, Class II, Division 2, Groups F,G Class III ɀ UL Standards: UL1203 – Hazardous (classified) locations ɀ CSA Standard: C22.2 No. 30 ɀ NEMA: 3, 3R, 4 ‡, 7BCD, 9EFG, 12 ‡ Enclosure not suitable for NEMA 4 with cover mounted operators. Breather and drain entries must be plugged for NEMA 4 rating. US: 1-866-764-5454 STIBOINFO((CRH:66008com:2C:347)) CH0 2 C- 1 5 CAN: 1-800-265-0502 Copyright© 2006 Cooper Crouse-Hinds 347 Zoom: 100 2: 5: SYS19: BASE2 PDFINFO 50: 95: 98: JOB: CRMAIN06-0348-1 Name: 2C-348 2C 100: DATE: JAN 19 2006 Time: 5:19:24 PM Operator: RB COLOR: CMYK TCP: 15001 Typedriver Name: TS name csm no.: 100 Cl. I, Div. 1 & 2, Groups B,C,D Cl. II, Div. 1, Groups E,F,G Cl. II, Div. 2, Groups F,G Cl. III NEMA 3,3R,4‡,7BCD,9EFG,12 Spectrum TM EBM Enclosures Supplied with Cutler-Hammer Advantage TM Starters Dimensions (inches): Ordering Information – Starters ɀ To order an enclosure, determine the electrical requirements of the system and locate the corresponding catalog number from the chart below. ɀ Enclosures can be ordered without starters, universal mounting plates with templates will still be provided. EBM ‘‘E’’ Series Enclosures for Cutler-Hammer Advantage Starters Single Speed, Non-Reversing - EBMCFM-E - EBMCFK-E Dimensions are approximate, not for construction purposes. Motor Starter Max. HP Polyphase Volts 71⁄2 240 10 480 10 600 15 240 25 480 25 600 30 240 50 240 50 480 50 600 100 240 100 480 100 600 200 480 200 600 NEMA Size 1 1 1 2 2 2 3 4 3 3 5 4 4 5 5 Enclosure Without Starter Cat. #‡ EBMSFA-E EBMSFA-E EBMSFA-E EBMSFA-E EBMSFA-E EBMSFA-E EBMSFD-E EBMSFD-E EBMSFD-E EBMSFD-E EBMSFK-E EBMSFD-E EBMSFD-E EBMSFK-E EBMSFK-E With Starter Cat. # EBMS1FA-W6213-E EBMS1FA-W6413-E EBMS1FA-W6613-E EBMS2FA-W6213-E EBMS2FA-W6413-E EBMS2FA-W6613-E EBMS3FD-W6213-E EBMS4FD-W6213-E EBMS3FD-W6413-E EBMS3FD-W6613-E EBMS5FK-W6213-E EBMS4FD-W6413-E EBMS4FD-W6613-E EBMS5FK-W6413-E EBMS5FK-W6613-E ‡ Note: ‘‘Enclosures only’’ are supplied with necessary operators, linkages, and mercury switch electronic overload resets. DIMENSIONS (inches) Enclosure **J Conduit Entry Only Dimensions Trade Size Cat. No. A B C D F G D&Tɍ w/RE K L EBMSFA-E 18.25 17.25 19.40 6.00 14.78 12.13 2⍯ 1.5⍯ 3.25 3.13 EBMSFD-E 28.25 27.25 29.40 6.00 14.46 12.13 3⍯ 2.5⍯ 3.25 3.13 EBMSFK-E 43.12 41.50 42.65 12.00 20.58 15.00 (2) 3⍯ (2) 2.5⍯ 2.50 3.00 ‘‘H‘‘ – Use 1⁄2⍯ diameter bolts for all enclosures listed above. * 1’’ Drilled & Tapped conduit entry for control conductors supplied with PLG plug (top & bottom). ** Conduit entrance for power conductors (top & bottom). (All conduit entrances supplied with RE reducer and PLG plug.) ɍ Drilled & Tapped. ‡ Enclosure not suitable for NEMA 4 with cover mounted operators. Breather and drain entries must be plugged for NEMA 4 rating. 348 STIBOINFO((CRH:66008com:2C:348)) CH0 2 C- 1 6 US: 1-866-764-5454 CAN: 1-800-265-0502 Copyright© 2006 Cooper Crouse-Hinds Zoom: 100 2: 5: SYS19: BASE2 PDFINFO 50: 95: 98: 100: JOB: CRMAIN06-0349-8 Name: 2C-349 DATE: JAN 19 2006 Time: 5:19:25 PM Operator: GK COLOR: CMYK EPC Magnetic Line Starters and Enclosures Cl. I, Div. 1 & 2, Groups C,D Cl. II, Div. 1, Groups E,F,G Cl. II, Div. 2, Groups F,G Cl. III NEMA 3,4,7CD,9EFG,12 TCP: 15001 Typedriver Name: TS name csm no.: 100 Explosionproof Dust-Ignitionproof Raintight Wet Locations Watertight 2C Application: EPC magnetic line starters and enclosures are used: ɀ for across-the-line starting of polyphase ac induction motors ɀ in locations, made hazardous, due to the presence of flammable vapors, gases or highly combustible dusts ɀ in damp, wet or corrosive locations ɀ indoors or outdoors at petroleum refineries, chemical and petrochemical plants and other process industry facilities where similar hazards exist ɀ to provide motor running protection, undervoltage protection, and remote starting and stopping Features: ɀ Quick-opening covers – less than two turns to remove or install ɀ Three section design for ease of installation ɀ Water-shedding construction with female threads on top cover, male threads on bottom cover, and top cover skirted ɀ Specially located stops and locks ensure adequate thread engagement and prevent overtightening ɀ Separate replaceable mounting bracket attached to the rear of the body provides three-point suspension for quick installation and leveling – one keyhole slot at top and two open slots at bottom ɀ Bodies have two taper tapped conduit hubs with integral bushings on the top, and two more directly below ɀ Universal mounting plate and reset mechanism will accommodate any of the motor starters in catalog listing ɀ When interior mounting plate is removed, line and load conductors are easily pulled into the wiring chamber. The interior assembly with starter attached is then replaced, final connections made, and covers assembled ɀ Furnished with third overload relay as standard Standard Materials: ɀ Bodies and covers – copper-free aluminum ɀ Reset handle – copper-free aluminum ɀ Reset shaft – stainless steel ɀ Interior parts – stainless steel Standard Finishes: ɀ Copper-free aluminum – natural ɀ Stainless steel – natural ɀ Sheet steel – electrogalvanized with chromate finish Electrical Rating Ranges: Certifications & Compliances: ɀ NEC/CEC: Class I, Division 1 & 2, Groups C,D Class II, Division 1, Groups E,F,G Class II, Division 2, Groups F,G Cl. III ɀ NEMA/EEMAC: 3, 4, 7CD, 9EFG, 12 ɀ UL Standard: 698 ɀ CSA Standard: C22.2 No. 30 Options: ɀ The following special options are available from factory by adding suffix to Cat. No. and many are available in kit form for field addition to existing units: See page 352 for listing of kits Suffix to be Added to Encl. Description Cat. # Control circuit transformer 600/480/240-120 volts, 50 or 60 hertz (Sizes 0 and 1 – 50VA, 100VA, Size 2 – 100VA-200VA) Fusible – Secondary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FT Primary and secondary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FTPS Automatic reset overload relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S1 Less overload relays (lighting contactor) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . CL Less overload relays (motor contactor). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . CM Auxiliary Contacts:* 1NO/1NC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S781 2NO/2NC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S782 3NO/3NC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S783 Pilot light holes drilled, tapped and plugged for future addition of pilot lights – one hole . . . . . . . . . . . . S541 two holes . . . . . . . . . . . S542 Side bosses drilled and tapped same size as standard hubs . . . . . . . . . . . . . . . . . . . . . . . . . . S366 Back boss drilled and tapped same size as standard hubs . . . . . . . . . . . . . . . . . . . . . . . . . . . . S367 Standard Breather (Cl. I, Groups C,D; Cl. II, Groups E,F,G; Cl. III) . . . . . . . . . . . . . . . . . . . . . . S219 Standard Drain (Cl. I, Groups C,D; Cl. II, Groups E,F,G; Cl. III) . . . . . . . . . . . . . . . . . . . . . . . . . S198 Standard Breather and Drain (Cl. I, Groups C,D; Cl. II, Groups E,F,G; Cl. III) . . . . . . . . . . . . S198V Universal Breather-Drain (Cl. I, Groups C,D; Cl. II, Groups F,G) . . . . . . . . . . . . . . . . . . . . . . . S454‡ (2) Universal-Breather Drains (Cl. I, Groups C,D; Cl. II, Groups F,G) . . . . . . . . . . . . . . . . . . S454V‡ Pushbuttons (heavy duty): START-STOP . . . . . . . . . . . . . . . . . . . . . . . PB3‡ Selector switches (standard duty): ON-OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . RR2‡ HAND-OFF-AUTO . . . . . . . . . . . . . . . . . . . RR3‡ Pilot lights: Red, 120 volt . . . . . . . . . . . . . . . . . . . . . . . . . . . J1 Green, 120 volt. . . . . . . . . . . . . . . . . . . . . . . . . J3 Pilot light transformers: 240 volt† . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . T2 480 volt† . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . T4 600 volt† . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . T5 Space heaters: 120 volt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . R11 240 volt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . R22 480 volt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . R44 ɀ Starter Sizes 0 to 2 inclusive * Application limited by starter or contactor design – consult factory † Required for pilot lights on other than 120 volt control circuits. One required for each lamp ‡ Not suitable for NEMA 4 US: 1-866-764-5454 STIBOINFO((CRH:66008com:2C:349)) CH0 0 2 C- 7 CAN: 1-800-265-0502 Copyright© 2006 Cooper Crouse-Hinds 349 Zoom: 100 2: 5: SYS19: BASE2 PDFINFO 50: 95: 98: 100: JOB: CRMAIN06-0350-6 Name: 2C-350 2C DATE: JAN 19 2006 Time: 5:19:26 PM Operator: JB EPC Magnetic Line Starters and Enclosures COLOR: CMYK TCP: 15001 Cl. I, Div. 1 & 2, Groups C,D Cl. II, Div. 1, Groups E,F,G Cl. II, Div. 2, Groups F,G Cl. III NEMA 3,4,7CD,9EFG,12 Dimensions (inches)* Single-Speed Non-Reversing Sizes 0, 1, and 2 Starters Cat. # EPC Int. Dia. a b c d e f g h j k l m n p 97-FT 97-FTPS 7⍯ Dimensionsɍ 105⁄8 2413⁄16 3713⁄16 1411⁄16 113⁄4 711⁄16 53⁄8 9 4 73⁄8 21⁄16 93⁄8 51⁄4 11⁄4 97 7⍯ Dimensions 105⁄8 1913⁄16 2513⁄16 1411⁄16 63⁄4 711⁄16 53⁄8 2 4 73⁄8 21⁄16 93⁄8 51⁄4 11⁄4 ɍ For units with Control Circuit Transformer (suffix FT or FTPS) * Dimensions are approximate, not for construction 350 STIBOINFO((CRH:66008com:2C:350)) CH0 0 2 C- 8 US: 1-866-764-5454 CAN: 1-800-265-0502 Copyright© 2006 Cooper Crouse-Hinds Typedriver Name: TS name csm no.: 100 Explosionproof Dust-Ignitionproof Raintight Wet Locations Watertight Zoom: 100 2: 5: SYS19: BASE2 PDFINFO 50: 95: 98: 100: JOB: CRMAIN06-0351-3 Name: 2C-351 DATE: JAN 19 2006 Time: 5:19:27 PM Operator: RB EPC Magnetic Line Starters and Enclosures Single-Speed Non-Reversing 3-Pole 60 hertz, 600VAC Maximum Ordering Information: COLOR: CMYK Cl. I, Div. 1 & 2, Groups C,D Cl. II, Div. 1, Groups E,F,G Cl. II, Div. 2, Groups F,G Cl. III NEMA 3,4,7CD,9EFG,12 Motor Starter To order an enclosure complete with starter, insert the manufacturer’s symbol in the designated position of the catalog number. Symbols are shown in the footnote at the bottom of this page. Specify hp, voltage, frequency, rpm, type and full load ampere rating of motor – or specify ampere rating of heaters. ɍɍ Starters are furnished with three heaters when heater ratings are fully specified. Enclosures only can be ordered. Select from listings. For starters that can be accommodated see Table 1 in Section 6C. Detailed information on starter and heater selection is given in Section 6C. TCP: 15001 Typedriver Name: TS name csm no.: 100 Explosionproof Dust-Ignitionproof Raintight Wet Locations Watertight 2C Enclosure Volts 120 NEMA/EEMAC Size 0 Hub Size 11⁄4 Int. Dia. 7 Without Starter Cat. # EPC97 With Starter Cat. # ɍɍ EPC970-†613 3 3 120 240 1 0 11⁄4 11⁄4 7 7 EPC97 EPC97 EPC971-†613 EPC970-†623 5 5 480 600 0 0 11⁄4 11⁄4 7 7 EPC97 EPC97 EPC970-†643 EPC970-†653 71⁄2 240 1 11⁄4 7 EPC97 EPC971-†623 10 10 480 600 1 1 11⁄4 11⁄4 7 7 EPC97 EPC97 EPC971-†643 EPC971-†653 Max. HP Polyphase 2 † Motor Starters: Manufacturer Allen-Bradley General Electric Square D Cutler-Hammer Symbol AB G D W US: 1-866-764-5454 STIBOINFO((CRH:66008com:2C:351)) CH0 0 2 C- 9 CAN: 1-800-265-0502 Copyright© 2006 Cooper Crouse-Hinds 351 Zoom: 100 2: 5: SYS19: BASE2 PDFINFO 50: 95: 98: 100: JOB: CRMAIN06-0352-1 Name: 2C-352 2C DATE: JAN 19 2006 Time: 5:19:28 PM Operator: RB COLOR: CMYK TCP: 15001 Typedriver Name: TS name csm no.: 100 Special Feature Kits For EPC Enclosures Pushbutton Station and Selector Switch Kits Pilot Light Kits EPC magnetic line starter and EPC combination line starter enclosures are provided as standard with switch operating shaft holes drilled, tapped and plugged. Pushbutton stations and selector switches can be assembled in these enclosures in the field, using kits listed below. When EPC magnetic line starter and EPC combination line starter enclosures have been ordered with pilot light holes drilled, tapped and plugged (Cat. No. suffix S541 and S542), pilot lights can be assembled in the field, using kits listed below. Description Applies to Cat. # Pilot light assembly less transformer 7⍯, 9⍯, 11⍯ EPC EMP015-J†-KIT Pilot light assemblies with transformer and transformer mounting strap (for single pilot light) suffix S541 7⍯ EPC only 9⍯ EPC only 11⍯ EPC only EPC87-J†-T†-KIT EPC892-J†-T†-KIT EPC813-J†-T†-KIT 2 pilot light assemblies with 2 transformers and transformer mounting strap (for double pilot light) suffix S542 7⍯ EPC only 9⍯ EPC only 11⍯ EPC only EPC87-J†-J†-T†-KIT EPC892-J†-J†-T†-KIT EPC813-J†-J†-T†-KIT Applies to 7⍯, 9⍯, 11⍯ EPC Description Cat. # START-STOP pushbutton station assembly EPC-PB3-KIT Replacement pushbutton station only for EPC-PB3-KIT 16320-N ON-OFF selector switch assembly (2 position) EPC-RR2-KIT Replacement pilot light transformer only (240V primary) All units 15129-A Replacement switch only for EPC-RR2-KIT ESWP126 Replacement pilot light transformer only (480V primary) All units 15130-A Replacement pilot light transformer only (600V primary) All units 15131-A HAND-OFF-AUTO selector switch assembly (3 position) EPC-RR3-KIT Replacement switch only for EPC-RR3-KIT ESWP126 † Insert color symbol from table below and add primary voltage symbol (T2 for 240, T4 for 480 or T5 for 600 volts). Example: EPC87-J†-J†-T†-KIT with red and green pilot lights for 480 volts is EPC-J1-J3-T4-KIT. 352 STIBOINFO((CRH:66008com:2C:352)) CH0 2 C- 1 0 US: 1-866-764-5454 CAN: 1-800-265-0502 Color Symbol Color Symbol Red Green Amber J1 J3 J6 Clear Blue J10 J11 Copyright© 2006 Cooper Crouse-Hinds Zoom: 100 2: 5: SYS19: BASE2 PDFINFO 50: 95: 98: 100: JOB: CRMAIN06-0353-6 Name: 2C-353 DATE: JAN 19 2006 Time: 5:19:29 PM Operator: GK COLOR: CMYK Cl. I, Div. 1 & 2, Groups C,D Cl. II, Div. 1, Groups E,F,G Cl. II, Div. 2, Groups F,G Cl. III NEMA 3,7CD,9EFG,12 EMN Manual Line Starters and Enclosures 600VAC Maximum TCP: 15001 Typedriver Name: TS name csm no.: 100 Explosionproof Dust-Ignitionproof Raintight Wet Locations 2C Application: EMN manual line starters and enclosures are used: ɀ for manual across-the-line starting of single and polyphase ac motors ɀ to provide motor running protection and manual starting and stopping ɀ in locations made hazardous due to the presence of flammable vapors, gases, or high combustible dusts ɀ for installation in petroleum refineries, chemical and petrochemical plants, and other process industry facilities ɀ in damp, wet, or corrosive locations Features: ɀ Compact, rectangular enclosure makes optimum use of internal space ɀ Operating handle may be padlocked in either ‘‘ON’’ or ‘‘OFF’’ position ɀ Compact design allows installation in area where space is limited ɀ Furnished with drilled and tapped conduit openings ɀ Polyphase manual starters are furnished with third overload relay as standard Standard Materials: Ordering Information: Specify hp, voltage, frequency, number of phases, rpm, type and full load ampere rating of motor – or specify ampere rating of heaters. ɀ Bodies, covers and toggle operator – copper-free aluminum ɀ Operating shaft – stainless steel ɀ Internal operating bail – sheet steel or aluminum Motor Starter NEMA Size Poles (Phase) Max. AC HP Ratings 208/ 115V 240V Standard Finishes: M-0 M-1 M-1P M-0 2 (1PH) 2 (1PH) 2 (1PH) 3 (3PH) 3 (1PH) 3 (3PH) 1 2 3 2 2 3 ɀ Copper-free aluminum – natural ɀ Stainless steel – natural ɀ Sheet steel – electrogalvanized with chromate finish Electrical Rating Ranges: M-1 2 3 5 3 3 71⁄2 ɀ Starter sizes 0, 1, 1P Enclosure Without Starter Certifications & Compliances: Starter Manufacturer Enclosure Cat. #§ Cutler-Hammer EMN24 ɀ NEC/CEC: Class I, Division 1 & 2, Groups C,D Class II, Division 1, Groups E,F,G Class II, Division 2, Groups F,G Class III ɀ NEMA/EEMAC: 3, 7CD, 9EFG, 12 ɀ UL Standard: 698 ɀ CSA Standard: C22.2 No. 14 Two pole starters require one heater; three pole starters have three heaters. See page 446 for starter and heater selection. For starter Cat. No. refer to Table 3 in Section 6C. 480/ 600V Enclosure With Starter Cat. # 5 EMN24-W20 EMN24-W21 EMN24-W21P EMN24-W30 10 EMN24-W31 Dimensions* (inches) Options: ɀ The following special options are available from factory by adding suffix to Cat. #: Suffix to be Added to Encl. Description Cat. # Standard Breather (Cl. I, Groups C,D; Cl. II, Groups E,F,G; Cl. III) . . . . . . . . . . . . S219 Standard Drain (Cl. I, Groups C,D; Cl. II, Groups E,F,G; Cl. III) . . . . . . . . . . . . S198 Standard Breather and Drain (Cl. I, Groups C,D; Cl. II, Groups E,F,G; Cl. III) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S198V Universal Breather-Drain (Cl. I, Groups C,D; Cl. II, Groups F,G). . . . . . . . S454 (2) Universal Breather-Drains (Cl. I, Groups C,D; Cl. II, Groups F,G) . . . . . . S454V US: 1-866-764-5454 STIBOINFO((CRH:66008com:2C:353)) CH0 2 C- 1 1 § Enclosures are furnished with two 11⁄4⍯ drilled and tapped openings with 11⁄4⍯ to 1⍯ reducers. * Dimensions are approximate, not for construction purposes. CAN: 1-800-265-0502 Copyright© 2006 Cooper Crouse-Hinds 353 Zoom: 100 2: 5: SYS19: BASE2 PDFINFO 50: 95: 98: JOB: CRMAIN06-0354-2 Name: 2C-354 2C 100: DATE: JAN 19 2006 Time: 5:19:30 PM Operator: JB EFD Manual Motor Starting Switches and Enclosures COLOR: CMYK TCP: 15001 Typedriver Name: TS name csm no.: 100 Cl. I, Div. 1 & 2, Groups B*,C,D Cl. II, Div. 1, Groups E,F,G Cl. II, Div. 2, Groups F,G Cl. III NEMA 3,7B*CD,9EFG,12 Explosionproof Dust-Ignitionproof Raintight Wet Locations Application: EFD manual motor starting and stopping switch enclosures are used: ɀ for manual starting of small ac or dc motors ɀ in locations, made hazardous, due to the presence of flammable vapors, gases or highly combustible dusts ɀ for installation at petroleum refineries, chemical and petrochemical plants and in other process industry facilities where similar hazards exist Features: ɀ Enclosure is small and compact ɀ Accurately ground flange on both body and cover for flame-tight joint ɀ Switch can be padlocked in either ‘‘ON’’ or ‘‘OFF’’ positions ɀ Dead end (EFD) or through feed (EFDC) hubs in 3⁄4⍯ to 1⍯ size EFD dead end EFDC through feed Standard Materials: ɀ Bodies and covers – Feraloy® iron alloy ɀ Operating handle – type 6/6 nylon ɀ Operating shaft – stainless steel Standard Finishes: ɀ Feraloy iron alloy – electrogalvanized and aluminum acrylic paint ɀ Type 6/6 nylon – natural (black) ɀ Stainless steel – natural Certifications and Compliances: ɀ NEC/CEC: Class I, Division 1 & 2, Groups B*,C,D Class II, Division 1, Groups E,F,G Class II, Division 2, Groups F,G Class III ɀ NEMA: 3, 7B*CD, 9EFG, 12 ɀ UL Standard: 698 ɀ CSA Standard: C22.2 No. 30 Without Overload Protection With Switches Poles Cat. # 2 Square D Class 2510 Type KO-1 GE-TC2368S 3 Poles 2 3 HP 115VAC 1 3⁄4 1 3⁄4 1 With Switch Cat. # EFD218-T8 EFD318-T8 EFD2419 EFD3419 Dimensions (inches) Poles Hub Size 2 3⁄4 3 3⁄4 1 1 conduit opening for Group B usage. STIBOINFO((CRH:66008com:2C:354)) CH0 2 C- 1 2 CAN: 1-800-265-0502 With Switch Cat. # EFDC218-T8 EFDC318-T8 EFDC2419 EFDC3419 Dimensions are approximate, not for construction purposes * Add GB suffix. Seals must be installed within 1-1/2⍯ of each US: 1-866-764-5454 460-575VAC 3 Through feed Hub Size Hub Size 3/4 1 354 230VAC 2 30A., 240VAC, 7-1/2 hp 20A., 600VAC, 15 hp Dead end Options: ɀ The following special options are available from factory by adding suffix to Cat. No.: Suffix to be Added to Encl. Description Cat. # For use in Group B Hazardous areas. . . . GB* Switch Ratings Amps 250VAC 600VAC 30 20 Copyright© 2006 Cooper Crouse-Hinds Dim. ‘‘h’’ 7/8 1 Dim. ‘‘a’’ 13/16 15/16 Zoom: 100 2: 5: SYS19: BASE2 PDFINFO 50: 95: 98: JOB: CRMAIN06-0355-5 Name: 2C-355 100: DATE: JAN 19 2006 Time: 5:19:31 PM Operator: JB EDS Factory Sealed Manual Motor Starting Switches and Enclosures COLOR: CMYK TCP: 15001 Cl. I, Div. 1 & 2, Groups B*,C,D Cl. II, Div. 1, Groups E,F,G Cl. II, Div. 2, Groups F,G Cl. III NEMA 3,7B*CD,9EFG Typedriver Name: TS name csm no.: 100 Explosionproof Dust-Ignitionproof Raintight Wet Locations 2C Standard Finishes: Feraloy iron alloy – electrogalvanized and aluminum acrylic paint ɀ Copper-free aluminum – natural ɀ Type 6/6 nylon – black ɀ Stainless steel – natural Certifications and Compliances: EDSC2199 ɀ NEC/CEC: Class I, Division 1 & 2, Groups B*,C,D Class II, Division 1, Groups E,F,G Class II, Division 2, Groups F,G Class III ɀ NEMA/EEMAC: 3,7B*CD,9EFG ɀ UL Standard: 894, 698 ɀ CSA Standard: C22.2 No. 30 EDS2299 Application: Factory sealed enclosures are installed in a rigid metallic conduit system for surface mounting adjacent to or remote from equipment being controlled and are used: ɀ to prevent arcing of enclosed device from causing ignition of a specific hazardous atmosphere or atmospheres external to the enclosure ɀ in industrial areas such as chemical plants, oil and gas refineries, paint and varnish manufacturing plants, gasoline bulk loading terminals, grain elevators, grain processing industries, coal processing or handling areas, or metal handling or finishing areas where atmosphere may contain hazardous gases and/or dust ɀ in non-hazardous areas where sturdy, durable enclosures are required ɀ in conjunction with magnetic starters or contactors for remote control of motors Manual motor starting switch enclosures are used: ɀ for manual starting of small ac or dc motors ɀ to provide manual starting and stopping and, in the case of units with heaters, motor running protection Options: Suffix to be Added to Cat. # Description For use in Group B hazardous areas. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . GB* Bodies and covers (single and two gang units) – copper-free aluminum. . . . . . . . . . . . . . . . . . . SA Standard Materials: ɀ Bodies – Feraloy® iron alloy (U.S.); copper-free aluminum (Canada). ɀ Shafts & bushings – stainless steel ɀ Sealing enclosures – copper-free aluminum Dimensions (inches) Features: Dimensions are approximate, not for construction purposes. Side Hub Dim. Dim. View Size ‘‘h’’ ‘‘i’’ 7⁄8 13⁄16 3⁄4 15⁄16 1 1 Front View Factory sealed devices have many distinct advantages: ɀ reduce installation problems ɀ eliminate external seals ɀ lower installation costs ɀ improve safety ɀ mounting lugs and taper tapped hubs with integral bushings ɀ large machine screws for fastening covers to bodies ɀ lockout hole for padlock having 1⁄4⍯ hasp is provided ɀ close tolerances in machining of wide, mating flanges and journalled shafts and bearings produce flametightness of enclosure joints ɀ dead end (EDS) or through feed (EDSC) hubs – 3⁄4⍯ or 1⍯ sizes Single gang Two gang Surface covers have same length and width as single & 2 gang bodies. * Seals must be installed within 11⁄2⍯ of each conduit opening in Division 1 US: 1-866-764-5454 STIBOINFO((CRH:66008com:2C:355)) CH0 2 C- 1 7 CAN: 1-800-265-0502 Copyright© 2006 Cooper Crouse-Hinds 355 Zoom: 100 2: 5: SYS19: BASE2 PDFINFO 50: 95: 98: 100: JOB: CRMAIN06-0356-4 Name: 2C-356 DATE: JAN 19 2006 Time: 5:19:32 PM Operator: RB With Allen-Bradley Bulletin 600 Switches With General Electric Switches Maximum HP Ratings Maximum HP Ratings Poles 115-230 Volts AC 1 2 1 hp 1 hp 115-230 Volts DC Cat. # Poles 115-230 Volts AC 115 Volts DC 3⁄4 A-B BUL 600 TOX4 A-B BUL 600 TOX5 1 2 1 hp 1 hp 1 hp 1 hp hp Single Gang Hub Poles Size 3⁄4 1 1 3⁄4 2 1 1 2 1 3⁄4 1 Typedriver Name: TS name csm no.: 100 230 Volts DC 1⁄4 hp 1 hp Explosionproof Dust-Ignitionproof Raintight Wet Locations Cat. # GE-CR101-Y GE-CR101-H Single Gang Dead end Cat. # EDS2199† EDS3199† EDS21100† EDS31100† Through feed Cat. # EDSC2199† EDSC3199† EDSC21100† EDSC31100† EDS2299† EDS3299† EDS22100† EDS32100† EDSC2299† EDSC3299† EDSC22100† EDSC32100† Hub Poles Size 3⁄4 1 1 3⁄4 2 1 Two Gang 3⁄4 TCP: 15001 Cl. I, Div. 1 & 2, Groups B*,C,D Cl. II, Div. 1, Groups E,F,G Cl. II, Div. 2, Groups F,G Cl. III NEMA 3,7B*CD,9EFG,12 EDS Factory Sealed Manual Motor Starting Switches and Enclosures 2C COLOR: CMYK Dead end Cat. # EDS21093† EDS31093† EDS21094† EDS31094† Through feed Cat. # EDSC21093† EDSC31093† EDSC21094† EDSC31094† EDS22093† EDS32093† EDS22094† EDS32094† EDSC22093† EDSC32093† EDSC22094† EDSC32094† Two Gang 1 2 3⁄4 1 3⁄4 1 These heaters are for motors rated 40°C continuously. For motors rated 50°C or 55°C, multiply full load motor current by 0.9 and use this value to select heaters. Symbol 0 (zero) must be used to indicate heater omitted. Heater Table (Allen-Bradley) Max. Motor Full-Load Amps 0.17 0.21 0.25 0.32 0.39 0.46 0.57 0.71 0.79 0.87 0.98 1.08 1.19 1.30 1.43 1.58 1.75 1.88 2.13 2.40 2.58 CrouseHinds Symbol Number P1 P2 P3 P4 P5 P6 P7 P8 P9 P10 P11 P12 P13 P14 P15 P16 P17 P18 P19 P20 P21 Max. Motor Full-Load Amps 2.92 3.09 3.32 3.77 4.16 4.51 4.93 5.43 6.03 6.83 7.72 8.24 8.9 9.6 10.8 12.0 13.5 15.2 Heater Table (General Electric) CrouseHinds Symbol Number P22 P23 P24 P25 P26 P27 P28 P29 P30 P31 P32 P33 P34 P35 P36 P37 P38 P39 Max. Motor Full-Load Amps .48 .53 .58 .65 .71 .78 .86 .95 1.04 1.14 1.25 1.37 1.49 1.63 1.78 1.95 2.13 2.32 2.53 2.76 CrouseHinds Symbol Number G2 G3 G4 G5 G6 G7 G8 G9 G10 G11 G12 G13 G14 G15 G16 G17 G18 G19 G20 G21 Max. Motor Full-Load Amps 3.01 3.27 3.56 3.88 4.22 4.60 5.00 5.43 5.90 6.41 6.98 7.60 8.25 8.95 9.75 10.6 11.4 12.5 13.6 14.8 16.0 CrouseHinds Symbol Number G22 G23 G24 G25 G26 G27 G28 G29 G30 G31 G32 G33 G34 G35 G36 G37 G38 G39 G40 G41 G42 † Includes one interchangeable heater. Select heater from the table below individual listings and use symbol number as second section of the Cat. No. Example: EDS2199-P5. Insert symbol 0 (zero) to omit heater. * Add GB suffix. Seals must be installed within 11⁄2⍯ of each conduit opening for Group B usage. 356 STIBOINFO((CRH:66008com:2C:356)) CH0 2 C- 1 3 US: 1-866-764-5454 CAN: 1-800-265-0502 Copyright© 2006 Cooper Crouse-Hinds Zoom: 100 2: 5: SYS19: BASE2 PDFINFO 50: 95: 98: JOB: CRMAIN06-0357-2 Name: 2C-357 100: DATE: JAN 19 2006 Time: 5:19:32 PM Operator: RB COLOR: CMYK Cl. I, Div. 1 & 2, Groups B*,C,D Cl. II, Div. 1, Groups E,F,G Cl. II, Div. 2, Groups F,G Cl. III EDS Factory Sealed Manual Motor Starting Switches and Enclosures TCP: 15001 Typedriver Name: TS name csm no.: 100 Explosionproof Dust-Ignitionproof Raintight Wet Locations 2C With Cutler-Hammer Switches Maximum HP Ratings 120-240 32 120 240 Poles Volts AC Volts DC Volts DC Volts DC Cat. # 1⁄4 hp 1⁄4 hp 1⁄4 hp WEST-MST01 1 1 hp 1⁄4 hp 1 hp 1 hp WEST-MST02 2 1 hp Single Gang Poles 1 2 Hub Size 3⁄4 1 3⁄4 1 Dead end Cat. # EDS21101† EDS31101† EDS21102† EDS31102† Through feed Cat. # EDSC21101† EDSC31101† EDSC21102† EDSC31102† EDS22101† EDS32101† EDS22102† EDS32102† EDSC22101† EDSC32101† EDSC22102† EDSC32102† Two Gang 1 2 3⁄4 1 3⁄4 1 These heaters are for motors rated 40°C continuously. For motors rated 50°C or 55°C, multiply full load motor current by 0.9 and use this value to select heaters. Symbol 0 (zero) must be used to indicate heater omitted. Heater Table (Cutler-Hammer) Max. Motor Full-Load Amps CrouseHinds Symbol Number Max. Motor Full-Load Amps CrouseHinds Symbol Number .43 .48 .53 .58 .64 .71 .78 .87 .95 1.03 1.15 1.27 1.35 1.51 1.67 1.83 1.99 2.23 2.47 2.71 W 1 W 2 W 3 W 4 W 5 W 6 W 7 W 8 W 9 W10 W11 W12 W13 W14 W15 W16 W17 W18 W19 W20 2.95 3.27 3.59 3.99 4.39 4.79 5.26 5.83 6.39 7.03 7.74 8.46 9.35 10.30 11.35 12.47 13.67 15.12 16.00 W21 W22 W23 W24 W25 W26 W27 W28 W29 W30 W31 W32 W33 W34 W35 W36 W37 W38 W39 † Includes one interchangeable heater. Select heater from the table below individual listings and use symbol number as second section of the Cat. No. Example: EDS21101-W5. Insert symbol 0 (zero) to omit heater. * Add GB suffix. Seals must be installed within 11⁄2⍯ of each conduit opening for Group B usage. US: 1-866-764-5454 STIBOINFO((CRH:66008com:2C:357)) CH0 2 C- 1 4 CAN: 1-800-265-0502 Copyright© 2006 Cooper Crouse-Hinds 357 Zoom: 100 2: 5: SYS19: BASE2 PDFINFO 50: 95: 98: JOB: CRMAIN06-0358-2 Name: 2C-358 2C 100: DATE: JAN 19 2006 Time: 5:19:33 PM Operator: RB COLOR: CMYK TCP: 15001 UL/cUL Listed Class I, Division 2, Groups A, B, C, D Class I, Zones 1 and 2, AEx de HB + H2, T5, T6 Class II, Division 1, Groups E, F, G (cUL) Explosion Protected Manual Motor Starters 25 Amp, 690 VAC Non-Metallic Enclosure Application Explosion protected manual motor starters are used in a metallic conduit or cable system for surface mounting to protect motors against overload and phase failure. Features ɀ Explosion protected factory sealed circuit breaker and manual motor starter ɀ Innovative break-line in cover allows full wiring access, making installation quick and easy. ɀ Switch handle provides clear indication of switch position ɀ Lockable handle meets OSHA lockout/ tagout requirements, provision for 3 padlocks ɀ Large rotary handle provides easy gripping with gloved hands ɀ Captive cover screws Certifications & Compliances ɀ UL/cUL Listed ɀ Class I, Division 2, Groups A, B, C, D ɀ Class I, Zones 1 and 2, Ex de IIB+H2, T6 ɀ Class II, Division 1, Groups E, F, G (cUL) ɀ CENELEC - PTB 99-ATEX 1162 ɀ EEx de IIC, T6, Zones 1 and 2. ɀ IP 66, NEMA 4X Standard Materials Enclosure - Fiberglass-reinforced polyester ɀ Nonmetallic, corrosion resistant ɀ Increased safety Ex-e protection ɀ Impact Resistant ɀ NEMA 4X, IP 66 Protection ɀ Enclorure meets UL 94-VO ɀ UV rated Enclosure Gasket - Silicon Handle - Impact-resistant thermoplastic Cover Screws - Stainless steel Conduit Entries: Zinc Myers Hubs Brass Mounting plate - Ground continuity Technical Data 358 STIBOINFO((CRH:66008com:2C:358)) CH0 6 F - 1 6 Type of Protection (A)Ex ed IIC T5, T6 Rated Voltage Rated Current Rated Current, aux. contact Short Circuit Under voltage trip Connection Terminals Connection terminals, aux. contact Up to 690 VAC Up to 25 A 2A See table on next page Tripping at 15% - 75% V-rated Switching - on when V> 80% V-rated Up to 10mm2 2 × 2.5 mm2 Conduit or Cable entries 2 × 3⁄4⍯ Myers hubs Weight 5.5 Ibs./ 2.5 Kg. US: 1-866-764-5454 CAN: 1-800-265-0502 Copyright© 2006 Cooper Crouse-Hinds Typedriver Name: TS name csm no.: 100 CENELEC - PTB 99, ATEX 1162 CERTIFIED EEx de IIC, T6, Zones 1 and 2 EEx de IIC, T6 Zones 21 and 22 IP66, NEMA 4X Zoom: 100 2: 5: SYS19: BASE2 PDFINFO 50: 95: 98: JOB: CRMAIN06-0359-3 Name: 2C-359 100: DATE: JAN 19 2006 Time: 5:19:34 PM Operator: TB COLOR: CMYK 25 Amp, 690 VAC Non-Metallic Enclosures Typedriver Name: TS name csm no.: 100 CENELEC - PTB 99, ATEX 1162 CERTIFIED EEx de IIC, T6, Zones 1 and 2 EEx de IIC, T6 Zones 21 and 22 IP66, NEMA 4X UL/cUL Listed Class I, Division 2, Groups A, B, C, D Class I, Zones 1 and 2, AEx de HB + H2, T5, T6 Class II, Division 1, Groups E, F, G (cUL) Explosion Protected Manual Motor Starters TCP: 15001 2C Short Circuit Protection Setting Range 230 VAC AIC 0.1 A - 1.6 A 1.6 A - 2.5 A 2.5 A - 4.0 A 4.0 A - 6.3 A 6.3 A - 9.0 A 9.0 A - 12.5 A 12.5 A - 16.0 A 16.0 A - 20.0 A 20.0 A - 25.0 A 400 VAC AIC 500 VAC AIC 690 VAC AIC 40 30 30 20 20 20 20 40 10 3 3 3 3 2 2 Short-circuit proof. No back-up fuse required 50 50 50 50 50 Wiring Diagram Dimensions (Inches) Ordering Information: Setting Range or rated current 0.1 - 0.16 A 0.16 - 0.25 A 0.25 - 0.40 A 0.40 - 0.63 A 0.63 - 1.0 A 1.0 - 1.6 A 1.6 - 2.5 A 2.5 - 4.0 A 4.0 - 6.3 A 6.3 - 9.0 A 9.0 - 12.5 A 12.5 - 16 A 16 - 20 A 20 - 25 A Catalog Number GHG 635 1101 L0101 GHG 635 1101 L0102 GHG 635 1101 L0103 GHG 635 1101 L0104 GHG 635 1101 L0105 GHG 635 1101 L0106 GHG 635 1101 L0107 GHG 635 1101 L0108 GHG 635 1101 L0109 GHG 635 1101 L0110 GHG 635 1101 L0111 GHG 635 1101 L0112 GHG 635 1101 L0113 GHG 635 1101 L0114 US: 1-866-764-5454 STIBOINFO((CRH:66008com:2C:359)) CH0 6 F - 1 6 Accessory Options 1 ⍧ without aux. contact ៑ 2 ⍧ with aux contact 1 NO + 1 NC CAN: 1-800-265-0502 Copyright© 2006 Cooper Crouse-Hinds 359 Zoom: 100 2: 5: SYS19: BASE2 PDFINFO 50: 95: 98: JOB: CRMAIN06-0360-3 Name: 2C-360 2C 100: DATE: JAN 19 2006 Time: 5:19:35 PM Operator: RB COLOR: CMYK TCP: 15001 Typedriver Name: TS name csm no.: 100 NEMA 3,4,12 Raintight Wet Locations MC Manual Motor Starting Switches and Enclosures Application: MC manual motor starting switches and enclosures are used: ɀ for manual starting of small ac and dc motors of one horsepower or less (see page 361 for ratings) ɀ in damp, wet or corrosive locations such as dairies, meat packing plants, chemical plants and outdoor locations ɀ to provide motor running protection and manual starting and stopping Features: ɀ Enclosure is compact and gasketed to meet NEMA/EEMAC 4 requirements for watertightness ɀ Switch can be padlocked in either the ‘‘ON’’ or ‘‘OFF’’ positions ɀ Provided with dead end (MC) or throughfeed (MCC) hubs – 1⁄2⍯ and 3⁄4⍯ sizes – with mounting feet MC dead end MCC through feed Standard Materials: ɀ Body and cover – Feraloy® iron alloy ɀ Operating handle – copper-free aluminum ɀ Operating shaft – stainless steel Standard Finishes: ɀ Feraloy – electrogalvanized and aluminum acrylic paint ɀ Copper-free aluminum – natural ɀ Stainless steel – natural Certifications and Compliances: Dimensions (inches)* ɀ NEMA/EEMAC: 3, 4, 12 ɀ UL Standard: 508 ɀ CSA Standard: C22.2 No. 14 Hub Size a b 360 STIBOINFO((CRH:66008com:2C:360)) CH0 0 2 C- 1 US: 1-866-764-5454 1⁄2 3⁄4 7⁄8 7⁄8 5⁄8 3⁄4 CAN: 1-800-265-0502 * Dimensions are approximate, not for construction purposes. Copyright© 2006 Cooper Crouse-Hinds Zoom: 100 2: 5: SYS19: BASE2 PDFINFO 50: 95: 98: JOB: CRMAIN06-0361-2 Name: 2C-361 100: DATE: JAN 19 2006 Time: 5:19:36 PM Operator: RB MC Manual Motor Starting Switches and Enclosures Poles 1 2 TCP: 15001 2C These heaters are for motors rated 40°C continuously. For motors rated 50°C or 55°C, multiply full load motor current by 0.9 and use this value to select heaters. Symbol 0 (zero) may be used to indicate heater omitted. Cat. # MST01 MST02 Heater Table Full Load Maximum Horsepower Ratings Volts 120/240 AC 32 DC 120/240 DC 240 DC 1-Pole 1 1⁄4 Motor Current 2-Pole 1 1⁄4 1 .40 — .43 .44 — .48 .49 — .53 .54 — .58 .59 — .64 .65 — .71 .72 — .78 .79 — .87 .88 — .95 .96 — 1.03 1.04 — 1.15 1.16 — 1.27 1.28 — 1.35 1.36 — 1.51 1.52 — 1.67 1.68 — 1.83 1.84 — 1.99 2.00 — 2.23 2.24 — 2.47 2.48 — 2.71 2.72 — 2.95 2.96 — 3.27 3.28 — 3.59 3.60 — 3.99 4.00 — 4.39 4.40 — 4.79 4.80 — 5.26 5.27 — 5.83 5.84 — 6.39 6.40 — 7.03 7.04 — 7.74 7.75 — 8.46 8.47 — 9.35 9.36 — 10.30 10.31 — 11.35 11.36 — 12.47 12.48 — 1.367 13.68 — 15.12 15.13 — 16.00 1⁄4 MC Single Gang (Dead End) Poles 1 1 2 2 Hub Size 1⁄2 3⁄4 1⁄2 3⁄4 Enclosure With Switch Cat. # MC1211† MC2211† Without Switch Cat. # MC1212B MC2212B MC1212† MC2212† MC1212B MC2212B MCC Single Gang (through feed) Poles 1 1 2 2 Hub Size 1⁄2 3⁄4 1⁄2 3⁄4 Enclosure With Switch Cat. # MCC1211† MCC2211† Without Switch Cat. # MCC1212B MCC2212B MCC1212† MCC2212† MCC1212B MCC2212B Typedriver Name: TS name csm no.: 100 NEMA 3,4,12 Raintight Wet Locations MC Manual Motor Starting Switches Manufacturer Cutler-Hammer Cutler-Hammer COLOR: CMYK Heater Rating .50 .55 .61 .67 .74 .81 .89 .98 1.10 1.20 1.30 1.45 1.60 1.70 1.90 2.10 2.30 2.50 2.80 3.10 3.40 3.70 4.10 4.50 5.00 5.50 6.00 6.60 7.30 8.00 8.80 9.70 10.60 11.70 12.90 14.20 15.60 17.10 18.60 Cooper CrouseHinds Symbol Number W1 W2 W3 W4 W5 W6 W7 W8 W9 W10 W11 W12 W13 W14 W15 W16 W17 W18 W19 W20 W21 W22 W23 W24 W25 W26 W27 W28 W29 W30 W31 W32 W33 W34 W35 W36 W37 W38 W39 † Includes one interchangeable heater. Select heater from table above and use symbol number as second section of the Cat. No. Example: MC1211-W5 US: 1-866-764-5454 STIBOINFO((CRH:66008com:2C:361)) CH0 0 2 C- 2 CAN: 1-800-265-0502 Copyright© 2006 Cooper Crouse-Hinds 361 Zoom: 100