PDF (Free)

advertisement

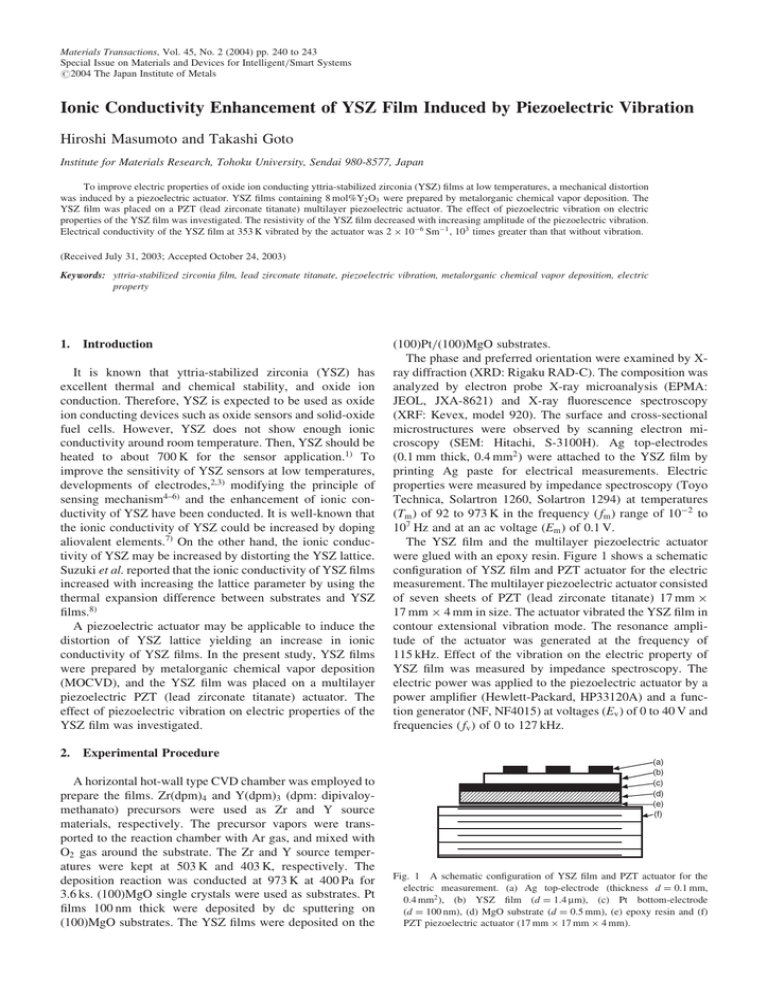

Materials Transactions, Vol. 45, No. 2 (2004) pp. 240 to 243 Special Issue on Materials and Devices for Intelligent/Smart Systems #2004 The Japan Institute of Metals Ionic Conductivity Enhancement of YSZ Film Induced by Piezoelectric Vibration Hiroshi Masumoto and Takashi Goto Institute for Materials Research, Tohoku University, Sendai 980-8577, Japan To improve electric properties of oxide ion conducting yttria-stabilized zirconia (YSZ) films at low temperatures, a mechanical distortion was induced by a piezoelectric actuator. YSZ films containing 8 mol%Y2 O3 were prepared by metalorganic chemical vapor deposition. The YSZ film was placed on a PZT (lead zirconate titanate) multilayer piezoelectric actuator. The effect of piezoelectric vibration on electric properties of the YSZ film was investigated. The resistivity of the YSZ film decreased with increasing amplitude of the piezoelectric vibration. Electrical conductivity of the YSZ film at 353 K vibrated by the actuator was 2 106 Sm1 , 103 times greater than that without vibration. (Received July 31, 2003; Accepted October 24, 2003) Keywords: yttria-stabilized zirconia film, lead zirconate titanate, piezoelectric vibration, metalorganic chemical vapor deposition, electric property 1. Introduction It is known that yttria-stabilized zirconia (YSZ) has excellent thermal and chemical stability, and oxide ion conduction. Therefore, YSZ is expected to be used as oxide ion conducting devices such as oxide sensors and solid-oxide fuel cells. However, YSZ does not show enough ionic conductivity around room temperature. Then, YSZ should be heated to about 700 K for the sensor application.1) To improve the sensitivity of YSZ sensors at low temperatures, developments of electrodes,2,3) modifying the principle of sensing mechanism4–6) and the enhancement of ionic conductivity of YSZ have been conducted. It is well-known that the ionic conductivity of YSZ could be increased by doping aliovalent elements.7) On the other hand, the ionic conductivity of YSZ may be increased by distorting the YSZ lattice. Suzuki et al. reported that the ionic conductivity of YSZ films increased with increasing the lattice parameter by using the thermal expansion difference between substrates and YSZ films.8) A piezoelectric actuator may be applicable to induce the distortion of YSZ lattice yielding an increase in ionic conductivity of YSZ films. In the present study, YSZ films were prepared by metalorganic chemical vapor deposition (MOCVD), and the YSZ film was placed on a multilayer piezoelectric PZT (lead zirconate titanate) actuator. The effect of piezoelectric vibration on electric properties of the YSZ film was investigated. 2. Experimental Procedure A horizontal hot-wall type CVD chamber was employed to prepare the films. Zr(dpm)4 and Y(dpm)3 (dpm: dipivaloymethanato) precursors were used as Zr and Y source materials, respectively. The precursor vapors were transported to the reaction chamber with Ar gas, and mixed with O2 gas around the substrate. The Zr and Y source temperatures were kept at 503 K and 403 K, respectively. The deposition reaction was conducted at 973 K at 400 Pa for 3.6 ks. (100)MgO single crystals were used as substrates. Pt films 100 nm thick were deposited by dc sputtering on (100)MgO substrates. The YSZ films were deposited on the (100)Pt/(100)MgO substrates. The phase and preferred orientation were examined by Xray diffraction (XRD: Rigaku RAD-C). The composition was analyzed by electron probe X-ray microanalysis (EPMA: JEOL, JXA-8621) and X-ray fluorescence spectroscopy (XRF: Kevex, model 920). The surface and cross-sectional microstructures were observed by scanning electron microscopy (SEM: Hitachi, S-3100H). Ag top-electrodes (0.1 mm thick, 0.4 mm2 ) were attached to the YSZ film by printing Ag paste for electrical measurements. Electric properties were measured by impedance spectroscopy (Toyo Technica, Solartron 1260, Solartron 1294) at temperatures (Tm ) of 92 to 973 K in the frequency ( fm ) range of 102 to 107 Hz and at an ac voltage (Em ) of 0.1 V. The YSZ film and the multilayer piezoelectric actuator were glued with an epoxy resin. Figure 1 shows a schematic configuration of YSZ film and PZT actuator for the electric measurement. The multilayer piezoelectric actuator consisted of seven sheets of PZT (lead zirconate titanate) 17 mm 17 mm 4 mm in size. The actuator vibrated the YSZ film in contour extensional vibration mode. The resonance amplitude of the actuator was generated at the frequency of 115 kHz. Effect of the vibration on the electric property of YSZ film was measured by impedance spectroscopy. The electric power was applied to the piezoelectric actuator by a power amplifier (Hewlett-Packard, HP33120A) and a function generator (NF, NF4015) at voltages (Ev ) of 0 to 40 V and frequencies ( fv ) of 0 to 127 kHz. (a) (b) (c) (d) (e) (f) Fig. 1 A schematic configuration of YSZ film and PZT actuator for the electric measurement. (a) Ag top-electrode (thickness d ¼ 0:1 mm, 0.4 mm2 ), (b) YSZ film (d ¼ 1:4 mm), (c) Pt bottom-electrode (d ¼ 100 nm), (d) MgO substrate (d ¼ 0:5 mm), (e) epoxy resin and (f) PZT piezoelectric actuator (17 mm 17 mm 4 mm). Ionic Conductivity Enhancement of YSZ Film Induced by Piezoelectric Vibration 241 Fig. 2 XRD pattern of YSZ (ZrO2 -8 mol%Y2 O3 ) film. (a) Fig. 4 The relationship between the real part of impedance (Z 0 ) and the imaginary part of impedance (Z 00 ) for the YSZ film measured at Tm ¼ 584 K without actuator vibration. 2 µm (b) Fig. 5 Effect of actuator voltage (Ev ) on the frequency ( fm ) dependence of resistivity for the YSZ film at applied frequency ð fv Þ ¼ 115 kHz. 2 µm Fig. 3 3. SEM images of YSZ film. (a) surface and (b) cross-section. Results and Discussion Figure 2 shows the XRD pattern of YSZ film, showing highly crystallized cubic-ZrO2 and a significant (200) orientation. The Y2 O3 content of the film was 8 mol%. Figure 3 shows the surface and cross-sectional microstructures of the film. The film was 1.4 mm in thickness consisting of fine grains about 400 nm in diameter and a columnar structure. Figure 4 shows the relationship between the real part of impedance (Z 0 ) and the imaginary part of impedance (Z 00 ) for the YSZ film measured at Tm ¼ 584 K without actuator vibration. One semicircle and so-called spike were observed at high and low measurement frequency, respectively. The capacitance (C) associated to the semicircle was about 1011 F, suggesting a bulk response. The spike and its associated large capacitance of 107 F imply the ionic conduction in the YSZ film. Figure 5 shows the effect of actuator voltage (Ev ) on the frequency ( fm ) dependence of resistivity for the YSZ film at applied frequency ð fv Þ ¼ 115 kHz. The vibration amplitude increased with increasing Ev . The resistivity of YSZ film decreased with increasing the vibration amplitude. The resistivity decreased with increasing Ev at low frequencies below fm ¼ 103 Hz. The resistivity without vibration after the measurement at Ev ¼ 40 V (Ev ¼ 0 V(2nd)) was in agreement with that before applying vibration (Ev ¼ 0 V(1st)). This implies that the resistivity change due to the vibration is repeatable being not resulted from some structural change 242 H. Masumoto and T. Goto Fig. 6 Effect of fv on fm dependence of the resistivity of YSZ film at Ev ¼ 40 V. such as permanent deformation or crack formation. Figure 6 shows the effect of fv on fm dependence of the resistivity of YSZ film at Ev ¼ 40 V. The resistivity of the YSZ film at fv ¼ 80 kHz and 127 kHz were in agreement with that at fv ¼ 0 kHz. The actuator has no vibration at fv ¼ 80 and 127 kHz. The decrease of resistivity has appeared only at the resonance frequency of 115 kHz. The mechanical strain due to the vibration could yield the decrease of resistivity. The temperature of the YSZ film increased from room temperature to 353 K during the measurement at Ev ¼ 40 V and fv ¼ 115 kHz. This was caused by the increase in actuator temperature. The resistivity of the YSZ film without vibration at 353 K was too large to measure being far different from that measured with vibration. Therefore, the decrease of resistivity measured with the vibration was not caused by the increase in temperature of YSZ film. Figure 7 shows the relationship between Z 0 and Z 00 for the YSZ film measured with and without vibration at 353 K. One semicircle and spike were observed in the YSZ film with Fig. 8 Temperature dependence of electrical conductivity for YSZ films. (a) and (b): this work, (9)–(14): reported data of reference numbers. vibration. The capacitance associated to the semicircle was about 1010 F, probably implying the bulk response. The semicircle for the YSZ film without vibration was too large to determine the resistivity and capacitance value. Figure 8 shows the temperature dependence of electrical conductivity for YSZ films measured in this study and reported values.9–14) The activation energy (Ea ) for the film prepared was about 1.0 eV that was in good agreement with reported values. The electrical conductivity of YSZ film measured with actuator vibration ( fv ¼ 115 kHz and Ev ¼ 40 V) is indicated in Fig. 8. The value of about 2 106 Sm1 was about 103 times greater than that without vibration. The actuator showed the displacement of about 500 nm according to the laser displacement tester at Ev ¼ 40 V. This would correspond to the strain about 0.003% in the YSZ film. Although the distortion of YSZ lattice would be very small, the mobility of ionic conductivity was enhanced by accelerating the hopping probability of oxide ions. The strain caused by the actuator vibration to the YSZ film might promote hopping conduction of oxide ions. 4. Fig. 7 The relationship between Z 0 and Z 00 for the YSZ film measured (a) with and (b) without vibration at 353 K. Summary Ionic conducting YSZ films containing 8 mol%Y2 O3 were prepared at 973 K by MOCVD. The YSZ film was placed on a PZT (lead zirconate titanate) multilayer piezoelectric actuator. The effect of piezoelectric vibration on electric properties of the YSZ film was investigated. The mechanical vibration induced by the piezoelectric actuator enhanced the ionic conduction of YSZ film. The electrical conductivity of the YSZ film at 353 K with vibration was about 2 106 Sm1 . That was 103 times greater than that without vibration. Ionic Conductivity Enhancement of YSZ Film Induced by Piezoelectric Vibration Acknowledgments This research was partly supported by a Grant-in-Aid for Scientific Research (No. 12555174 and 13650729) from the Japan Society for the Promotion of Science. This work was performed as a part of Nanostructure Coating Project carried out by New Energy and Industrial Technology Development Organization (NEDO), Japan. The X-ray fluorescence measurements were performed at the Advance Materials Laboratory, Institute for Materials Research, Tohoku University. The authors thanks to Mr. Mamiya of NEC Tokin Co. Ltd. for supplying the piezoelectric actuator. REFERENCES 1) M. Nakazawa, A. Asada and H. Osanai: IEEE Denshi Tokyo 23 (1984) 155–157. 2) T. Inoue, N. Seki, K. Eguchi and H. Arai: J. Electrochem. Soc. 137 (1990) 2523–2527. 3) S. J. S. Badwal: J. Electroanal. Chem. 146 (1983) 425–429. 243 4) L. Heyne: Measurement of Oxygen, (North Holland, Pub. Co., 1976) pp. 65–69. 5) A. Asada, Y. Isono and M. Nakasawa: Proc. 4th Sensor Symposium, (The Institute of Electrical Engineers of Japan, 1984) pp. 285–292. 6) K. Saji, H. Takahashi, H. Kondo, T. Takeuchi and I. Igarashi: Proc. 4th Sensor Symposium, (The Institute of Electrical Engineers of Japan, 1984) pp. 147–151. 7) H. Yamamura, N. Utsunomiya, T. Mori and T. Atake: Solid State Ionics 107 (1998) 185–189. 8) K. Suzuki, M. Kubo, Y. Oumi, R. Miura, H. Takabe, A. Fahmi, A. Chatterjee, K. Teraishi and A. Miyamoto: Appl. Phys. Lett. 73 (1998) 1502–1504. 9) E. S. Thiele, L. S. Wang, T. O. Mason and S. A. Barnett: J. Vac. Sci. Technol. A 9 (1991) 3054–3060. 10) C. Sakurai, T. Fukui and M. Okuyama: J. Am. Ceram. Soc. 76 (1993) 1061–1064. 11) M. Filal, C. Petot, M. Mokchah, C. Chateau and J. L. Carpentier: Solid State Ionics 80 (1995) 27–35. 12) G. Garcia, A. Figueras, J. Casado, J. Llibre, M. Mokchah, G. PetotErvas and J. Calderer: Thin Solid Films 317 (1998) 241–244. 13) K. Nakagawa, H. Yoshioka, H. Kuroda and M. Ishida: Solid State Ionics 35 (1989) 249–255. 14) N. Savvides and B. Window: J. Vac. Sci. Technol. 4 (1986) 504–508.