Thermal degradation of traction machines

advertisement

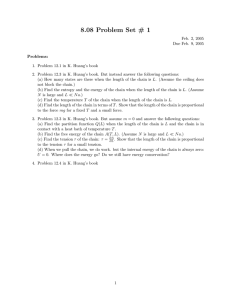

Thermal degradation of traction machines Project – DYMEDEC PhD fellow: Zhe Huang Project manager: Azra Selimovic Supervisors: Mats Alaküla, Avo Reinap Project info. Dynamic modeling of cooling for electrical drives (DYMEDEC) Industrial PhD project 2013-09-01 to 2016-05-31 3 088 500 SEK Partners: Volvo Group and Lund University Network: BEVI, SP, Chalmers, Dahrentråd... Volvo Group Trucks Technology Advanced Technology & Research, Zhe Huang, FFI Fordonskonferens 2 20160404 Project goal and approach – Dynamic thermal and lifetime model T*,* Vehicle and drive cycle Powertrain model Electrical machine losses Electrical machine cooling Volvo Group Trucks Technology Advanced Technology & Research, Zhe Huang, FFI Fordonskonferens 3 20160404 Qheat Thermal model Qcool Life model Degradation model and test verification Off line learning phase Identify critical failure modes Implement Impelement degradation measurement Choose degradation parameters Possible test object (full machine/ motorrete/ bearing...) Build degradation model Data collection and postprocessing Implement stress Impelement stress (lab environment: current induced thermal cycle) EM Degradation model Usage of degradation model Load cycles On line data monitoring Design EM with the required life span RUL Volvo Group Trucks Technology Advanced Technology & Research Research, Zhe Huang, FFI Fordonskonferens 4 20160404 Off line condition monitoring in workshop Detailed diagnostics + schedule spare part Results Volvo Group Trucks Technology Advanced Technology & Research, Zhe Huang, FFI Fordonskonferens 5 20160404 Conclusions Thermal and degradation model - Inputs: driving cycle, vhecile specifications, defined powertain Outputs: temperature distribution while driving, expected lifetime Design traction machine with required lifetime Accelerated lifetime test - Improved test method Stator segment VS single material Electrically heated winding and liquid cooling VS oven heating Thermal-mechanical model - Impregnation used to enhance the heat transfer induces mechanical stress to winding coating (primary insulation) under thermal stress improve the degradation model (thermal-mechanical stress VS insulation lifetime) Condition monitoring model - Global physical properties changes due to local insulation material aging improve the degradation model (usage time VS insulation quality) Prognostic measurement – State of Health (SOH) - Povide quick health check of the traction motor before vehicle start daily Simple hardware and software requirement (high frequency logging device needed) Volvo Group Trucks Technology Advanced Technology & Research, Zhe Huang, FFI Fordonskonferens 6 20160404 Publications Zhe Huang, Francisco J. Marquez-Fernandez, Yury Loayza, Avo Reinap, and Mats Alaküla. "Dynamic thermal modeling and application of electrical machine in hybrid drives." International Conference on Electrical Machines (ICEM), pp. 2158-2164. IEEE, 2014. Zhe Huang, Avo Reinap, and M. Alaküla. "Predictive monitoring of turn-to-turn insulation in single tooth coils." 10th International Symposium on Diagnostics for Electrical Machines, Power Electronics and Drives (SDEMPED), IEEE, 2015. Zhe Huang, Avo Reinap, and M. Alaküla. “Degradation and Fatigue of Epoxy Impregnated Traction Motors Due to Thermal and Thermal Induced Mechanical Stress – Part I: Thermal Mechanical Simulation of Single Wire due to Evenly Distributed Temperature”, 8th International Conference on Power Electronics, Machines and Drives (PEMD), IET, 2016. Zhe Huang, Avo Reinap, and M. Alaküla. “Degradation and Fatigue of Epoxy Impregnated Traction Motors Due to Thermal and Thermal Induced Mechanical Stress – Part II: Thermal Mechanical Simulation of Multiple Wires due to Evenly and Unevenly Distributed Temperature”, 8th International Conference on Power Electronics, Machines and Drives (PEMD), IET, 2016. Zhe Huang, Avo Reinap, and M. Alaküla. “Dielectric Properties Modeling and Measurement of Single Tooth Coil Insulation System under Accelerated Degradation Test”, International Conference on Electrical Machines (ICEM), IEEE, 2016, full paper submitted. Volvo Group Trucks Technology Advanced Technology & Research, Zhe Huang, FFI Fordonskonferens 7 20160404 Thanks for your attention! Thermal model Detailed Loss Model Mechanical Dynamics Model Detailed Thermal Model (1) Detailed Thermal Model (2) Volvo Group Trucks Technology Advanced Technology & Research, Zhe Huang, FFI Fordonskonferens 9 20160404 Lifetime model 10 5 • Degradation caused by thermal stress 4 Life Time [hours] Life time versus constant thermal stress - 𝐿 = 𝐴𝑒 𝐵/𝑇 - Hot spot temperature in winding is the critical parameter for lifetime 10 10 3 2 10 150 • Life time definition - Standard defines L50 - From L50 to Ln... Cumulative distribution function shape factor 𝛽 𝐹 𝑡 =1 𝑡 𝛽 − 𝜂 −𝑒 • Temperature cycle counting algorithms - Mean edge (MIL Handbook) - RainFlow (Fatigue estimation; consider the deepest cycle) Volvo Group Trucks Technology Advanced Technology & Research, Zhe Huang, FFI Fordonskonferens 10 20160404 Polyurethane TI155 Polyester TI180 Polyesterimide TI200 Polyester&Polyamide-imide TI220 200 250 o Temp [ C] 300 Lifetime model – results Diving Cycle US06 Thermal Index [°C] 155 180 200 220 Life time by Mean edge [hours] 4 773 24 389 124 741 935 644 Volvo Group Trucks Technology Advanced Technology & Research, Zhe Huang, FFI Fordonskonferens 11 20160404 Life time by RainFlow [hours] 2 495 20 550 105 104 1 005 422 Test set up Off line learning phase 160 140 Identify critical failure modes 120 100 0.025 Choose degradation parameters Implement Impelement degradation measurement 0.02 0.015 0.01 0.005 0.08 0 0.04 0.1 0.12 0.06 0.14 Possible test object (full machine/ motorette/ bearing...) High voltage DC – leakage current (transient: time constant; steady state: insulation R) Low voltage AC – impedance (insulation C) Volvo Group Trucks Technology Advanced Technology & Research, Zhe Huang, FFI Fordonskonferens 12 20160404 Implement stress Impelement stress (lab environment: current induced thermal cycle) Data collection and postprocessing Improve model step 1 – Thermalmechanical stress VS aging Volvo Group Trucks Technology Advanced Technology & Research, Zhe Huang, FFI Fordonskonferens 13 20160404 Improve model step 2 – Predictable properties change VS aging Single tooth winding under test Differnt winding configurations and fill factors Results – Insulation resistance developement during degradation: analytical modeling VS measurement Analytical modeling for condition monitoring Results – Insulation resistance at different aging time of EM and coating thickness Capacitance (phase to ground) change during degradation: measurement at different temperature cycle stresses FEA modeling for condition monitoring Volvo Group Trucks Technology Advanced Technology & Research, Zhe Huang, FFI Fordonskonferens 14 20160404 Degradation model application – Traction machine prognostics Theory - Traction machine on-line condition monitoring (State of Health) by parasitic capacitance changes with machine aging Meaurement set-up - On a PMSM (hybrid car traction) - Fault case: phase and ground failure - Results Method validation by lab equipment Small influence by rotor position – lock rotor Up to 10 Mhz logging and current sensing requirement -> higher than control need but can be shared with battery diagnostic Current response with and without phase to ground fault, in time domain (left) and in frequency domain (right) Volvo Group Trucks Technology Advanced Technology & Research, Zhe Huang, FFI Fordonskonferens 15 20160404 PMSM under measurement