Philips Ceramics Uden

advertisement

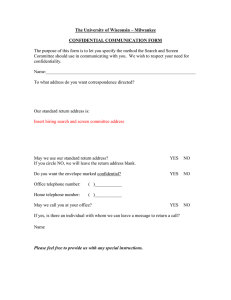

Philips Ceramics Uden Ceramic Materials, Processing and Applications Arno Brus Arno.Brus@Philips.com Botlek Studie Groep April 9th 2015 1 Confidential Introduction • Founded 1891 in Eindhoven, Headquarter in Amsterdam • Conglomerate of Businesses in Healthcare, Lighting and Consumer lifestyle • Turnover of EUR 21,391 million Euro and 113.678 employees (2014) • Globally present in 100 countries with factories and sales offices • An R&D force with expenditures of EUR 1,635 million (2014) 2 Confidential Philips Ceramics Uden (PCU) • PCU is the global competence center for ceramics for Philips and non-Philips customers – Product innovation – Process innovation – Production – Commercial and consultancy services • World leader in translucent ceramics • Locations : Uden (NL) Pila (Poland) 3 Confidential New Product Introductions (Injection Molding, Extrusion) Traditional products Philips Lighting PCA (Poly Crystalline Alumina) Main stream application area Shop Lighting/Interior Lighting Outdoor Lighting 4 Confidential 4 New Markets for Philips Ceramics Uden Ceramic membranes and substrate materials Replacement Technical Ceramics Sensor components and housing Service activities • • • • 5 Confidential Mainly Project based Product Development Material Development Firing/sintering services Why Ceramics? By Injection molding or Extrusion 6 Confidential Why Ceramics? 7 Confidential Design freedom due to manufacturing process Shaping Pressure Polycrystalline 1. Al2O3 powder • • • 8 2. Shaping 3. Sintering (1900°C) Complex shapes possible via Injection Molding Technology Efficient manufacturing processes, no additional machining required Sintering in hydrogen environment -> fully dense 99,99%, no pores Confidential Design freedom due to manufacturing process Shaping by Injection Molding or Extrusion • Feedstock made out of Alumina and plastic binders • Alumina isn’t moldable; plastic is • Ceramic particles encapsuled by plastic • Filling of mold by high pressure 9 Confidential Design freedom due to manufacturing process Shaping by Injection Molding or Extrusion • Feedstock made out of Alumina and plastic binders • Alumina isn’t moldable; plastic is • Ceramic particles encapsuled by plastic • Filling of mold by high pressure 10 Confidential Hardness of PCA (Al2O3) 11 Confidential Temperature and Inertness High Intensity Discharge lamp PCA 5000K 1500K T-Wall inner side PCA: Poly Crystalline Alumina Al2O3 In Dutch DGA; Doorschijnend Gasdicht Aluminiumoxide PCA Light 40 Bar Molten salts like Re, Tl, Na - Iodides Life time 32000 hrs 12 Confidential Characteristics: High operating temperature (>1500 °C) High thermal shock resistant High corrosive resistance for aggressive salts inside Mechanically very strong Very long life time What makes Philips Ceramics Uden special? 14 Confidential Unique position in the market…… Ceramic injection molding 8 folded molds Hot runner systems Furnace processing Unique HT furnaces, Philips Optimal cost price Mass production Very high accuracy Capacity. technology. Feedstock development Knowledge, link feedstock processing and injection molding/extrusion Translucent ceramics Build up knowledge over last decades. Link quality alumina versus translucency Sapphire like quality Mass production extrusion Unique (fast) drying technology Capacity Freedom of design/co developing Complex problems solved R&D capacity 15 Confidential Limited amount of manufacturers of high end feedstock Highly automated Lines Ceramic Injection Molding Philips Ceramics Uden pictures of Ceramic Injection Molding lines 16 Confidential 1 Superb chemical inertness due to full density Firing Process in hydrogen atmosphere Grains are ‘melting’ together and grow, pores are disappearing 1200°C 1600°C 1850°C Fully dense ceramics have sapphire like properties with respect to chemical inertness and hardness 17 Confidential Joining Technology Assembly via unique joining technology • • • Ceramic parts can be assembled and sintered to a monolithic structure Properties of ‘join’ identical to main body material Fully gastight connection Body part 1 Body part 1 Join Body part 2 18 Confidential Body part 2 Mechanical Strength joined parts Bursting Pressure measurement • • Water pressure applied from inside Wall thickness 2mm, outer diameter <20mm, bursting pressure >600bar) • Outer diameter 20mm, wall thickness 1mm Probability Plot (Outer Diameter 20mm) Normal - 95% CI 99.9 Mean StDev N AD P-Value 99 95 Percent 90 What influences strength? 80 70 60 50 40 30 20 10 5 1 0.1 19 271.6 13.07 225 2.698 <0.005 220 240 Confidential 260 280 Bursting 330W 300 320 • Local density variation by applied raw materials • Influenced Grain size distribution processing conditions • Typeand of porosity • Chemical impurities • Local defects Feedthrough / Metal-Ceramic connection Technology Feedthrough Technology • Gastight connection • Co-sintering process for sintering metal to ceramic • Feedthrough material and type depending on application • Types; Mo/Al2O3 cermet, Nb feedthrough, Mo coil, Ir cosintered Nb feedthrough and sealing glass 20 Confidential Gastight co-sintered feedthrough Philips Ceramics Uden (PCU) Characteristics; • Production volume • Employees – Total – Innovation • Turn over 26 Mio >30 Mio pieces/yr 155 FTE 21 FTE • Shaping technologies: Ceramic Injection Molding , Extrusion • High volumes, large capacity • Highly mechanized – robotics – automatic in line inspection, vision systems • Eco friendly materials, ROHS compliant 21 Confidential Material & Product Characteristics Material & Product • Highly inert • Translucent (optional) • Fully gas tight material • Gastight ceramic to metal feedthroughs • Sapphire like properties Product & Manufacturing • High accuracy in product details • Joining Technology (monolithic seals) • Freedom in shape by Injection Molding 22 Confidential Example applications for our Ceramics 23 Confidential Ceramic membrane applications • • • • 24 Carrier tubes/systems for pervaporation Porous tubes for Ultra and Micro filtration Connectors for gas separation module Metal/ ceramic or ceramic/ceramic interfaces/ connections Confidential (micro) reactor component • Chemical and Pharmaceutical industry • • • • • 25 Confidential Enabling high temperature and high pressure processes Superb resistance against corrosion Gastight Metal / ceramic connections Possibility for inline measurements (Infrared wavelengths) Milling, grinding, piercing • F.e Pharmaceutical and Food industry • Fully inert material • Heat conductive • Extreme lifetime due to hardness 26 Confidential Sensors • Sensor housing, component, carriers, capacitors • Design freedom by applying Injection Molding • Withstands extreme conditions (temperature, pressure, corrosive substances/gases) • Metal/ ceramic or ceramic/ceramic interfaces/ connections • Electrical insulator 27 Confidential Arno Brus Innovation Manager Ceramics Arno.Brus@philips.com www.philips.com/ceramics 28 Confidential