ITM # 43 - Transportation Research Board

advertisement

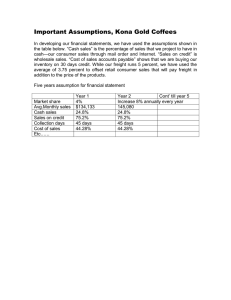

Paper Author (s) Jose Holguín-Veras, Rensselaer Polytechnic Institute (jhv@rpi.edu) Ivan Sanchez-Diaz (corresponding), Rensselaer Polytechnic Institute (sanchi2@rpi.edu) Miguel Jaller, Rensselaer Polytechnic Institute (jallem@rpi.edu) Catherine Theresa Lawson, State University of New York, Albany (lawsonc@albany.edu) Shama Campbell, Rensselaer Polytechnic Institute (campbs4@rpi.edu) Jeffrey Wojtowicz, Rensselaer Polytechnic Institute (wojtoj@rpi.edu) Xiaokun (Cara) Wang, Rensselaer Polytechnic Institute (wangx18@rpi.edu) Paper Title & Number Freight Generation And Freight Trip Generation Modeling [ITM # 43] Abstract The current transportation planning process does not effectively estimate freight activity necessary to assist decision makers when making infrastructure choices. This research seeks to provide improved freight generation (FG) and freight trip generation (FTG) models for different land use characteristics related to freight facilities and commercial operations to better inform state and local decision-making. Freight generation models are estimated using the largest and most complete establishment-based freight survey in the world (with 100,000 establishments samples): the Commodity Flow Survey. Freight Trip Generation models are estimated using data from more than 600 establishments in New York City. Statement of Financial Interest This research was developed as part of NCFRP 25 Project: “Freight Trip Generation and Land Use”. There is no further financial interest. Statement of Innovation This is the first time that freight generation models are developed using the Commodity Flow Survey micro-data.This is the largest sample ever used to estimate freight generation models (100,000 establishments for the US dataset).Freight generation (cargo) and freight trip generation (vehicle trips) are differentiated and the modeling methodology is adapted accordingly. The freight trip generation models use different specifications that take into account the role of logistic decisions in different industry sectors. 1 FREIGHT GENERATION AND FREIGHT TRIP GENERATION MODELING José Holguín-Veras, Ph.D., P.E. William H. Hart Professor Department of Civil and Environmental Engineering Rensselaer Polytechnic Institute, 110 Eighth St., Troy, New York 12180, USA Fax.: +518-276-4833, Email: jhv@rpi.edu Iván Sánchez-Díaz, M.S. Graduate Research Assistant, Department of Civil and Environmental Engineering Rensselaer Polytechnic Institute, 110 Eighth St., Troy, New York 12180, USA. Email: sanchi2@rpi.edu Miguel Jaller, Ph.D. Senior Researcher, Department of Civil and Environmental Engineering Rensselaer Polytechnic Institute, 110 Eighth St., Troy, New York 12180, USA. Email: jallem@rpi.edu Catherine T. Lawson, Ph.D. Associate Professor and Director of the Masters in Urban and Regional Planning Program, Department of Geography and Planning University at Albany, 1400 Washington Ave. Albany, NY, 12222 Phone: 518-442-4775. Fax: 518-442-4742, Email: lawsonc@albany.edu Shama Campbell, M.S. Graduate Research Assistant, Department of Civil and Environmental Engineering Rensselaer Polytechnic Institute, 110 Eighth St., Troy, New York 12180, USA. Email: campbs4@rpi.edu Jeff Wojtowicz, M.S. Senior Research Engineer, Department of Civil and Environmental Engineering Rensselaer Polytechnic Institute, 110 Eighth St., Troy, NY 12180, USA. Email: wojtoj@rpi.edu Cara Wang, Ph.D. Assistant Professor, Department of Civil and Environmental Engineering Rensselaer Polytechnic Institute, 110 Eighth St., Troy, NY 12180, USA. Email: wangx18@rpi.edu 1. STATEMENT OF FINANCIAL INTEREST This research was developed as part of NCFRP 25 Project: “Freight Trip Generation and Land Use”. There is no further financial interest. 2 2. STATEMENT OF INNOVATIONS This is the first time that freight generation models are developed using the Commodity Flow Survey micro-data. This is the largest sample ever used to estimate freight generation models (100,000 establishments for the US dataset). Freight generation (cargo) and freight trip generation (vehicle trips) are differentiated and the modeling methodology is adapted accordingly. The freight trip generation models use different specifications that take into account the role of logistic decisions in different industry sectors. 3 3. SHORT PAPER: FREIGHT GENERATION AND FREIGHT TRIP GENERATION MODELING 3.1 Introduction The lack of research and freight data affects all facets of transportation modeling: generation of cargo, distribution to intermediate and end users where the cargo is processed, stored, and ultimately consumed; mode choice, and traffic assignment. In particular, there is a great need for research to enhance the state of the quantitative aspects of freight generation. A better understanding of the variables driving the generation of freight demand would enable more accurate demand forecasts, and better quantification of the traffic impacts of freight activity. This knowledge can support a more effective decision-making for state transportation agencies and Metropolitan Planning Organizations which are constantly facing pressure to balance the conflicting objectives of the stakeholders involved and impacted by freight activity. This research provides an overview of the advances in the estimation of the freight generation (amount of cargo generated) and the freight trip generation (number of freight vehicle trips generated) realized in the context of NCFRP Project 25: Freight Trip Generation and Land Use. 3.2 Methodology It is important to start by defining the two types of freight demand, freight generation (FG) and freight trip generation (FTG). FG refers to the production and attraction of cargo, measured by tonnage or volume (e.g. m3). FTG, in contrast, measures the number of freight vehicle trips that are generated by the transport of FG. Treating FG and FTG as separate concepts is important because while FG is directly correlated with the size of the establishments, FTG may not (1). This is the result of the role played by the shipment size, which enables large business establishments to receive larger shipments minimally increasing the amount of vehicletrips produced. In consistency with the practices in passenger transport modelling, one could subdivide FG and FTG in attractions and productions (2), leading to the concepts of freight attraction (FA), freight production (FP), freight trip attraction (FTA), and freight trip production (FTP). For the analysis, FG is quantified as the amount of cargo (in tons) and FTG is quantified using the number of deliveries per establishment. This approach enables the estimation of FG and FTG as functions of land use or industrial sector and employment. Knowing establishment characteristics, FTG can be readily estimated. To estimate FG/FTG models, three different approaches were used: standard freight/freight trip generation rates; linear regression; and Multiple Classification Analysis (MCA). (For a description of MCA, see (2). The analyses were performed using the North American Industry Classification System (NAICS) to group establishments with similar economic activity. For the case of linear regression models, the analyses used total employees per establishment as the independent variable, after considering the data collection and forecasting implications of different explanatory factors. While for FG models the function specification always considers employment as an independent variable; for FTG models the estimates can be constant per establishment. The conceptual validity, the statistical significance and the Root Mean Square Error (RMSE) were the criteria used to assess which functional form is more suitable to estimate FG and FTG. 4 For FTG, when the regression analyses found that FTG depends on business size, MCA models were applied to estimate the trip rates for each stratum of employment and for each category of land use. (It does not make sense to use MCA stratified by employment level if this variable is not statistically related to FTG). The research explored different employee groupings to select the number and width of each interval class. MCA models were then estimated, where appropriate, for the different groupings and combinations of employee intervals. For FG modeling, the authors used the micro-data at the Census Bureau’s Center for Economic Studies. The Commodity Flow Survey (CFS) data is the largest and most complete establishment based freight survey in the world (with 100,000 establishments samples for times a year). This is the first time the CFS micro-data are used for freight generation modeling. These data contain information for selected warehousing, wholesale, retail and manufacturing sectors. For FTG modeling, the authors collected data from about 600 establishments including receivers and carriers in New York City. The information was obtained through telephone interviews and supplemented with records from the Dun and Bradstreet database. The resulting dataset includes FTG data (e.g., deliveries received, freight-trips made from the establishment on a typical day), company attributes (e.g., employment, and industry segment), and basic geographical information, see (1, 3, 4). 3.3 Results This section provides a summary of the results for New York State. In the case of FTG the results correspond to the NYC metropolitan area. In the tables, every row represents the model for an industry sector defined by a NAICS code. The dependent variable for FP models corresponds to the amount of cargo produced (in daily pounds). Table 1 shows the FP models estimated using the CFS micro-data. 5 Table 1: Freight Generation Regression Models for New York State Description NAICS Obs. Mining 212 66 Manufacturing Group 1: 31 171 food,tobacco,textile, apparel Manufacturing: food 311 98 Manufacturing: beverage and tobacco 312 26 Manufacturing: textile mills 313 13 Manufacturing: textile products mills 314 15 Manufacturing: apparel 315 19 Manufacturing Group 2: wood, paper, chemicals, petroleum, plastics, 32 468 nonmetallic Manufacturing: wood products 321 60 Manufacturing: paper 322 58 Manufacturing: printing and related 323 53 Manufacturing: petroleum and coal 324 17 Manufacturing: chemical 325 99 Manufacturing: plastics and rubber 326 90 Manufacturing: nonmetallic 327 91 Manufacturing Group 3: metal products, machinery, computer, equipment, 33 540 miscellaneous Manufacturing: primary metal 331 41 Manufacturing: fabricated metal 332 125 Manufacturing: machinery 333 94 Manufacturing: computer 334 72 Manufactruing: electrical equipment 335 31 Manufacturing: transportation equipment 336 48 Manufacturing: furniture products 337 51 339 78 Manufacturing: miscellaneous Wholesale 42 980 Wholesale: durable goods 423 540 Wholesale: nondurable goods 424 440 454 82 Retail: electronic shop and fuel 493 28 Warehousing 511 39 Information: newspaper 551 32 Management: corporate offices (1) Constant Rate per employee Adj. R2 1,181,292.6** 51,427.2** 0.36 RMSE 3,067,508 - 2,968.43** 0.35 851,044 - 2,332.1** 7,139.2** 117.7 168.8* 10.2* 0.42 0.59 0.30 0.60 0.16 645,147 1,404,852 16,966 14,093 4,081 304,238.8** 128.2** 0.00 1,061,092 187,484.5** - 2,760.5** 1,457.5** 412.1** 60,257.5 133.2** 555.3* 3,943.5** 0.41 0.44 0.75 0.31 0.06 0.35 0.18 180,306 376,299 48,834 4,053,051 640,043 165,197 1,081,073 - 172.2* 0.05 317,314 7,806.8* 4927.2* 62,225.2** 115,117.8** - 2,674.9** 219.9** 132.5* 3.0* 65.1* 319.9* 76.1* 24.2* 1,400.0** 1,148.6* 1,460.8* 884.5 2,920.9* 130.7* 847.5 0.43 0.19 0.36 0.13 0.39 0.62 0.21 0.11 0.04 0.01 0.12 0.23 0.58 0.67 0.22 865,117 89,916 60,571 6,599 26,112 160,345 26,137 18,262 695,353 817,215 501,540 271,765 868,740 44,304 726,910 Notes: FG is estimated in pounds/day; * significant at the 5% level, ** significant at the 1% level; (1) the model includes cargo sent from headquarters to branches of the firm. As shown, the models’ adjusted R2 range from 0.005 (for Group 2 of manufactures) to 0.75 (for printing and related products manufacturing). In terms of the specification, 7 out of the 31 models have an intercept and an employment term, 20 of the 31 models are a statistically significant employment rate, and for the remaining 4 models the employment term is not statistically significant. For the cases where there is no intercept, the largest coefficient was found for manufacturing of petroleum and coal products (60,257.5 daily pounds/employee) and the smallest for computer manufacturing (3 daily pounds/employee). Table 2 shows the disaggregate models for freight trip attraction (FTA) considering business size for different industry segments. To gain further insight into the relation between FTG and business size, the authors selected those industries that exhibited a combination of a constant per establishment and a term 6 based on employment to estimate MCA models. Table 3 shows the resulting MCA models for these industries. These estimates indicate that, on average, those establishments in the retail trade industry (NAICS 44) receive one more delivery than those in the accommodation and food service (NAICS 72) and wholesale trade (NAICS 42) industries. Table 2: Freight Trip Attraction (deliveries/day) Models by NAICS Description NAICS Construction* Manufacturing* Food, Beverage, Tobacco, Textile, Apparel, Leather & Allied Product Manufacturing Wood, paper, printing, petroleum and coal products, chemical, plastics, nonmetallic and mineral product manufacturing 23 31-33 Metal, machinery, computer, electronic, electrical, transportation, furniture and misc. manufacturing Wholesale Trade* 42 Retail Trade* 44-45 Motor vehicle, furniture, electronics, building material, food and beverage, health, gasoline, and clothing stores Sporting goods, hobby, book, and music stores Accommodation and Food* 72 25 51 Rate per RMSE employee 2.160 1.364 2.831 2.791 31 21 2.400 1.295 32 10 4.420 5.483 33 20 2.490 2.483 117 98 2.272 3.070 0.069 0.063 3.655 4.054 44 69 2.458 0.132 4.298 45 29 56 2.724 1.307 0.081 4.352 3.091 Obs. Constant * Group Models Source: Adapted from Holguín Veras et al. (5) Table 3: MCA Rates for Freight Trip Attraction (deliveries/day) Employees* Economic Classification System: NAICS 72: Accomodation 42: Wholesale trade 44: Retail trade and food 1-10 2.443 3.543 1.902 11-20 3.341 4.442 2.801 21-30 5.685 6.785 5.144 3.658 4.197 3.355 RMSE * For establishments with more than 30 employees results were not statistically significant Source: Adapted from Holguín Veras et al. (5) Similarly for FTP, Table 4 shows the resulting disaggregate models for the different NAICS codes. For FTP, 30% of the models are a constant per establishment, another 30% are employment rates, and the remaining 40% have a constant and an employment term. These results show, yet again, that a large number of industry sectors have a constant FTA that does not depend on business size. Table 4: Freight Trip Production (trips/day) Models by NAICS 7 Description NAICS Obs. Constant Rate per employee Best Model 23 - Construction* 23 9 E 1.586 31, 32 and 33 - Manufacturing* 31 - Food, beverage, tobacco, textile, apparel, leather and allied product manufacturing 32 - Wood, paper, printing, petroleum and coal products, chemical, plastics, nonmetalluc and mineral manufacturing 33 - Metal, machinery, computer, electronic, electrical, transportation, furniture and misc. manufacturing 31-33 28 2.214 S 3.599 31 13 2.846 S 4.990 32 7 E 0.648 33 8 1.750 S 1.639 42 - Wholesale Trade* 42 124 1.755 0.036 C 5.094 0.161 E 6.485 44 and 45 - Retail Trade* 44-45 44 - Motor vehicle, furniture, electronics, building material, food and beverage, health, 44 gasoline, and clothing stores 48 and 49 - Transportation and Warehousing* 48-49 48 - Air, rail, water, truck, transit, pipeline, scenic 48 and sightseeing, and support activities * Group models 0.068 RMSE 0.023 9 5 0.993 0.021 C 0.237 157 2.718 0.038 C 4.811 153 2.725 0.038 C 4.005 Source: Adapted from Holguín Veras et al. (5) Table 5 shows the MCA results for the different industries. These results indicate that establishments in the construction (NAICS 23) industry averaged approximately one more trip than those in the manufacturing (NAICS 32) industry. Establishments in the transport and warehousing (NAICS 42 and 48) industries both averaged at least one more trip than establishments in the retail trade (NAICS 44) industry. Table 5: MCA Models for Freight Trip Production (trips/day) 23 Construction Economic Classification System: NAICS 32 - Wood, 42 - Wholesale 44 - Motor paper, Trade vehicle, furniture, petroleum,coal, electronics, food chemical, and beverage plastics retail 1.303 2.946 1.685 48 and 49 Transportation 2.424 21-40 1.727 0.606 2.564 1.303 2.998 41-60 2.061 0.939 3.283 2.023 3.718 61-80 4.061 2.939 2.764 1.504 3.199 >80 5.121 4.000 7.609 6.348 8.043 RMSE 1.074 0.934 4.650 0.618 5.219 Employees 1-20 3.381 Source: Adapted from Holguín Veras et al. (5) For a comparison between estimating methodologies and for a description of models estimated for other industry classification systems and land use categories see Holguín-Veras et al. (1), Lawson et al. (6) and Holguin-Veras et al. (7). 8 3.4 Conclusions and Implications This paper provides an overview of the concepts of freight generation (FG) and freight trip generation (FTG) and the corresponding modelling processes. The estimates obtained for FG are of major importance as they are based on the largest and most complete establishment based freight survey in the world. The authors are currently conducting similar analysis to obtain FP estimates for the whole country. These models are an extraordinary contribution to the freight transportation modeling community and for practitioners, as they provide accurate estimates of FG for a good number of industries at the establishment level. Another important finding is the importance of treating FG and FTG as two different concepts. While FG is the amount of cargo generated by an establishment, FTG is the number of freight vehicle trips required to transport the cargo. In competitive markets, larger businesses are expected to produce proportionally more FG than small ones, thus FG increases with business size. This is not necessarily the case for FTG, since logistics decisions on shipment size, vehicle (and mode) choice and frequency of distribution come into play when determining the number of truck trips generated. Finally, while the FTG estimates were found to be transferable across different geographic contexts (7), this is not the case for FG models. 3.5 1. 2. 3. 4. 5. 6. 7. References Holguín-Veras, J., M. Jaller, L. Destro, X. Ban, C. Lawson, and H. Levinson. Freight Generation, Freight Trip Generation, and the Perils of Using Constant Trip Rates. Transportation Research Record, Vol. 2224, No. 2011, pp. 68-81. Ortúzar, J.D. and L.G. Willumsen Modelling Transport. New York, 2011. Lawson, C., J. Holguín-Veras, I. Sanchez-Diaz, M. Jaller, S. Campbell, and E. Powers Estimation of Freight Trip Generation Based on Land Use, (in press) Campbell, S., M. Jaller, I. Sanchez-Diaz, J. Holguin-Veras, and C. Lawson. Comparison Between Industrial Classification Systems in Freight Trip Generation (FTG) Modeling. In 91st Annual Meeting of the Transportation Research Board. 2011: Washington, D.C Holguín Veras, J., M. Jaller, I. Sánchez-Díaz, J. Wojtowicz, S. Campbell, H. Levinson, C. Lawson, E. Powers, and L. Tavasszy. NCHRP Report 739 / NCFRP Report 19: Freight Trip Generation and Land Use. T.R.B.o.t.N. Academies, Washington D.C., 2012. Lawson, C., J. Holguín-Veras, I. Sánchez-Díaz, M. Jaller, S. Campbell, and E. Powers. Estimated Generation of Freight Trips Based on Land Use. Transportation Research Record, Vol. 2269, No. 2012, pp. 65-72. Holguin-Veras, J., I. Sánchez-Díaz, C. Lawson, M. Jaller, S. Campbell, H.S. Levinson, and H.S. Shin. Transferability of Freight Trip Generation Models. Transport Research Record, Vol. (in print), No. 2013, pp.