Optimal road hump for comfortable speed reduction

advertisement

2nd meeting on ”Analysis of dynamic measurements”,

NPL London 18/11, 2008

Analysis and synthesis of speed limiting

Road Humps

Jan Peter Hessling

SP Technical Research Institute of Sweden,

Measurement Technology

P.Y. Zhu, Hunan Provincial Key Lab. of Health Maintenance for Mechanical

Equipment, Hunan Univ. of Science and Techn., Xiangtan, China

Mrigank Gupta, Indian Institute of Technology, Kanpur, India

1

Road bumps/humps for speed reduction

Patent:

(Engwall, Bertil. Device to prevent vehicles from passing a

temporarily speed-reduced part of a road with high speed.

United States Patent 4135839, 1979.)

’Solution’ used worldwide !!!

(Sweden, Great Britain, USA, China, India…)

Positive

• Speed reduction / efficiency

– Feel in stomach?

– Visual impact / disorientation?

– Risk of car damage?

Negative

• Risk of injury

– Spinal cord

• Reduced comfort at allowed speed

• Low efficiency

– Poor threshold effect

– ’Negative’ threshold

(Increased comfort at high speed!!!)

2

Often poor design of road humps!

”…the bus driver was exposed to some 1.6 MPa over the flat top

bumps at X, which is about 170% more than the 0.6 MPa achieved

over the flat tops at Y. …indicates that

the status of current speed humps is so poorly standardized

(design, construction,… tear and wear…), that each bump

should be regarded as an individual…*”

”…the maximum acceleration at the driver’s seat in the city bus

running at allowed speed was up to 1g when some humps were

passed…**”

Complaints common => public interest of our method

(JPH Sweden: two newspapers, one radio and one TV-station)

* Granlund J., Brandt A., “Bus Drivers’ Exposure To Mechanical Shocks Due To Speed Bumps”,

26th International Modal Analysis Conference (IMAC XXVI), Orlando, Florida, USA, Feb. 2008.

** Measurements in the city of Borås, Sweden 2008 by the health consultant Grönesjö L.

for the local bus company.

3

Design of road humps

Profile of hump matters!

Height (~5-10 cm) only scales the (dis-)comfort!

(linear response)

Changing the height is not a solution for poor design!

Variation of comfort with speed set by profile.

Profile Ù operating principle / efficiency / threshold effect

Established methods of evaluation – new and existing humps

Widely accepted quantitative analysis: None

Measurements, difficulties

¾ Many many combinations of vehicles, speed and humps

¾ Not practical method for optimizing profile

4

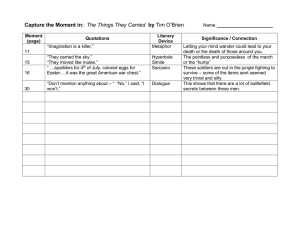

Design of road humps

Properties

• Efficiency / threshold

- Change in comfort with speed

• Risk of injury

Existing road hump

Analysis

Synthesis

Optimal road hump

0.1

0.09

Optima l roa d profile (m)

Less precise!

• Broad spectrum of vehicles

(Cars, buses, new/old etc.)

• Optimal hump for just one typical vehicle

• Uncertainty ‘irrelevant’

0.08

0.07

0.06

0.05

0.04

0.03

0.02

0.01

0

5

10

15

20

Dis ta nce (m)

25

30

5

35

Model of vehicle (car / bus)

Output 1:

Translation

car body

Output 2:

Rotation

car body

’Measurement system’

Input 1:

Front wheel

coordinate

Input 2:

Rear wheel

coordinate

Tools of dynamic [measurement]

systems

LTI (linear time-invariant)

MIMO (multiple input multiple output):

•

•

•

•

•

•

•

•

•

•

Dynamic Calibration /

Characterization

System Identification

Differential / difference equation

Transfer function / Frequency

response function

Impulse response

Auto- / cross- correlation

Signal processing

Digital filtering

Poles / zeros

Etc.

Road Hump

• Variable velocity

• Designed geometric profile

⇒ Transient pulse signal of variable

bandwidth and regularity

(different shapes)

6

Dynamic equations of motion – Vibration analysis

Newton’s force-law

∑

f kn = mk ∂ t2 xk ,

n

∑

n

µ kn

Λ

= ρ 2 mB ∂ t2 (Λθ )

al1F −a l1R

−l1F −l1R

For convenience

2

2

al1F −a l1R −a l1F +a l1R

T

• Topology

L = L = {K , C} =

(a = 1 − a )

•

State-space variables

Dynamic matrix equation

( y1

yk +d

− al1F

a l1R

l1F

l1R

y2

y3

y4 ) ≡

(w

Λθ

l1F

− al1F

−l1F −l 2 F

0

x1F

x1R )

≡ ∂ t yk , k = 1,2,3,4

x

1 0

0 1

∂ t y =

y + E 2 F

ˆ

0 M

K C

x2 R

Mˆ

= diag(M ρΛ m F m R ) ,

T

E

Solution (La-place transf.)

Y (s )

~

E (s )

D

l1R

a l1R

0

−l1R −l 2 R

0

0 L 0 ϕ2F

=

L

ϕ

0

0

0

2R

1

−1 ~

= [s − D ] E (s ) − sΛ X 2 F (s )

e v

T

0

0 L Φ 2 F (s ) m F

=

(

)

0

L

0

Φ

s

m

2R

R

1

0

= ˆ −1

ˆ −1C

M

K

M

(Φ n ≡ k n + scn )

7

Transfer function vehicle (measurement system)

’Direct’ transfer function,

road profile to car body translation and rotation

1

HW

−1 ~

(s ) = P[s − D ] E (s ) exp − sΛ

Hθ

v

P

1 0 0 L 0

=

0 1 0 L 0

Propagation:

• Input road profile – time delay front/rear

• Road profile => force, state space

• Through vehicle – dynamic matrix

• Projection to output

(x1F

x1R )

(" F = k + sc" ,

x1F = y3,

D(M , K , C )

(w = y1, Λθ = y2 )

x1R = y4 )

8

Time domain propagators – digital filtering

∏ (1 − s ~

z Fk ) ∏ (1 − s ~

p Fk ) +

The transfer function: H θ (s ) = − sΛ

~

~

(

)

(

exp

1

1

s

z

s

p Rk )

−

−

∏

∏

Rk

v

…’propagates’ road profile to car body translation and rotation.

• …’filter’ applied to the ’road profile signal’.

• …preferably realized in the time domain for road hump passage

• …approximated in discrete time, implemented as a digital filter

• …formulated in poles/zeros allows for exponential map

(sampling time TS )

qk = exp(q~k TS ), qk = z k , pk

Λ

−

(

(

(

(

z − zk )

z − zk )

1 − pk )

1 − pk )

vT

⇒ Gθ ( z ) = ∏

+z

∏

∏ (1 − z ) ∏ (z − p )

(1 − zk ) (z − pk )

k

k

S

⇒ Gθ ( z ) =

k

b

z

∑k

∑ ak z

k

+z

−

Λ

vTS

k

b

z

∑k

k

a

z

∑ k

9

Method – repeated digital filtering

•

•

⇒

•

⇒

•

Road profile input

Application of vehicle filters

Car body response

Application of seat filter

Seat response

Application of non-linear human body filter

– ISO 2631-5

– Pulse impact – not continuous spectrum!

– Fatigue model of spinal cord

⇒ Human body response – risk of injury

‘Calibration’:

• Vehicle

• Seat

• Human body – ISO 2631-5

Analysis Synthesis

Symmetry!

10

Part 0. Public interest

1. Newspaper articles: 2

– Borås Tidning (local Borås)

– TTELA (Trollhättan, where ’SAAB’ is made)

2. News on radio

3. News on public television (’prime time’, western part of Sweden)

11

Part 1. The Road Hump Toolbox

How to analyse/synthesize road humps in practice?

• Make a user-friendly toolbox with simple in-/output!

• Matlab ‘GUIDE’ development

• Mrigank Gupta student from IIT, Kanpur, India.

Summer internship at SP, Borås, Sweden in May-July 2008.

12

Part 2. Optimal hump profile – Synthesis

Desired acceleration profile

Synthesized road hump

0.04

0.1

0.03

0.09

Optima l roa d profile (m)

Acce le ra tion (g)

0.02

0.01

0

-0.01

-0.02

0.08

0.07

0.06

0.05

0.04

0.03

0.02

-0.03

0.01

-0.04

5

10

15

20

Dis ta nce (m)

25

30

35

0

5

10

15

20

Dis ta nce (m)

25

30

35

One axle model:

P.Y. Zhu, J.P. Hessling, D.S. Liu, “Optimal road hump for comfortable speed reduction”,

4th ISPMM’ 2008, International Symposium on Precision Mechanical Measurements,

Anhui, China, Aug. 25-29, 2008.

13

Part 3. Optimal hump length - Synthesis

Rotation particularly important for buses

– large separation seat and center of mass

Impulse response

(Car/Bus):

BUS : θ Λ

0.04

0.02

0

-0.02

-0.04

0

5

10

Dis tance (m)

15

20

CAR: θ Λ

0.04

0.02

0

5 km/h

30 km/h

60 km/h

-0.02

-0.04

0

5

10

Dis tance (m)

15

20

J. P. Hessling, P. Y. Zhu, “Analysis of Vehicle Rotation during Passage over Speed Control

Road Humps ”, ICICTA’ 2008, International Conference on Intelligent Computation Technology

and Automation, Changsha, China, Oct. 20-22, 2008.

14

0.03

Part 3. Cont’d.

Rotation and hump length 0.02

0.01

Λθ

2 axes vehicle,

2 sides of road hump

Ω

Λ

0

⇒ 2x2=4 pulses

-0.01

⇒ (2 pos., 2 neg.)

-0.02

Front s ide re s pons e

Re a r s ide re s pons e (Ω= 2m)

-0.03

CAR: Imp. res p. autocorr.

Auto-correlation of

ang. impulse response

=> optimal hump length!

Min. corr. => Max. response

Max. corr. => Min. response

BUS : Imp. res p. autocorr.

0

1

2

3

4

5

Tra ve lle d dis ta nce (m)

6

7

0.1

0.05

0

-0.05

-0.1

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

Lag (m)

0.1

0.05

15 km/h

30 km/h

45 km/h

0

-0.05

-0.1

15

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

Lag (m)

Part 3. Cont’d.

Variation of acceleration with speed

Large variation!

0.8

Ω = 4.5 m

0.6

5 km/h

10 km/h

30 km/h

2

BUS : ∂t θ Λ/g

0.4

∂ t2θ ∝ speed 2 ?

Acceleration

driver’s seat:

0.2

~ 1g @ 30 km h

0

10(!) times threshold

of discomfort!

-0.2

-0.4

-0.6

0

1

2

3

4

5

6 7 8 9

Dis ta nce (m)

10 11 12 13 14 15

Risk of injury*!

*ISO 2631-5: 2004 Evaluation of the Human Exposure to Whole-Body

Vibration, Geneva: International Standard Organization, 2004

16

Part 4. Calibration of a bus…

The question: How to obtain model of vehicles?

1. ’Ask’ for it

2. Calibration (!)

The hump=Excitation

The bus=‘Measurement system’

17

Part 4. Cont’d. The pulse calibration measurement

•

Hump profile: Height vs. distance

– Easy to measure!

• Velocity

– Determined from measurement:

delay of front/rear wheel response and axle separation

=> Height vs. time= Input pulse excitation

18

Part 4. Cont’d. Measured response

4 km/h

9.4 km/h

1

Front

Re a r

0.5

0.4

0.6

0.3

0.4

Acce le ra tion

Acce le ra tion

0.2

0.1

0

-0.1

-0.2

0.2

0

-0.2

-0.4

-0.3

-0.6

-0.4

-0.8

-0.5

20

Front

Re a r

0.8

21

22

23

24

Time (s )

25

26

27

-1

4

5

6

7

8

9

Time (s )

Analysis / parameter estimation remains!

Goal: Find method and general approach to determine vehicle filters.

19

Part 4. Cont’d.

Calibration bandwidth – variation with speed…

4 km/h

4.5

Roa d Hump

De -convolution

Ca libra tion ba ndwidth

4

3.5

3.5

3

S pe ctrum

S pe ctrum

Roa d Hump

De -convolution

Ca libra tion ba ndwidth

4

3

2.5

2

2.5

2

1.5

1.5

1

1

0.5

0.5

0

9.4 km/h

4.5

0

2

4

6

Fre que ncy (Hz)

8

10

12

0

0

2

4

6

Fre que ncy (Hz)

8

10

12

Calibration bandwidth very important !!!

Bandwidth increase with velocity

- but also the mixing of front/rear wheel responses:

“Correlation time of impulse response longer than delay between

impacts!”

- Optimal speed for calibration???

20

Remaining: Road hump analysis and synthesis…

Decided (-2009):

• Road hump toolbox

– Finalize (polishing and testing)

– Report (Mrigank G)

• Joint publication method / toolbox(?)

• Apply for funding (Swedish road authority)

– Spread use of toolbox

– Preferably joint project with consultant of road authority (’Profilograf’)

• Joint presentation/article ’Calibration of a bus’ (IMEKO 2009 if possible…)

Optional:

• Export to license-free executable SW (compiler)

• Provide support/consultation

• Make display-window for dynamic analysis at SP:

’Road hump analysis’ for free (SW at SP, internet login)

• Extend toolbox to include calibration (thesis worker in control theory)

21

Concluding… Why study road hump design???

Discussion!

• What’s the benefit for dynamic analysis of measurement systems?

– Short time (<1yr)

– Long time

• Visibility

• Financial support

• ’Simplicity of question’

• ’Complexity of answer’

• Spread

– Geographic

– People

– Disciplines

• Challenges?

• High precision analysis, ’traceability’ etc.

22

Thanks for your

attention!

peter.hessling@sp.se

zhu.pingyu@gmail.com

mrigank@iitk.ac.in

23