www.ae2s.com

SHOP DRAWING

TRANSMITTAL NO.

PROJECT TITLE:

P1A

8/18/2011

Bismarck Horizontal Collector Well Phase III

AE Project Number:

Reviewed By:

Date Received:

P00501-0012-02

Damon Chmela, Jasper Klein

Contractor:

Weir Floway

Owner:

City of Bismarck

Address:

PO Box 164

Address:

PO Box 5503

Fresno CA 93707

Terry Lake – Proj. Eng.

Attention:

Date Transmitted:

No. of

Copies

Attention:

Keith Demke, PE

8/30/2011

Spec Section

1

Bismarck ND 58506-5503

Action

Taken

Description

Raw Water Pumps - Resubmittal

B

The action designated above is in accordance with the following legend:

A – No Exceptions

B – Make Corrections Noted

C – Amend & Resubmit

D - Rejected - See Remarks

E - Engineer’s review not required

1. Inadequate information

2. No reproducibles submitted

1. Submittal not required.

3. Copies illegible

4. Not enough copies submitted

2. Submittal retained for informational

purposes.

5. Wrong sequence number

6. Wrong submittal suffix

3. Information reviewed and approved on

prior submittal.

7. See comments

4. See comments.

Comments:

1. Revise all motor (250HP and 600HP) main terminal box conduit penetrations from 3.5”

(submitted), to 4” for the 480V power circuitry.

2. If possible, relocate all the conduit penetrations into the main motor terminal box on the 600HP

motor to the bottom of the box to facilitate entry of large VFD cables. Presently two of the

three conduit locations on the box are shown on the side of the box and only one is located

on the bottom. Overall constructability will be greatly improved if all three conduit entries can

be located on the bottom of the box.

3. Contractor/Vendor shall fill out and submit the Motor Data Sheets from Section 16150 upon

completion of final engineering of motors.

By: Twila Kemp

Advanced Engineering and Environmental Services, Inc.

t: 701.221.0530

Date: 8/30/2011

1815 Schafer Street, Suite 301

f: 701.221.0531

Bismarck, ND 58501

Weir Floway, Inc.

2494 S. Railroad Ave.

P.O. Box 164

Fresno, CA 93706

SUBMITTAL TRANSMITTAL

Tel:(559) 442-4000

Fax:(559) 442-3098

www.weirminerals.com

PLEASE RETURN

APPROVALS AND COMMENTS

TO DANAE VALENZUELA

Terry Lake

SENDER:

559-443-6476

Phone:

To:

City of Bismarck

Phone:

Job Name. Bismarck Horizontal Collector

PO Box 5503

Well - Raw Water Pumps

221 North 5th Street

Bismarck, ND 58506-5503

Customer P.O. No.: P00501-0012-02

Attention: Ken Weber (AE2S Eng)

Phone:

UPS

Ground

Ground

DHL

EMAIL

Int'l

Express

Nxt AM

TODAY'S DATE:

REQUIRED MAILING DATE:

August 1, 2011

August 1, 2011

1 No. of Copies

FEDEX

Nxt Day 2nd Day

Floway C.O. No.: 70041

Enclosed is documentation as follows:

559-443-6468

MAILING METHOD -- (Bold Mailing

Choice)

2nd Day

Floway Quote No.: 152622

701-221-0530

Mick Delgado

AE:

How Packaged: (BOLD)

Loose

Folders

Binders

Special

Submittal

X

Re-Submittal

Additional Submittal Information

Documentation forwarded:

X

For approval (no production)

For review and comment

Other:

Remarks: Submittal Package emailed to Twila Kemp ("Twila.Kemp@AE2S.com"), Jasper Klein ("Jasper.Klein@AE2S.com"), Ken Weber

Ken Weber ("Ken.Weber@ae2s.com")

Copy of letter to:

Copy of letter with enclosure to:

FILE

Van Bergen & Markson (Bruce Nelson "bruce@vbminc.com")

DOCUMENT INDEX

Description

Document Number

Rev

Date

Pages

Submittal Cover Letter

1

See Table of Contents

61

Page 1 of 1

C:\Documents and Settings\terrylip\Desktop\SUBMITTAL PAGES\ST

EN 026 R03

Weir Floway, Inc.

2494 S. Railroad Ave.

Tel: (559) 442-4000

From the office of:

P.O. Box 164

Fax: (559) 442-3098

Danae Valenzuela

559-441-4079

Fresno, CA 93706

www.weirminerals.com

danae.valenzuela@weirminerals.com

City of Bismarck

PO Box 5503

221 North 5th Street

Bismarck, ND 58506-5503

SHOP DRAWING REVIEW

REVIEW IS FOR GENERAL COMPLIANCE

WITH CONTRACT DOCUMENTS.

NO RESPONSIBILITY IS ASSUMED FOR

CORRECTNESS OF DIMENSIONS OR DETAILS.

NO EXCEPTIONS TAKEN

Date:

August 1, 2011

x

MAKE CORRECTIONS NOTED

MAKE CORRECTIONS NOTED

AMEND & RESUBMIT

REJECTED - SEE REMARKS

Subject:

Submittal Package

COMMENTS ATTACHED

DATE

Project:

Bismarck Horizontal Collector

Floway C.O. No.:

8/30/2011

BY

JDK

AE2S

70041

Enclosed is our submittal package for your approval.

Please review this submittal package upon receipt to make sure it is complete and correct. Floway's project

engineering staff will follow-up within 1 week to verify receipt and help address any technical questions or

comments you might have. Contact information for this submittal may also be found listed below. Floway

welcomes any opportunity for a real-time engineering design review to facilitate the approval process.

The allotted submittal review time is per Floway's quote and Order Acceptance Letter. Any delay in receiving

formal acceptance of this submittal may have an impact on the validity of our pricing and/or delivery.

For technical questions, please contact

Terry Lake 559-443-6476 .

For commercial questions, please contact

Mick Delgado 559-443-6468 .

For scheduling and delivery questions, please contact

Customer Service (559) 442-4000 .

All submittal packages should be returned to my attention.

Sincerely,

Danae Valenzuela

Document Control Technician

(559) 441-4079

Page 1 of 1

\\midas\Jobs\70000\70041\ENGINEERING\SUBMITTAL\TO\2011-07-29\SUBMITTAL PAGES\SL

Prepared 8/1/2011

TABLE OF CONTENTS

Weir Floway, Inc.

2494 S. Railroad Ave.

P.O. Box 164

Fresno, CA 93706

Tel: (559) 442-4000

Fax: (559) 442-3098

CUSTOMER:

JOB NAME:

CUSTOMER P.O. NUMBER:

FLOWAY C.O. NUMBER:

City of Bismarck

Bismarck Horizontal Collector

P00501-0012-02

70041

Document Number

Rev

Date

Pages

Comments and Clarifications

ISO 9001:2000 Certification

70041CC

Det Norske Veritas

1

08/01/11

10/22/09

3

1

SECTION 2: Raw Water Pumps 1 & 2

Performance Curve

Certified Outline Drawing

(Non-Certified) Motor Data

Mechanical Seal Data

Flanged Spacer Coupling Data

7004101PC

7004101COD

Nidec (US)

John Crane 5610

John Crane Metastream

0

0

1

06/02/11

05/18/11

08/01/11

06/02/11

06/02/11

1

1

15

5

4

SECTION 3: Raw Water Pumps 3 & 4

Performance Curve

Certified Outline Drawing

(Non-Certified) Motor Data

Mechanical Seal Data

Flanged Spacer Coupling Data

7004104PC

7004104COD

Nidec (US)

John Crane 5610

John Crane Metastream

0

1

1

06/02/11

05/20/11

07/20/11

06/02/11

06/02/11

1

1

18

5

4

Nov. 2004

2

SECTION 1: General Reference Material

SECTION 4: Miscellaneous Reference Material

Coating Systems Data

Page 1 of 1

Carboline 891 Epoxy

C:\Documents and Settings\terrylip\Desktop\SUBMITTAL PAGES\TOC

Prepared 8/1/2011

SECTION 1

GENERAL REFERENCE MATERIAL

COMMENTS AND CLARIFICATIONS

Weir Floway, Inc.

2494 S. Railroad Ave.

P.O. Box 164

Fresno, CA 93706

Tel: (559) 442-4000

Fax: (559) 442-3098

CUSTOMER:

JOB NAME:

CUSTOMER P.O. NUMBER:

FLOWAY C.O. NUMBER:

City of Bismarck

Bismarck Horizontal Collector

P00501-0012-02

70041

1. A response to this submittal package is required within 30 days. If not received during this period, it may impact

pricing and shipment schedule.

2. Unless otherwise stated, the equipment to be provided by Floway Pumps will be in accordance with the

152622

contract specifications and documents noted in Quote #

3. Please verify all dimensions given in Certified Outline Drawing. Any changes to the drawing must be submitted in

writing to Floway Pumps, and may impact pricing and shipment schedule.

4. The following items will not be supplied by Floway Pumps.

●

Oil or grease

●

Valves, gauges, thermostats

●

VFD's, controls, control relays

●

Anchor bolts

●

Installation supervision (supplied by Van Bergen and Marksen)

●

Sales Tax

5. Submittal is based on non-certified motor data. Floway will notify you in a timely manner of any changes in the

Certified Outline Drawing as a result of any revisions in the certified motor data.

6. Motors are Premium Efficient.

7. Please verify that the motor conduit box taps are compatible with the field conduit sizes available. Please advise if

special conduit box location is required, as conduit box can be rotated in 90 degree increments.

8. Installation and Maintenance Manuals to follow with final data.

9. Soleplates are quoted per Floway standard dimensions, as drawings provided by the customer do not show plate

dimensions.

11. The pump will ship sub-assembled as a bowl assembly and a head assembly, with column pipe, shafting and

couplings shipped loose.

12. A mutually satisfactory contract/order must be signed prior to start of order entry and engineering.

PUMP COMMENTS & CLARIFICATIONS:

11210-1 1.03.A.~Clarifying our shipment lead time is as offered on our quote and Letter of Shipment Guarantee.

11210-3 1.04.D~Clarifying the tests offered are non-witness. The factory vibration tests offered are for record only as

we are testing with calibrated test lab drivers and cannot duplicate jobsite conditions. Due to length, the units will be

tested with reduced quantity of column pipe.

11210-4 1.06~ Clarifying that our offering does not include Maintenance and Service. This will be supplied separately

by our authorized representative, Van Bergen and Markson.

11210-5 1.08.A~Clarifying that only the epoxy coating offered is NSF certified.

Page 1 of 3

Document No. 70041CC-Rev.1

Date: 8/1/11

112105 1.10~Clarifying that our offering is per our standard terms and conditions with payment terms as outlined in

our quote and Comments and Clarifications letter.

11210-6 1.11.A~Clarifying our warranty offered is as outlined in our standard terms and conditions.

11210-6 2.02.A.4~Clarifying that only the epoxy coating offered is NSFcertified.

11210-7 2.02.C.1.k~Clarifying that the pumps offered for RWP-1 & -2 have 77.5% pump efficiency with 87% bowl

efficiency.

11210-7 2.02.C.2.k~Clarifying that the pumps offered for RWP-3 & -4 have 80.4% pump efficiency with 85.9% bowl

efficiency.

Additional comment to 11210-7 2.02.C.2.k: It was discovered during the preparation of the submittal curve that the

proposal curve was incorrectly based on the 65' primary operating head being at the bowl and not at the pump

discharge flange as we believe it should be. The submittal curve now reflects pump performance which includes the

head and column losses to achieve the required pump head at the discharge flange. Unfortunatly, this raised the

horsepower requirement and so now the maximum HP is 599. The specifications state that we cannot exceed the

nameplate rating of the motor anywhere on the curve. If everything is perfect and the pump test reflects the submittal

curve, we will not overload the motor. However, if we have a pump test where the rated head is at 65' and we exceed

the 600 HP, we would like to know if we can have the option of a -2% range on the head value. Where Hydraulic

Institue has a test acceptance head tolerance of +5%,-0%, API 610 has a test acceptance head tolerance of +5%,2%. We ask for permission to use the API 610 acceptance tolerance if we get into a situation where this is the only

way to reduce the maximum HP.

01730-41.07.C~Clarifying that our offering does not include factory final inspection.

AE2S Raw Water Pumps 3 & 4 Drawing - Exhibit C:

Please note that as shown on our pump outline drawing 7004104COD-Rev.2, the combined height of the

pump and motor now exceeds the Elevation of 1660'-0.06" by almost 3.31". We have reduced the height of

the motor and the pump discharge head as much as we can.

Addendum#1

2.~Clarifying the minimum pump efficiency offered at rated head during parallel operation is 73% in lieu of the 75%

specified.

3.~Clarifying the minimum pump efficiency offered at rated head during parallel operation is approx. 62%.

7. ~Clarifying the coating offered is Carboline Carboguard 891, which is NSF certified, and we offer as an approved

equal.

7.~Clarifying our offering includes cast iron bowl and suction assemblies as specified in 11210-102.02.E.4.a.

MOTOR VENDOR COMMENTS & CLARIFICATIONS:

11210(1-14)

[Clarification] 2.02D.2.–NEMA Design B does not apply to the 600 HP rating.

[Exception] 2.02D.3.–Exception is taken to hermetically sealed winding on 250 HP. Nidec does not offer this feature

on random wound, NEMA frame motors. Nidec is offering VPI-2000 epoxy insulation system, which meets NEMA

definition for moisture-resistant winding per NEMA MG1-1.27.1.

[Clarification] 2.02D.5.–Motor will be rated 1.15 service factor on sine wave power & 1.0 service factor on vfd power.

[Clarification] 2.02D.7.–The minimum speed should not be below 200 RPM, so to prevent the NRR from engaging.

Page 2 of 3

Document No. 70041CC-Rev.1

Date: 8/1/11

[Exception] 2.02D.16.–Exception is taken to providing Aegis SGR bearing protection ring with Aegis Colloidal Silver

Shaft Coating. As alternate, Nidec is offering an Inpro MGS (Motor Grounding Seal).

Section16150(1-10)

[Clarification] 1.05B.&1.05AA.1.–Motor will be rated 1.15 service factor on sine wave power & 1.0 service factor on vfd

power.

[Clarification] 1.05C.–NEMA Design B does not apply to the 600 HP rating.

[Clarification] 1.05G.–Quoting WPI enclosure, as per11210-82.02.D2.

[Clarification] 1.05I.1.–250 HP will be special balanced to meet 0.08IPS-Peak & 600 HP will be special balanced to

meet 0.06IPS-Peak.

[Exception] 1.05R.1.–Exception is taken to KVA Code F. Quoting KVA Code G on both ratings.

[Exception] 1.05T.1.f.–Exception is taken to providing Aegis SGR bearing protection ring with Aegis Colloidal Silver

Shaft Coating. As alternate, Nidec is offering an Inpro MGS (Motor Grounding Seal).

General Comment 600 HP contains an Extra-High-Thrust bearing arrangement that utilizes preload springs to prevent

bearing skidding. In order to properly seat the thrust bearing and unload the guide bearing, the motor must be

subjected to at least 8000 lbs of external downthrust during all operation, with exception of momentary excursions of

reduced down-thrust or up-thrust at startup and/or shutdown. Failure to provide adequate down-thrust may result in

premature damage to the motor bearings that would not be covered under warranty.

Note that :Motor Data Sheet" from specification section 16150 to be provided after final engineering of motors.

Page 3 of 3

Document No. 70041CC-Rev.1

Date: 8/1/11

DET NORSKE VERITAS

MANAGEMENT SYSTEM CERTIFICATE

Certificate No. CERT-08412-2006-AQ-HOU-RvA/ANAB

This is to certify that

Weir Floway, Inc.

at

2494 S. Railroad Avenue, Fresno, CA 93706 USA

has been found to conform to the Management System Standard:

ISO 9001:2008

This Certificate is valid for the following product or service ranges:

THE DESIGN, MANUFACTURE AND REPAIR OF VERTICAL TURBINE PUMPS

Initial Certification date:

Place and date:

November 20, 1996

Houston, Texas, October 22, 2009

for the Accredited Unit:

DET NORSKE VERITAS CERTIFICATION

INC., HOUSTON, TEXAS, AND

DNV CERTIFICATION B.V.,

THE NETHERLANDS

This Certificate is valid until:

October 22, 2012

The audit has been performed under the

supervision of

Rudy Frueboes

John Siemak

Lead Auditor

Accredited by the RvA

Management Representative

Lack of fulfillment of conditions as set out in the Certification Agreement may render this Certificate invalid.

Page 1 of 1

HEAD OFFICE: DET NORSKE VERITAS CERTIFICATION, INC. 1400 RAVELLO DRIVE, KATY, TEXAS 77449. TEL: (281) 396-1000. FAX: (281) 396-1903

SECTION 2

RAW WATER PUMPS 1 & 2

Weir Floway - Fresno Main Office

Multi-Speed Performance Curve

Parallel Operating Point

80% of Full Speed

Customer

Address

Location

Project

: City of Bismark

: , Bismark, ND

:

: Bismark+RUL]RQWDO&ROOHFWRU:HOO

Raw Water Pumps

Bowl/Pump

:

Eff (bowl / pump)

: 86.96 / 77.49 %

Power (bowl / pump) : 224 / 226 hp

NPSH required

: 24.93 ft

Pump Type

# of Stages

Quantity

Flow

Head

Speed

Fluid Density

Viscosity

Impeller Trim

: 23TKH-1

Order number

:1

Customer PO #

:2

CO #

: 10,750.0 USgpm Item #

: 65.00 ft

: 1,185 rpm

Serial #

: 1.000 / 1.000 SG Drawing #

: 1.00 cP

Drawn By

: 13.85 in

Last Modified

: CO70041-1

: P00501-0012-02

: 70041-1

: RWP-1 & -2

: 70041-1-1/2

: 7004101PC

: TL

: 02 Jun 2011 10:21 AM

The head and power may be different than that shown in accordance with Hydraulic Institute / API 610 Standards

Additional Notes:

Copyright © 2009, Weir Floway, Inc. All Rights Reserved

Weir Floway - Fresno Main Office Quote No. CO70041

02 Jun 2011 10:21 AM

NIDEC MOTOR CORPORATION

8050 WEST FLORISSANT AVE.

ST. LOUIS, MO 63136

DATE: 4/22/2011

P.O. NO.:

P000238782

Order/Line NO.: 20110750 SO 100

(Rev.1 8/1/11)

TO:

Floway Pumps

Weir Floway Inc

PO Box 164

Fresno, CA, 93707

ATTN: DOCTECH2

Model Number:

Catalog Number:

PO P000238782 CO 68174-2

AE MD

REVISIONS:

NA

NA

(NONE)

Rev.1 8/1/11

(Deleted Space Heaters)

Submittals

CONF,LLC,SUBMITTALS

ALL DOCUMENTS HEREIN ARE CONSIDERED CERTIFIED BY NIDEC MOTOR CORPORATION.

THANK YOU FOR YOUR ORDER AND THE OPPORTUNITY TO SERVE YOU.

Features:

HOLD PRODUCTION

Horsepower .............. 00250.00~00000.00 ~ KW: 186.5

Enclosure ............... WPI

Poles ................... 06~00 ~ RPM: 1200~0

Frame Size .............. 447~VP

Phase/Frequency/Voltage.. 3~060~460 ~ Random Wound

Service Factor .......... 1.15

Insulation Class ........ Class "H" ~ VPI-2000

Altitude In Feet (Max) .. 3300 Ft.(1000 M)

Ambient In Degree C (Max) +40 C

Efficiency Class ........ Premium Efficiency

Application ............. Vertical Centrifugal Pump

Customer Part Number .... CO 68174-2

16.5" Base

Non-Reverse Ratchet

Pricebook Thrust Value (lbs).. 11250

Customer Down Thrust (lbs) ... 4937

Customer Shutoff Thrust (lbs).

Up Thrust (lbs): ~

Inverter Duty Rating:

Load Type (Base Hz & Below) .. Variable Torque

Speed Range (Base Hz & Below). 10:1

"AK" Dimension (Inches).. NA

Shaft Dimensions:~U=2.375 ~ AH/V=5.000

KEYWAY=0.625 ~ ES=3.500

Temperature Rise (Sine Wave): "B" Rise @ 1.0 SF (Resist)

NEMA Design ............. B

KVA Code Letter ......... "G"

Starting Method ......... Direct-On-Line Start

Duty Cycle .............. Continuous Duty

Efficiency Value ........ 95.4 % ~ NEMA Nominal

Load Inertia (lb-ft2): NEMA ~ NEMA Inertia: 2744.00 ~ 1.00

Number Of Starts Per Hour: NEMA

Motor Type Code ............ RVI4

Rotor Inertia (LB-FT²)

74.7 LB-FT²

Qty. of Bearings PE (Shaft) 1

Qty. of Bearings SE (OPP)

1

Bearing Number PE (Shaft)

6215-J

Bearing Number SE (OPP)

7322 BEM

Nidec trademarks followed by the ® symbol are registered with the U.S. Patent and Trademark Office.

Page 1 of 16

NIDEC MOTOR CORPORATION

8050 WEST FLORISSANT AVE.

ST. LOUIS, MO 63136

DATE: 4/22/2011

P.O. NO.:

P000238782

Order/Line NO.: 20110750 SO 100

TO:

PO P000238782 CO 68174-2

AE MD

Floway Pumps

Weir Floway Inc

PO Box 164

Fresno, CA, 93707

ATTN: DOCTECH2

Model Number:

Catalog Number:

REVISIONS:

NA

NA

(NONE)

Rev.1 8/1/11

(Deleted Space Heaters)

Submittals

CONF,LLC,SUBMITTALS

ALL DOCUMENTS HEREIN ARE CONSIDERED CERTIFIED BY NIDEC MOTOR CORPORATION.

THANK YOU FOR YOUR ORDER AND THE OPPORTUNITY TO SERVE YOU.

Accessories:

100,000 Hours L-10 Brg. Life

Inpro MGS Ground Seal

CCW Rot. FODE w/Rotation Arrow

Ground Lug In Conduit Box

Insul. Bearing - Upper Bracket

115 Volt Space Heaters (space heaters deleted)

Special Balance

Bearing RTD-100 Ohm,3 Lead

Both Bearings

Multiple Thermal Protection

VFD Duty

Thermostats - Normally Closed

Q-6 Winding RTD-100 Ohm,3 Lead

Q-2 Accessory Outlet Boxes ~ Same Side As Main O/B

1" NPT Both Boxes

One Box with Terminal Board

Pre-Wire One Accessory Box

Test Requirements:

Short Commer. Test - Unwit

Calibration Test-Unwit.

USE THE DATA PROVIDED BELOW TO SELECT THE APPROPRIATE DIMENSION PRINT

Horsepower

Pole(s)

Voltage(s)

Frame Size

Shaft U Diameter

Outlet Box AF

Outlet Box AA

Accessory Outlet Box DM

250

06

460

447VP

2.375

10.00

3.50

1-1

Nidec trademarks followed by the ® symbol are registered with the U.S. Patent and Trademark Office.

Page 2 of 16

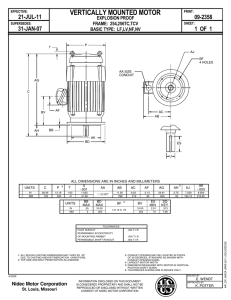

VERTICAL MOTORS

EFFECTIVE:

20-APR-11

PRINT:

09-2629-44

WEATHER PROTECTED TYPE I

FRAME: 447VP, VPA, VPB

BASIC TYPE: RV4

SUPERSEDES:

NEW

SHEET:

1 OF 1

XO

VIBRATION

DETECTOR

AF

AG

DM1 SIZE

CONDUIT

(WINDING

AND BEARING

ACCESSORY

LEADS)

BV

BE

AH

AK

DM2 SIZE CONDUIT

(WINDING SPACE

HEATER LEADS)

BD

EW

EX

ES

U

BB

R .03

MAX

AJ

P

BF

4 HOLES

EU

ALL DIMENSIONS ARE IN INCHES AND MILLIMETERS

447VP

447VPA

447VPB

UNITS

BD

MAX

IN

16.50

MM

419

AC

IN

20.00

AA

MM

508

3 NPT

IN

24.50

MM

622

2

DM1

DM2

3 1/2 NPT

1 NPT

3/4

4 NPT

1 1/4 NPT

1

UNITS

P

AB

AC

AF

AG

AJ

IN

26.94

24.25

18.75

10.00

55.00

14.750

MM

684

616

476

254

1397

374.65

BE

BF

BV

UNITS

AK

BB

+.005

MIN

IN

13.500

.25

1.00

.69

MM

342.90

6

25

18

8-POLE &

4-POLE

6-POLE

300 & DOWN

200 & DOWN

ALL

350 TO 400

250

---

SLOWER

HP

UNITS

EW

AB

AA SIZE

CONDUIT

EX

XO

+.002

-.005

26.19

.375

.750

27.50

665

9.53

19.05

699

U

-.001

AH

ES

EU

±.063

MIN

-.005

SQ

KEY

IN

2.125

4.50

3.00

1.750

.500

MM

53.98

114.30

76

44.45

12.70

IN

2.375

5.00

3.50

2.000

.625

MM

60.33

127.00

89

50.80

15.88

1: DIMENSIONS MAY VARY .25" DUE TO CASTING AND/OR FABRICATION VARIATIONS.

2: LARGEST MOTOR WIDTH.

3: TOLERANCES SHOWN ARE IN INCHES ONLY.

ISSUED BY

09-2629/-

Nidec Motor Corporation

St. Louis, Missouri

INFORMATION DISCLOSED ON THIS DOCUMENT

IS CONSIDERED PROPRIETARY AND SHALL NOT BE

REPRODUCED OR DISCLOSED

WRITTEN

Page 3 ofWITHOUT

16

CONSENT OF NIDEC MOTOR CORPORATION

V. PAWAR

APPROVED BY

M OT O R S

P. ALLGEYER

IHP_DP_NMCA (MAR-2011) PROENGINEER

FRAME

CATALOG NUMBER:

NAMEPLATE PART #:

MODEL

FR

SHAFT

END BRG

PH

3

INSUL

CLASS

H

HP

MAX

AMB

Asm.

Pos.

40 C

ID#

1185

365.0

95.4

94.5

B

CODE

G

77.0

KiloWatt

186.500

HZ

60

UL DATA (IF APPLICABLE):

DIVISION

TEMP CODE

VFD DATA (IF APPLICABLE):

VOLTS

AMPS

WPI

7322 BEM - QTY 1

(ref: Order#: 20110750, Type: SO, Line#: 100)

CONT

HP

319.0

DESIGN

NOM

PF

MAX

KVAR

ENCL

DUTY

RPM

1.15

RVI4

OPP

END BRG

460

SF

NEMA NOM

EFFICIENCY

GUARANTEED

EFFICIENCY

TYPE

6215-J - QTY 1

250

VOLTS

FL

AMPS

SF

AMPS

447VP

422707-005

RPM

VOLTS

FL

AMPS

SF

AMPS

SF

NEMA NOM

EFFICIENCY

GUARANTEED

EFFICIENCY

CLASS I

CLASS II

DESIGN

NOM

PF

MAX

KVAR

CODE

GROUP I

GROUP II

460

335.0

TORQUE 1

1107.6LB-FT

TORQUE 2

VFD LOAD TYPE 1

VT/PWM

VFD LOAD TYPE 2

VFD HERTZ RANGE 1

6-60

VFD HERTZ RANGE 2

VFD SPEED RANGE 1

120-1200

VFD SPEED RANGE 2

SERVICE FACTOR

NO. POLES

VECTOR MAX RPM

Radians / Seconds

1.00

FL SLIP

MAGNETIZING AMPS

Encoder PPR

Encoder Volts

TEAO DATA (IF APPLICABLE):

HP (AIR OVER)

FPM AIR

VELOCITY

HP (AIR OVER

M/S)

FPM AIR

VELOCITY M/S

RPM (AIR

OVER)

FPM AIR

VELOCITY SEC

Page 4 of 16

RPM (AIR OVER

M/S)

HZ

Decal / Plate

Notes

Max Temp Rise

Thermal (WDG)

Altitude

Regulatory Notes

COS

Balance

3/4 Load Eff.

Motor Weight

Sound Level

Vertical Thrust

Thrust Percentage

Bearing Life

Starting Method

Number of Starts

200/208V 60Hz Max Amps

190V 50 hz Max Amps

380V 50 Hz Max Amps

NEMA Inertia

Sumpheater Voltage

Special Accessory Note 1

Special Accessory Note 2

Special Accessory Note 3

Special Accessory Note 4

Special Accessory Note 5

Special Accessory Note 6

Special Accessory Note 7

Special Accessory Note 8

Special Accessory Note 9

Special Accessory Note 10

Special Accessory Note 11

Special Accessory Note 12

Special Accessory Note 13

Special Accessory Note 14

Special Accessory Note 15

ADDITIONAL NAMEPLATE DATA:

WD=499495

Customer PN

Non Rev Ratchet

80C RISE/RES@1.00SF

OPP/Upper Oil Cap

OVER TEMP PROT 2

SHAFT/Lower Oil Cap

0.08 IN/SEC

95.9

2100

11250

100% HT

100K

BEARING SET POINTS

ALARM= 90C

SHUTDOWN= 100C

Regulatory Compliance

Marine Duty

Arctic Duty

Inrush Limit

Direction of Rotation

Special Note 1

Special Note 2

Special Note 3

Special Note 4

Special Note 5

Special Note 6

SH Max. Temp.

SH Voltage

SH Watts

Load Inertia

Sumpheater Wattage

Special Accessory Note 16

Special Accessory Note 17

Special Accessory Note 18

Special Accessory Note 19

Special Accessory Note 20

Special Accessory Note 21

Special Accessory Note 22

Special Accessory Note 23

Special Accessory Note 24

Special Accessory Note 25

Special Accessory Note 26

Special Accessory Note 27

Special Accessory Note 28

Special Accessory Note 29

Special Accessory Note 30

NIDEC MOTOR CORPORATION

ST. LOUIS, MO

TYPICAL NAMEPLATE DATA

ACTUAL MOTOR NAMEPLATE LAYOUT MAY VARY

SOME FIELDS MAY BE OMITTED

Nidec trademarks followed by the ® symbol are registered with the U.S. Patent and Trademark Office.

Page 5 of 16

CO 68174-2

NRR

5.50 QT/5.2 L

GREASE

SH VOLTS=115V

SH WATTS=192W

AFFIX N/P 915591

MODEL NO.

CATALOG NO.

PHASE

TYPE

FRAME

NA

NA

3

RVI4

447VP

ORDER NO.

20110750

LINE NO.

MPI:

HP:

POLES:

VOLTS:

HZ:

SERVICE FACTOR:

EFFICIENCY (%):

100

89407

250

6

460

60

1.15

S.F.

FULL

3/4

1/2

1/4

94.8

95.4

95.9

95.7

93.4

S.F.

FULL

3/4

1/2

1/4

NO LOAD

LOCKED ROTOR

77.7

77

73.3

63.7

42.4

2.6

25.9

S.F.

FULL

3/4

1/2

1/4

NO LOAD

LOCKED ROTOR

365

319

250

192

148

130.4

1825

G

B

1185

95.4

94.5

88.3

40

3300

30

85

POWER FACTOR (%):

AMPS:

NEMA CODE LETTER

NEMA DESIGN LETTER

FULL LOAD RPM

NEMA NOMINAL EFFICIENCY (%)

GUARANTEED EFFICIENCY (%)

MAX KVAR

AMBIENT (°C)

ALTITUDE (FASL)

SAFE STALL TIME-HOT (SEC)

SOUND PRESSURE (DBA @ 1M)

TORQUES:

BREAKDOWN{% F.L.}

LOCKED ROTOR{% F.L.}

FULL LOAD{LB-FT}

The Above Data Is Typical, Sinewave Power Unless Noted Otherwise

NIDEC MOTOR CORPORATION

ST. LOUIS, MO

Nidec trademarks followed by the ® symbol are registered with the U.S. Patent and Trademark Office.

Page 6 of 16

207

126

1107.6

499495

Motor Wiring Diagram

T1

T1

or

T3

DELTA

Connection

T2

T3

WYE

Connection

LEAD CONNECTION

1

2

3

Line

Each lead may consist of one or more cables having the

same lead number.

499495

To reverse direction of rotation interchange connections L1 and L2.

Each lead may be comprised of one or more cables.

Each cable will be marked with the appropriate lead number.

EFFECTIVE: 2/27/96

SUPERCEDES: X736618, 96441, 179879, 284138

Connection Plate: 499495

Connection Decal: 912113

Page 7 of 16

T2

THERMOSTATS

1. MOTOR IS EQUIPPED WITH QTY-3 (1 PER PHASE) NORMALLY CLOSED THERMOSTATS.

THERMOSTATS ARE SET TO OPEN AT HIGH TEMPERATURE.

2. CONTACT RATINGS FOR THERMOSTATS: 120-600 VAC, 720 VA

N. C. THERMOSTATS

P1

P2

NOTE: THERMOSTATS LEADS MAY BE LOCATED IN EITHER THE MAIN OUTLET BOX OR IF SO

EQUIPPED, AN AUXILIARY BOX.

ACCESSORY LISTING

QTY-3 N.C. THERMOSTATS

REVISION DESCRIPTION FOR: MISC

STL0211 - UPDATED FORMAT .

SCALE

UNITS

TITLE

NONE

IN

TOLERANCES ON DIMENSIONS

(UNLESS OTHERWISE SPECIFIED)

INCHES

MATERIAL:

mm

NIDEC MOTOR CORPORATION 24-Feb-11

NMCA (JAN-2011)

MUST BE COMPLIANT TO RoHS DIRECTIVE EU 2002/95/IEC

AND REGULATION EC 1907/2006 (REACH) AS AMENDED

ISSUED BY

APPROVED BY

R. KING

---

NIDEC CONFIDENTIAL

NIDEC MOTOR

CUSTOMER

CONNECTION DIAGRAM CORPORATION

CODE

Page 8 of 16

ANGLES X°= ±1°

REVISION DATE

24-FEB-11

C. CADE

DWG NO.

REV

0834066

G

SHEET

NUMBER

1

OF

DWG

SIZE

1

A

SOLIDEDGE

WINDING RTD'S

1. THERE ARE QTY-6 RESISTANCE TYPE TEMPERATURE

DETECTORS (RTD) INSTALLED IN THE STATOR WINDING, 2

PER PHASE. REFER TO NAMEPLATE ATTACHED TO THE MOTOR

ADJACENT TO ACCESSORY OUTLET BOX FOR RATING THE RTD'S

2. DETECTORS ARE INSTALLED IN PHASES AS SHOWN.

PHASE

RTD NO.

A

1,11

WINDINGS RTD'S

(RED)

(WHITE)

(WHITE)

B

2,22

C

3,33

C1

T1

T1

C11

T11

T11

C2

T2

T2

C22

T22

T22

RTD NO.

C

T

T

REVISION DESCRIPTION FOR: MISC

STL0211 - UPDATED FORMAT.

SCALE

NONE

UNITS

IN

TOLERANCES ON DIMENSIONS

(UNLESS OTHERWISE SPECIFIED)

MATERIAL:

NIDEC CONFIDENTIAL

--- - BE

- -COMPLIANT TO RoHS DIRECTIVE EU 2002/95/IEC

MUST

NIDEC MOTOR CORPORATION 23-Feb-11 AND REGULATION EC 1907/2006 (REACH) AS AMENDED

NMCA (JAN-2011)

C3

T3

T3

C33

T33

T33

INCHES

mm

TITLE

NIDEC MOTOR

CUSTOMER

CONNECTION DIAGRAM CORPORATION

ISSUED BY

APPROVED BY

R. KING

CODE

Page 9 of 16

ANGLES X°= ±1°

REVISION DATE

23-FEB-11

C. CADE

DWG NO.

REV

0833989

D

SHEET

NUMBER

1

OF

DWG

SIZE

1

A

SOLIDEDGE

BEARING RTD'S

1. THERE ARE QTY-1 OR 2 (3 LEAD) BEARING RTD'S INSTALLED,

ONE PER BEARING.

A = UPPER/ODE (OPPOSITE DRIVE END)

B = LOWER/DE (DRIVE END)

BEARING RTD'S

UPPER/ODE

LOWER/DE

A1

B1

A2

B2

A2

B2

(RED)

(WHITE)

(WHITE)

ACCESSORY LISTING

QTY 1 OR 2 BEARING RTD'S (3 LEAD)

REVISION DESCRIPTION FOR: MISC

STL0211 - UPDATED FORMAT.

SCALE

NONE

UNITS

IN

TOLERANCES ON DIMENSIONS

(UNLESS OTHERWISE SPECIFIED)

MATERIAL:

INCHES

mm

TITLE

CUSTOMER CONNECTION

DIAGRAM

ISSUED BY

CODE

NIDEC CONFIDENTIAL

--MUST BE COMPLIANT TO RoHS DIRECTIVE EU 2002/95/IEC

NIDEC MOTOR CORPORATION 24-Feb-11 AND REGULATION EC 1907/2006 (REACH) AS AMENDED

NMCA (JAN-2011)

APPROVED BY

R. KING

Page 11 of 16

ANGLES X°= ±1°

C. CADE

DWG NO.

0338312

NIDEC MOTOR

CORPORATION

REVISION DATE

24-FEB-11

REV

C

SHEET

NUMBER

1

OF

DWG

SIZE

1

A

SOLIDEDGE

FRAMES 324 THRU 445 - OPEN DRIPPROOF MOTORS

TYPES: RU, RUE, RUI, RUS, RUSI, RV, RV4, RVE, RVE4, RVI, RVI4, RVS, RVS4

HIGH THRUST - WEATHER PROTECTED TYPE 1 - P BASE

HOLLOSHAFT & SOLIDSHAFT MOTORS

ITEM

NO.

QTY

1

2

3

4

1

3

1

1

5

4

6

7

8

9

10

11

12

13

1

1

2

1

1

4

1

1

NAME OF PART

Canopy Cap

Hex Head Cap Screws (Canopy Cap)

Upper Bracket Assembly

Oil Retaining Tube

Hex Head Cap Screw & Lockwasher (Bracket to

Stator)

Special Plug

Reflector Disc

Gasket - Sight Gauge

Sight Gauge Window

Sight Gauge Housing

Oval Head Screw (Sight Gauge)

Nipple Fitting (Oil Drain)

Gasket or "O" Ring

WARNING:

Any disassembly or repair work on explosionproof motors will

void the Underwriters Laboratories, Inc.label unless done by the

manufacturer, or a facility approved by the Underwriters

Laboratories, Inc.Refer to your nearest U.S. Elecrical Motors

office for assistance.

ITEM

NO.

QTY

14

15

16

17

18

19

20-25

26

27

1

1

1

1

1

3

1

1

28

3

29

30

3

1

NAME OF PART

Drain Cap

Locking Arm

Hex Head Cap Screw & Lockwasher

Dust Ring

Gasket (Dust Ring)

Hex Head Cap Screw & Lockwasher

NOT USED THIS ASSEMBLY

Coupling (RU & RUE only)

Gib Key

Hex Head Cap Screw & Lockwasher

(Bearing Mounting)

Spring Pin

Locknut / Lockwasher

BEARINGS:

Refer to motor nameplate for the bearing

numbers.

PRICES:

Parts stocking distributors: refer to

USEM renewal parts numerical index.All

Others: refer to your nearest USEM

parts distributor.

reference: Renewal Parts Section 700, Pages 149 & 150

Page 12 of 16

FRAMES 324 THRU 445 - OPEN DRIPPROOF MOTORS

TYPES: RU, RUE, RUI, RUS, RUSI, RV, RV4, RVE, RVE4, RVI, RVI4, RVS, RVS4

HIGH THRUST - WEATHER PROTECTED TYPE 1 - P BASE

HOLLOSHAFT & SOLIDSHAFT MOTORS

ITEM

NO.

QTY

31

32

33

34

1

1

1

1

35

1

36

1

37

7

38

39

40

41-45

46

47

48

49

50

51

52

53

54

55

56

57

58

1

1

1

1

1

1

1

1

1

1

4

1

1

1

4

1

59

4

60

4

NAME OF PART

Bearing Mounting

Square Key

Ball Bearing (Upper) (Refer to Section 775)

Metering Plate (Used on 444 & 445 frames only)

Hex Head Cap Screw & Lockwasher

(Used on 444 & 445 frames only)

Air Deflector (Upper)

Self-Tapping Screw (Air Deflector) Use Qty. 8

on 404 & 405 frame & Qty. 6 on 444 & 445 frame

Rotor Assembly (Includes items 39 & 40)

Rotor Core

Rotor Shaft

NOT USED THIS ASSEMBLY

Wound Stator Assembly

Grill (Upper Fame)

Expansion Spring

Grill (Lower Frame)

Expansion Spring

Gasket (Outlet Box Base)

Outlet Box Base

Hex Head Cap Screw

Hex Head Countersunk Pipe Plug

Gasket (Outlet Box Cover)

Outlet Box Cover

Hex Head Cap Screw (Outlet Box Cover)

Lower Bracket "P" Base

Hex Head Cap Screw

(Not used on 404 & 405 frames)

Stud / Nut & Washer

(Used on 404 & 405 frames only)

WARNING:

Any disassembly or repair work on explosionproof motors will

void the Underwriters Laboratories, Inc. label unless done by the

manufacturer, or a facility approved by the Underwriters

Laboratories, Inc. Refer to your nearest U.S. Elecrical Motors

office for assistance.

ITEM

NO.

QTY

61-65

66

1

67

68

69

70

71

72

73

74

75

76

77

120

121

NAME OF PART

NOT USED THIS ASSEMBLY

Grease Fitting

Cap

1 Plastic

(Used on frames 404, 405, 444 & 445 only)

1 Pipe Plug

1 Lower Air Deflector

1 Lower Screen

Hex Head Cap Screw & Lockwasher

4 (Qty. 8 on 404 & 405 frames, Qty. 6 on 444 & 445

frames)

1 Lower Bearing Cap

3 Hex Head Cap Screw / Lockwasher

1 Ball Bearing (Lower) (Refer to Section 775)

1 Bearing Spacer (Lower)

1 Snap Ring

1 Water Deflector

FOR UNITS WITH STABILIZER BUSHINGS, OMIT

ITEM NO. 77 & ADD THE FOLLOWING:

1 Stabilizer Bushing

2 Socket Set Screws

FOR UNITS WITH NON-REVERESE RATCHETS,

OMIT ITEM NO.'s 15, 17 & 19 AND ADD THE FOLLOWING:

150

151

152

153

154

1

3

1

12

1

155

6

156

3

Stationary Ratchet

Socket Head Cap Screws

Rotating Ratchet

Steel Balls

Ball Retaining Ring

Round Head Machine Screws, Lockwasher

& Plain Washers

Hex Head Cap Screws

BEARINGS:

Refer to motor nameplate for the bearing

numbers.

PRICES:

Parts stocking distributors: refer to

USEM renewal parts numerical index. All

Others: refer to your nearest USEM

parts distributor.

reference: Renewal Parts Section 700, Pages 149 & 150

Copyright © 2010 Nidec Motor Corporation. All rights reserved.

Page 13 of 16

USEM MODEL NO: NA

USEM CATALOG NO: NA

Frame: 447VP Type: RVI4

REED CRITICAL FREQUENCY:

29

HZ

CENTER OF GRAVITY:

22

IN

DEFLECTION @ CENTER OF GRAVITY:

0.012

IN

UNIT WEIGHT:

2100

LBS.

BASE DIAMETER:

16.5

IN.

27

IN.

MAXIMUM MOTOR DIAMETER:

DATE:

4/22/2011

Home Email

Copyright © 2010 Nidec M otor Corporation. All rights reserved.

Page 14 of 16

Suitability of Integral Horsepower (IHP)* Motors

on Variable Frequency Drives

Variable Frequency Drives (VFD)

Nidec Motor Corporation’s Inverter Grade® insulated motors exceeded

NEMA®† MG-1 Part 30 & 31 before the standards were established.

We are a leader in the development of electric motors to withstand pulse

width modulated (PWM) drives evolution from power transistors to higher switching frequency insulated gate bipolar transistors (IGBTs).

Today, as the need for light and medium duty motor inverter applications

grows, Nidec Motor Corporation provides products to meet these

demands.

Through continued research and development, Nidec Motor Corporation

has included the insulation wire from its Inverter Grade® motors on all

Premium, Energy and Standard Efficient motors, enhancing their potential

inverter compatibility.

Inverter compatibility with motors is complex. As a result, many variables

must be considered when determining the suitability of certain types of

motors. These variables include:

• Torque requirements (Constant or Variable)

• Speed Range

• Line/System Voltage

• Cable Length between VFD & Motor

• Drive Switching (Carrier) Frequency

• Motor Construction

Wider speed ranges, higher voltages, higher switching frequencies and

increased cable lengths all add to the severity of the application and

therefore the potential for premature motor failure. Nidec Motor

Corporation has differentiated its products into families for your ease of

selection for various inverter applications.

Nidec Motor Corporation’s U.S. Motors® brand is available in the following

Inverter Grade® insulated motors:

• Inverter Duty motors good for 10:1 Variable Torque & 5:1 Constant

Torque, including Vertical Type RUSI

• Inverter Duty motors good for 10:1 Constant Torque

• ACCU-Torq® and Vector Duty Motors with full torque to 0 Speed &

1024 PPR, 5-28VDC Encoder

• 841 Plus® motors that meet IEEE®† 841 Standards and are suitable

for 5:1 Constant Torque

Applying Premium Efficient Motors on

Variable Frequency Drives

Meet NEMA®† MG-1, Section IV, Part 31.4.4.2. They can be used with

adjustable frequency drives under the following parameters: Up to 4:1

speed range on constant torque loads, standard two-year limited warranty (see page ix).

Cable Distances for Applying Premium Motors

Maximum Cable Distance VFD to Motor

Warranty Guidelines

Switching Frequency

460 Volt

230 Volt

380 Volt

3 Khz

196 ft

481 ft

295 ft

6 Khz

168 ft

340 ft

209 ft

9 Khz

113 ft

278 ft

170 ft

12 Khz

98 ft

241 ft

148 ft

15 Khz

88 ft

215 ft

132 ft

20 Khz

76 ft

186 ft

114 ft

The information within this section refers to the motor and drive application guidelines and limitations for warranty.

Applying Standard & Energy Efficient Motors

on Variable Frequency Drives

Hazardous Location Motors

Meet NEMA®† MG-1, Section IV, Part 30.2.2.8. They can be used with

adjustable frequency drives under the following parameters: Up to 2:1

speed range on constant torque loads, one year limited warranty (see

page ix).

Use of a variable frequency drive with the motors in this catalog, intended

for use in hazardous locations, is only approved for Division 1, Class I,

Group D hazardous location motors with a T2B temperature code, with a

limitation of 2:1 constant torque or 10:1 variable torque output. No other

stock hazardous location motors are inherently suitable for operation with

a variable frequency drive. If other requirements are needed, including

non-listed Division 2, please contact your Nidec Motor Corporation territory manager to conduct an engineering inquiry.

Cable Distances for Applying EPAct & Standard Motors

Maximum Cable Distance VFD to Motor

Applying Inverter Grade® Insulated Motors on

Variable Frequency Drives

The products within this catalog labeled “Inverter Duty” or “Vector Duty”

are considered Inverter Grade® insulated motors. Inverter Grade® motors

exceed the NEMA®† MG-1 Part 31 standard.

Nidec Motor Corporation provides a three-year limited warranty (see page

ix) on all Inverter Grade® insulated motors and allows long cable runs

between the motor and the VFD (limited to 400 feet without output filters). These motors may be appropriate for certain severe inverter application or when the factors relating to the end use application are undefined

(such as spares).

Switching Frequency

460 Volt

230 Volt

380 Volt

3 Khz

103 ft

435 ft

218 ft

6 Khz

73 ft

307 ft

154 ft

9 Khz

59 ft

251 ft

126 ft

12 Khz

51 ft

217 ft

109 ft

15 Khz

46 ft

194 ft

98 ft

20 Khz

40 ft

168 ft

85 ft

All Nidec Motor Corporation motors have 40°C ambient, 1.0 SF on

Inverter Power, 3300 ft. max altitude, 460 voltage or less line power,

up to 10:1 speed range on Variable Torque and Class F Insulation. 575volt motors can be applied on inverters when output filters are used.

*This information applies only to Integral Horsepower (IHP) motors as defined on the Agency Approval page, under UL®† & CSA®† listings where indicated.

† All marks shown within this document are properties of their respective owners

Page 15 of 16

www.nidec-motor.com

vii

Motor/ Inverter

Compatibility

Thermal Overloads and Single Phase Motors

Multiple Motors on a Single VFD

Motors with thermal overloads installed may not operate properly on a

VFD. The current carrying thermal overload is designed for sine wave

power. Operation on a VFD may cause nuisance tripping or potentially

not protect the motor as would be expected on line power. Thermostats or thermistors installed in the motor and connected properly to

the VFD may provide suitable thermal overload protection when operating on a VFD. (Consult Codes)

Special considerations are required when multiple motors are powered

from a single VFD unit. Most VFD manufacturers can provide guidelines

for proper motor thermal considerations and starting/stopping of

motors. Cable runs from the VFD and each motor can create conditions

that will cause extra stress on the motor winding. Filters may be required

at the motor to provide maximum motor life.

Single phase motors and other fractional horsepower ratings are not

designed to be operated on a VFD. Within Nidec Motor Corporation

standard products, all motors NEMA®† 48 frame (5.5” diameter) and

smaller are not suitable for VFD applications. Three phase 56 and

143/145 frame applications should be noted on the catalog price page;

or if in doubt ask an Nidec Motor Corporation technical representative

for recommendations on compatibility with a VFD.

Slow Speed Motors

Grounding and Cable Installation Guidelines

Proper output winding and grounding practices can be instrumental in

minimizing motor related failures caused by PWM waveform characteristics and installation factors. VFD manufacturers typically provide detailed

guidelines on the proper grounding of the motor to the VFD and output

cable routing. Cabling manufacturers provide recommended cable types

for PWM installations and critical information concerning output wiring

impedance and capacitance to ground.

Vertical Motors on VFDs

Motors with a base design of slower than six poles require special consideration regarding VFD sizing and minimizing harmonic distortion created at the motor terminals due to cable installation characteristics.

Additional external PWM waveform filters and shielded motor cables

designed for PWM power may be required to provide acceptable motor

life. Harmonic distortion on the output waveform should be kept to a

minimum level (less than 10%).

690V Applications

Motors that will be applied to 690Vac PWM VFDs require the use of an

external filter to limit peak voltage spikes and the use of an Inverter

Grade® motor. Where available, an alternative to using an output filter is

to upgrade to a 2300V insulation system.

Low Voltage TITAN® Motors

The use of 449 frame and larger motors on PWM type VFDs should use

the cable length limits of the second chart from the previous page as a

guide for inverter application or consider the use of an external filter and

shielded motor cables designed for PWM power to minimize harmonic

distortion and peak voltages at the motor terminals. Harmonic distortion on the output waveform should be kept to a minimum level (less

than 10%).

Bearing Currents related to PWM waveform

Due to the uniqueness of this condition occurring in the field, protection of the motor bearings from shaft currents caused by common

mode voltages is not a standard feature on sinewave or Inverter Duty

motor products, unless explicitly noted. Some installations may be

prone to a voltage discharge condition through the motor bearings

called fluting.

Fluting damage is related to characteristics of the PWM waveform, VFD

programming and characteristics and installation.

Bearing fluting as a result of VFD sine wave characteristics may be prevented by the installation of a shaft grounding device such as a brush or

ring and/or correction of the installation characteristics causing the

shaft voltage condition.

Vertical motors operated on VFD power present unique conditions that

may require consideration by the user or installation engineer:

• Slowest rpm that can be utilized and not cause the non-reversing

ratchet to operate properly (in the range of 200 –300 rpm)

• Unexpected / unacceptable system vibration and or noise levels

caused by the torque pulsation characteristics of the PWM waveform,

a system critical frequency falling inside the variable speed range of

the process or the added harmonic content of the PWM waveform

exciting a system component

• Application related problems related to the controlled acceleration/deceleration and torque of the motor on VFD power and the

building of system pressure/ load.

• The impact the reduction of pump speed has on the down thrust

reflected to the pump motor and any minimum thrust requirements

of the motor bearings

• Water hammer during shutdown damaging the non-reversing ratchet

Humidity and Non-operational Conditions

The possible build-up of condensation inside the motor due to storage in

an uncontrolled environment or non-operational periods in an installation, can lead to an increased rate of premature winding or bearing failures when combined with the stresses associated with PWM waveform

characteristics. Moisture and condensation in and on the motor winding

over time can provide tracking paths to ground, lower the Megohm

resistance of the motor winding to ground and lower the Corona

Inception Voltage level of the winding.

Proper storage and maintenance guidelines are important to minimize

the potential of premature failures. Space heaters or trickle voltage heating methods are the preferred methods for drying out a winding that has

low megaohm readings. Damage caused by these factors are not covered by the limited warranty provided unless appropriate heating methods are properly utilized during non-operational periods and prior to

motor start-up.

NEMA®† Application Guide for AC Adjustable Speed Drive Systems:

http://www.nema.org/stds/acadjustable.cfm#download

*This information applies only to Integral Horsepower (IHP) motors as defined on the Agency Approval page, under UL®† & CSA®† listings where indicated.

† All marks shown within this document are properties of their respective owners

Page 16 of 16

viii

www.nidec-motor.com

Single O-Ring Seals

– Face/Primary Ring

– Seat/Mating Ring

– Secondary O-Ring

– Nonclogging

Wave Spring

E – Sleeve

F – Gland

A

B

C

D

F

E

B

C

A

D

Product Description

The Universal Cartridge 5600 Series is a modular

cartridge seal family that includes interchangeable

elastomer bellows, Sealol® metal bellows, and

elastomer o-ring pusher seal designs.

■

■

■

Type 5610 and 5610Q single seal arrangements

incorporate an elastomer o-ring as the secondary

sealing member.

A common seal head/mating ring set, utilized

throughout all versions, is reversible to allow rotating

seat/mating ring or rotating seal head operation, and

is interchangeable with metal bellows seal heads.

Seal has an optional quench gland (5610Q) with

carbon ring throttle bushing.

Performance Capabilities

■

Temperature:

-30˚C to 205˚C/-20˚F to 400˚F

■

Pressure:

Up to 75mm/3.000":

21 bar g/300 psig max.

75mm/3.000" and Over: 13 bar g/200 psig max.

■

Speed:

Up to 25 m/s / 5000 fpm

■

End Play/Axial Float Allowance:

0.13mm/0.005"

■

Runout/Out of Squareness:

0.05mm/0.002"

Design Features

■

■

■

■

Reversible Seal Head

Fits ANSI B73.1M, ISO 3069 and DIN 24960

Seal Chambers

Optimized Primary Ring Design for Greater Reliability

Nonclogging Wave Spring Outside the Product

Sealol is a registered trademark of John Crane.

Page 1 of 5

6/2/11

5610/5610Q

TYPE 5610/5610Q

TYPE 5610/5610Q

Single O-Ring Seals

Basic Pressure Rating

Pressure (bar g)

25

Pressure (psig)

350

Carbon vs. Silicon Carbide

at 3600 rpm & Silicon Carbide

vs. Silicon Carbide to 1800 rpm

20

300

250

15

200

150

10

100

50

0

0

20

50

1

2

80

3

110

140

5

4

(mm)

6 (inches)

Seal Size

The Basic Pressure Rating is for a standard seal, as shown in the typical arrangement, when installed according to the criteria

given in this data sheet and generally accepted industrial practices.

The Basic Pressure Rating assumes stable operation at the speeds indicated on the above chart in a clean, cool, lubricating,

nonvolatile liquid with an adequate flush rate. When used with the multiplier factors, the Basic Pressure Rating can be adjusted

to provide a conservative estimate of the dynamic pressure rating. For process services outside this range or a more accurate

assessment of the dynamic pressure rating, contact John Crane for more information.

Multiplier Factors

Selection Considerations

Sealed Fluid

Lubricity

(applies to Silicon

Carbide vs. Silicon

Carbide only)

Sealed Fluid

Temperature

(applies to Carbon

vs. Silicon Carbide,

sizes 100mm/4"

and above)

Multiplier

Factor

Petrol/Gasoline, Kerosene, or Better

Water and Aqueous Solutions

(<80˚C/176˚F)

Flashing Hydrocarbons*

x 1.00

x 0.75

Up to 80°C/175°F

From 80°C to 120°C/175°F to 250°F

From 120°C to 180°C/250°F to 355°F

Above 180°C/350°F

x

x

x

x

x 0.60

*The ratio of sealed pressure to vapor pressure must be greater than 1.5,

otherwise consult John Crane. If the specific gravity is less than 0.60,

consult John Crane.

1.00

0.90

0.80

0.65

Example for Determining Pressure Rating Limits:

Seal: 50.8mm/2" diameter Type 5610

Product: Aqueous Solution

Face Materials: Silicon Carbide vs. Silicon Carbide

Operating Temperature: 80°C/175°F

Operating Speed: 2950 rpm

Using the Pressure Rating Limits graph, the

maximum pressure would be 18.5 bar g/268 psig.

From the Multiplier Factors chart, apply the multipliers

for the specific service requirements to determine the

maximum operating pressure for the application:

18.5 bar g/268 psig x 0.75 x 1 = 13.9 bar g/201 psig

The maximum operating pressure for this 50.8mm/2"

Type 5610 is 13.9 bar g/201 psig.

Page 2 of 5

6/2/11

CUT LINE FOR SHORT PAGE

Silicon Carbide vs.

Silicon Carbide at speeds

1800 to 3600 rpm

5

TYPE 5610/5610Q

Single O-Ring Seals

Type 5610 Typical Arrangement/Dimensional Data

FLUSH

Clockwise

Rotation

L90 MIN. TO NEAREST OBSTRUCTION

L39

L23

L91 MIN.

BOX DEPTH

L56

NOTE: For tangential tappings

only. Gland can be

rotated to fit both ISO

and ANSI pump types.

M

L92

D26

SLOT

WIDTH

N

CUT LINE FOR SHORT PAGE

MIN. TURN DIAM.

D4

D2

16µm/63µ"

Ra

L12

D1

+ 0.000mm/0.000"

- 0.051mm/0.002"

Type 5610 Dimensional Data (inches)

Seal Size/D1

(inches)

1.000

1.125

1.250

1.375

1.500

1.625

1.750

1.875

2.000

2.125

2.250

2.375

2.500

2.625

2.750

2.875

3.000

3.125

3.250

3.375

3.500

3.625

3.750

3.875

4.000

4.125

4.250

4.500

4.750

5.000

5.250

5.500

D4

D2

1.375

1.500

1.625

1.750

1.937

2.062

2.170

2.312

2.437

2.562

2.687

2.812

3.062

3.312

3.312

3.375

3.625

3.750

3.750

4.000

4.125

4.218

4.343

4.468

4.593

4.718

4.843

5.093

5.343

5.843

6.093

6.343

Min.

1.445

*

*

*

2.007

2.132

2.240

2.382

2.507

2.632

2.757

2.882

*

*

*

*

*

3.853

3.853

4.125

4.250

4.343

4.468

4.593

4.718

4.843

4.968

5.218

5.468

5.968

6.218

6.468

Max.

1.889

2.015

2.294

2.421

2.680

2.812

2.918

2.918

3.015

3.360

3.485

3.610

3.891

4.062

4.062

4.186

4.469

4.600

4.600

4.850

4.975

5.100

5.199

5.375

5.500

5.625

5.750

6.000

6.313

7.260

7.510

8.000

*Not applicable. Completely outside mounted.

D26

4.000

4.125

4.250

4.375

4.875

5.000

5.250

5.250

5.500

5.859

6.500

6.500

6.750

6.750

6.750

7.000

7.750

7.875

7.437

8.125

8.250

8.375

8.750

8.750

9.000

9.000

9.250

9.500

10.375

12.000

12.250

12.687

L12

1.989

2.062

2.062

2.062

2.156

2.156

2.156

2.156

2.375

2.375

2.375

2.484

2.484

2.500

2.500

2.500

2.500

2.562

2.562

2.562

2.562

2.562

2.562

2.562

2.562

2.562

2.562

2.562

2.562

2.953

2.953

2.953

L23

1.353

1.446

1.446

1.446

1.487

1.487

1.487

1.487

1.601

1.601

1.601

1.717

1.717

1.625

1.625

1.725

1.787

1.593

1.593

1.593

1.593

1.593

1.593

1.593

1.593

1.593

1.593

1.593

1.593

1.749

1.749

1.749

L39

1.954

2.062

2.062

2.062

2.125

2.125

2.125

2.125

2.312

2.312

2.312

2.466

2.562

2.500

2.500

2.500

2.562

2.562

2.510

2.562

2.562

2.562

2.562

2.562

2.562

2.562

2.562

2.562

2.562

3.043

3.043

3.043

L56

0.531

0.531

0.531

0.531

0.593

0.593

0.593

0.593

1.063

0.593

0.593

0.625

0.625

0.625

0.625

0.625

0.685

**

**

**

**

**

**

**

**

**

**

**

**

**

**

**

L90

2.000

2.125

2.125

2.125

2.187

2.187

2.187

2.187

2.375

2.375

2.375

2.528

2.625

2.562

2.562

2.562

2.625

2.687

2.635

2.687

2.687

2.687

2.687

2.687

2.687

2.687

2.687

2.687

2.687

3.168

3.168

3.168

**L56 not applicable. Refer to L23 for sizes over 3".

L91

0.160

0.125

0.125

0.125

0.156

0.156

0.156

0.156

0.187

0.187

0.187

0.143

0.125

0.125

0.125

0.125

0.125

0.125

0.177

0.125

0.125

0.125

0.125

0.125

0.125

0.125

0.125

0.125

0.125

0.125

0.125

0.125

L92

0.035

*

*

*

0.031

0.031

0.031

0.031

0.062

0.062

0.062

0.018

*

*

*

*

*

*

0.052

*

*

*

*

*

*

*

*

*

*

*

*

*

M

0.525

0.525

0.525

0.525

0.525

0.562

0.562

0.562

0.562

0.687

0.687

0.687

0.687

0.687

0.687

0.687

0.812

0.812

0.812

0.812

0.812

0.687

0.687

0.812

0.812

0.812

0.812

0.812

0.812

0.812

0.812

0.937

N

2.805

2.933

3.213

3.338

3.599

3.766

3.875

3.875

4.000

4.469

4.566

4.719

5.000

5.170

5.170

5.312

5.720

5.845

5.845

6.095

6.220

6.250

6.770

6.636

6.761

6.886

7.011

7.261

7.574

10.000

10.250

10.500

Page 3 of 5

6/2/11

TYPE 5610/5610Q

Single O-Ring Seals

Materials of Construction

SEAL COMPONENTS

MATERIALS

CUT LINE FOR SHORT PAGE

Description

Standard

Options

Face/Primary Ring

Resin-Impregnated Carbon

Sintered Silicon Carbide

Nickel Binder Tungsten Carbide

Seat/Mating Ring

Sintered Silicon Carbide

Nickel Binder Tungsten Carbide

Sleeve

Gland Plate

Collar

Retainer

Drive Ring

Anti-Extrusion Ring

316 Stainless Steel

Alloy 20CB3 SS (UNS N8020)

Alloy C-276 (UNS N10276)

Titanium

O-Ring

Fluoroelastomer

Ethylene Propylene

Perfluoroelastomer

Buna-N

Neoprene

Gland Gasket

Glass-Filled PTFE

—

Spring

Alloy C-276 (UNS N10276)

—

Quench Bushing

(5610Q)

Resin-Impregnated Carbon

—

Application Criteria

The Type 5610 and 5610Q Cartridge seals may be customized for specific installations after review and evaluation

by John Crane Engineering. The following data is needed to evaluate the proposed service:

■

Make and Model of Equipment

■

Shaft or Sleeve OD

■

Seal Cavity Dimensions

■

Speed

■

Quench Fluid (if applicable)

■

Process Fluid

• Specific Gravity

• Box Pressure

• Vapor Pressure

• Temperature

• Viscosity

Page 4 of 5

6/2/11

TYPE 5610/5610Q

Single O-Ring Seals

Europe

Slough, UK

Latin America

São Paulo, Brazil

Middle East, Africa, Asia

Dubai, United Arab Emirates

North America

Morton Grove, Illinois USA

Tel: 44-1753-224000

Fax: 44-1753-224224

Tel: 55-11-3371-2500

Fax: 55-11-3371-2599

Tel: 971-4-3438940

Fax: 971-4-3438970

1-800-SEALING

Tel: 1-847-967-2400

Fax: 1-847-967-3915

For your nearest John Crane facility, please contact one of the locations above.

If the products featured will be used in a potentially dangerous and/or hazardous process, your John Crane representative should be consulted prior to their selection and use.

In the interest of continuous development, John Crane Companies reserve the right to alter designs and specifications without prior notice. It is dangerous to smoke while handling

products made from PTFE. Old and new PTFE products must not be incinerated.

©2003 John Crane Inc. Print 10/02 reprint 2/03

www.johncrane.com

ISO 9001 and QS-9000 Certified

Page 5 of 5

6/2/11

S-5610/5610Q

®

CPLR & CPAT

Type CPLR & CPAT

C-Series Rigid Couplings

A – Motor hub and

split ring to

NEMA standard

B – Variable length

spacer

C – Externally

adjustable shaft

nut

D – Pilot fits insure A

repeatable

concentric

installation

D

B

C

Design Features

Product Description

Metastream® C-Series Couplings incorporate a

segmented, piloted locating design. This eliminates the

shaft distortion associated with conventional ‘clam shell’

coupling designs. The CPLR is for industrial applications

and the CPAT is for higher speed applications:

n

Designed to transmit torque between vertical mounted

equipment including:

- Vertical Pumps.

- Vertical Turbines.

- Vertical Mixers.

n

Easily adjustable for setting vertical clearance.

n

CPAT meets requirements of API 610 8th Edition.

n

Infinite life.

n

Optional materials & coatings available.

n

Corrosion-resistant phosphate coating on AISI 1040 steel.

n

Electrically insulated design available.

n

Robust design.

Metastream is a registered trademark of John Crane Inc.

Page 1 of 4

6/2/11

CPLR & CPAT

Type CPLR & CPAT

®

C-Series Rigid Couplings

Dimensions and Technical Data

C

B

MAX.

Motor Hub

F

E

D

L

J

H

Spacer

D

K

D

A

H

Adjusting Nut

G

H

Pump Hub

D

E

Hole for

Key Stop

Pin

B

MAX.

C

Coupling HP/100

Trust

Fit NEMA

CAP.-LB

Frame

2.7

4500

182-215

4

1/4

3.00

1.125

1.75

0.38

2.00

0.375

1.25

0.125

0.016

4.44

1.63

0.89

8.0

11000

254-326

6

5/16

4.00

1.625

2.50

0.44

2.25

0.375

1.50

0.125

0.016

4.44

1.75

0.89

2125

17.9

28500

364-445

6

1/2

5.13

2.125

3.13

0.63

2.69

0.375

1.75

0.125

0.016

4.44

2.63

0.89

2625

33.8

28500

No std

6

1/2

5.88

2.625

3.88

0.63

2.94

*

3.50

0.125

0.016

4.44

2.63

0.89

2875

44.4

28500

No std

6

1/2

6.38

2.875

4.38

0.75

3.44

*

3.50

0.125

0.016

4.44

2.88

0.89

3125

57.0

38000

No std

8

1/2

6.75

3.125

4.63

0.75

4.00

*

3.50

0.125

0.016

4.44

2.88

0.89

3875

109

66000

No std

6

3/4

8.94

3.875

5.88

0.81

4.38

*

4.00

0.125

0.016

4.44

3.13

0.89

5000

310

159000

No std

8

1

11.75

5,000

7.50

1.00

6.00

*

3.00

0.250

0.125

No std 4.50

1.38

6000

404

199000

No std

10

1

13.25

6,000

9.00

1.13

9.25

0.625

2.38

0.250

0.125

No std 4.75

1.63

7250

712

278000

No std

14

1

15.00

7.250

10.75

2.25

10.75

0.750

3.69

0.313

0.125

No std 7.06

1.94

8500

1148

294000

No std

12

1-1/8

17.25

8.500

12.50

2.25

15.00

0.750

3.56

0.313

0.125

No std 7.31

1.94

10500

2164

352000

No std

12

1-1/8

20.50 10.500 15.00

2.75

18.38

0.750

4.19

0.313

0.125

No std 8.31

1.94

Size

RPM

1125

1625

Bolts

Bolt

A

B

C

D

E

F

G

H

K

J

Per FLG DIA.

STD

L

MIN

Notes:

1. Driver hub bores are in 0.25" increments from 0.875" to and including 3.875" then any diameter up to 10.500". Standard bores are

to AGMA 9002 Class 2 clearance and keyways to AGMA 9002 commercial tolerance for both driver and driven hubs.

2. John Crane Flexibox does not furnish the key stop pin.

3. 3/8 or 1/2 inch thick split rings are standard options on sizes 2625 thru 3875 and 1/2 or 3/4 inch on size 5000.

4. Adjusting nuts can be supplied blank or threaded. Standard threads are ANSI UN Class 2B, left or right hand.

5. NEMA frame sizes apply to VP and HP series.

Table refers to Standard Range. Modified designs to meet specific customer requirements are available.

Page 2 of 4

6/2/11

Type CPLR & CPAT

C-Series Rigid Couplings

®

Configurations

Style 1

Non-spacer style provides easy assembly on driver and

rotating driven equipment shafts. Usually used on

equipment where there is a minimum of distance

between shaft ends.

Style 2

Non-spacer style with an adjusting nut so that vertical

clearances in the driven equipment may be attained.

Usually used on equipment where there is a minimum

of distance between shaft ends.

Style 3

Spacer Coupling style offers a spacer whereby the driven

equipment may be worked on without the disassembly or

removal of the driver.

Style 4

Spacer Type Rigid Coupling offers a removable spacer for

easy maintenance of driven equipment and an adjusting

nut assembly, whereby the vertical clearance in the driven

equipment may be attained.

Style 4

Style 3

Style 2

Style 1

N

M

Coupling

M

1125

4.00

P

N

Size

5.25

R

P

R

STD

MIN

STD

MIN

8.31

5.50

9.56

6.75

1625

4.50

6.00

8.81

6.13

10.31

7.63

2125

5.38

7.13

9.69

7.88

11.44

9.63

2625

5.88

9.38

10.19

8.38

13.69

11.88

2875

6.88

10.38

11.19

9.63

14.69

13.13

3125

8.00

11.50

12.31

10.75

15.81

14.25

3875

8.76

12.75

13.07

11.76

17.06

15.75

5000

12.00

15.00

No std

16.50

No std

19.50

6000

18.50

20.88

No std

23.00

No std

25.38

7250

21.50

25.19

No std

28.25

No std

31.94

8500

30.00

33.56

No std

37.00

No std

37.00

10500

36.76

40.94

No std

44.76

No std

48.94

Page 3 of 4

6/2/11

Type CPLR & CPAT

C-Series Rigid Couplings

®

Selection Procedure

Step 1

Determine the shaft diameter of the driver and compare to the

maximum sized hub bore in column B of the dimensions

shown on page 2. If the driver is a standard Nema HP or VP

series motor, use the column marked ‘Fit Nema Frame’ to

determine the coupling size required.

Step 2

Determine the shaft diameter of the driven equipment and

compare to the maximum sized hub bore in column B of the

dimensions shown on page 2. The shaft size of the driven

equipment should not exceed the maximum bore size to

determine the coupling size.

Step 3

The largest size shaft of either the driver or driven equipment

will determine the ultimate coupling size.

Step 4

Specify the coupling configuration and type, bore size for the

driver and driven equipment hubs, type of fit, and adjusting

nut thread details.

Step 5

Select type CPLR for standard coupling tolerances or type

CPAT for API 610 8th edition tolerances.

Balance Recommendations

As supplied, standard CPLR and CPAT couplings meet AGMA Balance Class 8 with clearance fit bores. The standard CPAT

coupling meets AGMA Balance Class 9 with transition/interference fit bores. While dynamic balancing is not normally

required, if specified, John Crane Flexibox recommends component balancing. Any potential benefits of assembly balancing

are negated by the installation fits and adjustable nature of the application. Contact John Crane Flexibox if your application

warrants balancing consideration.

Europe

Slough, UK

North America

Houston

Latin America

São Paulo, Brazil

Middle East & Africa

Dubai, United Arab Emirates

Tel: 44-1753-224000

Fax: 44-1753-224224

Tel: 1-713-944-6690

Fax: 1-713-946-8252

Tel: 55-11-3371-2500

Fax: 55-11-3371-2599

Tel: 971-4-3438940