NONMETALLIC ENCLOSURES SPECIFICATION CATALOG

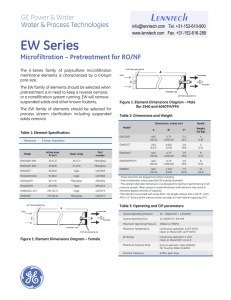

advertisement