Reliability Consulting

advertisement

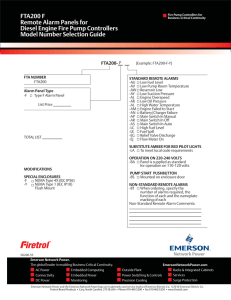

Heighten Operational Readiness Thank You Emerson Confidential 27-Jun-01, Slide 1 Heighten Operational Readiness for the Power Industry Moderator: Sara Larrabee, Marketing & Communications Specialist, New England Controls Jim Racca Kristin Scharf Greg Witte Energy Industry Leader New England Controls Reliability Technology Consultant New England Controls Reliability Business Development Manager New England Controls Emerson Confidential 27-Jun-01, Slide 2 Renewable Power and Abundant Natural Gas Has Changed the Industry… Challenges Opportunities Former baseload plants operate in load follow 60-80% of plant failures are related to cycling Equipment & control modifications reduce thermal stresses & associated costs Reliability is a top industry concern, yet many plants have limited reliability programs Condition monitoring tools & reliability programs improve plant availability About 50% of the industry’s workforce will retire within 10 years Productivity improvements gained from technology, training & staff support Emerson Confidential 27-Jun-01, Slide 3 Dispatching Renewables Requires Flexible Fossil Unit Operations Increased load following Lower minimum load Increased ramp rates More frequent shutdowns Emerson Confidential 27-Jun-01, Slide 4 Plant Cycling is Increasing O&M Costs A major root cause of increased O&M costs for many fossil units is cycling -NREL, Power Plant Cycling Costs, Apr 2012 Emerson Confidential 27-Jun-01, Slide 5 Gaining Insight into Equipment Health Raises Plant Availability Emerson Confidential 27-Jun-01, Slide 6 • Reduce forced outages • Streamline maintenance Enabling Predictive Technologies Raises Plant Availability Digital valves tell you about excessive wear, improper installation or process variations that may cause service interruption…and tell you how to correct Vibration sensors detect early onset problems well before any impact on plant operations Digital automation and asset management systems let you make decisions to optimize production and availability Emerson Confidential 27-Jun-01, Slide 7 Measurement devices can warn you of developing problems…with time to correct and avoid a shutdown Use of Enabling Predictive Technologies Raises Plant Availability Reduce plant incidents Improved reliability of critical motors/fans Generate predictive diagnostics for turbines Predictive maintenance of critical machinery Reduced work orders Emerson Confidential 27-Jun-01, 01, Slide 8 “We expect this integrated equipment health monitoring system to result in high availability with lower maintenance costs.” Jason Bryant, EDF, West Burton Station How to Engage in Reliability– Big “R” versus little “r” Reliability: Holistic facility-wide focus driving Top Quartile Performance reliability: Business leaders see Emerson as a preferred reliability partner in achieving “Top Quartile Performance” Reliability Consulting • Emerson Confidential • Slide 9 Focus on a single asset that contributes to overall Reliability Benchmarks for Monitoring Reliability $2.5 million Savings* - $4 million PER YEAR! * Per $100 Million CAPEX $6.5 million QUARTILE MAINT$ (% RAV) STORES$ (% RAV) % VIB % IR MECH % IR ELEC % OIL ANAL % OTHER NDT % ON PM % ON BOM Power Generation Top 1st 0.9% 0.3% 91.8% 71.0% 100.0% 38.1% 63.9% 21.0% 75.0% Middle 1st 2.5% 0.6% 82.5% 60.9% 92.0% 35.7% 55.9% 23.0% 69.0% Top 2nd 3.5% 0.7% 69.5% 51.7% 88.1% 29.8% 49.9% 25.0% 61.0% 56.1% 41.2% 24.3% 41.0% 27.0% DATA 57.0% Middle 2nd COST 1.6% 5.0% HEALTH 85.1% Top 3rd 6.5% 2.8% 42.8% 34.6% 79.8% 19.8% 35.9% 29.0% 55.0% Middle 3rd 7.8% 3.9% 35.2% 21.2% 74.5% 15.4% 28.9% 32.0% 49.0% Top 4th 9.1% 4.7% 26.1% 15.0% 68.7% 10.8% 22.1% 34.0% 46.0% Middle 4th 13.7% 6.7% 13.2% 3.6% 60.9% 5.1% 15.9% 35.0% 39.0% Bottom 4th 16.2% 10.2% 5.1% 0.0% 52.1% 1.0% 9.8% 39.0% 33.0% © 2009 Management Resources Group, Inc. Reliability Consulting • Emerson Confidential • Slide 10 Proprietary and Confidential Better maintenance performers depend on more asset health information Emerson’s Reliability Portfolio Reliability Consulting Machinery Health Management • • • • • Maintenance and reliability consulting Machinery protection and diagnostics Reliability engineering and project delivery Vibration monitoring, analysis and prediction Foundational data services and management • Online, wireless, and portables solutions Machinery Health Management • Integrated equipment health monitoring and performance analysis • Asset Performance Management services Plant Asset Management Smart field sensor health and control element management •• Integrated equipment monitoring and performance analysis • Asset Performance Management services • Smart field sensor and control element management Lifecycle Services • Asset monitoring and performance improvement services Lifecycle Services •• •• • System maintenance and optimization Asset monitoring and performance improvement services Training, repair and field services System maintenance and optimization Training, repair and field services Reliability Consulting • Emerson Confidential • Slide 11 Project Services • Machinery protection and diagnostics Asset Management •Plant Vibration monitoring, analysis and prediction • Online, wireless, and portables solutions NIPSCO Sugar Creek Power Generation Station Reliability Consulting Value $168K 565 Megawatt, 2X1 Combined Cycle Facility Indiana, USA Solution Vibration Pressure $270K Flow 17 assets including pumps and cooling towers instrumented for predictive maintenance $240K Analytical Level $131K 2012 Pacesetter Plant Award Combined Cycle Journal Reliability Consulting • Emerson Confidential • Slide 12 $70K $64K $97K Temperature Installation Services Emerson’s Reliability Portfolio Reliability Consulting Machinery Health Management • • • • • Maintenance and reliability consulting Machinery protection and diagnostics Reliability engineering and project delivery Vibration monitoring, analysis and prediction Foundational data services and management • Online, wireless, and portables solutions Machinery Health Machinery Health Management Management • Integrated equipment health monitoring and performance analysis • Asset Performance Management services Plant Plant Asset Asset Management Management Smart field sensor health and control element management •• Integrated equipment monitoring and performance analysis • Asset Performance Management services • Smart field sensor and control element management Lifecycle Services • Asset monitoring and performance improvement services Lifecycle Lifecycle Services Services •• •• • System maintenance and optimization Asset monitoring and performance improvement services Training, repair and field services System maintenance and optimization Training, repair and field services Reliability Consulting • Emerson Confidential • Slide 13 Project Services Project Services • Machinery protection and diagnostics Asset Management •Plant Vibration monitoring, analysis and prediction • Online, wireless, and portables solutions Prediction for Condition Monitoring PeakVue Detects Problems Sooner As a problem worsens, PeakVue value increases PeakVue 0 10 20 40 Machine Condition Good Have maintenance check Action plan must be in place Machine will fail Detects bearing faults, defects, misalignments,etc. on fans, pumps, motors, and gearboxes Emerson Confidential 27-Jun-01, Slide 14 Methods for Detecting Machine Problems Critical Assets - CSI 6500 ATG Introducing Flexible I/O Single card concept, Nothing additional in the back Communication Emerson Confidential 27-Jun-01, Slide 15 Universal Monitor Process Input Relay What about an Upgrade from GE Bently to CSI 6500 ATG? Yes, you can upgrade Yes, you can use the installed GE BN sensors Yes, it will have the integrated predictive features as well with GE BN sensors Emerson Confidential 27-Jun-01, Slide 16 CSI 6500 ATG Information Availability Information at your finger tip, wherever you are in your facility Emerson Confidential 27-Jun-01, Slide 17 CSI 6500 ATG Simplify the Configuration Emerson Confidential 27-Jun-01, Slide 18 MicroSoft Office oriented Easy and intuitive Real time analytical tools Ability to store templates You want more, graduate to AMS Machinery Manager CSI 6500 ATG Simplify the Configuration In addition to the online predictive capability, the measurement cards store the last • run up or • coast down Speed over time and the main value for both channels are available as Bode diagram Time wave form FFT-Amplitude Emerson Confidential 27-Jun-01, Slide 19 FFT-Phase Emerson Confidential 27-Jun-01, Slide 20 Essential Assets – Wireless Monitoring • Online continuous vibration trend for early warning, maintenance planning Major Pumps Compressors • Temperature monitoring of thermal cycle loss due to leakages to increase megawatt generation and lower emissions • Online control valve diagnostics for early warning, outage planning Cooling Towers Emerson Confidential 27-Jun-01, Slide 21 FD & ID Fans, Ammonia Blowers • Add continuous online measurements without adding cable, conduit, and I/O infrastructure Tracking Bearing Failure on a Fan Overall Vibration vs. PeakVue Impacting 0.15 / 3.7 Minimal Warning Minimal Warning Good 0.4 FAULT 7.5 0.2 ALERT 5.0 Good 0.15 / 3.8 Good 0.16 / 4.0 Good? 0.18 / 4.5 OK? 0.30 / 7.5 Failure occurs!!! PeakVue Early Warning with Severity 50 0 Good 40 10 Alert – Notify maintenance 20 Problem getting serious. 30 Near end of life 40 Take action! Bearing failure imminent Emerson Confidential50 27-Jun-01, Slide 22 Failure occurs!!! 0.1 2.5 0.0 0.0 Onset of Fault PeakVue (g’s) 9.0 0.3 0.15 / 3.7 g’s No Warning! FAULT 30 20 10 0 ALERT After Repair mm/s Bearing Failure in/s Vibration Vibration Vibration 12.5 0.5 Robust and Tolerant to All Types of Interference Based on IEEE 802.15.4 radio standard – – – – Channel hopping DSSS modulation Clear channel assessment Channel black listing Coexistence Technical White Paper Available Non-interfering – Low transmit power – Very short messages bursts Coexists with other wireless 2.4 GHz networks such as IEEE 802.11b/g Wi-Fi Emerson Confidential 27-Jun-01, Slide 23 WirelessHART + Wi-Fi Unique ‘Always-On’ Security Protection Support Description Encryption √ Scrambled, message is kept secret (AES-128) Authentication √ Login/Password (Network ID / Join key) to join network. Not over the air Verification √ Data integrity checksum: Not tampered with Anti-Jamming √ Channel hopping Key Management √ Encryption keys rotate automatically (hard to crack), access control list (ACL) Sequence Number √ Messages cannot be replayed later Security Technical White Paper Available ISA99 / IEC 62443 security Security always on, can’t be turned off No direct TCP/IP addressing Emerson Confidential 27-Jun-01, Slide 24 Wireless Online Continuous Vibration Monitoring System Architecture Control System or Plant Historian AMS Machinery Manager 1. 2. 3. 4. 5. Easy to install Self-configuring Self-healing Fully scalable Open standard Emerson Confidential 27-Jun-01, Slide 25 AMS Device Manager Wireless Gateway Wireless Online Continuous Vibration Monitoring System Architecture Control System or Plant Historian AMS Machinery Manager AMS Device Manager Optimum Path 1. 2. 3. 4. 5. Easy to install Self-configuring Self-healing Fully scalable Open standard Emerson Confidential 27-Jun-01, Slide 26 Wireless Gateway New Path Obstacle CSI 9420 Wireless Vibration Transmitter Mount transmitter away from machine Most Equipment Most Equipment Types Types Most Applications Applications Most Up to 100 ft / 30 m Accel Accel ) This image cannot currently be displayed. ) Wireless Vibration Wireless Vibration Transmitter Transmitter Outputs (scalar Outputs (scalar values) values) 1. Overall Vibration 2. PeakVue® Vibration Units: Range: Comment: G’s Peak 1,000 Hz – 20,000 Hz Quantify early bearing & gearbox defects, need for lubrication, pump cavitation 3. Temperature -30 to +250 F / -34 to +120 C If applicable Emerson Confidential 27-Jun-01, Slide 27 Range: Comment: Serial (Modbus RTU) 750 ft / 228 m CSI 9420 CSI 9420 Units: Range: Comment: ) OPC, Modbus TCP, or Ethernet IP Velocity (in/sec or mm/sec) 2 Hz – 1000 Hz (per ISO 10816 standard). Identifies problems like imbalance, looseness, misalignment 1420 Smart Wireless Gateway Cooling Tower Fans Diagnosing Faults Using Vibration Bearing Bearing Defects Looseness AMS Suite Coupling Issue Control System Smart Wireless Gateway CSI 9420 Wireless Vibration Transmitters Imbalance Emerson Confidential 27-Jun-01, Slide 28 Shaft Misalignment Lubrication Broken / Chipped / Worn Tooth Online Vibration Case History – Monitor 9420 alerts and watch trends in order to prevent failures 4 days before failure 9 days before failure 30 days before failure Overall Vibration PeakVue Emerson Confidential 27-Jun-01, Slide 29 Bearing G’s PeakVue Overall Vibration (In/Sec) Belt Driven Fan - Inboard Bearing Smart Valves Allow In-Service, Predictive Diagnostics Plugging of I/P Travel Deviation Insufficient Air Supply Failed Diaphragm Diaphragm Leaks O-ring Failures in Actuators Friction and Deadband External Leaks Many others Emerson Confidential 27-Jun-01, Slide 30 Performance Diagnostics: Run On-Line Diagnostics Tests for Troubleshooting or Prior to an Outage No Alert Valve Friction – High Friction Alert Supply Pressure – Air Leak Alert Emerson Confidential 27-Jun-01, Slide 31 Ensure that the supply pressure to the actuator is adequate; detect and quantify droop in the air supply during large travel excursions Air Mass Flow – Supply Pressure Alert Determine valve friction & dead band on a valve while it is online, in-service Detect leaks downstream of the relay (in the actuator or tubing to the actuator) I/P and Relay Integrity – Incorrect relay adjustment – I/P nozzle starting to plug Advanced Diagnostics: Run Out of Service Diagnostics at Valve During a Shutdown 50 Valve Signature 11LAB30AA101 14 Jul 2003 08:09:32 1st 2nd Best Fit 1st 11LAB30AA101 22 Apr 2003 09:23:13 2nd 11LAB30AA101 22 Apr 2003 09:23:13 30 20 Closed Actuator Pressure (psi) Actuator Pressure (psi) Actuator Pressure (psi) 40 • Aqua & magenta shows valve signature “as found” with badly damaged trim • Red & blue shows valve signature with new valve internals (verify operation before putting valve back in service) 10 X: 3.12 0 Y: 40.18 Valve Travel (in.) -10 -0.5 0 0.5 1.0 1.5 Travel (in) Valve Travel (in.) Emerson Confidential 27-Jun-01, Slide 32 2.0 2.5 3.0 Essential Control Valves Typical Combined Cycle Plant (2 Units) CT #1 IP to Cold Reheat 2nd Stage Outlet Temp Control 3rd Stage Outlet Temp Control 4th Stage Outlet Temp Control Steam Cooling Inlet Steam Cooling Outlet Seal Oil H2 Side TE Pressure Diff Seal Oil H2 Side CE Pressure Diff Emerson Confidential 27-Jun-01, Slide 33 CT #2 IP to Cold Reheat 2nd Stage Outlet Temp Control 3rd Stage Outlet Temp Control 4th Stage Outlet Temp Control Steam Cooling Inlet Steam Cooling Outlet Seal Oil H2 Side TE Pressure Diff Seal Oil H2 Side CE Pressure Diff HRSG #1 LP Drum Feedwater HRSG #2 LP Drum Feedwater IP Drum Feedwater IP Drum Feedwater HP Drum Feedwater HP Attemperator HRH Attemperator HP Drum Feedwater HP Attemperator HRH Attemperator HP Sky Vent HP Sky Vent HRH Bypass HRH Bypass HP Bypass HP Bypass LP Bypass LP Bypass Steam Turbine/BOP HP to Aux Steam CRH to Aux Steam HP Aux Steam Attemperator Gland Seal Steam Inlet Gland Seal Steam to Condenser Seal Oil H2 Side Temperature Seal Oil H2 Side TE Pressure Diff Seal Oil H2 Side CE Pressure Diff Balance of Plant Assets – Route Based Analysis Tools Colored parameter alarms provide immediate indication of Machinery Health M1H - RPM May 2007 – July 2007 A A A A B Fault Next Freq Trend Ampl: 1713.47 Fault Frequencies help identify the source of the vibration Trends provide historical reference for immediate evaluation of current status Fault Frequencies Emerson Confidential 27-Jun-01, Slide 34 June 12 2007 Trend Parameter Alarms B B Prev Trend See what parameter is in alarm and its severity immediately at the point of data collection B Essential/BOP Rotating Assets Typical Combined Cycle Plant (2 Units) CT #1 CT #2 Steam Turbine ACC CLCW Fans Fire Pump House (BOP) #1 AC L.O. Pump #1 AC L.O. Pump #1 AC L.O. Pump K11 Fan Motor CLCW HE Fan Motor #11 Cond Make Pump Motor #1 #2 AC L.O. Pump #2 AC L.O. Pump #2 AC L.O. Pump K12 Fan Motor CLCW HE Fan Motor #12 Cond Make Pump Motor #2 DC L.O. Pump DC L.O. Pump DC L.O. Pump D1 Fan Motor CLCW HE Fan Motor #21 Back Wash Motor Pump #1 DC Seal Oil Pump DC Seal Oil Pump DC Seal Oil Pump K13 Fan Motor CLCW HE Fan Motor #22 Back Wash Motor Pump #2 #1 Vapor Extractor #1 Vapor Extractor #1 Vapor Extractor CLCW HE Fan Motor #31 Raw Water Pump Motor #1 #2 Vapor Extractor #2 Vapor Extractor #2 Vapor Extractor K21 Fan Motor CLCW HE Fan Motor #32 Raw Water Pump Motor #2 Rotor Air Cooling Fan Mtr Rotor Air Cooling Fan Mtr Generator Casing Inlet K22 Fan Motor CLCW HE Fan Motor #41 Service Water Pump Motor #1 Enclosure Fan #1 Enclosure Fan #1 Generator Casing Aft-end D2 Fan Motor CLCW HE Fan Motor #42 Service Water Pump Motor #2 Enclosure Fan #2 Enclosure Fan #2 Bently Nevada K23 Fan Motor Enclosure Fan #3 Enclosure Fan #3 Turning Gear Motor Enclosure Fan #4 Enclosure Fan #4 #1 Gland Steam Exhaust Fan Mtr Enclosure Fan #5 Enclosure Fan #5 Enclosure Fan #6 Diesel Fire Pump T-HALL Roof & HRSG Fans Electric Fire Pump K31 Fan Motor Main Turbine Hall Fan #1 Jockey Pump #2 Gland Steam Exhaust Fan Mtr K32 Fan Motor Main Turbine Hall Fan #2 Enclosure Fan #6 Clean Drains Pump Motor #1 D3 Fan Motor Main Turbine Hall Fan #3 Fuel Oil / Well Water / WTB Starting Motor Starting Motor Clean Drains Pump Motor #2 K33 Fan Motor Main Turbine Hall Fan #4 Surge Raw Water Pump # 1 Generator Casing Inlet Generator Casing Inlet EH Pump Motor #1 Main Turbine Hall Fan #5 Surge Raw Water Pump # 2 Generator Casing Aft-end Generator Casing Aft-end EH Pump Motor #2 K41 Fan Motor Main Turbine Hall Fan #6 Fuel Forwarding Pump Motor #1 Bently Nevada Bently Nevada K42 Fan Motor Main Turbine Hall Fan #7 Fuel Forwarding Pump Motor #2 Main Fuel Oil Pump Main Fuel Oil Pump BOP D4 Fan Motor Main Turbine Hall Fan #8 Well Water Pump Motor #1 Turning Gear Motor Turning Gear Motor Main Condensate Pmp Mtr #1 K43 Fan Motor Well Water Pump Motor #2 Main Condensate Pmp Mtr #2 Well Water Pump Motor #3 HRSG Bldg Lower Roof HRSG Bldg Upper Roof Boiler Feed Pump Motor #1 Separator Lift Pump Motor #1 HRSG Exhaust Fan #6 HRSG Exhaust Fan #1 Boiler Feed Pump Motor #2 Separator Lift Pump Motor #2 HRSG Exhaust Fan #7 HRSG Exhaust Fan #2 CLCW Pump Motor #1 Back Wash Sump Pump Motor #1 HRSG Exhaust Fan #8 HRSG Exhaust Fan #3 CLCW Pump Motor #2 Back Wash Sump Pump Motor #2 HRSG AHU #1 HRSG AHU #2 HRSG Exhaust Fan #4 HRSG Exhaust Fan #5 Int Blowdown Tank Pmp Mtr #1 Int Blowdown Tank Pmp Mtr #2 Back Wash Filt Feed Pmp Motor #1 Back Wash Filt Feed Pmp Motor #2 Oily Waste Sump Pmp Mtr #1 Fuel Oil Off Loading Pump #1 Oily Waste Sump Pmp Mtr #2 Fuel Oil Off Loading Pump #2 Chemical Sump Pump Motor #1 Fuel Oil Off Loading Pump #3 Chemical Sump Pump Motor #2 Intrument Air Cooling Fan # 1 Intrument Air Cooling Fan # 2 Emerson Confidential 27-Jun-01, Slide 35 Demographic Shifts Require the Preservation of Skills & Experience Emerson Confidential 27-Jun-01, Slide 36 • Retain critical knowledge • Keep your staff trained • Supplement your workforce The Growing Labor Imbalance Approximately half of the work force in the electric utility sector will retire in the next 10 years. - US Bureau of Labor and Statistics An estimated 31% of employers worldwide find it difficult to fill positions because of talent shortages in their markets. - Emerson Ernst Confidential & Young, Six Global Trends Shaping the World 27 Jun 01, Slide 37 27-Jun-01, Technology Will Help Supplement Staffing and Knowledge Shortfalls Remote Collaboration & Supplemental Staffing Embedded Expertise Simulation & Analytics Emerson Confidential 27-Jun-01, Slide 38 Embedded Expertise Informs Plant Before Operations is Impacted Business (ERP) Operations Emerson Confidential 27-Jun-01, Slide 39 Maintenance & Reliability Meaningful Information, Like Advice From a Senior Staff Member Emerson Confidential 27-Jun-01, Slide 40 This valve has a maintenance issue that needs investigation A click of a button reveals a travel deviation with clear guidelines to fix the problem Simple action taken today can avoid a problem that reduces unit availability Remote Rotating Machinery Condition Monitoring Process 2. Emerson Remote Monitoring Service Reports via Email or WWW Data Export Expert Analysis of Export Data 1. Customer Site AMS Machinery Health Manager collects data from machinery via CSI online hardware. Emerson Confidential 27-Jun-01, Slide 41 3. Customer Site Emerson Local Service Providers work with customer to interpret the information provided by the monitoring service. Service Implementation • New England Controls Reliability Engineer travels to site to implement the below process • Time estimate: 50 machines per day Machinery data provided Emerson Confidential 27-Jun-01, Slide 42 Database build Data collection training Data transfer process implemented Remote Monitoring Process Sense Acquire Transfer Analyze Act Service leverages batch or continuous data collection – Routes are collected monthly by customer with CSI 2130/CSI 2140 handheld vibration analyzers (analyzers can be leased from Emerson as part of program) – CSI 9420 or CSI 6500 online monitoring systems continuously collect data on specific intervals or when alarm levels are reached Emerson Confidential 27-Jun-01, Slide 43 Remote Monitoring Process Sense Acquire Transfer Analyze Act Vibration data is transferred to Emerson analysts via secure FTP or Secure Remote Desktop Data is stored in secure Emerson servers Emerson Confidential 27-Jun-01, Slide 44 Remote Monitoring Process Sense Acquire Transfer Analyze Act Vibration data is reviewed by ISO 18436-2 Level 3 analysts Analysts generate monthly reports based on machinery conditions Reports include problem identified, recommended actions and potential root cause Emerson Confidential 27-Jun-01, Slide 45 Remote Monitoring Process Sense Acquire Transfer Analyze Act New England Controls to lead follow up meeting to ensure appropriate corrective maintenance actions are taken Customer or New England Controls performs corrective maintenance Emerson Confidential 27-Jun-01, Slide 46 Remote Rotating Machinery Condition Monitoring Process - Sample Report Customer XYZ Example Report Alarm Summary Overview matrix showing machine condition Emerson Confidential 27-Jun-01, Slide 47 Detailed Analysis Remote Control Valve Condition Monitoring Process – Sample Report High Level Health Values and Monthly Valve Data Emerson Confidential 27-Jun-01, Slide 48 Remote Control Valve Condition Monitoring Process – Sample Report Control Valve Specific Data Raw Data from Valve Diagnostic Tests Expert Analysis and Recommendations Emerson Confidential 27-Jun-01, Slide 49 Emerson Confidential Proprietary Emerson Can Help You Improve Plant and Fleet Performance Raise Plant Reliability Emerson Confidential 27-Jun-01, Slide 50 Enhance Staff Effectiveness Improve unit and fleet availability with online condition monitoring Use technology to supplement retirements and skill shortages Gain earliest possible insight into developing problems with enabling technologies Leverage 3rd party partners to optimize and shorten outages Enhanced training will elevate staff performance Thank You Thank You Emerson Confidential 27-Jun-01, Slide 51 Heighten Operational Readiness for the Power Industry Jim Racca Energy Industry Leader, New England Controls (508) 339-5522 Jim.Racca@newenglandcontrols.com Kristin Scharf Reliability Technology Consultant, New England Controls Kristin.Scharf@newenglandcontrols.com Greg Witte Reliability Business Development Manager, New England Controls Greg.Witte@newenglandcontrols.com