Firestop Resource Guide 2586.1kB

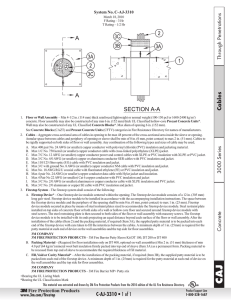

advertisement