Photovoltaic Power Systems and the National Electrical Code

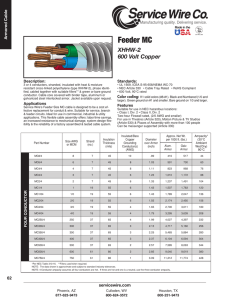

advertisement