Effect of Differences Core and Cavity Temperature on Injection

advertisement

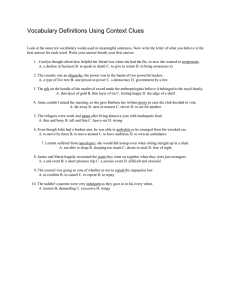

International Journal of Engineering & Technology IJET-IJENS Vol:10 No:06 125 Effect of Differences Core and Cavity Temperature on Injection Molded Part and Reducing the Warpage by Taguchi Method Z. Shayfull*1, M.F. Ghazali1, M. Azaman1, S.M. Nasir1, N.A. Faris2 1 School of Manufacturing Engineering, Universiti Malaysia Perlis, Malaysia 2 Politeknik Sultan Abdul Halim Mu’adzam Shah (POLIMAS), Malaysia shayfull@unimap.edu.my Abstract— Warpage is a common issue related with injection moulding process and frequently be the main target by mould designers to eliminate. The existence of warpage is considered a defect and shall be minimized. Therefore many researches and publications were made on this topic, to study the behavior of warpage occurred at moulded parts particularly on plastic parts. In this study, two parts of plastic products was decided as a model. One is a thin plate and another one is a thin shell. Polycarbonate/Acrylonitrile Butadiene Styrene (PC/ABS) thermoplastic is used as a plastic material. Taguchi Method is applied to determine the optimum value of injection molding parameters and Moldflow Plastic Insight software is used to simulate the injection molding process. The temperature differences on core and cavity plates are considered in simulation and the experimental shows that the differences mould temperature helps to minimize the warpage value. This finding is definitely a good way to prevent stress on a critical point of warped parts after assembly process. Index Term— Injection moulding; Plastic Injection Mould; Warpage; Taguchi Method; ANOVA I. INTRODUCTION THE warpage The warpage issue is one of common effects on moulded parts after taken out from an injection molding process. It is important issue to predict the warpage issue before manufacturing takes place. Many researches and publications were made on this topic, both on theoretical simulation and on experimental results to study the behavior of warpage occurred at moulded parts particularly on plastic parts. Jacques [1] underwent a simulation on the thermal warpage resulted from unequal cooling on a plate of amorphous polymer, and it is understood that the warpage issue comes from the bending moment due to the asymmetrical stress distribution over the thickness of plastic parts. The thinnest spot on moulded parts is normally the most affected area of warpage due to its relatively small second moment of area in bending. Warpage is also studied by Matsuoka et al. [2] using simulation and experimental studies. It can be predicted from the temperature difference between the surfaces, the heat distribution, shear stress, shrinkages and mechanical properties caused by the orientation of materials. Huang and Tai [4] examined the effects of warpage that is seen in thin shell parts produced by injection molding using simulation software. Taguchi method used to determine the optimum value of injection parameters and this led to a finding that packing pressure is the most significant factor that affects warpage and gate locations as well as filling time have only small effects over warpage. Taguchi method was also applied by Tang [3] in designing a plastic injection mould to reduce warpage. The thin plate mold was fabricated and at the same time gate dimension and mould temperature factors were eliminated while ANOVA was used to determine the significant factor affected the warpage mainly. As a result, melting temperature was found to be the most important factor that contributes to the existence of warpage. Results acquired by Liao et al. [5] also agrees that packing pressure is the most influential parameter in injection moulding process. His study was done purposely to determine the reactions of a thin walled part according to shrinkage and warpage issues where mould temperature, melt temperature, packing pressure and injection speed were taken as the injection parameters [6]. From the research, it is found that packing pressure is a big factor contributes to the occurrence of warpage. Basic design principles for assembly suggest that removing the fastener on the product for to reduce costs. For that reason, a snap fit concept is introduced to replace fasteners where it can reduce the assembly time by eliminating the screwing process [7]. However, there is an issue identified on the snap fit concept which is the gap around the product is uneven because of this concept cannot close the assembled gap tightly as compared to screwing method. The situation become worse when the snap fit concept is to bind between warped parts. Although this situation can be improved by adding more snap fits, but the more snap fits in a design, the higher number of side pull and lifter is needed and this therefore increases the cost of fabricating mould. As far as this issue is concerned, the 109006-8686 IJET-IJENS © December 2010 IJENS IJENS International Journal of Engineering & Technology IJET-IJENS Vol:10 No:06 126 challenge for the manufacturing engineers nowadays is to produce moulded parts at minimum warpage. II. FEED SYSTEM DESIGN A mold designer must determine the type of mold, mold dimension, materials for cavity insert, core insert and mold base in designing a mould [8]. For a thin plate parts (120 x 50 x 1) mm, the type of gate to be used is an edge gate (two-plate mold). Pin point gate (three-plate mold) is used for thin shell part (120 x 50 x 8)mm with thickness 1mm. Fig. 1 and 2 shows the feed system used for both of parts respectively. Fig. 4. Pin point gate design for thin shell plate Figs. 5 and 6 show the size in millimeters of the cavity and core insert and cooling channel design. The size of cooling channel is Ø6mm. Fig. 1. Feed system design for thin plate (two-plate mold) Fig. 5. Cooling channel design for thin plate Fig. 2. Feed system design for thin shell plate (three-plate mold) The detail dimensions in millimeters of feed system are shown in Fig. 3 and 4. Fig. 6. Cooling channel design for thin shell plate III. EXPERIMENT There are many factors affecting the injection molding process, which may include types of plastic material used, types of mold base material, types of cavity insert material, types of machine, the shape of the product, the selection of coolant runners as well as selection of the coolant liquid. However, to make the experimentations and simulations achievable according to the scope of research, only some major factors are considered. Thus, the analysis is carried out under the following assumptions: i. Gate dimension factor is eliminated because the gating systems design for every part is different. ii. The temperature of the environment is assumed constant. iii. The coolant is pure water. iv. Only the effects of the filling, packing, and cooling processes are discussed. v. The layout of the cooling channels is assumed to maintain a constant temperature everywhere in the mold. The Fig. 3. Edge gate design for thin plate 109006-8686 IJET-IJENS © December 2010 IJENS IJENS International Journal of Engineering & Technology IJET-IJENS Vol:10 No:06 effects due to the shape and size of the mold and product are neglected due to varieties of product’s shapes. vi. The plastic material used in all of the simulations is the amorphous thermoplastic PC/ABS blend, Cycoloy C2950HF from GE. Its viscosity is between 102 and 104 poise where the shear rate is in the 102-103 s-1 range. The range of melt temperature is between 220 and 400oC approximately. The basic physical and mechanical properties of PC/ABS are shown in Table I. TABLE I THE PHYSICAL PROPERTIES OF PC/ABS Taguchi method is used in the design of the experiments in this research. There are six factors identified to control the injection process; cavity temperature (A), core temperature (B), melt temperature (C), filling time (D), packing pressure (E), and packing time (F). Each factor consists of five levels where an orthogonal array L25 56 is chosen and all parameters have been identified. These three factor-level, orthogonal array variance and parameters control factors are shown in Table II, III and IV respectively. TABLE II THE FIVE LEVEL OF EFFECTIVE FACTOR FOR EXPERIMENT VARIANCE Cavity temperature, A (°C) 1 45 2 55 Level 3 65 75 5 85 74 Core temperature, B (°C) 45 55 65 75 85 2.63 x 103 Specific heat, Cp (J/kgoC) 1871 Glass transition temperature, Tg (oC) 112 Thermal expansion coefficient, α (mm/moC) Elastic modulus, E (MPa) 127 Factor 4 Melt temperature, C (°C) 230 245 260 0.23 Filling time, D (s) 0.1 0.2 0.3 275 0.4 290 Poisson's ratio, υ Thermal conductivity, K (w/moC) 0.27 Packing pressure, E (MPa) 50% 60% 70% 80% 90% Packing time, F (s) 0.6 0.7 0.8 0.9 1.0 The parts to be simulated are inclusive of both cavities divided into 12000 pieces of triangular elements for the thin plate and 18192 pieces of triangular elements for thin the shell plate. The meshes of the parts are shown Fig. 7 and 8. Signal-to-noise (S/N) ratio is calculated according to Table 4. The deflection of the thin plates and thin shell plates obtained from the experiment is used to calculate the signal-tonoise (S/N) ratio to acquire the best setting of parameters arrangement. From this method, the percentage of contribution has been calculated to determine which of the factor will affect the warpage significantly. Fig. 7. Cooling channel design for thin plate 0.5 TABLE III L25 ORTHOGONAL ARRAY VARIANCE Trial No. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 A 1 1 1 1 1 2 2 2 2 2 3 3 3 3 3 4 4 4 4 4 5 5 5 5 5 Control Factor B C D E 1 1 1 1 2 2 2 2 3 3 3 3 4 4 4 4 5 5 5 5 1 2 3 4 2 3 4 5 3 4 5 1 4 5 1 2 5 1 2 3 1 3 5 2 2 4 1 3 3 5 2 4 4 1 3 5 5 2 4 1 1 4 2 5 2 5 3 1 3 1 4 2 4 2 5 3 5 3 1 4 1 5 4 3 2 1 5 4 3 2 1 5 4 3 2 1 5 4 3 2 F 1 2 3 4 5 5 1 2 3 4 4 5 1 2 3 3 4 5 1 2 2 3 4 5 1 Fig. 8. Cooling channel design for thin shell plate 109006-8686 IJET-IJENS © December 2010 IJENS IJENS International Journal of Engineering & Technology IJET-IJENS Vol:10 No:06 TABLE IV THE COMBINATION PARAMETERS FOR THE CONTROL FACTORS Control Factor Trial No. A B C D E F 45 45 230 0.1 50% 0.6 1 2 3 4 5 6 7 8 9 10 11 45 45 45 45 55 55 55 55 55 65 55 65 75 85 45 55 65 75 85 45 245 260 275 290 245 260 275 290 230 260 0.2 0.3 0.4 0.5 0.3 0.4 0.5 0.1 0.2 0.5 60% 70% 80% 90% 80% 90% 50% 60% 70% 60% 0.7 0.8 0.9 1.0 1.0 0.6 0.7 0.8 0.9 0.9 12 13 14 15 16 17 18 19 20 21 22 23 24 25 65 65 65 65 75 75 75 75 75 85 85 85 85 85 55 65 75 85 45 55 65 75 85 45 55 65 75 85 275 290 230 245 260 275 230 245 260 290 230 245 260 275 0.1 0.2 0.3 0.4 0.2 0.3 0.4 0.5 0.1 0.4 0.5 0.1 0.2 0.3 70% 80% 90% 50% 90% 50% 60% 70% 80% 70% 80% 90% 50% 60% 1.0 0.6 0.7 0.8 0.8 0.9 1.0 0.6 0.7 0.7 0.8 0.9 1.0 0.6 The warpage data obtained from the simulation process are also analyzed using Analysis of Variance (ANOVA) and the level of confidence is set at 0.05. The results are used by comparing it with the results obtained from the SN ratio method. In addition, the interaction effect of factors is identified and the contribution of each factor to the total effect is to be calculated. From this method, the percentage of contribution has been calculated to determine which of the factor will affect the warpage most significantly. IV. RESULT AND DISCUSSION In determining the S/N ratio, the smaller the better quality characteristic has been targeted. MSD is the mean square deviation, represents the observation and is the number of tests in one trial. Table 5 and 6 show the S/N for the thin plate and thin shell plate obtained from the experiment. 128 TABLE V SUMMARY OF THE RESULTS FOR THIN PLATE Control Factor Trial No. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 A 45 45 45 45 45 55 55 55 55 55 65 65 65 65 65 75 75 75 75 75 85 85 85 85 85 B 45 55 65 75 85 45 55 65 75 85 45 55 65 75 85 45 55 65 75 85 45 55 65 75 85 C 230 245 260 275 290 245 260 275 290 230 260 275 290 230 245 275 290 230 245 260 290 230 245 260 275 D 0.1 0.2 0.3 0.4 0.5 0.3 0.4 0.5 0.1 0.2 0.5 0.1 0.2 0.3 0.4 0.2 0.3 0.4 0.5 0.1 0.4 0.5 0.1 0.2 0.3 E 50% 60% 70% 80% 90% 80% 90% 50% 60% 70% 60% 70% 80% 90% 50% 90% 50% 60% 70% 80% 70% 80% 90% 50% 60% F 0.6 0.7 0.8 0.9 1.0 1.0 0.6 0.7 0.8 0.9 0.9 1.0 0.6 0.7 0.8 0.8 0.9 1.0 0.6 0.7 0.7 0.8 0.9 1.0 0.6 Thin Plate Max, z S/N 0.0073 42.7327 0.0076 42.3807 0.0066 43.6051 0.0060 44.4370 0.0057 44.8812 0.0053 45.5129 0.0061 44.2946 0.0081 41.8310 0.0065 43.7366 0.0059 44.5842 0.0070 43.0980 0.0059 44.5842 0.0066 43.6051 0.0061 44.2946 0.0078 42.1610 0.0089 41.0122 0.0073 42.7335 0.0075 42.4949 0.0079 42.0482 0.0069 43.2239 0.0064 43.8722 0.0068 43.3536 0.0091 40.8197 0.0067 43.4775 0.0067 43.4775 TABLE VI SUMMARY OF THE RESULTS FOR THIN SHELL PLATE Control Factor Trial No. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 A 45 45 45 45 45 55 55 55 55 55 65 65 65 65 65 75 75 75 75 75 85 85 85 85 85 B 45 55 65 75 85 45 55 65 75 85 45 55 65 75 85 45 55 65 75 85 45 55 65 75 85 109006-8686 IJET-IJENS © December 2010 IJENS C 230 245 260 275 290 245 260 275 290 230 260 275 290 230 245 275 290 230 245 260 290 230 245 260 275 D 0.1 0.2 0.3 0.4 0.5 0.3 0.4 0.5 0.1 0.2 0.5 0.1 0.2 0.3 0.4 0.2 0.3 0.4 0.5 0.1 0.4 0.5 0.1 0.2 0.3 E 50% 60% 70% 80% 90% 80% 90% 50% 60% 70% 60% 70% 80% 90% 50% 90% 50% 60% 70% 80% 70% 80% 90% 50% 60% F 0.6 0.7 0.8 0.9 1.0 1.0 0.6 0.7 0.8 0.9 0.9 1.0 0.6 0.7 0.8 0.8 0.9 1.0 0.6 0.7 0.7 0.8 0.9 1.0 0.6 Thin Shell Plate Max, z S/N 0.0073 42.7327 0.0076 42.3807 0.0066 43.6051 0.0060 44.4370 0.0057 44.8812 0.0053 45.5129 0.0061 44.2946 0.0081 41.8310 0.0065 43.7366 0.0059 44.5842 0.0070 43.0980 0.0059 44.5842 0.0066 43.6051 0.0061 44.2946 0.0078 42.1610 0.0089 41.0122 0.0073 42.7335 0.0075 42.4949 0.0079 42.0482 0.0069 43.2239 0.0064 43.8722 0.0068 43.3536 0.0091 40.8197 0.0067 43.4775 0.0067 43.4775 IJENS International Journal of Engineering & Technology IJET-IJENS Vol:10 No:06 The data in Table V and VI are also analyzed using Analysis of Variance (ANOVA) where the relative percentage contribution of all factors is determined by comparing the relative variance. The ANOVA will then compute the degrees of freedom, variance, F-ratio, sums of squares, pure sum of square and percentage contribution. The examples of calculations are shown below and the results of S/N ratio for both Thin Plate and Thin Shell Plate are listed in Table 7 and 8. 129 Fig. 9. S/N response for cavity temperature Fig. 10. S/N response for core temperature TABLE VII THE RESPONSE TABLE OF S/N RATIO FOR THIN PLATE Level A B C D E F 1 43.607 43.246 43.492 43.019 42.587 43.232 2 43.992 43.469 42.585 43.012 43.038 43.120 3 43.549 42.471 43.540 43.925 43.739 42.774 4 42.303 43.599 43.068 43.452 44.027 43.134 5 43.000 43.666 43.766 43.042 43.060 44.190 1.689 1.195 1.181 0.913 1.440 1.416 Fig. 11. S/N response for melt temperature Fig. 12. S/N response for filling time TABLE VIII THE RESPONSE TABLE OF S/N RATIO FOR THIN SHELL PLATE Level A B C D E F 1 12.954 14.953 15.760 13.334 14.737 9.669 2 13.748 13.951 16.481 12.994 13.169 10.408 3 14.953 12.090 12.262 14.195 11.692 14.197 4 10.782 11.589 10.485 11.348 15.603 15.289 5 13.352 13.206 10.801 13.919 10.588 16.225 4.171 3.364 5.996 2.847 5.015 6.556 Fig. 13. S/N response for packing pressure Fig. 9 – 14 show S/N response diagram constructed for thin plate based on data from Table 7. Fig. 14. S/N response for packing time 109006-8686 IJET-IJENS © December 2010 IJENS IJENS International Journal of Engineering & Technology IJET-IJENS Vol:10 No:06 Fig. 15 – 20 show S/N response diagram constructed for thin shell plate based on data from Table 8. 130 From the S/N ratio response in Table 7 and Table 8, it is identified that the best combination of parameters can be identified by selecting the highest value of each factor. Table 9 shows the summary of best parameters setting for thin plate and thin shell plate. The result can also be observed from S/N response diagram in Figs. 9–14 for thin plate and Figs. 15-20 for thin shell plate. TABLE IX BEST SETTING OF COMBINATION PARAMETERS Fig. 15. S/N response for cavity temperature Factor Cavity temperature, (°C) Core temperature, (°C) Melt temperature, (°C) Filling time, (s) Packing pressure, (MPa) Packing time, (s) Fig. 16. S/N response for core temperature Fig. 17. S/N response for melt temperature Thin plate 55 85 290 0.3 80% 1.0 Thin shell plate 65 45 245 0.3 80% 1.0 Besides, the difference between levels in Table 8 and 9 also shows which factor is more significant that give effects on warpage for thin plate as well as thin shell plate. The most significant factor that has an effect on warpage for thin plate are cavity temperature (A) followed by packing pressure (E), packing time (F), core temperature (B), melting temperature (C) and filling time (D). On the other hand, for thin shell plate, the most significant factors are packing time (F) followed by melt temperature (C), packing pressure (E), cavity temperature (A), core temperature (B) and filling time (D). The data in Table 5 and 6 is also analyzed using Analysis of Variance (ANOVA). The ANOVA computes the quantities such as sums of squares, degrees of freedom, variance and percentage contribution. The examples of calculations for these quantities are shown below and the results for thin plate and thin shell plate are summarized in Table 10 and Table 11 respectively. Fig. 18. S/N response for filling time Total sum of squares, Fig. 19. S/N response for packing pressure Fig. 20. S/N response for packing time 109006-8686 IJET-IJENS © December 2010 IJENS IJENS International Journal of Engineering & Technology IJET-IJENS Vol:10 No:06 131 TABLE XI ANOVA TABLE FOR THIN SHELL PLATE Source Cavity temperature, (°C) Core temperature, (°C) Melt temperature, (°C) For error, S V F P(%) 4 0.03177 0.0079425 - 9.63 4 0.00468 0.00117 - 1.42 4 0.08632 0.02158 - 26.16 Filling time, (s) Packing pressure, (MPa) 4 0.02566 0.006415 - 7.78 4 0.05375 0.0134375 - 16.29 Packing time, (s) 4 0.12780 0.03195 - 38.73 Pooled error 0 0 Total 24 0.32998 100 The last column in Table X and XI show the percentage of contribution for each factor. For thin plate, cavity temperature contributes the most which is 24.59% followed by packing pressure 19.54%, melt temperature 16.06%, packing time 15.4%, core temperature 14.78% and filling time 9.63%. It proves that packing pressure, melt temperature, cavity temperature, packing time and core temperature are the significant factor where filling time does not have much effect on warpage issue. For thin shell plate, packing time contributes the most which is 38.73% followed by melt temperature 26.16%, packing pressure 16.29%, cavity temperature 9.63%, filling time 7.78% and core temperature 1.42%. This explains that all factors except filling time and core temperature give significant effects on warpage defects. Variance for factor A, Variance for error, F-ratio for factor A, Percentage contribution (P) for factor A, TABLE X ANOVA TABLE FOR THIN PLATE Source Cavity temperature,(°C) Core temperature, (°C) Melt temperature, (°C) f f S V F P(%) 4 5.418 x 10-6 1.354 x 10-6 - 24.59 4 3.258 x 10-6 8.145 x 10-6 - 14.78 4 3.538 x 10-6 0.8845 x 10-6 - 16.06 Filling time, (s) Packing pressure, (MPa) 4 2.122 x 10-6 0.5305 x 10-6 - 9.63 4 4.306 x 10-6 1.077 x 10-6 - 19.54 Packing time, (s) 4 3.394 x 10-6 0.8485 x 10-6 - 15.4 Pooled error 0 0 Total 24 22.038x10-6 V. CONCLUSION There are many plastic products produced by injection molding and some factors must be determined in order to design a mould such as feed system, cooling channel position, gate size. These factors have effects on the quality of product produced and by the help of simulation technology, it reduces time taken to test moulds by simulating it in software as compared to traditional trial and error concept which also requires higher costs. In addition, Taguchi method helps to simplify the experiment in identifying the best setting parameters to produce parts with minimum defects. Previous studies used fixed temperature value for mold temperature (cavity temperature and core temperature). For instance, Tang [3] and Huang and Tai [4] maintained same temperature for cavity and core temperature in simulation and experimental of warpage on thin plate and thin shell plate. In contrast, this research focuses the effect of difference value of temperature on core and cavity on thin plate and thin shell plate. The conclusions of the research are as follows. 100 109006-8686 IJET-IJENS © December 2010 IJENS IJENS International Journal of Engineering & Technology IJET-IJENS Vol:10 No:06 132 1. Cavity temperature is the most significant which is 24.59% followed respectively by packing pressure 19.54%, melt temperature 16.06%, packing time 15.4%, core temperature 14.78% and filling time 9.63%. The mold temperature (cavity and core temperature) has shown a large contribution rate of 39.37%, which must not be neglected. 2. For thin shell part, the most effective factor contributes to warpage is packing time 38.73% followed by melt temperature 26.16%, packing pressure 16.29%, cavity temperature 9.63%, filling time 7.78% and core temperature 1.42%. The mold temperature (cavity and core temperature) has also shown a contribution rate of 11.05%, which is significant. 3. Taguchi orthogonal array can effectively reduce the number of trials in mold testing. The effective factors can be determined using ANOVA. i. For thin plate, results show that cavity temperature, packing pressure, melt temperature, packing time and core temperature are the significant factors while filling time is insignificant. ii. Result for thin shell plate shows that packing time, melt temperature, packing pressure and cavity temperature are the significant factors while filling time while core temperature is trivial. 4. The influence of all factors that contributes to warpage has been characterized believed to be helpful in determining more precise process conditions in determining injection molding parameters. REFERENCES [1] [2] [3] [4] [5] [6] [7] [8] M.St. Jacques, An analysis of thermal warpage in injection molded at parts due to unbalanced cooling, Polym. Eng. Sci. 22 (1982) 241-245. T. Matsuoka, J. Takabatake, A. Koiwai, Y. Inoue, S. Yamamoto, H.Takahashi, Integrated simulation to predict warpage of injection molded parts, Polym. Eng. Sci. 31 (1991) 1043. Huang MC, Tai CC. The effective factors in the warpage problem of an injectionmolded part with a thin shell feature. Journal of Material Processing Technology 110 (2001) 1-9. S.H. Tang, Y.J. Tan, S.M.Sapuan, S.Sulaiman, N. Ismail, R. Samin, The use of Taguchi method in the design of platis injection mould for reducing warpage, Journal of Material Processing Technology 182 (2007) 418-426. Liao SJ, Chang DY, Chen HJ, Tsou LS, Ho JR, Yau HT, et al. Optimal process conditions of shrinkage and warpage of thinwall parts. Polym Eng Sci 2004;44(5):917–28. Think Thin, Asian Plastics News, July/August 1996, pp. 12-14. G. Boothroyd, P. Dewhurst, W. Knight, ‘Product Design for Manufacture and Assembly’, 2nd Edition, Marcel Dekker Inc., 2002. David O. Kazmer, Injection Mould Design Engineering, Hanser Publisher, Munich, 2007, p 67. 109006-8686 IJET-IJENS © December 2010 IJENS IJENS