Application and sintering of nanotubes

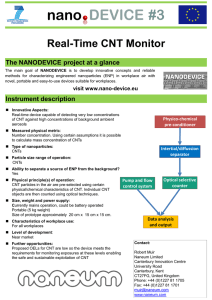

advertisement

Application and sintering of nanotubes Lecture 10 MTX9100 Nanomaterials OUTLINE -What are NT good for? - Where can NT be used? - Can NT-based transistors exist? - How to make nanotubes? 1 Carbon nanotubes Fantastic Mechanical properties • stiffness &strength due to Sp2 bond • Much stronger structure than diamond • May replace steel in the future Construction purposes like using nanocomposites -bridges and dams Light- Low mass. Aerospace industry to build aircrafts and satellites. Thermal and Electrical conductivity • 2 Electrical devices as interconnects transistors , CMOS industry, Nanowires Schematic illustrations of the structures 3 Applications of CNT • Carbon nanotubes can be inert and can have a high aspect ratio, high tensile strength, low mass density, high heat conductivity, large surface area, and versatile electronic behavior including high electron conductivity. • Their secondary structures such as ropes, fibers, papers, thin films with aligned tubes, etc., have their own specific properties. • High quality single shell carbon nanotubes can cost 50–100 times more than gold. Current applications 4 – Near field microscope probes – Field-emission based devices – Chemical sensors – Catalyst support Electrical properties 5 Nanoelectronics CNTs have been sought as the new generation of interconnect structures as well as field-effect transistors. Interconnects, which carry the electrical signals between transistors, are currently made of copper, but as electronic circuits continue to shrink, copper interconnects will suffer from overheating. Electronic transport in metallic SWNTs occurs ballistically along the nanotube length, allowing the conduction of high currents with no heating. Due to the lack of phonon and/or impurity scattering perpendicular to the tube, CNTs behave as 1-D ballistic conductors. 6 Electronic applications CNT transistor 7 Field-effect transistor components The current flows through a CNT with semiconductor properties along a path called the channel. When a small voltage is applied to the silicon substrate, which acts as a gate in FETs, the conductivity of the CNT can change by more than a million times, allowing a FET to amplify a signal. By controlling the current, the top CNTs can be made to contact the bottom CNTs, producing a metal-semiconductor junction that acts as a switch. 8 SWNT transport properties • SWNTs are ideal quantum wires. • Metallic SWNTs can transport huge current densities (max. 109 A/cm2) without being damaged, i. e. about three orders of magnitude higher than in Cu. • SWNTs are model systems to study one-dimensional charge transport phenomena. • Visible light is strongly absorbed. It has been observed that flash illumination with a broadband light can lead to spontaneous burning of a macroscopic sample of agglomerated (i. e., ropes) carbon nanotubes in air and room temperature. 9 • SWNT thermal conductivity is comparable to that of high purity diamond. Fuel cells and batteries CNTs have been sought to store hydrogen, particularly for automotive applications, where hydrogen should be contained in small volumes and weights, yet enabling reasonable driving distances 10 Still in the area of fuel cells, there is currently an increasing interest in using CNTs as a support material for the catalyst nanoparticles present in the cathode and anode electrodes of a fuel cell. The introduction of CNTs is expected to enhance the conductivity of the support and reduce the mobility of the catalyst nanoparticles. Supercapacitors CNTs exhibit high porosity, large specific surface area, high electrical conductivity, and chemical stability. In a conventional capacitor, energy is typically stored by the transfer of electrons from one metal electrode to another one separated by an insulating material. The capacitance depends on the separation distance and the dielectric material inserted between electrodes. In the case of a supercapacitor, there is instead an Each layer contains a highly porous electrical double layer. electrode suspended within an electrolyte. An applied potential on the positive electrode attracts the negative ions, whereas the potential on the negative electrode attracts the positive ions. A dielectric between the electrodes prevents the charges from crossing between two electrodes. If the electrodes are made of CNTs, the effective charge separation is about a nm, compared with separations on the order of micrometers for ordinary capacitors. This small separation, combined with a 11 large surface area, is responsible for the high capacitance of these devices Nanotube nanocomposites Due to the outstanding modulus and tensile strength resulting from the covalent bonds between the carbon atoms, CNTs are one of the strongest materials known. In addition, CNTs exhibit a high aspect ratio. Therefore, CNTs are ideal as a reinforcement phase. Attaching chemical groups – benzyne – nanotubes in polyepoxide 12 soldier’s armour Epoxy glue 3 times harder Carbide strength – alternative layers polymer, nanotubes Thin layer of composite on other materials, nanocomposite paint, grease Water filtration Limited water source ,water contamination, toxic pollutants and hazardouse chemicals is a great danger for animals and human . Dye =toxic polutant (textile, paper and carpet industries waste water ) cause environmental contamination they accumulate in nature and cause hight toxicity chronic effect on human health (concentration and time of exposure) f-MWNT can remove dyes High aspect ratio (surface to volume) it has high porosity and ability to adsorb substances . f-MWNT are hydrophilic and they have the ability to form bonds with organic materials c=c. Adsorption is considered superior technique for filtration purposes: Low cost, availability, simplicity and ease of operation. 13 Even after oxidation with nitric acid CNTs showed exceptional enhanced adsorption. Comparison of other materials to CNT Material Young’s Modulus (GPa) (Modulus of Elasticity) Yield Strength (Gpa) Concrete, High Strength 30 0.04 ? Aluminum 69 0.095 Titanium Alloy 105-120 0.73 Si 170 ? Steel 200 0.69 Diamond 1050-1200 ? SWCNT/MWCNT 1050/1200 (same as diamond) ~200 CNT cable Super strong, light weight 14 NT new structures AY-branch, the defects are marked in blue. Introduction of defects can also result in various new structures such as Y-branches Tbranches or SWNT junctions. Under certain circumstances, these defects 15can be introduced in a ‘controlled’ way. A transition from a metallic to a semiconducting SWNT. The change is made by insertion of pentagons and heptagons. Images of NT multiwall nanotubes from batch arc reactor HRTEM image of 3 Ao CNT formed inside MWNT. The diameter of 3 Ao CNT and the interlayer space of MWNT, 3:4 Ao, are indicated by a pair of lines marked by arrows. Each end is marked by two horizontal arrows, A and A’, and is capped by half of a C12 cage containing two tetragons. 16Smallest Carbon Nanotube Is 3 Ao in Diameter – Physical Review Letters (92, 12, March 2004) X. Zhao,1,* Y. Liu,2 S. Inoue,1 T. Suzuki,1 R.O. Jones,2 and Y. Ando1 1Department of Materials Science and Engineering, 21st Century COE Program ‘‘Nano Factory,’’ Meijo University, Nagoya 468-8502, Japan Making nanotubes Electric arc - batch reactor scale up - continuous reactor cathode deposit batch reactor operation 17 Arc discharge method In arc discharge, a vapour is created by an arc discharge between two carbon electrodes with or without catalyst. The carbon arc discharge method is the most common and perhaps easiest way to produce CNTs. It is a technique that produces a complex mixture of components, and requires purification - to separate the CNTs from the soot and the residual catalytic metals present in the crude product. This method creates CNTs through arcvaporization of two carbon rods placed end to end, separated by approximately 1mm, in an enclosure that is usually filled with inert gas at low pressure. Arc discharge in hydrogen Recent investigations have shown that it is also possible to create CNTs with the arc method in liquid nitrogen. A direct current of 50 to 100A, driven by a potential difference of approximately 20 V, creates a high temperature discharge between the two electrodes. The discharge vaporizes the surface of one of the carbon electrodes, and forms a small rod-shaped HREM image of multiwalled carbon deposit on the other electrode. nanotube (MWNT) prepared by arc Producing CNTs in high yield discharge in hydrogen. Note a single wall depends on the uniformity of the 3 Å diameter carbon nanotube plasma arc, and the temperature AA’ inside MWNT of the deposit forming on the [X. Zhao et al., Phys. Rev. Lett. 92 (2004) 125502] carbon electrode. Laser production In the laser ablation technique, a high-power laser beam impinges on a volume of carbon –containing feedstock gas (methane or carbon monoxide). Now laser ablation produces a very small amount of pure nanotubes, while an arc‐discharge method produces in general large amounts of the impure material. 20 Chemical vapour deposition (CVD) Acetylene over iron Also can use suspended catalyst nanoparticles to form suspended NT nanoparticles 700OC forms MWNT covered with amorphous C on outer layer Ethylene, hydrogen + methane over Co, Ni, Fe nanoparticles at 1000OC forms 70-80% SWNT uncapped 2CO -> C + CO2 also forms NT Low stiffness, strength of NT compared with those from high T arc production 21 CVD results in MWNTs or poor quality SWNTs. The SWNTs produced with CVD have a large diameter range, which can be poorly controlled. But on the other hand, this method is very easy to scale up, what favours commercial production. CVD CVD process has mostly two main steps which first is preparing substrate by sputtering then to use thermal annealing to have catalyst nanoparticles on the substrate . Large scale production and high yield production Low cost Continuous production instead of batch production Control of the quality and CNT Ability to manipulate No separation of unwanted by-products 22 Difficulties in NT production An issue that is important in the fabrication of CNTs is the large concentration of impurities that remain embedded inside the CNT network after processing. As a consequence, the powder needs to be filtered to reduce the amount of impurities present. This is normally achieved by acid oxidation, gas oxidation, or filtration. However, these methods may dissolve some of the CNTs, cause structural damage to CNTs, or be unable to remove large particle aggregates. In addition, these purity-driven techniques tend to be very expensive. 23 Purification techniques (1) Oxidation By oxidation we can partially purify CNTs from impurities ( time and temperature of exposure of the process are very important) While oxidation –COOH or –OH groups are generated which help the attachment of organic or inorganic material to increase solubility. Best way is to mildly oxidize them with H2O2 and H2SO4 which only causes oxide defects. Acid treatment By acid treatment mostly metal catalysts are removed by the reaction with Nitric acid or Sulfuric acid or a mixture of both. Annealing In this method a high temperature is applied (800-1800 °C) in a vacuum atmosphere which caused CNT atoms to rearrange and form a perfect CNT, metal is melted and also can be removed from the reaction 24 Purification techniques (2) Ultrasonication Ultrasonic created a low pressure and high pressure waves in the liquid and it improves the reaction and causes reactants to be mixed. It forces particles to vibrate and disperse in the liquid evenly. Magnetic Purification Microfiltration by using a membrane. 25 Endohedral functionalization Modification of CNT by putting nanoparticles inside the tube. Change the hydrophobic structure to hydrophilic and make them as solvents. Filling Nanotubes with nanoparticles to add the characteristics of the Nanoparticles inside the Carbon Nanotubes to fantastic phenomenal of CNT. This method itself is sub categorized to two methods: 1. Putting CNT inside the suspension containing nanoparticles so that it can penetrate the tube internal site and stay inside the CNT Depends on surface energy (surface tension ) of the liquid. Experiments show that if surface tension of the liquid is more than 200 mN/m, liquid can fill the Nanotubes 2. Filling with a material which reacts with it and then produces 26 nanoparticles which are trapped Exohedral functionalization Modification of external part of CNTs like side walls. This method itself is subcategorized into three main methods : 1. Covalent Exohedral functionalization - Defects defect in CNT = best place for functionalization. 2. Covalent Exohedral functionalization -Functional groups Side wall functionalization & to attach more functionalized group. 3. Noncovalent exohedral functionalization- Polymer wrapping wrapping CNT in polymer, surfactants and peptides (smaller amino 27 acids in length). By wrapping the polymer around the CNT there is a phenomena called Pi stacking. Pi stacking is when the P orbitals of CNT and functionalized group interact with each other and cause less stability. In this type of functionalization electrical and optical properties of CNTs are not damaged and perturbed but because of poor interaction of p orbitals, stability is quite low. As experiments show there is an improved electrical property of the polymer